Design and Implementation of PMSM Vector Control Technology Based on FPGA

Design and Implementation of PMSM Vector Control Technology Based on FPGA

Bao Chaowei1, Fan Wei2, Xiong Gengfan2, Tang Wantao1

(1. Unisoc Tongchuang Electronics Co., Ltd.; 2. College of Engineering, Huazhong Agricultural University)

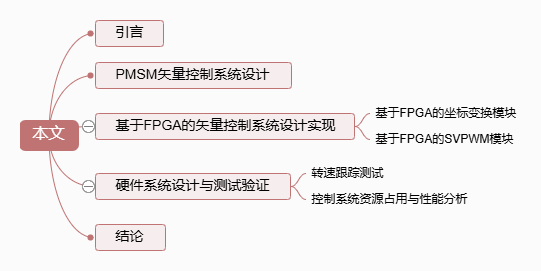

Abstract: In response to the current issues of dynamic accuracy and poor portability of complex vector control algorithms widely used in Permanent Magnet Synchronous Motor (PMSM) control, which rely on MCU and DSP serial computation, a PMSM vector control system based on domestic FPGA has been established. Using a modular design approach with Hardware Description Language (HDL) and Electronic Design Automation (EDA), key low-level modules such as feedforward dual closed-loop PI control strategy, Space Vector Pulse Width Modulation (SVPWM) algorithm, coordinate transformation, and encoder feedback were independently designed and developed on domestic FPGA. Logic and timing simulation tests of key functional modules were conducted using ModelSim. Ultimately, a PMSM vector control system experimental platform based on domestic FPGA was constructed, which performed SVPWM waveform testing, speed tracking accuracy tests under various input signals such as step signals and square wave signals, and chip resource performance analysis tests, validating the effectiveness of this system.

Highlights:

Highlights: Permanent Magnet Synchronous Motors (PMSM) are widely used in transportation, industrial machinery, home appliances, and other fields due to their high power factor and large torque inertia ratio, making them an indispensable power source in modern industry. With continuous technological advancements, the performance requirements for PMSM control systems are also increasing, and achieving more precise and efficient control has become a key issue that researchers urgently need to address.

Permanent Magnet Synchronous Motors (PMSM) are widely used in transportation, industrial machinery, home appliances, and other fields due to their high power factor and large torque inertia ratio, making them an indispensable power source in modern industry. With continuous technological advancements, the performance requirements for PMSM control systems are also increasing, and achieving more precise and efficient control has become a key issue that researchers urgently need to address.

The team led by Tang Wantao from Unisoc Tongchuang Electronics Co., Ltd. published a paper titled “Design and Implementation of PMSM Vector Control Technology Based on FPGA” in the 2025 issue 6 of Integrated Circuits and Embedded Systems, bringing new opportunities for the development of PMSM control technology.

Research Background and Pain Points

PMSM is widely used in transportation, industrial machinery, home appliances, and other fields due to its high power factor and large torque inertia ratio. However, traditional PMSM control systems based on microcontrollers or DSPs face issues such as slow processing speeds and difficulty in meeting high-performance servo requirements. Although the DSP/ARM+FPGA architecture can partially alleviate these problems, it increases system complexity and reduces reliability, and due to the serial execution characteristics of DSP and ARM, real-time performance is difficult to guarantee. In the current complex and changing global trade environment, key semiconductor devices like FPGA and DSP face risks of supply chain changes, making the promotion of domestic FPGA applications in industrial control particularly important.

Highlights of the Vector Control System Design

The PMSM vector control system designed in this study includes several key modules, such as feedforward dual closed-loop PI control strategy, Space Vector Pulse Width Modulation (SVPWM) algorithm, coordinate transformation, and encoder feedback. The feedforward dual closed-loop PI control strategy introduces a feedforward decoupling module based on FPGA into the traditional FOC control, allowing for timely response to torque fluctuations and eliminating the mutual influence of d-axis and q-axis currents, reducing the control system’s sensitivity to disturbances, improving control accuracy, and simplifying the control model. The coordinate transformation module uses methods such as Clarke transformation and Park transformation to convert the PMSM mathematical model from a three-phase stationary coordinate system to a dq rotating coordinate system, simplifying the complexity of motor control. The SVPWM algorithm module is based on the average value equivalent principle, combining basic voltage vectors within the switching period to accurately simulate circular trajectory rotation in the PWM waveform output by the inverter, improving motor operating efficiency and control accuracy.

Implementation and Advantages Based on Domestic FPGA

The research team selected the domestic Unisoc Tongchuang AXPGL50H FPGA as the core control chip and built a complete experimental platform. Through carefully designed interface circuits and hardware connections, seamless communication and collaboration between the FPGA and other components such as the driver board and ADC chip were achieved. During hardware testing, the SVPWM waveform was meticulously tested, and the results indicated that the constructed hardware testing system was stable and effective, providing reliable hardware support for subsequent control algorithm validation. The speed tracking test results showed that the designed feedforward dual closed-loop FOC control system exhibited excellent performance under different input signals, quickly and accurately responding to speed changes, meeting the high dynamic performance requirements of motor control systems in industrial applications. Furthermore, this design significantly reduced resource consumption in Look-Up Tables (LUT), Flip-Flops (FF), Digital Signal Processing (DSP) modules, and Block RAM (BRAM), not only lowering power consumption and costs but also enabling the servo control system to operate stably on low-cost, small-scale FPGA devices. Additionally, the domestic FPGA retains ample logic resources and pins, providing sufficient space for future functional expansions and complex applications such as multi-motor control, demonstrating strong scalability and flexibility.

Performance Comparison and Significance of Results

In performance comparison tests with FOC control implemented on STM32, this design significantly outperformed the STM32 solution in terms of control frequency and control accuracy. Especially under high-speed conditions, the speed error was smaller, and control accuracy was higher, providing strong technical support for the demand for high-speed and high-precision control in industrial applications. The PMSM vector control technology design and implementation based on domestic FPGA not only provides researchers with new research ideas and technical references but also brings practical high-performance solutions for real-world applications in the industrial control field. It demonstrates significant advantages and potential in improving control system performance, reducing power consumption and costs, enhancing system reliability, and promoting domestic substitution, providing a solid technical guarantee for the development of strategic emerging industries such as industrial automation and intelligent manufacturing in China, and is expected to gradually realize the transition of China’s semiconductor industry from import dependence to self-control.

Citation format: Bao Chaowei, Fan Wei, Xiong Gengfan, et al. Design and Implementation of PMSM Vector Control Technology Based on FPGA[J]. Integrated Circuits and Embedded Systems, 2025, 25(6): 58-67. BAO C W, FAN W, XIONG G F, et al. Design and Implementation of PMSM Vector Control Technology Based on FPGA[J]. Integrated Circuits and Embedded Systems, 2025, 25(6): 58-67 (in Chinese).Previous IssueNext Issue