Currently, both internationally and domestically, the reliable operation and efficient utilization of medical equipment have become fundamental, critical, and urgent issues faced by hospitals.

There are many problems in the field of medical equipment operation and maintenance, mainly due to two reasons:

First, most of the current medical equipment still belongs to non-intelligent devices, which cannot achieve fully automated data collection;

Second, hospital equipment management personnel and service providers are unaware of the equipment’s status when providing services, needing to check on-site for analysis before formulating maintenance plans, leading to long service cycles that severely impact clinical use and subsequently decrease patient satisfaction.

With the arrival of the smart era, the drawbacks of traditional maintenance methods are becoming increasingly apparent.

Remote operation and maintenance services are not equivalent to “long distance”; they primarily involve the collection of operational state data from smart equipment/products, utilizing data analysis and expert systems to provide users with remote online detection, fault warning, fault diagnosis and repair, predictive maintenance, operational optimization, remote upgrades, and benefit analysis services.

However, due to the existence of multiple types and brands of medical equipment, achieving practical and meaningful results is challenging.

01 Key Issues Addressed by Remote Operation and Maintenance Management of Medical Equipment

1. Change the traditional manual management model of equipment status.

By deploying a large number of collectors to gather key status information, enrich data sources, and enhance the real-time nature and frequency of data collection, a solid foundation for big data analysis is established.

2. Reduce the labor intensity of management personnel.

The data collection tasks for remote maintenance of medical equipment are undertaken by an online signal acquisition system, allowing management personnel to focus on emergency responses, thereby reducing labor intensity and ensuring personal safety.

3. Improve the ability to monitor the status of medical equipment.

By enhancing the timeliness and accuracy of equipment detection, achieving automatic alarm protection, recording technical data before and after faults for diagnosis, determining fault points, and inferring the causes of faults, the efficiency of fault resolution is improved.

4. Change the traditional planned maintenance model to achieve predictive maintenance of medical equipment.

By establishing analytical and early warning models to analyze the vast amounts of collected data, predictive and foresight maintenance of medical equipment status can be achieved, significantly reducing sudden failures and spare parts inventory.

5. Enhance personnel and equipment efficiency.Utilizing data analysis to achieve precise operational management of key equipment (large equipment) across all business processes including procurement, maintenance, upkeep, measurement, and quality control.

6. Improve the compatibility and integration of medical equipment with maintenance management platforms, achieving interconnectivity of big data from medical equipment to support intelligent maintenance management.

02 Solutions for Remote Operation and Maintenance Management of Medical Equipment

1. Develop real-time online monitoring devices using advanced data collection technologies to solve the problem of collecting real-time data on equipment status, replacing traditional manual collection methods.

2. Learn from industrial internet technologies to solve data transmission issues among various types and brands of medical equipment in medical scenarios through automatic data transmission technology, achieving IoT for multiple types of medical equipment, interconnectivity of multiple systems, integration of multi-professional data, and human-computer interaction.

3. Employ adaptive early warning models, intelligent diagnostic models, degradation trend prediction models, big data analysis models, spare parts storage models, and maintenance models to address challenges in monitoring the operational status of medical equipment, fault identification, lifespan prediction, predictive maintenance, and benefit analysis, enabling remote intelligent decision-making on equipment status.

4. Develop cloud-based functionalities for data storage, analysis, knowledge base, apps, and expert remote connections, combined with intelligent devices such as smart glasses and helmets to provide remote maintenance support services.

5. Apply network information security technologies to construct a system information security architecture, implementing security measures to safeguard the information security of the remote maintenance platform.

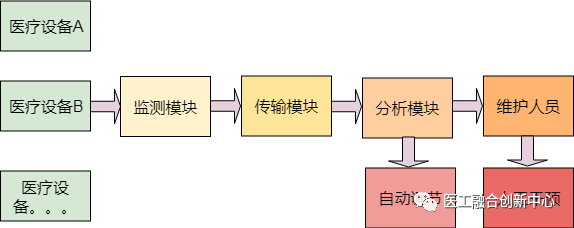

Therefore, the designed remote maintenance management system for medical equipment mainly consists of state monitoring and data collection modules, network transmission modules, data analysis and maintenance decision-making modules, and regulation modules, as shown in the figure below:

Figure 1. Remote Operation and Maintenance Management Diagram for Medical Equipment

(1) State Monitoring and Data Collection Module:

For various types and brands of medical equipment, research the relevant interface functions or communication protocols supported by each device.

The monitoring module integrates different types of sensors and processors to collect real-time operational state data from various medical devices, such as voltage, current, temperature, humidity, and logs, and transmits the data via a built-in IoT card for subsequent work.

At the same time, the power supply for the monitoring module is provided via USB.

(2) Network Transmission Module:

The monitoring module transmits the collected operational state data of medical equipment to the data analysis module through a built-in IoT card, with the option for scheduled transmission to ensure timely data collection and transmission.

(3) Data Analysis and Maintenance Decision-Making Module:

Based on the received real-time state data of the equipment, utilizing big data and expert knowledge base technologies for data mining and analysis, comparing with normal parameters to determine if the equipment is functioning properly, and evaluating the current state of certain components while predicting future trends. The comparison subjects can be single machines or clusters.

Single machine comparison refers to using the historical health data of the device itself to establish a baseline model through machine self-learning; when unhealthy trends are detected in the device parameters, alerts are issued.

However, single machine comparison has certain limitations; for example, the incompleteness of collected data types can easily lead to inaccurate predictions.

Cluster comparison uses technologies such as the internet, big data, and cloud computing to compare and analyze differences among similar machines, providing more reliable health assessments and diagnostic results, achieving cluster management and prediction for medical equipment across the entire hospital or even larger areas.

The system conducts feasibility analysis of maintenance based on the knowledge base and related algorithms according to the results of data analysis, providing a visual maintenance plan that includes the time, location, personnel, and content of maintenance.

When abnormal data occurs with the medical equipment, this module, through its powerful data processing capabilities, displays different types of operational states such as pending, alert, alarm, and error based on the severity of the issue.

For minor issues like overheating, parameter settings, or insufficient disk space, the system can send commands to complete automatic adjustments; if the system encounters issues that cannot be resolved automatically, engineers can refer to the diagnostic suggestions provided by the maintenance decision-making system and choose to handle the problem remotely via AR or on-site.

03 Economic and Social Benefits of Remote Maintenance Management of Medical Equipment

The data involved in health diagnostics and repair processes related to medical equipment operation and maintenance can be shared across all business segments, strongly promoting the effective formation of intelligent remote maintenance service models for medical equipment.

Once implemented, the economic benefits generated by this research can be reflected as follows:

(1) Reduced Maintenance Costs for Medical Equipment

Taking imaging equipment as an example, if a preventive maintenance model is adopted, maintenance costs can be effectively controlled.

(2) Increased Efficiency

In terms of personnel efficiency, using a system that automatically collects regional status data online significantly reduces the need for personnel involvement; simultaneously, the use of intelligent diagnostics can save a lot of time costs.

In terms of equipment efficiency, timely detection of equipment faults and anomalies during regular use, as proposed in this paper with real-time monitoring and diagnostic technology, can effectively eliminate sudden equipment failures, increase equipment uptime, and reduce spare parts consumption.

Thus, it can greatly enhance repair efficiency and the utilization efficiency of medical equipment, saving more costs for hospitals.

(3) Promoting the Transformation of Service Models

The adoption of a remote maintenance service model for medical equipment based on smart IoT not only increases the utilization and uptime of medical equipment but also provides better auxiliary services for clinical settings, thereby generating more economic benefits.

The social benefits of this research: The remote maintenance platform for medical equipment, through application verification in daily maintenance, demonstrates good applicability across the entire medical equipment industry, enabling online control of operational status, making maintenance more targeted and effective, improving the precision of medical equipment functionality, reducing downtime, minimizing spare parts consumption, and saving costs for hospitals.

The series of intelligent judgment models and methods for medical equipment state, software platforms, and so on developed from this research can ensure the safe and stable operation of medical equipment, providing better services for a large number of patients.

At the same time, this maintenance management model can be promoted to other hospitals, enhancing the implementation effects of this project and subsequently improving the level of remote maintenance management of medical equipment in the region.

About Us