“

From April 7 to April 13, semiconductor industry upstream and downstream market information.

01

Upstream and Midstream

1. Inovance Technology’s market value exceeds170 billion yuan, new motor project about to be put into production

Inovance Technology’s stock price has reached a historical high, with a total market value of174.4 billion yuan. Its investment of5 billion yuan in the Suzhou motor project is entering the countdown to production, with an expected annual output of high-performance servo motor controllers2 million units, targeting the industrial robot and new energy vehicle markets.

2. Infineon collaborates with Panasonic to develop normally closed600V GaN power devices

Infineon and Panasonic announced a joint development of gallium nitride (GaN) power devices based on silicon substrates, aimed at applications in new energy vehicle electronic control systems. Both parties will share technology patents, with mass production expected in2026, promoting the development of electronic control systems towards higher energy efficiency and miniaturization.

3. Shanghai Electric Drive showcases integrated electronic control solutions at the Munich Electronics Show

Shanghai Electric Drive presented a multi-in-one electric drive system at the2025 Munich Shanghai Electronics Show, focusing on the application of silicon carbideMOSFET in motor controllers, and has reached supply chain cooperation intentions with international manufacturers such as Infineon and TDK.

4. Panasonic restructures home appliance business, accelerates layout in the new energy field

Panasonic announced the split of its home appliance business into three subsidiaries: smart living, cold chain, and electrical engineering, while divesting its loss-making television business. The strategic focus is shifting towards new energy vehicle electronics and industrial automation, with plans to expand factories in China to enhance the production capacity of automotive-grade motor controllers.

5. BYD releases1500V SiC chip and obtains torque control patent

At the Supere platform launch, BYD introduced a1500V automotive-grade silicon carbide (SiC) chip, setting a new industry voltage level record. At the same time, it obtained the invention patent for“vehicle torque steering compensation” to optimize the dynamic response of motor controllers to drive motors.

6. Infineon releasesDrive Core scalable motor control platform

Infineon launched theDrive Core platform based onAURIX™,TRAVEO™, andPSOC™, supporting motor control needs from entry-level to high-performance, covering electric vehicles, industrial automation, and more. The platform reduces development cycles by30% through modular design and is compatible with various sensor interfaces.

02

Downstream

1. Tesla’sOptimus robot’s next-generation actuator is about to be released

TeslaCEO Elon Musk showcased the latest walking video of theOptimus robot, emphasizing its fine motion control capabilities achieved through reinforcement learning. The next-generation actuator is expected to be released alongside theGen3 version, further enhancing motion control precision and driving breakthroughs in humanoid robot motor control technology.

2. Nissan releases the third generatione-Power system

Nissan launched the third generatione-Power hybrid system, integrating a five-in-one motor unit and optimizing internal combustion engine power generation efficiency. The new system improves fuel economy by15%, planned to be equipped in mass production vehicles in2026, strengthening Nissan’s competitiveness in the electric drive integration field.

3. Fangzheng Motor increases investment in subsidiary, accelerates expansion of new energy drive systems

Fangzheng Motor announced an investment of100 million yuan in its wholly-owned subsidiary Deqing Fangzheng to expand the production line for new energy drive motor stators and rotors. Previously, the company received an order from Volkswagen (Tianjin) for1.2 million drive motors, which are expected to enter mass production in the third quarter of2025.

4. CRRC Times Electric leads the motor controller installation volume ranking

In March2025, data from the new energy electronic control market shows that Fudi Power (BYD), Inovance Joint Power, and Huawei Digital Energy occupy the top three positions, with a combined share of nearly50%. CRRC Times Electric, leveraging its rail transit technology accumulation, has seen significant growth in the commercial vehicle electronic control market.

5. From groundbreaking to topping out in just a hundred days, Inovance5 billion investment motor project enters countdown to production

On March25, 2025, the Inovance new energy vehicle component production base (Phase I) with a total investment of5 billion yuan successfully topped out in Wuzhong District, Suzhou. The project started and was completed in just2 months, with the time from groundbreaking to topping out taking only a hundred days, showcasing remarkable construction speed and demonstrating the project’s“acceleration”. The motor controllers and electric drive assemblies produced at this base will serve models such as Xiaomi’sSU7, with an expected annual production capacity exceeding3 million sets.

6. The policy dividends of China’s motor controller industry continue to be released

The Ministry of Industry and Information Technology’s “Green Low-Carbon Transformation Industry Guidance Catalog (2024 Edition)” lists efficient motor controllers as a key support direction, promoting enterprises to enjoy tax reductions and subsidies. According to the Huajing Industry Research Institute, the domestic market scale is expected to exceed80 billion yuan by2025, with a CAGR of22%.

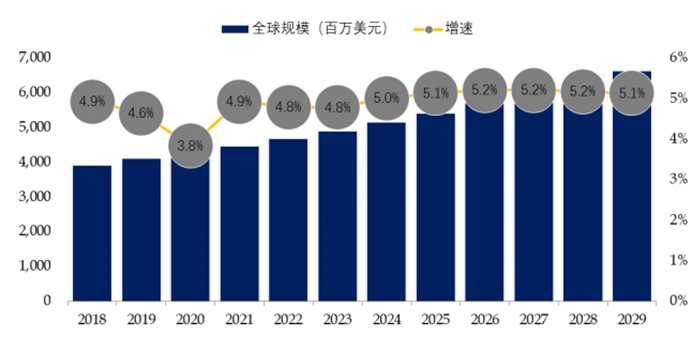

Analyst Comments: In 2025, the motor controller market is undergoing a dual transformation of technological iteration and industrial pattern reshaping. From a global perspective, according toResearch And Markets data, the global motor controller market size is expected to reach approximately5.1 billion USD in 2025, with a compound annual growth rate (CAGR) of5.15%. China, with a share of28.08%, is closely following the United States, playing an increasingly important role. New energy vehicles, drones, humanoid robots, and home appliances are potential downstream fields.

Data Source:Research And Markets

In terms of technological trends, the application of silicon carbide (SiC) materials in electronic control is accelerating. The use of silicon carbide materials can reduce controller losses from6.6% to2.0%, improving system efficiency by2%-4%, and achieving a10% increase in range in new energy vehicle inverters (for example, after using silicon carbide inverters, the charging time of TeslaModel 3 is reduced by20%).

The high-frequency characteristics of silicon carbide allow switching frequencies to reach5-10 times that of silicon-based devices, effectively reducing the size of inductors and capacitors, shrinking the motor controller size by30%-50%.

Currently, companies such as Huawei and BYD are enhancing power density and reliability through silicon carbide technology and integrated design (such as seven-in-one electric drive systems) and patent innovations (such as BYD’s busbar capacitor optimization technology). It is foreseeable that silicon carbide technology will drive motor controllers towards high efficiency, miniaturization, and intelligence.

In terms of the supply chain, domestic companies such as Tianke Heda and Tianyu Semiconductor have achieved mass production of6 inch SiC substrates, while midstream packaging companies like SIDA Semiconductor and Hongwei Technology have launched automotive-grade SiC MOSFET modules, which also have certain cost advantages, but high-end packaging technologies (such as double-sided water cooling) still rely on imports; downstream companies are led by automakers, with BYD and Tesla developing their own SiC electronic control systems, accounting for over40% of the installation volume, while third-party manufacturers like Inovance provide multi-in-one electric drive solutions compatible with all vehicle platforms. The latest products generated from Inovance’s new production base are expected to exceed3 million sets in annual production capacity by2025, assisting automakers in achieving further technological upgrades.

Silicon carbide in the motor controller supply chain exhibits characteristics of “accelerated technological breakthroughs, rise of domestic substitution, and diversification of application scenarios.” In the short term, material and cost bottlenecks need to be overcome; in the long term, with the mass production of8 inch substrates and the improvement of ecological collaboration, silicon carbide will reshape the power electronics industry landscape, becoming a core support for efficient energy systems.

Chinese companies, with policy support and vertical integration capabilities, are expected to occupy a more important position in the global supply chain.

This article is an original piece from the Semiconductor Device Application Network and may not be reproduced without permission and authorization; otherwise, legal responsibility will be strictly pursued. — Previous Recommendations —

— Previous Recommendations —

END

More quality public account recommendations

▲ Click the card above to follow

Deeply track the dynamics of major connector manufacturers and analyze industry hot technology trends

▲ Click the card above to follow

Focus on the latest news and authoritative interpretations in the electronic transformer and inductor industry

Star us · Don’t miss every new push

① Click the card area “…”

② Click “Set as Star”

Looking forward to your one-click three connections~

Like

Forward

Looking