Industry 4.0

Data stream platforms enhance overall factory efficiency

by connecting devices

-

Just-In-Time (JIT) forecasting -

Building factory capacity -

Staffing and shift conditions -

Fluctuations in raw material and product prices

-

Making production processes more efficient -

Cost-effective and fast -

Minimizing error rates

When to Use Kafka, MQTT, and OPC-UA

-

Agents at millions of customer levels (e.g., mobile applications) -

API management platforms -

Databases for complex queries and batch analysis -

IoT platforms with device management and other functions -

A technology for hard real-time applications

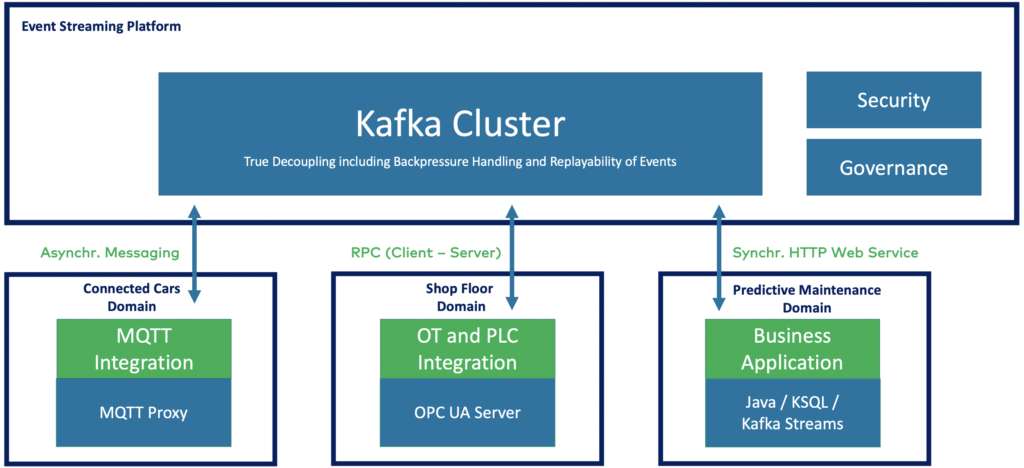

Using Domain-Driven Design and True Decoupling for Separation

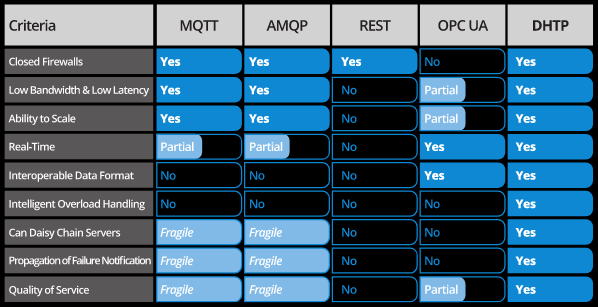

OPC-UA, MQTT, HTTP, and Others

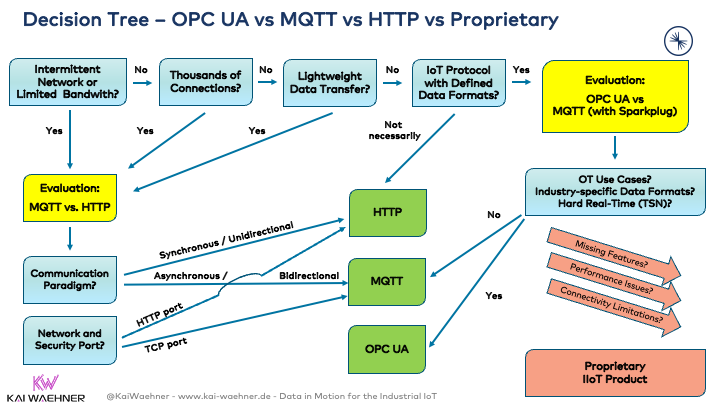

Decision Tree for Evaluating IoT Protocols

-

HTTP/REST is very suitable for simple use cases (keep it as simple as possible). The understandable and easy-to-use nature of HTTP applies to almost any scenario. It does not require additional tools, APIs, or middleware, and its communication is synchronous “request-response.” If you can use HTTP (S) ports 80 or 443 instead of other TCP ports, you can also get the cooperation of the security team smoothly. Of course, HTTP belongs to one-way communication. For example, connected cars need an HTTP server to obtain data pushed from the cloud, and they will use pub/sub. -

MQTT is very suitable for scenarios with tens of thousands or hundreds of thousands of devices, using limited bandwidth and intermittent networks (e.g., connected car infrastructure). Its communication uses an MQTT broker as an intermediary for asynchronous publish and subscribe. MQTT does not use a standard data format, but developers can use Sparkplug to build additional components. MQTT is very lightweight, and its Quality of Service (QoS) and last will features solve various requirements of IoT use cases out of the box. At the same time, MQTT is very suitable for two-way communication (e.g., connected car<–>cloud communication) and other IT use cases. Additionally, LoRaWAN and other low-power wide-area networks are very suitable for MQTT. -

OPC-UA is very suitable for industrial automation (e.g., machines on the production line). Today’s communication is usually client/server but also supports publish/subscribe. It uses standard data formats and provides rich, powerful, complex functionalities, components, and industry-specific data format sets. OPC-UA is very suitable for scenarios where OT and IT are integrated. The TSN (Time-Sensitive Networking) of OPC UA is an optional component. It is an Ethernet communication standard that can provide open, deterministic, and hard real-time communication. -

Proprietary protocols are suitable for specific problems that standardized implementations cannot solve. These protocols often have their pros and cons. They often bring powerful high performance but are also expensive and have limitations.

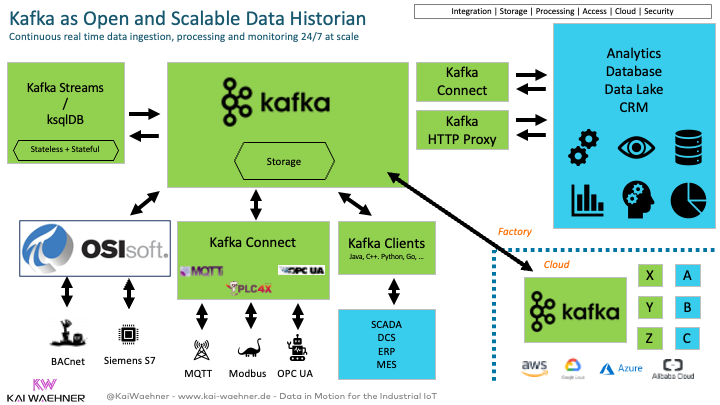

Integration of MQTT, OPC-UA, and Kafka

-

Kafka Connect connectors: can achieve native Kafka integration at the protocol level. Confluent Hub (https://www.confluent.io/hub/) can serve as an alternative. Some companies often build their custom Kafka Connect connectors. -

Custom integration: integration through low-level MQTT/OPC-UA APIs (e.g., using Kafka’s HTTP/REST proxy) or Kafka clients (e.g., .NET/C++ for Windows environments). -

Open third-party IoT middleware: general open-source integration middleware (e.g., Apache Camel with IoT connectors), IoT-specific frameworks (e.g., Apache PLC4X or Eclipse Ditto), or proprietary third-party IoT middleware based on standard APIs. -

Commercial IoT platforms: suitable for existing legacy deployments and can act as a “glue” for code and protocols (e.g., Modbus, Siemens S7, etc.). Traditional historical data, proprietary protocols, monolithic architectures, limited scalability, and ETL batch processing platforms are very suitable for adopting commercial IoT platforms to bridge the gap between on-premises and cloud services.

Using OPC-UA or MQTT to Connect Machines and Devices

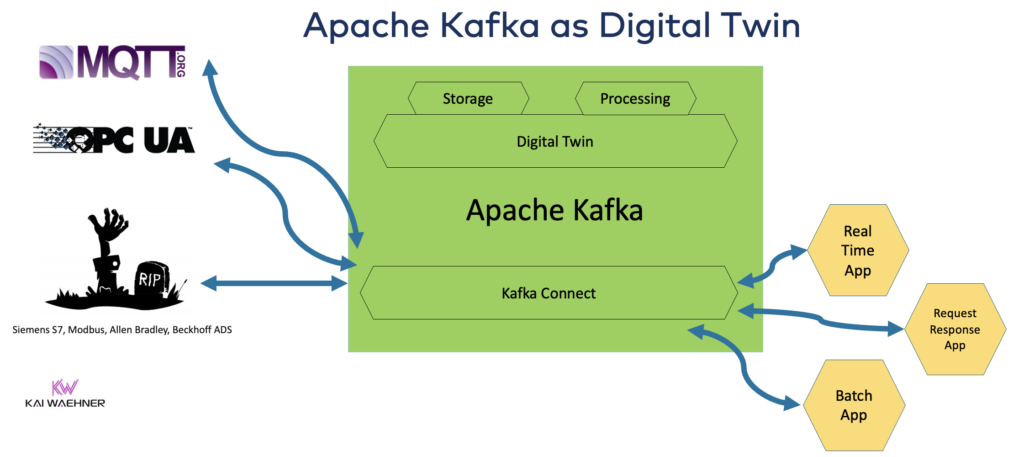

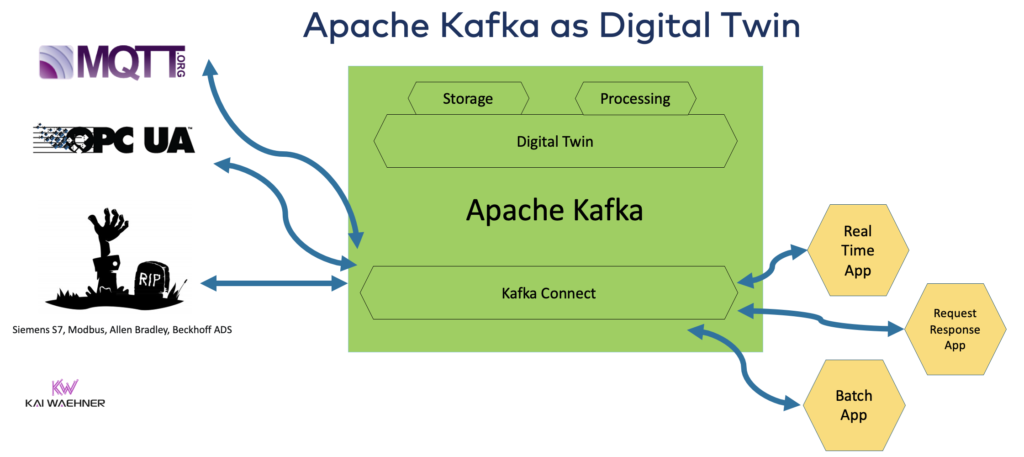

Developing and Predicting Simulations of Digital Twins

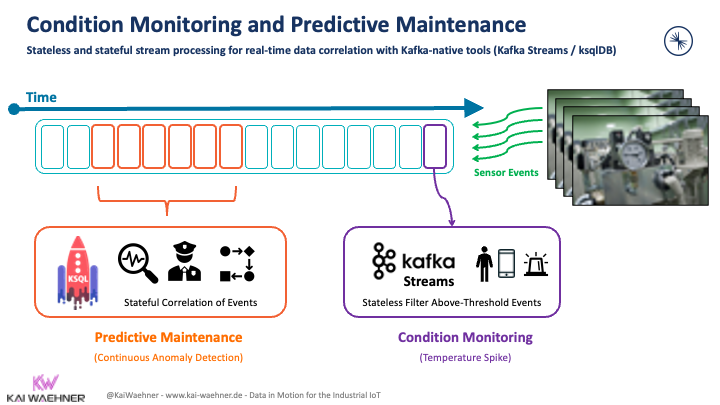

Condition Monitoring and Predictive Maintenance

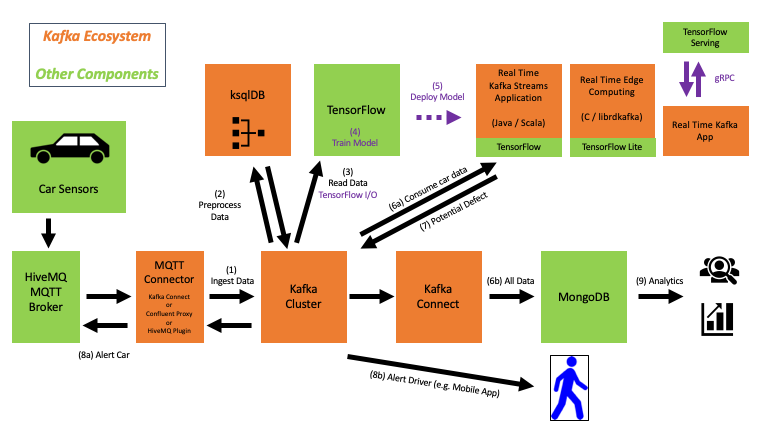

Connected Cars and Streaming Machine Learning

BMW Case Study

Implementing Manufacturing 4.0 with Smart Factories and Cloud Services

-

Acquire IoT data without impacting other services and transmit it to the correct location -

Collect once, process and consume multiple times (different consumers at different times using different communication paradigms, such as real-time, batch processing, request-response) -

Achieve scalable real-time processing and shorten time to market

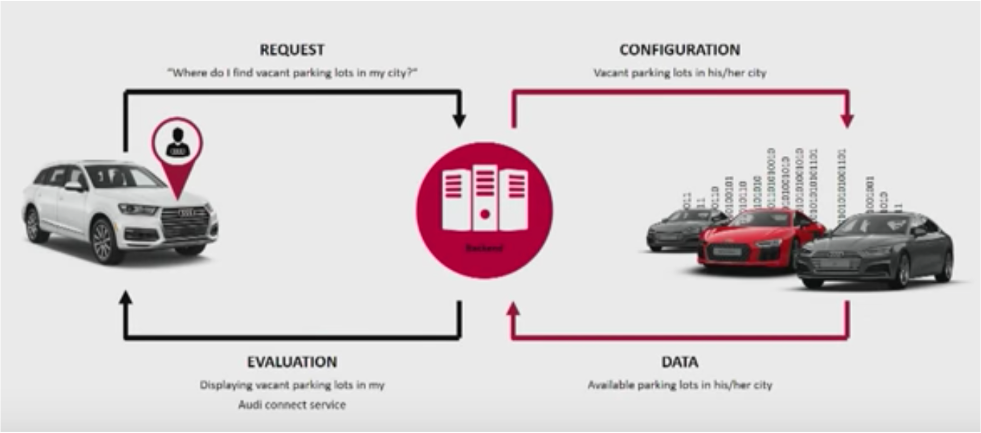

Audi Case Study

Connected Cars with Swarm Intelligence

Aside