To ensure the Internet of Things (IoT) progresses far, the development of sensors is crucial. From information collaboration between machines, measurement, analysis to control, sensors are essential for collecting information.

Whoever masters the sensors will control the future of the IoT.

At the same time, for China to secure a place in the IoT and even the Industrial Internet of Things (IIoT), sensors are the most suitable entry point. The past experiences in manufacturing and the semiconductor industry will effectively assist China in gaining a foothold in the future of the IoT.

If there are no sensors to detect critical production data such as pressure, position, and temperature, the IIoT would not have developed as it has today. Essentially, the growth of both IIoT and Consumer Internet of Things (IoT) has been accompanied by the expansion of the sensor market, and innovations and research in sensing technology will stimulate the potential and development of the IoT industry.

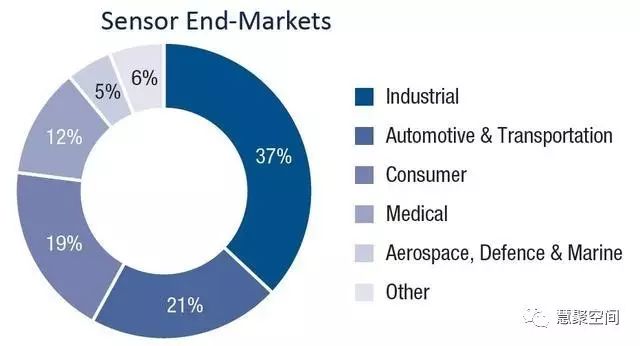

Sensors still dominate the industrial sector, accounting for 37% of the market:

The demand for sensors in the industrial and automation sectors remains high.

The proportion of sensors used in the automation industry is increasing, with connected cars and autonomous vehicles having a high demand for sensors, accounting for 21% of the sensor market. The medical industry also shows growth in sensor demand, relying on sensors for monitoring patient health and medical diagnostics, currently accounting for 12% of the sensor market. However, the industrial sector still holds the largest market share at 31%.

Industrial applications typically focus on producing high-end products rather than mass production, thus the demand for sensors leans towards reliable, precise, and compact devices that can operate in harsh environments. As Machine-to-Machine (M2M) connections become more sophisticated, the role of sensors has evolved from passive monitoring to proactive detection, preventive maintenance, asset management, and data analysis, helping to increase production efficiency.

In the field of automated processes, systems for process control, process safety, operations management, and asset utilization require sensors to measure, analyze, and control system settings. Integrating multiple sensing technologies with software analysis tools will facilitate faster and more accurate information dissemination, leading to a cost-optimized environment capable of producing high-end products.

Currently, to seize this trend, companies in the US, UK, and Europe are actively collaborating with tech companies to acquire firms specializing in real-time data management, asset management, and sensor equipment. Mergers and acquisitions in the sensor market are creating a whirlwind, as this allows companies to bypass certain entry barriers. Traditional sensor companies are also keen to collaborate with enterprises in new industrial sectors, while tech manufacturers are joining the fray in the sensor battle.

This trend of mergers and acquisitions in the sensor market will critically guide us towards a more interconnected and automated world. In several major industries, such as manufacturing and IoT, as the level of automation increases, the use of sensors will become more widespread. Such high market demand and limitless business opportunities will attract more participants to the market.

Sensors assist smart factory examples: using laser sensors to automatically detect liquids, saving a lot of time and costs!

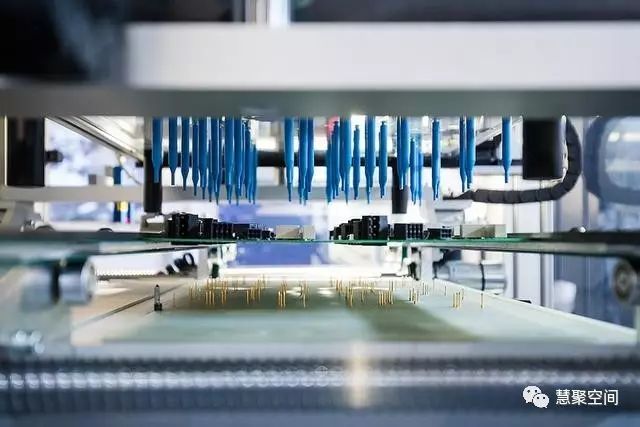

As computer services and data are pushed to the cloud, the structural evolution of IoT will be based on devices, where not only the cloud holds intelligence, but devices will also need an independent operational brain. In the industry, many innovative methods are already utilizing sensors to manage production processes and optimize production efficiency.

Real-time measurement of the height, volume, and mass of powders and bulk solids in large containers has always been a concern for operators. To manage assets and processes, very precise measurement results are required; however, most of the time, owners of these materials must manually measure this data. Even with the assistance of laser technology, they still have to stop the process entirely, taking several hours to obtain the results.

However, after the introduction of the 5708 scanner, operators can perform these measurements without interrupting operations, even for materials like fly ash or low-dielectric substances that are difficult to measure with other technologies, they can accurately obtain data through sensors. This scanner can even simulate the irregular surfaces of solid materials and provide minimum and maximum heights, total volume, and a 3D visual model.

On the other hand, for long-distance and large-area temperature control, sensors are also essential. The DTSX3000 optical detection technology designed by Yokogawa solves this issue. Traditional technologies rely on multiple monitoring cameras, thermocouples, resistance temperature detectors, or other temperature sensors, which can be cumbersome in operation, installation, and maintenance. The sensors developed by Yokogawa can measure temperature along fiber optic networks up to fifty kilometers long, with each meter as a spatial unit.

Some sensor developments already hint at the future world. For example, an Israeli company has developed the world’s first nanotechnology “electronic nose” that can detect national security threats such as bombs, biological weapons, and toxins, even detecting the smallest components. The company’s CEO, Dr. Ricardo Osiroff, stated that this nanometer sensor, referred to as the “lab-on-a-chip,” can detect various types of chemical threats, such as explosives and biological weapons, from gas, liquid, and solid samples, significantly outperforming existing technologies and surpassing the capabilities of drug detection dogs or other detection animals.

The key to IoT development lies in the collaboration between machines, with sensors being its heart.

The “high-speed integration technology of sensor chips” allows for the selection of different wireless sensor blocks to create a brand new sensor chip. For example, a chip center can combine motion sensors, capacitive sensing signal reading, low-power processing units, Bluetooth wireless transmission, and battery power management circuits to produce an “intelligent backpack sensor chip”. When the backpack moves quickly and significantly, it may indicate that a climber has fallen into a valley, instantly sending a distress signal to designated contacts. The chip center can also combine deformation sensors, resistance sensing signal reading, RFID wireless transmission, and electromagnetic energy harvesting circuits to create an “intelligent bone plate chip”. When the injured bone plate fully heals and no longer undergoes deformation, it will send a signal to notify the doctor that the plate can be surgically removed.

Foreign companies primarily integrate sensor technology into industrial processes, while China can bring this technology closer to everyday life. Transportation, medical care, rescue, and wearable devices are all worthy investment fields. The key to IoT development lies in the collaboration between machines and information transmission, with sensors playing an indispensable role in these machine networks and the broader interconnected world.