Three-Axis High Sensitivity

Ensuring Automotive Safety

With the rapid development of the automotive industry, people are increasingly focusing on the comfort of driving and riding, where a quiet cabin has become a key factor for a relaxed and enjoyable driving experience. However, the power systems of electric vehicles tend to be quieter, making the noise generated by the contact between tires and the road surface more noticeable. These low-frequency sounds are not only unpleasant but can also increase driver fatigue, thereby affecting driving safety.

To meet noise regulation standards and enhance customer satisfaction, reducing cabin noise has become crucial. Traditional soundproofing materials can reduce noise but add weight to the vehicle and limit design flexibility. Therefore, active noise control technology has emerged as a lighter, space-saving solution. The RNC vibration sensor can achieve high-precision noise cancellation and can be adjusted in real-time according to driving scenarios, ensuring that the automotive sound system remains in silent mode, thus enhancing comfort and safety in the cabin. This technology not only helps improve the driving experience but is also an indispensable part of modern automotive design.

Product Features

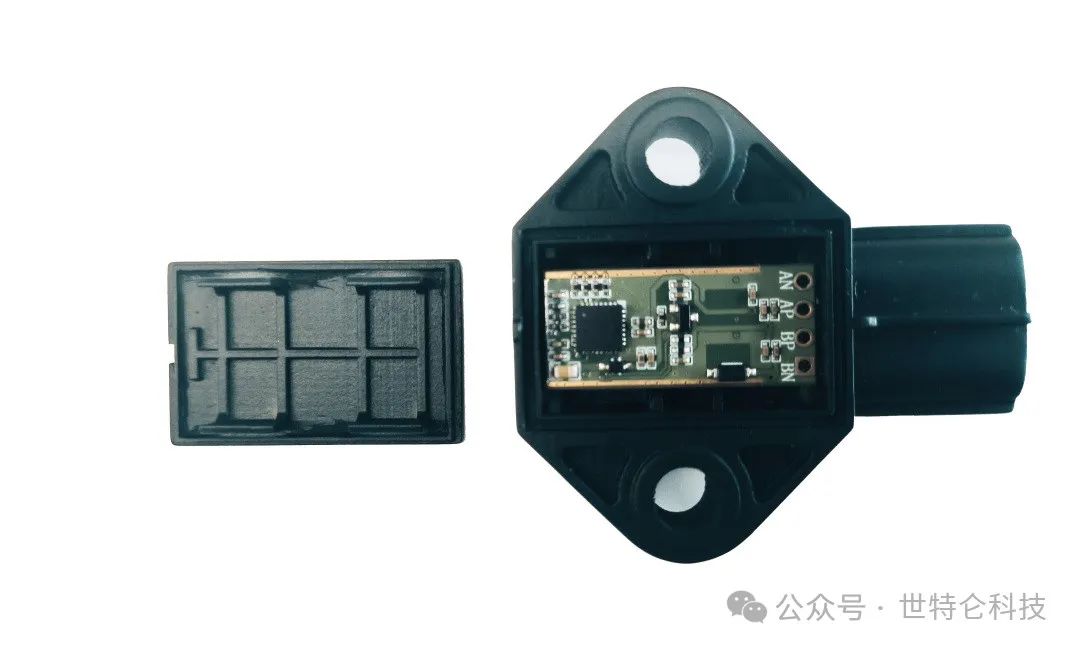

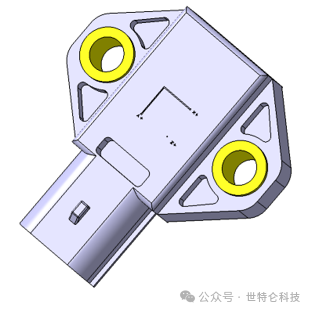

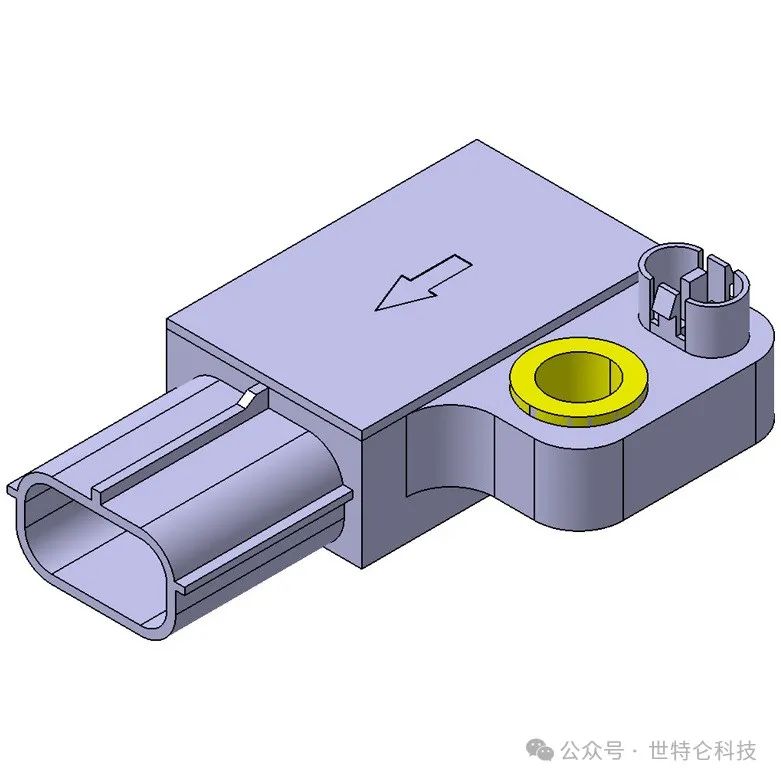

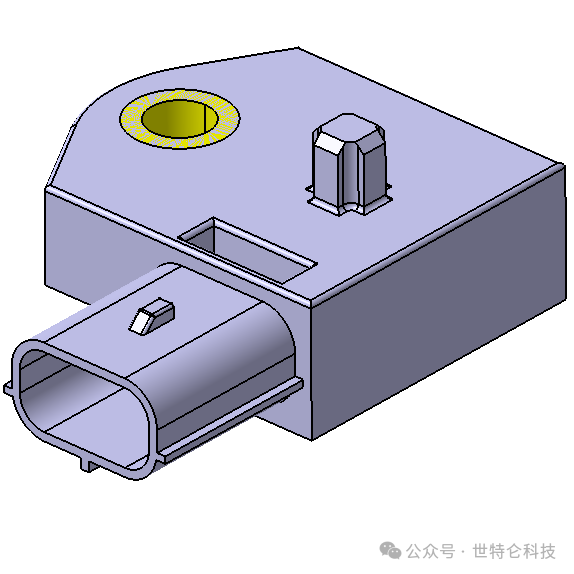

1. Material and Design:

– Shell Material: PBT-GF30, known for its high strength, chemical resistance, and temperature resistance, ensuring the sensor’s stability and durability in harsh environments.

– Appearance Dimensions: 54mm (length) x 50mm (width) x 13.5mm (height), compact design facilitates installation and integration.

– Weight: Only about 0.025kg, lightweight design allows easy deployment without adding extra burden to the vehicle.

2. Electrical Performance:

– Operating Voltage: 7-9V, providing a wide voltage range to adapt to different power environments.

– Standard Voltage: 8V, ensuring optimal performance under standard operating conditions.

– Input Current: 10-19mA, with a standard current of 14mA, ensuring high efficiency and low power consumption of the sensor.

3. Environmental Adaptability:

– Operating Temperature and Storage Range: -40℃ to 85℃, a wide temperature range allows the sensor to function in extreme environments.

– Dust and Water Resistance: IP67, meaning the sensor can withstand dust and short-term immersion in water, protecting the system from harsh automotive environments (water and dust).

4. Sensing Performance:

– Axial Sensing: X, Y, Z three-axis, capturing vibration data from all directions, providing comprehensive vibration analysis.

– Sensitivity: Maximum sensitivity can reach 81 mV/g at 8.0V supply, ensuring high sensitivity and accurate capture of subtle vibrations.

– Measurement Range: ±8g, with a resolution of 14Bit and frequency response range of 30Hz to 1KHz, providing high-precision vibration data.

5. Technology and Installation:

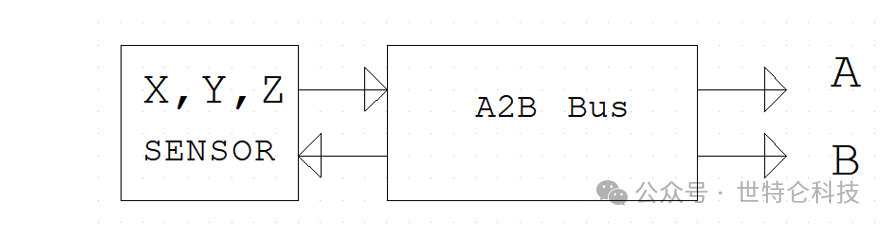

– Measurement Principle: The vibration sensor collects vibration acceleration from the wheel, suspension, or body in real-time at high sampling frequency through the chip, outputting digital signals with minimal delay.

– Transmission: Transmitted into the RNC system via the vehicle’s A2B audio bus, this transmission method supports long-distance communication with low latency and high synchronization, converting vehicle chassis vibrations and air noise into signals. This signal generates cancellation sound waves, thereby reducing unwanted noise in the cabin.

– Installation: This vibration sensor is designed with compatibility and integration with automotive structures in mind. It is compact, lightweight, and sturdy, making it easy to integrate and install within various automotive frames.

Conclusion

With the continuous advancement of technology, our automotive vibration sensors represent a new standard for intelligent driving safety. They not only enhance driving comfort but also provide a solid guarantee for driving safety through precise vibration monitoring. The sensor’s three-axis high-sensitivity design ensures that key vibration data can be captured under various road conditions, achieving real-time noise cancellation and optimizing the driving environment.

END

Zhejiang Shitelun Technology Co., Ltd. focuses on intelligent acoustic control (sound generation, active noise cancellation, sound field zoning, sound field reproduction, etc.) in intelligent cabins and the development of practical products for intelligent cabin personnel.

The company has established strategic cooperation with Zhejiang University, Wuhan University of Engineering, and other units to conduct cutting-edge technology research and industrial development in various aspects of intelligent cabin acoustics, noise reduction, sound field zoning, and personnel comfort.

Shitelun has two professional R&D teams – one R&D center (company-level) and one joint R&D center (cooperation with Zhejiang University). It has established several self-designed production lines capable of online automatic programming and automatic testing, with an annual production capacity of 200,000 sets; it has a complete production chain workshop for controller-type products (SMT, assembly, testing, etc.).

Scan to Follow Us