1. Background of the ResearchWith the increasing demand in the industry to reduce concrete-related emissions, 3D printed concrete (3DPC) has gained attention as an emerging technology due to its advantages such as no need for molds, simplified production processes, and ease of modular construction. However, there is relatively little research on the design and structural performance of reinforced 3DPC truss structures, which limits its widespread application in practical engineering. Therefore, this study aims to propose a workflow that integrates topology optimization, reinforcement design, and structural performance assessment into the design of reinforced 3DPC truss beams to enhance current design methods and improve structural performance.2. Research Methodology• Design Workflow: A stress-driven design-to-performance workflow is proposed, integrating topology optimization, reinforcement design, and structural performance assessment. This workflow involves multiple software environments, including programming software for generating topology optimized truss configurations, tool path planning, slicing, and generating machine instructions, as well as computer-aided engineering (CAE) software for nonlinear numerical analysis.• Topology Optimization: The Solid Isotropic Material with Penalization (SIMP) technique is used for topology optimization, aiming to minimize material volume as the objective function while considering stress constraints based on the Tsai-Wu criterion. The optimization process incorporates a central axis algorithm and minimum size control to ensure printability.• Path Planning: A graph-driven path planning method is employed to convert the input contour polygon into an undirected graph and generate an Eulerian circuit to achieve a single-stroke path, which is then converted into G-code.• Reinforcement Design: Four types of truss reinforcement configurations are designed based on the bond performance between the reinforcement and 3DPC and the stress flow. Reinforcement selection criteria are proposed, considering factors such as rib height, diameter, 3DPC cover thickness, and anchorage length on bond performance.• Material and Mechanical Properties: A printable cementitious material mixture is prepared using ordinary Portland cement (OPC), fly ash, silica fume, and polycarboxylate superplasticizer, with polypropylene (PP) microfibers added to reduce crack formation. Mechanical performance tests are conducted on 3DPC and reinforcement samples.• Manufacturing Equipment and Reinforcement Placement: A Kawasaki RS020N 6-degree-of-freedom industrial robotic arm 3D printing system is used for printing, controlling the reinforcement placement time for each layer to reduce interlayer bond weakening.• Bending Tests: Three-point bending tests are conducted on the reinforced 3DPC truss beams to measure the deflection and strain of the beams and record the loading process.

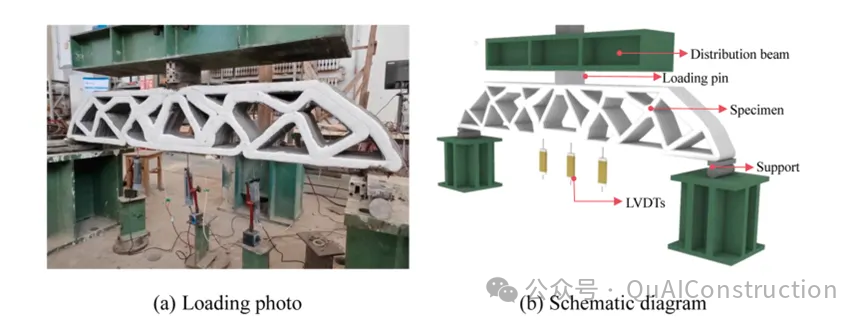

1. Background of the ResearchWith the increasing demand in the industry to reduce concrete-related emissions, 3D printed concrete (3DPC) has gained attention as an emerging technology due to its advantages such as no need for molds, simplified production processes, and ease of modular construction. However, there is relatively little research on the design and structural performance of reinforced 3DPC truss structures, which limits its widespread application in practical engineering. Therefore, this study aims to propose a workflow that integrates topology optimization, reinforcement design, and structural performance assessment into the design of reinforced 3DPC truss beams to enhance current design methods and improve structural performance.2. Research Methodology• Design Workflow: A stress-driven design-to-performance workflow is proposed, integrating topology optimization, reinforcement design, and structural performance assessment. This workflow involves multiple software environments, including programming software for generating topology optimized truss configurations, tool path planning, slicing, and generating machine instructions, as well as computer-aided engineering (CAE) software for nonlinear numerical analysis.• Topology Optimization: The Solid Isotropic Material with Penalization (SIMP) technique is used for topology optimization, aiming to minimize material volume as the objective function while considering stress constraints based on the Tsai-Wu criterion. The optimization process incorporates a central axis algorithm and minimum size control to ensure printability.• Path Planning: A graph-driven path planning method is employed to convert the input contour polygon into an undirected graph and generate an Eulerian circuit to achieve a single-stroke path, which is then converted into G-code.• Reinforcement Design: Four types of truss reinforcement configurations are designed based on the bond performance between the reinforcement and 3DPC and the stress flow. Reinforcement selection criteria are proposed, considering factors such as rib height, diameter, 3DPC cover thickness, and anchorage length on bond performance.• Material and Mechanical Properties: A printable cementitious material mixture is prepared using ordinary Portland cement (OPC), fly ash, silica fume, and polycarboxylate superplasticizer, with polypropylene (PP) microfibers added to reduce crack formation. Mechanical performance tests are conducted on 3DPC and reinforcement samples.• Manufacturing Equipment and Reinforcement Placement: A Kawasaki RS020N 6-degree-of-freedom industrial robotic arm 3D printing system is used for printing, controlling the reinforcement placement time for each layer to reduce interlayer bond weakening.• Bending Tests: Three-point bending tests are conducted on the reinforced 3DPC truss beams to measure the deflection and strain of the beams and record the loading process. 3. Research Results or Conclusions• Topology Optimization and Path Planning: By integrating the central axis algorithm and minimum size control into the SIMP method, printable truss configurations were successfully generated, and single-stroke path planning was achieved, ensuring precise manufacturing of complex 3DPC truss configurations.• Reinforcement Selection Criteria: The proposed reinforcement selection criteria can optimize reinforcement characteristics to achieve the desired failure mode. As experimental data accumulates, the coefficients and mathematical formulas in the criteria will be further refined.• Failure Modes and Load-Deflection Curves: The failure process of the reinforced 3DPC truss beams includes elastic, elastic-plastic, post-yield, and local failure stages. Local failure arises from insufficient reinforcement of the external compression chord. The truss reinforcement has a minor impact on the stress conditions of the truss units under low loads, but at high loads, extensive cracking of the 3DPC disrupts the ideal stress distribution. The beams with different reinforcement configurations show little difference in load-deflection curves and mechanical performance metrics, which may be due to the same reinforcement ratio in the lower chord units of the three beams.

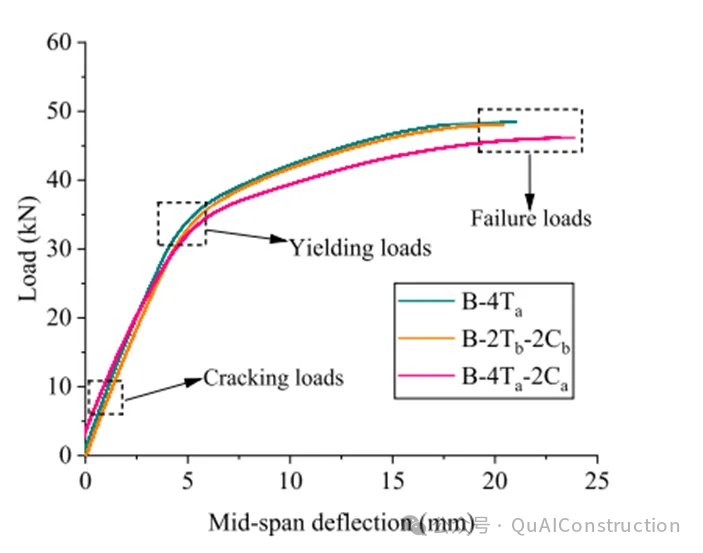

3. Research Results or Conclusions• Topology Optimization and Path Planning: By integrating the central axis algorithm and minimum size control into the SIMP method, printable truss configurations were successfully generated, and single-stroke path planning was achieved, ensuring precise manufacturing of complex 3DPC truss configurations.• Reinforcement Selection Criteria: The proposed reinforcement selection criteria can optimize reinforcement characteristics to achieve the desired failure mode. As experimental data accumulates, the coefficients and mathematical formulas in the criteria will be further refined.• Failure Modes and Load-Deflection Curves: The failure process of the reinforced 3DPC truss beams includes elastic, elastic-plastic, post-yield, and local failure stages. Local failure arises from insufficient reinforcement of the external compression chord. The truss reinforcement has a minor impact on the stress conditions of the truss units under low loads, but at high loads, extensive cracking of the 3DPC disrupts the ideal stress distribution. The beams with different reinforcement configurations show little difference in load-deflection curves and mechanical performance metrics, which may be due to the same reinforcement ratio in the lower chord units of the three beams. • Nonlinear Finite Element Analysis: Nonlinear finite element analysis of the reinforced 3DPC truss beams is performed using ABAQUS software, employing a concrete damage plasticity (CDP) model to simulate 3DPC and a bilinear formula to simulate the stress-strain relationship of the reinforcement. Interlayer bonding behavior is simulated using a traction-separation law, validating the accuracy of the numerical model.

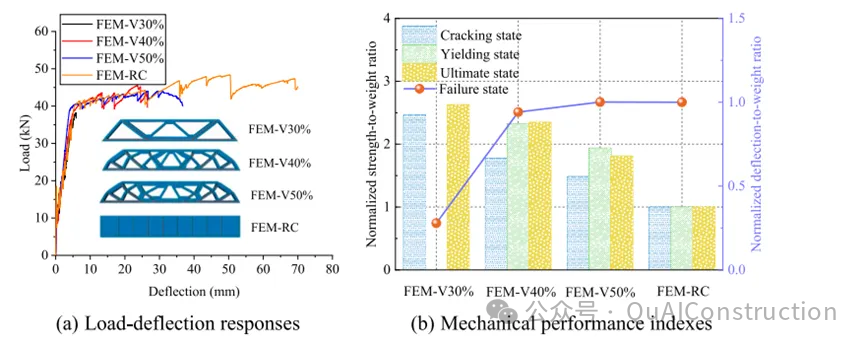

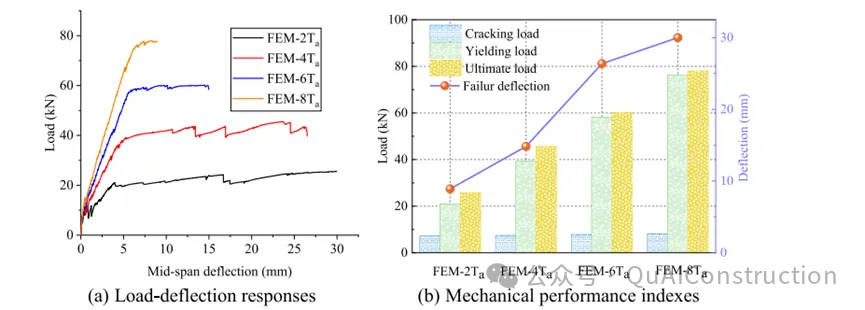

• Nonlinear Finite Element Analysis: Nonlinear finite element analysis of the reinforced 3DPC truss beams is performed using ABAQUS software, employing a concrete damage plasticity (CDP) model to simulate 3DPC and a bilinear formula to simulate the stress-strain relationship of the reinforcement. Interlayer bonding behavior is simulated using a traction-separation law, validating the accuracy of the numerical model. • Parametric Study: A finite element model is used to evaluate and optimize the design of the reinforced 3DPC truss beams, studying the effects of reinforcement content, 3DPC compressive strength, reinforcement yield strength, and truss configuration on beam performance. It is found that increasing material volume can delay local failure and improve beam ductility; higher 3DPC strength can reduce cracking and extend failure displacement without affecting load-bearing capacity; reinforcement content and strength are key factors for beam performance. Beams designed through the stress-driven workflow show a 48-94% improvement in strength-to-weight ratio compared to traditional RC beams while maintaining a comparable deflection-to-weight ratio.

• Parametric Study: A finite element model is used to evaluate and optimize the design of the reinforced 3DPC truss beams, studying the effects of reinforcement content, 3DPC compressive strength, reinforcement yield strength, and truss configuration on beam performance. It is found that increasing material volume can delay local failure and improve beam ductility; higher 3DPC strength can reduce cracking and extend failure displacement without affecting load-bearing capacity; reinforcement content and strength are key factors for beam performance. Beams designed through the stress-driven workflow show a 48-94% improvement in strength-to-weight ratio compared to traditional RC beams while maintaining a comparable deflection-to-weight ratio.