Abstract

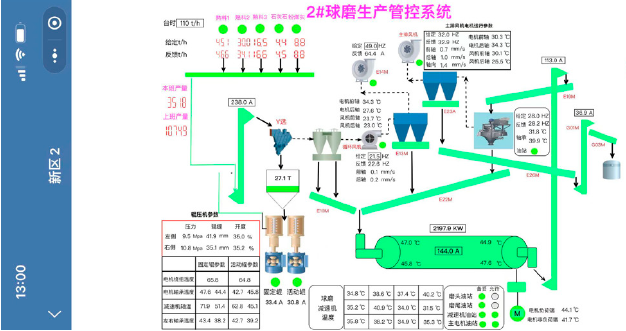

Using the Siemens S7-400 PLC as the main controller, this system integrates an edge computing gateway for real-time communication with the PLC, enabling data collection and protocol conversion. Data is sent to the cloud platform via the Internet of Things (IoT). After editing on the cloud platform, remote PCs can monitor the operational data of production equipment, while a WeChat mini-program allows for control of the cement production system. The system features alarm monitoring, historical trends, SMS notifications, and more, facilitating precise management of the production system’s operational status.

With the rapid development of computer and automatic control technologies, wireless communication is increasingly applied in industrial control, significantly improving the efficiency of information acquisition. The commercial rollout of 5G technology, with its low latency and high reliability, provides unlimited development space for future industrial intelligence.

In the field of industrial control, on one hand, the cost of applying wireless communication technology continues to decrease, and its stability improves, making industrial control products irreplaceable in enhancing production efficiency and diagnosing equipment failures. On the other hand, as the demographic dividend gradually disappears and labor costs continue to rise, the demand for automation is increasing, with a trend towards less human intervention and unmanned control. In recent years, the cement industry has accelerated the construction of smart factories; only by mastering detailed data can production defects be deeply analyzed and production efficiency improved. To enhance data acquisition, in addition to using advanced industrial equipment, older equipment can also undergo digital transformation, connecting to industrial edge computing gateways to efficiently transmit production information through standardized data transmission structures, achieving comprehensive awareness and control of the entire production process at limited costs.

Most industrial systems use PLCs as the main controller. By integrating a gateway, wireless remote communication can be achieved. The system primarily uses the TCP/IP protocol to interconnect the local area network of the company’s production control system, facilitating data exchange between the S7-400 PLC, the central control room PC, and the edge computing gateway SC-GN980-G. This allows the edge computing gateway to collect data from the ball mill system’s S7-400 PLC, which is then packaged and uploaded to the cloud platform for display or storage. Remote monitoring of the equipment can be achieved from any computer or mobile device with internet access. Company managers, under authorized projects, can monitor equipment operational data and perform remote operations through the WeChat industrial cloud mini-program. This article introduces this transformation.

1 Edge Computing Gateway

1 Edge Computing Gateway

The SC-GN980-G device is an industrial edge computing gateway box, serving as a remote communication device in the industrial Internet, facilitating data collection from on-site equipment, remote PLC program uploads, downloads, and fault diagnosis. This product simplifies complex processes, featuring multiple communication interfaces, embedded with various communication protocols, supporting web configuration, and enabling cloud-based remote configuration, allowing industrial control technicians to easily achieve remote monitoring. Additionally, the device boasts data security, offline storage, and strong anti-interference capabilities. Through the Ethernet function of the LAN port, the gateway connects with the Siemens 400 PLC within the same local area network, with each device having a unique BOX serial number to ensure data transmission security. The gateway connects to the network via 4G and links to the IoT platform for real-time monitoring of on-site network data, triggering alarms, and historical queries.

2 Network Configuration

2 Network Configuration

2.1 Edge Computing Gateway Setup

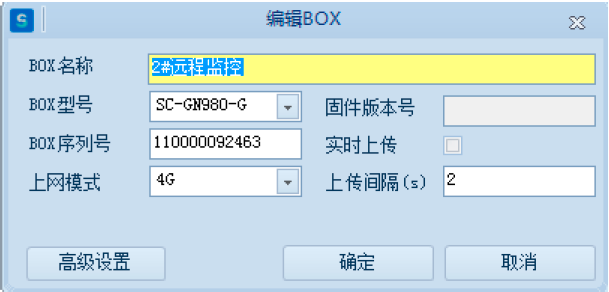

The gateway box’s default IP address is 192.168.10.100. Set the computer’s IP address to the 192.168.10.X subnet. Open the SC-GNConfig editing software, add the BOX in the BOX list, input the correct model and serial number, select 4G for the network mode, and set the upload interval to 2 seconds (see Figure 1).

Figure 1 Gateway Box BOX Settings

Enter the Ethernet settings interface and disable the routing function. Set the IP address (BOX address) to 172.29.155.26 (ensure the set address is within the company’s production local area network and is unique), with a subnet mask of 255.255.255.0. The device IP should be the IP address of the Siemens 400 PLC to be communicated with (172.29.155.10). In the detailed parameters, the rack number is 0, and the slot number must be set to 3. After completing the settings, download directly to the BOX.

Once the download is complete, place the gateway box in the central control room, connect the LAN port of the box to the industrial switch with a standard network cable, insert a 4G SIM card into the gateway box’s SIM slot, and adjust the antenna position to ensure both signal quality lights are on. When the data communication light flashes once per second, it indicates normal communication.

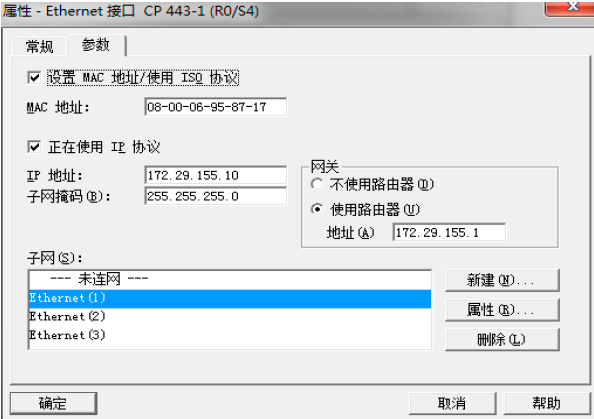

2.2 STEP7 Settings

In the STEP7 programming software, locate the program, enter hardware configuration, and set the IP address of CP443-1 (172.29.155.10) and the subnet mask (255.255.255.0), ensuring the gateway box and PLC are on the same subnet. After completing this, download the hardware configuration, as shown in Figure 2.

Figure 2 CP443 Settings in STEP7

Open the SC-GNConfig configuration software, and under the newly created ball mill PLC, add analog input groups and digital input groups to facilitate quick variable connections in the next step of cloud configuration. For digital inputs, for example, a variable I15.3 from the 400 PLC, when establishing the variable, select address type I, directly input address offset 15.3, select data type bool, and read/write type as read-only. For analog inputs, for example, the mill current in the 400 PLC is addressed as DB60.DBD64. When establishing the variable, select address type DB, address offset 60; address type 2 select DBD, address offset 64, data type float32, and read/write type based on needs, either read-only or writable. For most data, read-only is sufficient; for data that needs remote modification, the read/write type can be set to writable. After all variables are established, select save and upload to the cloud. This completes the data collection from the 400 PLC and uploads it to the cloud.

3 Cloud Server Editing

3 Cloud Server Editing

3.1 PC Monitoring

Once communication is normal, use any host that can access the external network to enter the cloud platform, click “Project Center” → “Device Monitoring” → “Edit Configuration”, and set the “PC Starting Screen” and “Mobile Starting Screen”. In the project editing, draw the process flow diagram based on the actual production process diagram and connect the variables. This process is similar to WINCC screen editing and can be quite tedious, especially for process diagrams with many devices, requiring individual connections for each variable and color changes for bars or boxes based on device operational status. The editing screen provides various controls such as control variables, button controls, bar graphs, dynamic text, reports, etc. Once editing is complete, click run to monitor remote device operations.

It is particularly important to note that during variable connections, device parameters, such as hourly output, can be modified. Simply check the checkbox in front of the variable control when connecting analog variables, allowing for remote modification of key parameters via web or mobile.

3.2 Mobile Monitoring

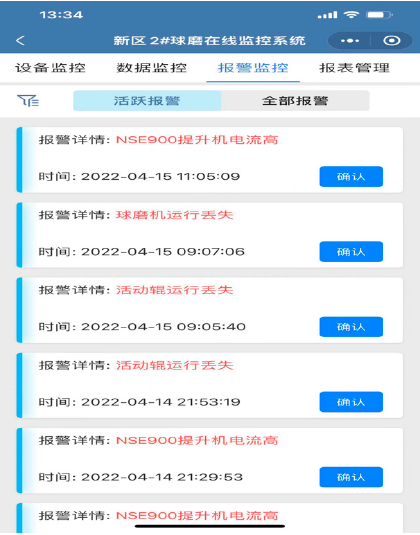

After binding a new account in the WeChat mini-program, users can view the screens and configurations, as shown in Figure 3.

Figure 3 Mobile Mini-Program Remote Monitoring of Device Operational Status

3.3 Alarm and Historical Trend Functions

When establishing variables using the SC-GNConfig configuration software, alarm values can be added for any analog or digital quantity. For example, if the hoist current exceeds 300 A, an alert for high hoist current is triggered; if the ball mill is not running, an alert for ball mill operation loss is triggered. Equipment anomalies can be notified in real-time, achieving unattended operation and reduced maintenance, further lowering labor costs, as shown in Figure 4.

Figure 4 Mobile Query for Alarm Information

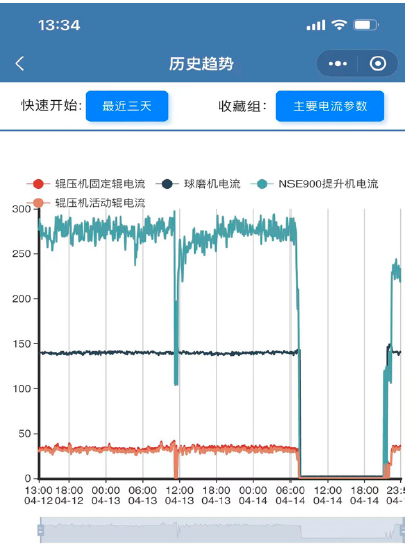

During the variable establishment process, the default setting for variable storage is not to store. If archiving of certain data is required for trend analysis via mobile, periodic storage of variables can be set, with collection periods selectable as 1 min, 5 min, or longer, as shown in Figure 5.

Figure 5 Current Trend of Some Devices

4 Other Functions

(1) The edge gateway provides a standard OPC interface, meeting the communication requirements of third-party industrial software. On any PC that can connect to the network, using WINCC7.0 software, after simple communication parameter settings and variable modifications, remote monitoring and operation of devices in different locations can be achieved. It can also connect to configuration software like KingView, offering significant promotional value.

(2) For already edited projects, personal customers can be added from customer management and project authorization can be granted, allowing other personnel to remotely view device operational status via mobile, facilitating managers in controlling product quality and equipment operational status, enhancing the management of the cement production system, and creating favorable conditions for efficient and stable operations.

(3) The gateway features remote programming capabilities, allowing engineering technicians to select remote programming in the SC-GNConfig software, set the virtual network card address and mask, initiate the connection, and once communication is normal, use STEP7 software to upload and download programs via the Ethernet port. This is particularly useful when industrial control technicians are off-duty or not on-site, enabling program uploads, downloads, monitoring, and modifications from any computer with STEP7 programming software, reducing maintenance time and significantly improving work efficiency.

5 Conclusion

5 Conclusion

By utilizing the Internet of Things, enterprises can adopt small-scale solutions that integrate big data, edge computing, and IoT within a localized area, which can be easily expanded without major renovations to existing infrastructure. The edge computing gateway is cost-effective, easy to network, and maintainable, allowing engineers with basic programming knowledge to connect to the network via 4G, achieving data communication with any PLC within the company’s local area network, and enabling intelligent control of the cement production system via a WeChat mini-program, making it convenient and efficient. As enterprises rapidly enhance their levels of informationization, automation, and intelligent management, IoT technology will have excellent promotional value and application prospects in the field of industrial control.

Author: Shandong Lubijian Material Co., Ltd.

Recommended Reading1. Welcome to publish advertisements in the 2023 “Cement” magazine

2. Ten benefits of enterprises participating in standard formulation

3. Assessment of CO2 reduction from alternative fuels, raw material technology for coal gangue to replace cement clinker, pre-treatment technology for municipal waste, and preparation technology for municipal waste

4.Upgrading and transformation of roller press technology (high-pressure small circulation) and intelligent grinding systems

5. Technical comic | Hydraulic dual sliding rail roller press feeding device

6. Development and application of dual-curved feeding devices for roller presses

7. Energy-saving transformation of preheater systems

8. NOx reduction technology and review for cement kiln flue gas

9. Solutions to belt conveyor belt cleaning issues

10. Practice of using phosphogypsum-industrial molasses composite production of retarding cement for road base

11. Research on the impact of waste residue batching on the pressure steam expansion performance of high magnesium clinker

12. Discussion on the co-disposal of hazardous waste in cement kilns

13. Practice of effectively controlling the water-soluble hexavalent chromium content in cement by adjusting raw materials

14. Analysis of factors affecting gypsum dehydration efficiency in cement kiln wet desulfurization systems

15. Key technology analysis for ultra-low emission transformation of cement kiln bag dust collectors

16. Further discussion on the analysis and calculation of coupling heating expansion

17. Comparative analysis of common feeding devices for roller presses

18. Technical upgrades for roller presses (with extrusion effect as the key)

19. Transformation of the raw material mill using a sealed small bin and a sealed chain plate feeder

20. Application of dry desulfurization and SCR denitrification in flue gas treatment for magnesium-calcium brick firing tunnel kilns

21. Discussion on the capture and purification (reduction) of carbon dioxide in new dry cement kilns

22. [Conference Notice] 2023 Cement Industry Firing and Environmental Protection Technology Exchange Conference