A PLC (Programmable Logic Controller) is a digital electronic system used for controlling, executing, and monitoring automated machinery. It is widely applied in various fields such as building equipment control, water treatment, energy, and industrial automation, forming a large market scale. With the development of the “New Four Modernizations” in automotive electronics, the growth rate of the PLC market is expected to accelerate further. According to market intelligence company Mordor Intelligence, the PLC market size is projected to reach $12.8 billion by 2024, with a compound annual growth rate of 4.32%, while the Asia-Pacific region is the largest and fastest-growing application market.

Overview of Jihai APM32F407 PLC Applications

The performance metrics of PLC are primarily evaluated through scan cycle, storage capacity, and functionality, with the scan cycle playing a decisive role. The scan cycle is mainly influenced by the number of I/O input points, the execution of instructions by the main control chip, and computations. In cases of complex functionality, higher frequency requirements are also necessary.

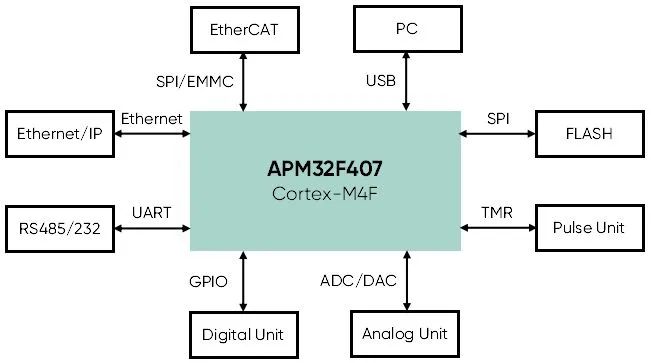

The Jihai APM32F407 microcontroller, based on the Arm®Cortex®-M4F advanced core, has a maximum frequency of 168MHz, and supports both floating-point and signed numerical operations. This helps improve the PLC scan cycle performance, allowing for basic logic controls such as bitwise AND, OR, NOT, and XOR.

Block diagram of APM32F407 PLC application scheme

Advantages of Jihai APM32F407 PLC Applications

-

Short instruction execution cycle, fast data computation speed, supports symbolic and floating-point calculations

-

Integrates rich resources such as digital communications, I/O control, pulse control, and analog control

-

Strong expandability: integrates expansion board interfaces, allowing for module installation based on different scene requirements

-

Strong anti-interference and stability: uses electrically isolated input/output interfaces

-

Supports data backup

Application fields: cutting machine tools, conveyor belts, elevators, packaging workshops, smart greenhouses, etc.

Introduction to Jihai APM32F407 Chip

-

High Performance: Uses 55nm production technology, based on the Arm®Cortex®-M4F advanced core, supports single-precision floating-point FPU

-

Large Capacity: Built-in 192+4KB SRAM, 1MB FLASH

-

Rich Peripheral Resources: Integrates USB_OTG, Ethernet, CAN, EMMC, etc., enriching the functionality between controller boards to meet various development needs

-

Durability: Operating temperature ranges from -40℃ to 105℃, with higher tolerance for electromagnetic and high-temperature environments, suitable for complex industrial working environments

The programmable logic controller application scheme based on Jihai APM32F407, with advantages of high reliability, strong flexibility, easy expansion, and user-friendliness, has been recognized by many leading manufacturers in industrial control and automotive electronics.

In 2024, focusing on the mid-to-high-end fields in industrial automation, Jihai will further improve the APM32 series industrial-grade MCU product line, supporting the serialization of high-performance real-time control MCU products; in the field of new energy, Jihai will actively layout high-performance analog and mixed-signal chips, providing MCU+ products and application scheme support; aiming to provide more powerful domestic chips and mature solutions for industrial automation and digital transformation.