The microcontroller (MCU) serves as the heart of electronic products and is widely used in consumer and industrial electronics. Today, the development of industrial automation, next-generation vehicles, smart analytics, and the Internet of Things has raised the performance requirements for edge MCUs, leading to increasing demands for performance, real-time control capabilities, and diverse and high-speed communication in MCU products. For example, in specific industrial applications: emerging applications require higher levels of system integration and edge intelligence; industrial and automotive systems rely on precise real-time control and decision-making; distributed communication and automation trends require higher network bandwidth…

Three Key Technologies for Achieving Industrial Automation

The large-scale development of Industry 4.0 and industrial automation allows real-time control, industrial networking, and edge analytics to effectively improve efficiency and productivity in automated factories.

Real-Time Control: Due to the strict time requirements of systems, real-time control necessitates the system’s ability to process raw data and control signals within the required precise timeframe. Precise control of analog signals is crucial, and this process can leverage improved control algorithms to enhance the reliability of motor drivers and the efficiency of electric vehicles. These processing demands have exceeded the functional capabilities of traditional MCUs.

Industrial Networking: Factories require different types of data exchange, so they must quickly adopt various industrial Ethernet standards to support real-time communication between machines, thereby improving system performance, security, and reliability. Therefore, an integrated networking solution is needed that is not only compatible with various protocol standards but also operates at speeds up to 1Gbps.

Edge Analytics: Improvements in machine learning algorithms can facilitate local optimization, allowing each machine or node to operate without waiting for centralized decision-making. Edge processing can significantly reduce response times, enabling better and safer human-machine collaboration.

In many factory systems such as motor control and robotics, processors supervise the analog-to-digital and digital-to-analog conversion processes. However, the high-performance computing and control demands of users are placing greater requirements on the functionality of processors.

Recently, TI launched the new Sitara AM2x series MCUs to address the design challenges of systems requiring high computing power, high communication rates, and high reliability.

Processor-Level Computing Performance with MCU Design Simplicity

TI’s Sitara brand has a long history and has been widely used in the industrial field. The AM2x series MCU is a new series of microcontrollers under the Sitara brand, characterized by combining processor-level high-performance computing capabilities with MCU-level design convenience and ease of use.

(Image source: TI)

MCU is a complete system that includes a CPU, flash memory, and RAM, along with general control requirements such as motor control, power processing, and fast IO control. Real-time peripherals are a prominent advantage of MCUs; moreover, an increasing number of MCU products emphasize functional safety and information security, integrating many security-related accelerators or coprocessors into traditional MCUs or embedding related functions.

The most notable feature of traditional MPU processors is their high CPU core performance, essentially reaching 1 GHz or higher, and they are mostly multicore. To date, the largest share of MPUs in the market utilizes high-end ARM processor cores. At the same time, MPUs integrate high-performance RAM and DDR interfaces to achieve high-speed performance in system memory and data throughput. As the demand for computing power on MPUs increases, processors internally integrate coprocessors for deep learning, DSP, and real-time control cores. The communication bus rate, real-time capabilities, and confidentiality requirements of processors are increasingly high, leading to the integration of industrial communication interfaces such as Gigabit Ethernet and TSN for high-speed communication cores needed in industrial environments.

The Sitara AM2x is a product that combines traditional MCUs and traditional MPUs. Ying Shi, Director of Embedded and DLP® Applications at TI China, introduced that TI has integrated high-performance ARM cores, high-performance RAM, high-speed signal processing, and industrial communication high-speed real-time bus interfaces, along with common functional safety and information security features found in MCUs, and the unique real-time peripherals of MCUs, to design the Sitara AM2x series MCUs. Compared to traditional flash-based MCU products, engineers can leverage the AM2x series to increase computing capability by tenfold.

Low-Power MCU Achieving Processor-Level Performance

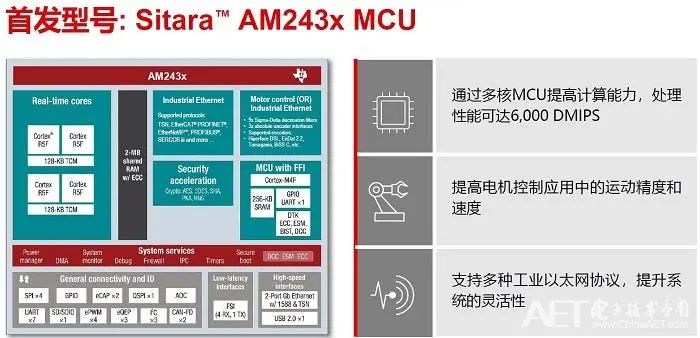

The AM243x MCU is the first model of the AM2x series, featuring up to four Arm Cortex®-R5F cores, with each core running at frequencies up to 800MHz. These four R5F Cortex cores, along with some internal accelerators and coprocessors, can provide up to 6000 DMIPS of computing power.

(Image source: TI)

In factory equipment such as robotics, rapid computing capabilities combined with high-speed access to internal memory in MCUs can simultaneously enhance the motion accuracy and speed of robots, thereby improving productivity. In typical applications, the AM243x device can achieve 6000 DMIPS computing performance levels while consuming less than 1W of effective power.

Integrated Design Achieving Real-Time Control and Multi-Protocol Network Support at the Edge

The Sitara AM243x MCU integrates sensing and driving peripherals, enabling it to work with processors to complete high-precision motor control or fast IO control tasks, achieving low-latency real-time processing and control in factory automation.

The AM243x device expands TI’s support for multiple Gigabit industrial Ethernet protocols and Time-Sensitive Networking (TSN), facilitating the next generation of factory networks. With the AM243x, engineers can utilize certified protocol stacks directly provided by TI to comprehensively support industrial communication standards such as EtherNet/IP™, EtherCAT®, PROFINET®, and IO-Link master stations, while also providing proprietary support for industrial automation customers to customize their unique TSN or industrial Ethernet-based private protocols.

Meeting SIL3 Standards, Ensuring Safety

The on-chip security features of the AM243x MCU support new encryption requirements, integrating functional safety mechanisms, diagnostics, and auxiliary functions to help system integrators meet the safety integrity level (SIL) 3 requirements of the IEC 61508 standard in their industrial designs, or the Automotive Safety Integrity Level (ASIL)-D, in compliance with the functional safety standards required in industrial and automotive fields.

TI has integrated all functionalities and performance into a single chip, allowing the AM2x series to achieve real-time control of industrial communications, analytical processing, information security, and functional safety at the edge. Furthermore, to further reduce design and development complexity, TI’s official website offers many easy-to-use development tools, such as the AM243x LaunchPad evaluation kit for the Sitara AM2x MCU, along with software packages, SDKs, and other supporting software; additionally, through the new online resource MCU+ Academy, engineers can define their learning content and course pace to complete their learning of processors and supporting tools and SDKs, thus helping engineers accelerate their product design.

Currently, for the AM243x series, TI offers pre-production versions AM2431, AM2432, and AM2434 in 17mm × 17mm or 11mm × 11mm packages, targeting a wide range of applications including industrial automation, PLCs, motor control, robotic arms, and industrial multi-protocol with high-speed communication interfaces.

The industrial application field involves various terminal devices, each with different requirements for electronic control systems. TI’s Sitara AM2x series fills the “shortcomings” of MCUs in processing performance, allowing a single chip to integrate usability, real-time capabilities, high processing power, and safety, thus meeting the diverse application scenarios’ needs for high-performance computation, real-time control, real-time communication, high integration, and ease of use, enabling customers to expand their design options. MCU or MPU? Try the Sitara AM2x MCU!

☞ Business Cooperation: ☏ Please call 010-82306118 / ✐ Or email [email protected]