If you ask: What is the best programming language for robots?

Computer vision programmers will give different answers than cognitive robot developers. Everyone disagrees on what is the “best programming language”; the first language to learn is often the most practical answer, as it depends on the type of application you are developing and the systems you are using.

Top 10 Popular Programming Languages for Robots

There are over 1500 programming languages in the world, and here are the ten most popular programming languages currently used in robotics. Each language has different advantages for robots:

10

BASIC / Pascal

BASIC and Pascal are foundational to several industrial robot languages. BASIC is designed for beginners (it stands for Beginner’s All-purpose Symbolic Instruction Code), allowing novices to start learning from a very simple programming language. Pascal was designed to encourage good programming practices and introduces constructs like pointers, making Pascal a “gateway” language from BASIC to more complex languages.

Today, these two languages might be considered somewhat outdated as good “everyday use” programming languages. However, if you plan to do a lot of low-level coding or want to familiarize yourself with other industrial robot programming languages, learning them can still be useful.

9

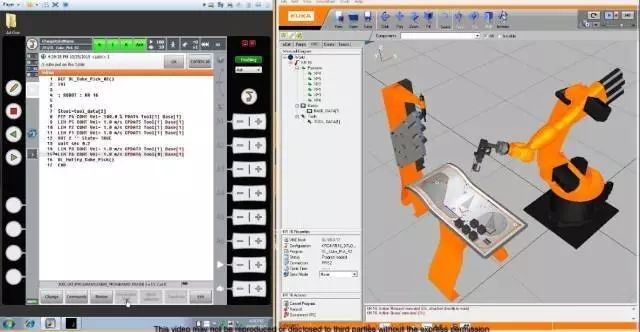

Industrial Robot Languages

Almost every robot manufacturer has developed its own proprietary robot programming language. You can familiarize yourself with a few by learning Pascal. However, every time you start with a new robot, you still need to learn a new language.

ABB has the RAPID programming language. KUKA has KRL (Kuka Robot Language). Comau uses PDL2, Yaskawa uses INFORM, and Kawasaki uses AS. Then, Fanuc robots use Karel, Stäubli robots use VAL3, and Universal Robots use URScript.

In recent years, programming options like ROS Industrial have begun to provide programmers with more standardized options. However, if you are a technician, you are more likely to use the manufacturer’s language.

8

LISP

LISP is the second oldest programming language in the world (FORTRAN is older by just a year). It is not as widely used as many other programming languages on this list; however, it remains very important in artificial intelligence programming. Part of ROS is written in LISP, although you do not need to know it to use ROS.

7

Hardware Description Language (HDL)

Hardware Description Languages are essentially programming methods for describing electronic devices. These languages are quite familiar to some robotic experts as they are used to program Field Programmable Gate Arrays (FPGAs). FPGAs allow you to develop electronic hardware without actually producing silicon chips, making them a faster and easier development option.

If you are not into electronic prototyping, you may never use HDL. Even so, it is important to know they exist, as they are completely different from other programming languages. For one, all operations are executed in parallel rather than in a processor-based language.

6

Assembly

Assembly allows you to program at the 0 and 1 level. Essentially, this is the lowest level of programming language. Until recently, the lowest level electronics required Assembly for programming. With the rise of Arduino and other microcontrollers, you can now conveniently program at a low level using C/C++. This means Assembly may become less necessary for most robotics experts.

5

MATLAB

MATLAB, along with its associated open-source resources like Octave, is particularly favored by some robotic engineers, as it is used for data analysis and control system development. There is also a very popular robotics toolbox—MATLAB. I know of experts who can develop entire robotic systems using only MATLAB. If you want to analyze data, generate advanced images, or implement control systems, you might want to learn MATLAB.

4

C# / .NET

C# is a proprietary programming language provided by Microsoft. I include C#/ .NET here mainly because it is used as the primary language in Microsoft Robotics Developer Studio. If you are going to use this system, you may need to use C#. However, learning C/C++ first may be a good choice for long-term development of coding skills.

3

Java

Some computer science degrees teach Java as their first programming language. Java hides low-level memory functions from the programmer, making it easier to program than C, but this also means you have less understanding of what your code is actually doing. If you come to robotics from a computer science background (many do, especially in research), you may have learned Java.

Like C# and MATLAB, Java is an interpreted language, meaning it is not compiled into machine code. Instead, the Java Virtual Machine interprets instructions at runtime. The theory behind using Java is that, due to the Java Virtual Machine, you can use the same code on many different machines. In practice, this does not always work and can sometimes lead to slower code execution. However, Java is very popular in certain aspects of robotics, so you may need it.

2

Python

Python has seen a significant resurgence in robotics in recent years. One reason could be that Python (and C++) are the two main programming languages found in ROS. Like Java, it is an interpreted language. Unlike Java, the primary focus of the language is ease of use. Many people find this very appealing.

Python saves a lot of boilerplate code that takes time in programming, such as defining and converting variable types. Additionally, there are many free libraries, which means that when you need to implement some basic functionality, you do not have to “reinvent the wheel.” And because it allows simple bindings to C/C++ code, this means that performance-critical parts of the code can be implemented in those languages to avoid performance degradation.

1

C / C++

Finally, we arrive at the number one programming language for robots! Many believe that C and C++ are a good starting point for new robotics engineers. Why? Because many hardware libraries use these two languages. These languages allow interaction with low-level hardware and enable real-time performance; they are very mature programming languages.

Nowadays, you might use C++ more than C because the former has more features. C++ is essentially an extension of C. Learning a bit of C will be useful, especially when you find that a hardware library is written in C. C/C++ is not as easy to use as Python or MATLAB. Likewise, achieving the same functionality in C will take significantly more time and require more lines of code. However, since robotics heavily relies on real-time performance, C and C++ are the programming languages closest to what we robotics experts consider the “standard language.”

One of the main features of robots is their versatility, and the programmability of robots is an important means of achieving this feature. Robot programming inevitably involves robot languages. Robot languages are methods of describing robot actions using symbols, enabling robots to perform various operations according to the programmer’s intentions.

The emergence and development of robot languages are closely related to the development of robotics technology and computer programming languages. The core issue of programming systems is the motion control problem.

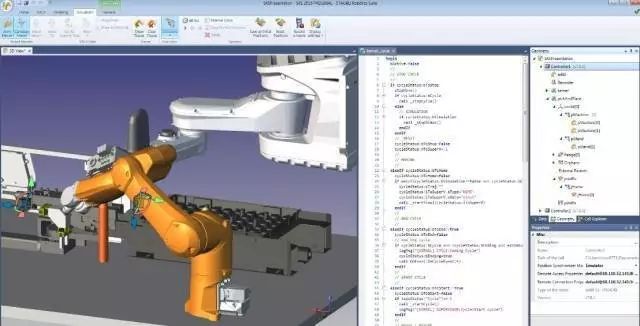

Robot Programming Systems and Methods

Robot programming is the intersection of robot motion and control issues, and it is one of the most critical issues in robotic systems. Currently, practical industrial robots often use offline programming or teaching methods. During the debugging phase, the compiled program can be executed step by step through a teaching control box, and once debugging is successful, it can be put into formal operation.

Robot language operating systems include three basic operational states:

1. Monitoring state: used for overall system supervision and control;

2. Programming state: provides operators with the ability to compile or edit programs;

3. Execution state: used to execute the robot program.

The robot source program is converted into machine code so that the robot control cabinet can read and execute it directly, significantly speeding up the running of the compiled program.

Different programming is required based on the robot’s various work requirements. Programming capability and methods are closely related; the programming method determines the robot’s adaptability and operational capability. With the widespread application of computers in industry, computer programming for industrial robots has become increasingly important.

Programming languages are also diverse, and currently, the programming methods for industrial robots include the following:

1

Sequential Control Programming

In sequential control machines, all control is achieved through mechanical or electrical sequential control, generally without the requirement for program design. The flexibility of sequential control is limited because all work processes are pre-edited, controlled by mechanical stops or other determinate methods. Many automata operate under sequential control, and the main advantages of this method are low cost, ease of control, and operation.

2

Teaching Method Programming

Currently, most industrial robots have the capability to be programmed using the teaching method. Teaching method programming can generally be divided into two types: hand-guided teaching programming and teaching box programming:

(1) Hand-guided Teaching Programming: This is mainly used in industrial robots for tasks such as painting and arc welding that require continuous trajectory control. The specific method involves using a teaching handle to guide the end effector through the required positions, while sensors detect the coordinate values at each joint of the industrial robot, and the control system records and stores this data. In practice, the control system of the industrial robot will reproduce the taught trajectory and operational skills.

Hand-guided teaching programming can also achieve point control; unlike CP control, it only records the positions of the two endpoints of the trajectory program, with the speed of the trajectory movement determined by the functional data corresponding to each segment of the trajectory program.

(2) Teaching Box Programming Method involves manually using the buttons on the teaching box to drive the joints of the industrial robot, performing single-axis movements or coordinated movements of multiple joints in the required order to complete the teaching programming for positions and functions. Teaching box programming is generally used for large robots or in hazardous conditions.

3

Offline Programming or Pre-Programming

Offline programming and pre-programming mean the same thing; it refers to programming using robot programming languages in advance through teaching methods. The advantages of offline programming include:

(1) Programming can be done without using the robot, freeing it up for other tasks;

(2) Operational plans and cycles can be optimized in advance;

(3) Previously completed processes or subprograms can be incorporated into the newly programmed program;

(4) External information can be detected using sensors, allowing the robot to respond accordingly. This response enables the robot to work in an adaptive manner;

(5) Control functions can incorporate existing Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) information;

(6) Pre-run programs can simulate actual movements, avoiding hazards and assisting programming by simulating robot movements on screen;

(7) For different work purposes, only a portion of the pending program needs to be replaced.

In non-adaptive systems, there is no feedback from the external environment; the only input is the measurement values from joint sensors, allowing for the use of simple programming design methods.

Programming Requirements for Robots:

1. Ability to establish a world model;

2. Ability to describe the robot’s tasks;

3. Ability to describe the robot’s movements;

4. Allow users to specify execution processes;

5. Provide a good editing environment.

Types of Robot Editing Languages:

1. Action Level

(AL language system, LUNA language and its features)

2. Object Level

(AUTOPASS language and its features, RAPT language and its features)

3. Task Level

Source: Yizhang Robot, Control Engineering Network

If there are copyright issues, please contact us for resolution.

Selected Past Articles

-

The first national industrial robot vocational skills competition training camp is now open for registration!

-

The “Harbin Institute of Technology Cup” Industrial Robot Virtual Simulation Competition 2017 is starting, waiting for you to join!

-

Finally found it all! Various clear dynamic principle diagrams of industrial robots!