LIN is a subnet of the CAN bus system, also known as a “local subsystem.” Data exchange between all systems controlled by the LIN bus in automobiles must be achieved through the CAN bus control unit.

As a beneficial supplement to the CAN bus, the LIN bus can complete vehicle functions more economically and effectively. The LIN structure is relatively simple, consisting of only one data line, which can only be used for simple data transmission between sensors and actuators. Unlike the CAN bus, the control units on the LIN bus are divided into master and slave; the master control unit connects to the CAN bus and controls other slave control units on the LIN bus. This means that only after the master control unit has finished sending information can the slave control units send data information.

1.LIN Bus Applications

The LIN bus, known as a data loop bus, is a single bus, meaning that data information is repeatedly sent and transmitted on the bus regardless of whether there is a request or change, allowing sensors and actuators to receive data information from the bus at any time.

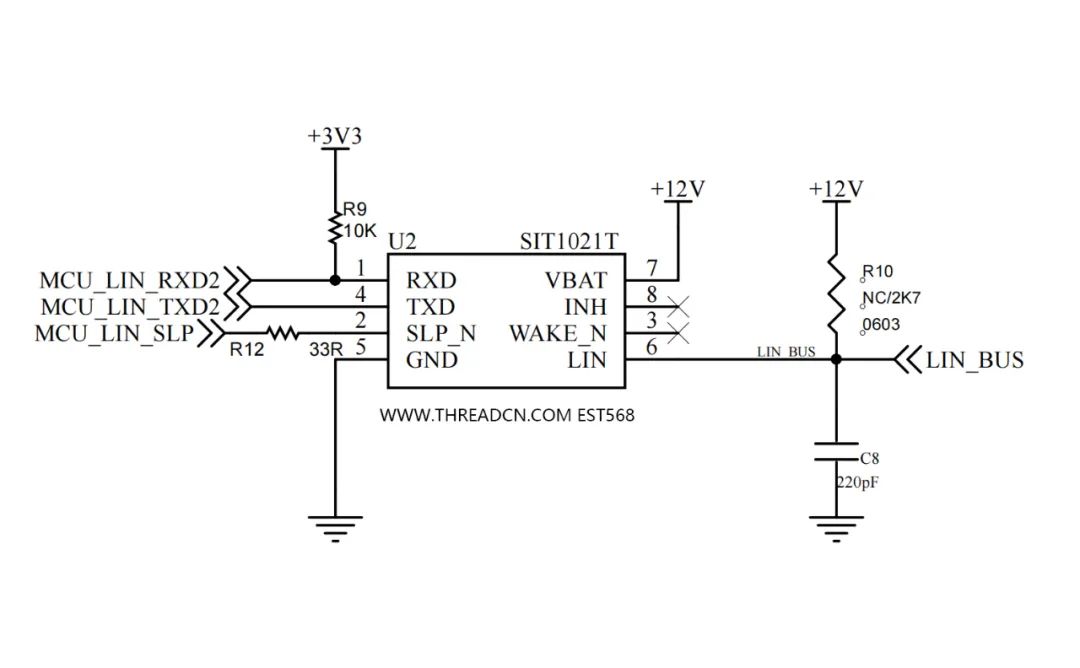

SuRuiDe has been developing CAN bus data applications for 11 years and is also very familiar with the automotive LIN bus. Since the LIN bus is a newly developed automotive onboard electronic bus system based on the CAN bus, it is designed to establish a bus system with limited transmission speed, simple structure, and excellent performance. As shown in the circuit diagram design, it only requires one data transmission line and can use low-cost components.

The LIN bus saves structural space by using simple electronic devices, with a maximum transmission speed of 20 kbit/s. Due to several automotive manufacturers publicizing the standard, it has promoted the development of the LIN bus in automotive lighting control systems and some simple systems, ensuring that the CAN bus system is not only not replaced but has also been expanded. The single master/multiple slave principle ensures safety. The application solutions of the LIN bus system are simple, and the lower transmission speed is suitable for applications in scenarios where timing is not so critical, such as comfort entertainment systems, automotive fragrance systems, automotive lighting control systems, door lock systems, ambient light control systems, automatic air conditioning systems, rearview mirror control systems, sunroof control systems, automatic wiper control systems, and washing systems.

2.Features of the LIN Bus

The LIN bus is a new low-cost serial communication system for automotive distributed electronic control systems, based on the UATR data format, with a master/slave structure, and is a single-wire 9-10.5V bus communication system, mainly used for serial communication between intelligent sensors and actuators.

Structurally, the LIN bus uses a low-cost single-wire connection with a maximum transmission speed of 20 kbit/s; its media access adopts a single master/multiple slave mechanism, which does not require arbitration like the CAN bus, and does not need a crystal oscillator for self-synchronization in nodes. Currently, LIN chips are not expensive, so the LIN part alone reduces the cost of hardware platform development.

The main purpose is to provide auxiliary functions for the existing vehicle networkCAN, targeting low-end systems (mainly referring to low-speed requirements) that do not require the performance, bandwidth, and complexity of the CAN bus. It can be said that the LIN bus is an auxiliary bus network.

The LIN bus system generally consists of one master control unit and up to 16 slave control units, with the master control unit requesting data from the slave control units and issuing control commands. To communicate with other control units in the vehicle, the master control unit connects to other buses. The LIN bus master control unit has an address code in automotive diagnostic detection, responsible for diagnosing the connected slave control units. For example, on a CAN bus, two LIN control units A and B are connected, where LIN control unit A controls air conditioning, air blower, and windshield heating (divided into left and right), while control unit B manages the sunroof, headlights, motors, etc., in the roof module. It can also include the adjustment of the horizontal position of the lights in the lighting control system (high and low beams), doors, locks, electronic brakes, air conditioning, cruise control, seats, instrument panels, heating, tail lights, rearview mirror electronic devices, and horizontal adjustment motors for the rearview mirror.

3.SuRuiDe Design Solutions

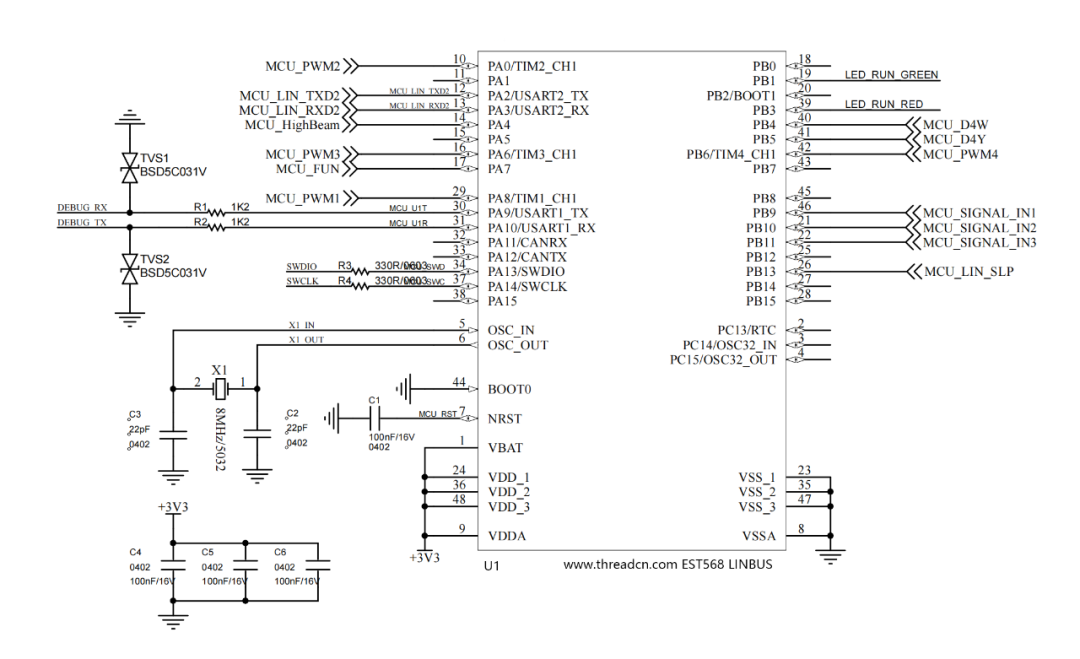

SuRuiDe has centralized control in lighting control systems for Tesla, BMW, BYD, Ford, Cadillac, etc., by adding lighting control system units. The structural schematic of the main control microcontroller is as follows:

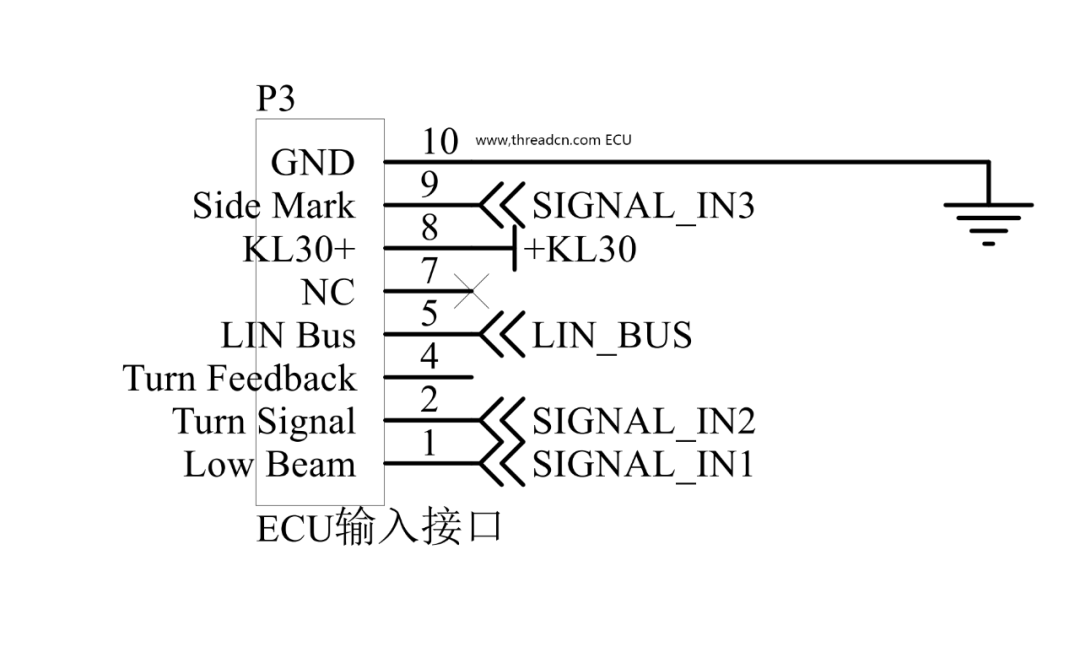

This lighting control system includes interfaces for high beam rotary switch, headlight dimming interface, left front headlight LIN assembly control interface, right front headlight LIN assembly control interface, steering column electronic device control unit, data bus diagnostic interface, and reserved CAN positions, which can connect to the combination instrument control panel unit, vehicle power control unit, and BMS and other devices. It can control the dimming switch, high and low beam control for left and right lights, hazard status, and marker light status, etc. The principle is that by rotating the light or receiving signals from the control unit, the internal lighting control system connects to the high beam controller contacts, randomly receiving the analog signal for high beam activation. The automotive lighting control system converts this analog signal into a digital signal and sends the data to the vehicle ECU control unit and instrument panel control unit via the CAN bus.

Whenever the turn signal comes in, the lighting control system internally connects to the overtaking light control contacts, and then the control system uses the original vehicleLIN protocol to send an analog signal for activating the overtaking lights to drive the original factory headlights to flash. This set of lighting control system components can not only drive the original factory headlights but also can drive aftermarket headlights and modified headlights.

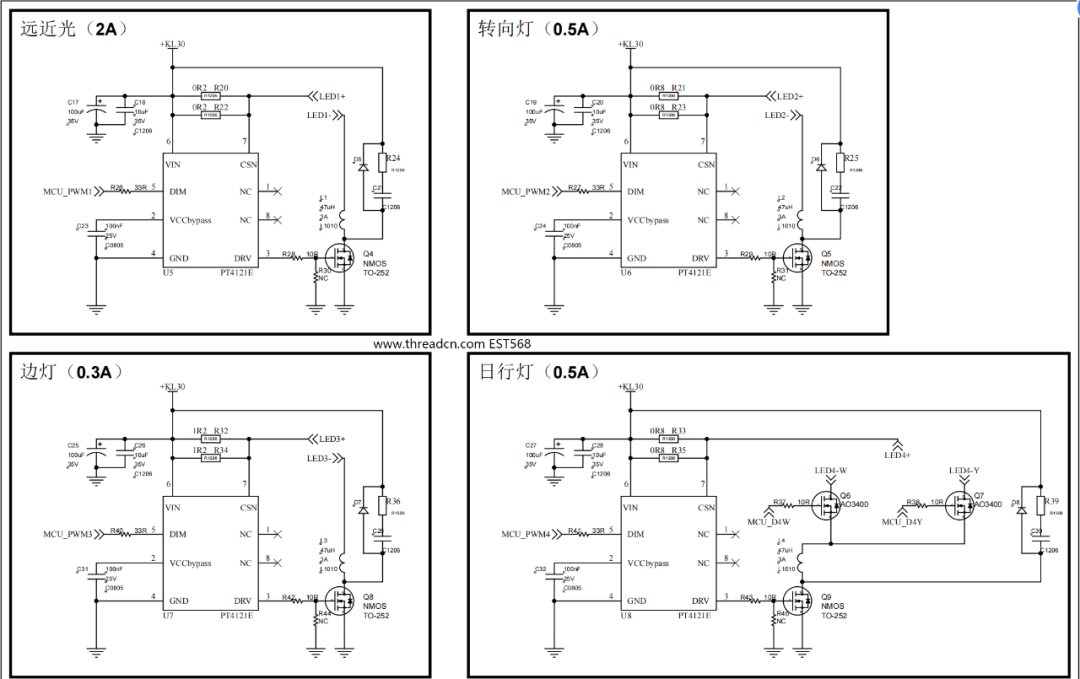

4.Automotive LED

To enhance the coolness and increase the brightness of high beams and overtaking lights, aftermarket and modified headlight assemblies mostly useLED modules for lighting. LEDs emit visible light when electrons recombine with holes, used in circuits and instruments as indicator lights or to form textual or numerical displays. Gallium arsenide emits red light, gallium phosphide emits green light, silicon carbide emits yellow light, and gallium nitride emits blue light. The structure of automotive headlight assemblies includes a housing, turn signal light module, daytime running light module, LED driver power module, high and low beam LED units, daytime running light LED module, low beam LED units, and a stack of circuits and MOSFETs for management.

Generally, ultra-brightLEDs are used, making them into automotive high beams, low beams, brake lights, running lights, turn signals, matrix lights, and can also be used for instrument illumination and interior lighting, such as ambient lights. LEDs have advantages such as vibration resistance, energy saving, and long lifespan. When used as brake lights, the response time is 60 ns, much faster than the 140 ns of typical incandescent or LED lights. Therefore, when driving on typical highways, it increases the safety distance by 4-6 meters.

5.Functions and Processes

The automotive lighting control system developed by SuRuiDe also manages other data, such as battery voltage, ignition status, engine speed, generatorDFM signals, achieving functions like external lighting control, comfort lighting control, wiper control, washing pump control, indicator light control, load management, interior lighting control, rear window heating, terminal control, fuel pump pre-supply control and management state monitoring, etc. As for the internal software of SuRuiDe, it can be customized and developed based on different vehicle models, application scenarios, and business needs.

The automotive lighting control system receives the original vehicleLIN messages or analog signals from the original vehicle LIN messages, respectively activating the control signals for the left front and right front headlight assemblies, allowing all lights to achieve status and control.

The combination instrument receives signals from the automotive lighting control system, illuminating the high beam indicator light on the dashboard to inform the driver of the lighting status.

When the driver pulls the dimming switch up, the switch internally connects to the overtaking light control contacts, and immediately the automotive lighting control system receives the analog signal for activating the overtaking lights. The automotive lighting control system converts this analog signal into a digital signal and sends the data to the vehicle ECU control unit and combination instrument control unit via the comfortCAN.

After receiving this signal, the automotive lighting control system activates the left and right front headlight assemblies, providing control signals and illuminating all high beams. The combination instrument panel control unit receives the signals from the automotive lighting control system, lighting up the high beam indicator light on the dashboard to inform the driver of the lighting status.

6.Development and Pain Points

Currently, automotive headlights in China are transitioning from functional headlights to intelligent headlights. The electronic and intelligentization of automobiles has driven the development of the headlight industry, enabling headlights to carry more functions beyond traditional lighting, such as auxiliary driving, signal transmission, and continuously extending technology,ADB, DLP, HD, etc. With the increasing penetration of intelligent headlights with higher unit value in vehicles, the headlight industry will also usher in a new round of accelerated growth.

Insufficient lighting, low configurations, and dazzling high beams severely affect vehicle safety and are direct causes of high accident rates at night. To address these issues, intelligent lights based on LED technology have emerged. Compared to traditional headlights, intelligent lights have added perception, decision-making, and execution architectures, making the systems more complex. The more powerful the lighting functions, the more the price will increase exponentially.

SuRuiDe’s development of this lighting control system is aimed at the lower level, based on the interaction ofLIN data and CAN data to create a versatile controller, which compensates for future intelligent light controllers and is also a necessary terminal for current aftermarket and secondary products. Based on an understanding of the LIN bus and CAN bus, as well as the application logic in scenarios, it has been optimized for actuator control, processing unit compilation, transmission path bridging, and digital signal input from sensor groups. Currently, it mainly interfaces with LEDs and some intelligent light groups (e.g., matrix headlights), while low-end halogen headlights or halogen + LED combinations are not frequently encountered.

With the rapid development of vehicle network technology, the number of bus nodes used in automobiles is increasing, and the complexity and cost of the network are also rising. The automotive lighting control system is becoming more advanced, and implementing the SuRuiDe control system for network node upgrades and improvements has practical significance in terms of operability, feasibility, and speed. It also marks the beginning of hierarchical management of automotive lighting and illumination network systems.