Skip to content

For more products and services, visit our official website:https://www.si-era.com/

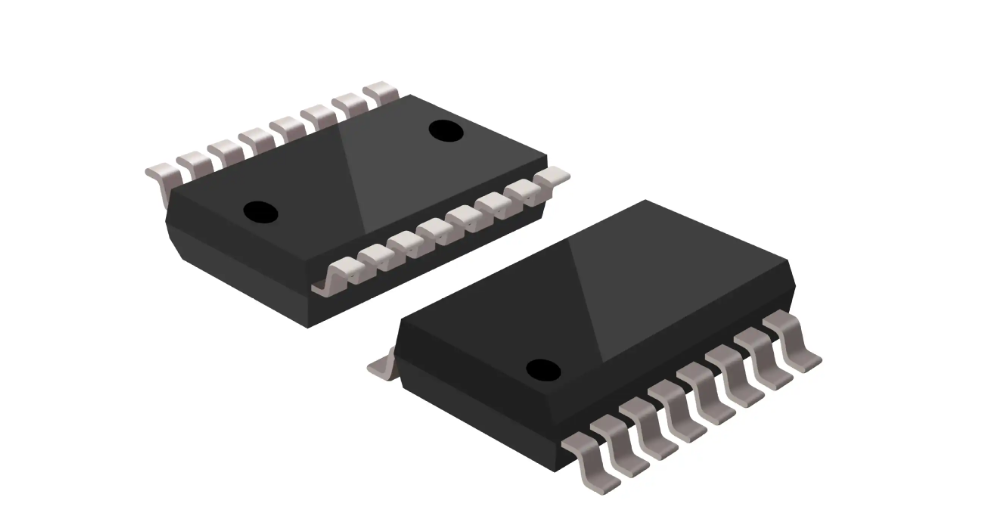

In the field of semiconductor packaging, SOP (Small Outline Package) and SOP8 often cause confusion. Today, we will clearly reveal the differences and characteristics between SOP and SOP8 through a Q&A format.

If we often meet, click above to follow us and set us as a star!

A:SOP, or Small Outline Package, is a type of surface mount technology (SMT). It directly solders the pins of electronic components onto the surface of a printed circuit board (PCB), eliminating the need for through-hole connections, achieving miniaturization and lightweight design of products. SOP packaging is widely used in various electronic products due to its compact size and efficient performance.

A:SOP8 is a specific specification within the SOP series, featuring 8 pins arranged in a 2×4 configuration, meaning two rows of four pins each. SOP8 packaging is physically smaller while maintaining stable performance and efficient heat dissipation. It is primarily used in specific fields such as analog circuits, DC/DC power supplies, and chargers.

Q3: What are the main differences between SOP and SOP8?

A:The main differences between SOP and SOP8 lie in their packaging forms and application fields. SOP is a general packaging form with various pin counts and arrangements, capable of adapting to different circuit design needs. Conversely, SOP8 is a specific specification within the SOP packaging form, featuring a fixed 8 pins and a specific pin arrangement, typically used in certain circuit designs. Additionally, SOP8 is relatively smaller in physical size, making it more suitable for space-constrained electronic products.

Q4: What performance differences exist between SOP and SOP8?

A:In terms of performance, both SOP and SOP8 maintain high stability and reliability. They utilize soldering connection technology, capable of withstanding various mechanical shocks and vibrations, ensuring stable operation of electronic products. Additionally, both SOP and SOP8 have good heat dissipation capabilities, helping electronic products remain cool during prolonged operation.

Q5: How to choose between SOP and SOP8 packaging technology?

A:When choosing between SOP and SOP8 packaging technology, it is essential to consider the specific circuit design requirements and application scenarios. If the circuit design has specific requirements for packaging size and pin count, or needs to be used in space-constrained electronic products, SOP8 may be a better choice. On the other hand, if the circuit design is more flexible and needs to accommodate different pin counts and arrangements, SOP is a more general option.

Through the above Q&A format, we believe you now have a clearer understanding of SOP and SOP8 packaging technology. In future electronic product design and development, selecting the appropriate packaging technology will help improve product performance and reliability, bringing more convenience and enjoyment to your life.

Recently, some friends messaged us: Why haven’t we seen the articles in time? Because WeChat has changed its push rules!!! If you haven’t clicked「Like」 or「Looking」, or haven’t marked us as「Star」, this situation may occur.

Mark us as a star, so you won’t get lost! Important things are said three times!If you don’t want to miss exciting articles, after reading the article, please click「Like」 or「Looking」, and setMicro-Nano Research Institute as a「Star」, so you can meet us on time every day!

Share with your friends! ↓