Copyright Statement

This article is authorized by New Materials Online (WeChat ID: xincailiaozaixian) for reprinting. For other media wishing to reprint, please contact the editor of New Materials Online (WeChat ID: 13510323202).

Introduction

3D Printing is a technology that manufactures three-dimensional products by layering materials according to designed 3D models using 3D printing equipment. This layering technology is also known as additive manufacturing. 3D printing integrates cutting-edge technologies from various fields such as digital modeling technology, mechatronics, information technology, materials science, and chemistry, making it a kind of rapid prototyping technology and hailed as the core technology of the third industrial revolution.

World’s first 3D printed car manufacturer Local Motors (left)

Philips 3D printed razor (right)

3D printed automatic rifle in the USA

Cambridge University’s oracle bone 3D printed replica

(Image source: Pumpkin Network)

>>>>3D printing manufacturing technology mainly consists of three key elements:

First, products need precise three-dimensional design, using computer-aided design (CAD) tools for comprehensive and accurate positioning;

Second, powerful forming equipment is required;

Third, materials that meet the performance and forming process of the products are needed.

Since 3D printing manufacturing technology has completely changed the methods and principles of traditional manufacturing industries, it has disrupted traditional manufacturing models. Therefore, 3D printing materials have become the main bottleneck limiting the development of 3D printing, as well as the key and difficulty for breakthroughs and innovations in 3D printing. Only by developing more new materials can the application fields of 3D printing technology be expanded. Currently, 3D printing materials mainly include polymer materials, metal materials, ceramic materials, and composite materials.

3D Printing Polymers

3D printed drone (Image source: Pumpkin Network)

1. Engineering Plastics

Engineering plastics refer to industrial plastics used for industrial parts or shell materials, characterized by excellent strength, impact resistance, heat resistance, hardness, and aging resistance. Engineering plastics are currently the most widely used type of 3D printing materials, commonly including acrylonitrile-butadiene-styrene copolymer (ABS), polyamide (PA), polycarbonate (PC), polyphenylsulfone (PPSF), and polyetheretherketone (PEEK).

1) ABS

ABS material is the preferred engineering plastic for 3D printing through melting deposition due to its good thermal meltability and impact strength. Currently, ABS is mainly prefabricated into filaments or powdered for use, covering almost all daily necessities, engineering products, and some mechanical goods. In recent years, ABS has not only gradually expanded its application areas but also continuously improved its performance. With the strong adhesion and strength of ABS, modifications to ABS have enabled its application as a 3D printing material in a wider range.

In 2014, an ABS plastic 3D printer was used to print parts for the International Space Station; the latest ABS material ABS-M30 developed by Stratasys, the world’s largest 3D printing material company, is specifically designed for 3D printing manufacturing, with mechanical properties improved by 67% compared to traditional ABS materials, thus expanding the application range of ABS.

3D printed ABS planetary gear and bike chain model (Image source: Stratasys)

3D printed ABS planetary gear and bike chain model (Image source: Stratasys)

2) PA

PA has high strength and certain flexibility, allowing direct use of 3D printing manufacturing equipment for parts. PA carbon fiber composite plastic resin parts made using 3D printing exhibit high strength and toughness, suitable for replacing metal tools in mechanical applications. Additionally, due to PA’s adhesive properties and powder characteristics, it can be mixed with ceramic powder, glass powder, metal powder, etc., achieving low-temperature 3D printing through adhesion. Solvay, as a global expert in PA engineering plastics, uses PA-based engineering plastics for 3D printed samples, applicable for engine peripheral parts, door handle kits, brake pedals, etc. Replacing traditional metal materials with engineering plastics ultimately solves the lightweight issue of automobiles.

3) PC

PC has excellent strength, about 60% higher than that of ABS materials, making it suitable for applications in super strong engineering products. Solvay, as a global expert in PA engineering plastics, uses PA-based engineering plastics for 3D printed samples, applicable for engine peripheral parts, door handle kits, brake pedals, etc. The PC2605 developed by Bayer in Germany can be used for 3D printing of bulletproof glass, resin lenses, headlight covers, astronaut helmet visors, smartphone bodies, mechanical gears, and other irregular components.

3D printed blow molding molds (Image source: Stratasys)

4) PPSF

PPSF has the highest heat resistance, toughness, and chemical resistance, making it the best-performing among various rapid prototyping engineering plastics. Through composite processing with carbon fiber and graphite, PPSF exhibits extremely high strength, suitable for 3D printing of high-load bearing products, becoming the preferred material to replace metal and ceramics.

5) PEEK

PEEK has excellent wear resistance, biocompatibility, chemical stability, and Young’s modulus closest to human bone, making it an ideal material for artificial bone replacement, suitable for long-term implantation in the human body. The 3D printing technology based on the principle of fused deposition is safe and convenient, does not require the use of lasers, and has simple post-processing. By combining with PEEK materials, bionic artificial bones can be manufactured.

6) EP

EP (Elasto Plastic) is a newly developed 3D printing raw material by Shapeways company, which can avoid the brittleness issues of wearable items or deformable products printed with ABS. As the name suggests, Elasto Plastic is a new type of soft 3D printing material that adopts the “layered sintering” principle like ABS during shaping, but the printed products have good elasticity and are easy to restore deformation. This material can be used to make products like 3D printed shoes, phone cases, and 3D printed clothing.

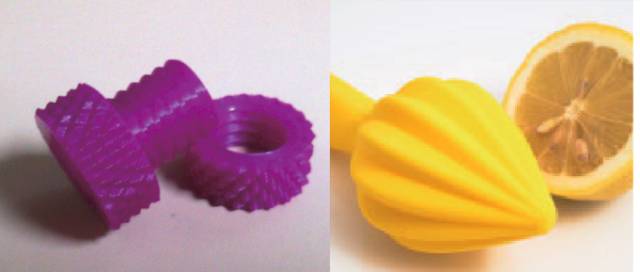

3D printed EP shoes and EP phone cases

7) Endur

Stratasys has launched a new 3D printing material – Endur, which is an advanced polypropylene-like material that meets various application needs. Endur material has high strength, good flexibility, and high-temperature resistance. Products printed with it have good surface quality and dimensional stability, with minimal shrinkage. Endur exhibits excellent polypropylene-like properties, suitable for printing moving parts, engagement parts, as well as small boxes and containers.

3D printed Endur pen holder

2. Bioplastics

3D printing bioplastics mainly include polylactic acid (PLA), polyethylene terephthalate glycol (PETG), polyhydroxybutyrate (PHB), polyhydroxyvalerate (PHBV), polybutylene succinate (PBS), and polycaprolactone (PCL), which have good biodegradability.

Source: 3D Systems Company

1) PLA

PLA (Poly Lactic Acid) is probably the best raw material initially used for 3D printing, available in various translucent colors and glossy textures. As an environmentally friendly plastic, PLA can biodegrade into active compost. It is derived from renewable resources – corn starch and sugarcane, rather than non-renewable resources – fossil fuels. Tan K H and others from Nanyang Technological University in Singapore have researched the application of PLA in manufacturing tissue engineering scaffolds, using 3D technology to form biodegradable polymer materials, creating high porosity PLA tissue engineering scaffolds. Through tissue analysis of this scaffold, it was found to have growth capabilities.

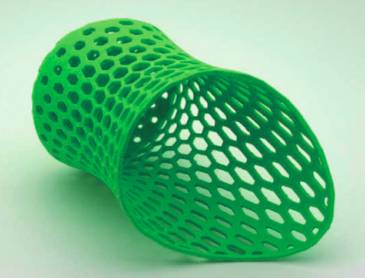

3D printed PLA bolts and nuts, PLA lemon juicer pusher

2) PETG

PETG is a bio-based plastic synthesized from bio-based ethylene produced from sugarcane. It has outstanding thermoformability, toughness, and weather resistance, with a short thermoforming cycle, low temperature, and high yield. As a new type of 3D printing material, PETG combines the advantages of both PLA and ABS. During 3D printing, the material’s shrinkage rate is very low, and it has good hydrophobicity, requiring no storage in a closed space. Due to its low shrinkage rate and temperature, PETG emits almost no odor during the printing process, giving it broader development and application prospects in the field of 3D printing products.

3) PCL

PCL is a biodegradable polyester with a low melting point of about 60°C. Like most biomaterials, it is often used for special purposes such as drug delivery devices and sutures, and it also has shape memory properties. In 3D printing, due to its low melting point, it does not require high printing temperatures, achieving energy-saving purposes. In the medical field, it can be used to print heart stents and others.

3. Thermosetting Plastics

Thermosetting resins such as epoxy resins, unsaturated polyesters, phenolic resins, amino resins, polyurethane resins, organic silicone resins, and aromatic heterocycle resins have high strength and fire resistance, making them very suitable for the powder laser sintering process of 3D printing. Material scientists at Harvard University’s School of Engineering and Applied Sciences, in collaboration with the Wyss Institute for Biologically Inspired Engineering, have developed a 3D printable epoxy-based thermosetting resin material, which can be 3D printed into building structural components for lightweight constructions.

Singapore will attempt to use 3D printing technology to construct public housing (Image source: Pumpkin Network)

4. Photosensitive Resins

Photosensitive resins are composed of polymer monomers and prepolymers. Due to their good liquid flowability and instant light curing characteristics, liquid photosensitive resins are the preferred materials for 3D printing consumables used for high-precision product printing. Photosensitive resins have a fast curing speed, excellent surface dry performance, and smooth appearance after forming, presenting transparent to semi-transparent matte finishes. Especially, photosensitive resins have low odor and low irritant components, making them very suitable for personal desktop 3D printing systems.

3D printed radiator fan and earplug case (Image source: Stratasys)

5. Polymer Gels

Polymer gels exhibit good intelligence, with sodium alginate, cellulose, animal and plant gums, peptone, polyacrylic acid, and other polymer gel materials used in 3D printing. Under certain temperatures and the influence of initiators and crosslinking agents, they undergo polymerization to form special network polymer gel products. For example, when ionic strength, temperature, electric fields, and chemical substances change, the gel’s volume will also change accordingly, used for shape memory materials; gel swelling or shrinkage occurs during volume changes, used for sensor materials; the controllability of gel pore sizes can be used for smart drug release materials.

3D Printing Metals

Currently, most 3D printing consumables are plastics, but the good mechanical strength and conductivity of metals make researchers extremely interested in printing metal items.

3D Systems printed aerospace metal components for GE (left)

3D printed Oscar “little golden man” (right)

Image source: 3D Systems

1. Black Metals

1) Stainless Steel

Stainless steel is the cheapest metal printing material. The high-strength stainless steel products printed through 3D printing have a slightly rough surface and exhibit pitting. Stainless steel offers various polished and matte surfaces, commonly used for jewelry, functional components, and small sculptures.

3D printed stainless steel jewelry

2) High-Temperature Alloys

High-temperature alloys, due to their high strength, stable chemical properties, and difficulty in forming processing, as well as high costs of traditional processing technologies, have become the main 3D printing materials used in the aerospace industry. With long-term research and further development of 3D printing technology, 3D printed aircraft parts have been widely applied due to their processing time and cost advantages.

3D printed IN718 nickel-based high-temperature alloy rotor produced using 3D printing technology in the USA

2. Non-Ferrous Metals

1) Titanium

Components made of titanium alloy using 3D printing technology exhibit very high strength and precise dimensions, with the smallest size achievable being 1mm, and their mechanical properties outperform those of forged processes. Metalysis in the UK successfully printed automotive parts such as impellers and turbochargers using titanium metal powder. Furthermore, titanium metal powder consumables will have broad application prospects in 3D printing for the automotive, aerospace, and defense industries.

3D printed titanium watch and turbine blades

2) Magnesium-Aluminum Alloys

Magnesium-aluminum alloys are widely used in manufacturing due to their lightweight and high strength. In 3D printing technology, they have also become a preferred material among major manufacturers.

Canon in Japan used 3D printing technology to manufacture a special curved top cover for a high-end DSLR camera made of magnesium-aluminum alloy

3) Gallium

Gallium (Ga) is primarily used as a 3D printing material for liquid metal alloys, exhibiting metallic conductivity with a viscosity similar to water. Unlike mercury (Hg), gallium is non-toxic and does not evaporate. Gallium can be used in flexible and stretchable electronic products, with liquid metals applied in soft stretchable components of variable antennas, soft storage devices, ultra-stretchable wires, and soft optical components.

3D printed liquid metal gallium

3) Gallium-Indium Alloy

Michael Dickey, an associate professor of chemical and biomolecular engineering at North Carolina State University, used a gallium (Ga) and indium (In) liquid metal alloy to create a three-dimensional self-supporting structure at room temperature through 3D printing technology. This miracle was made possible by the reaction of gallium-indium alloy with oxygen in the air, forming an oxide film that maintains the shape of the parts. This technology is used in 3D printing to connect electronic components.

3D printed gallium-indium liquid alloy

4) Precious Metals

The influence of 3D printed products in the fashion industry is increasing. Jewelry designers around the world seem to benefit the most from using 3D printing rapid prototyping technology as a powerful creative industry that conveniently replaces other manufacturing methods. Commonly used 3D printing materials in jewelry include gold, pure silver, and brass.

3D printed leaf-shaped gold ring, mycelium silver ring, brass ring

Ceramics

Aluminosilicate ceramic powder can be used for 3D printing ceramic products. The 3D printed ceramic products are waterproof, heat-resistant (up to 600°C), recyclable, and non-toxic, but their strength is not high, making them ideal for cookware, tableware (cups, bowls, plates, egg cups, and coasters), candle holders, tiles, vases, and home decorative materials.

3D printed ceramic milk tray and ceramic teacup

Composite Materials

Arevo Labs in Silicon Valley has 3D printed high-strength carbon fiber reinforced composite materials. Compared to traditional extrusion or injection molding methods, 3D printing allows for precise control over the orientation of carbon fibers, optimizing specific mechanical, electrical, and thermal properties, and enabling strict setting of comprehensive performance. Since 3D printed composite parts can only be manufactured one layer at a time, each layer can achieve any desired fiber orientation. The complex-shaped parts printed with enhanced polymer materials exhibit excellent high-temperature and chemical resistance.

3D printed ultra-strong polymer parts

Note: Images without source annotations are from China Knowledge Network