Click the blue text to follow us

In today’s wave of industrial intelligence, PLC (Programmable Logic Controller) plays a crucial role as a core tool in the field of industrial automation. Through PLC programming, industrial production lines can achieve intelligent and precise control, thereby improving production efficiency, reducing costs, and realizing the goal of intelligent manufacturing.

Working Principle of PLC

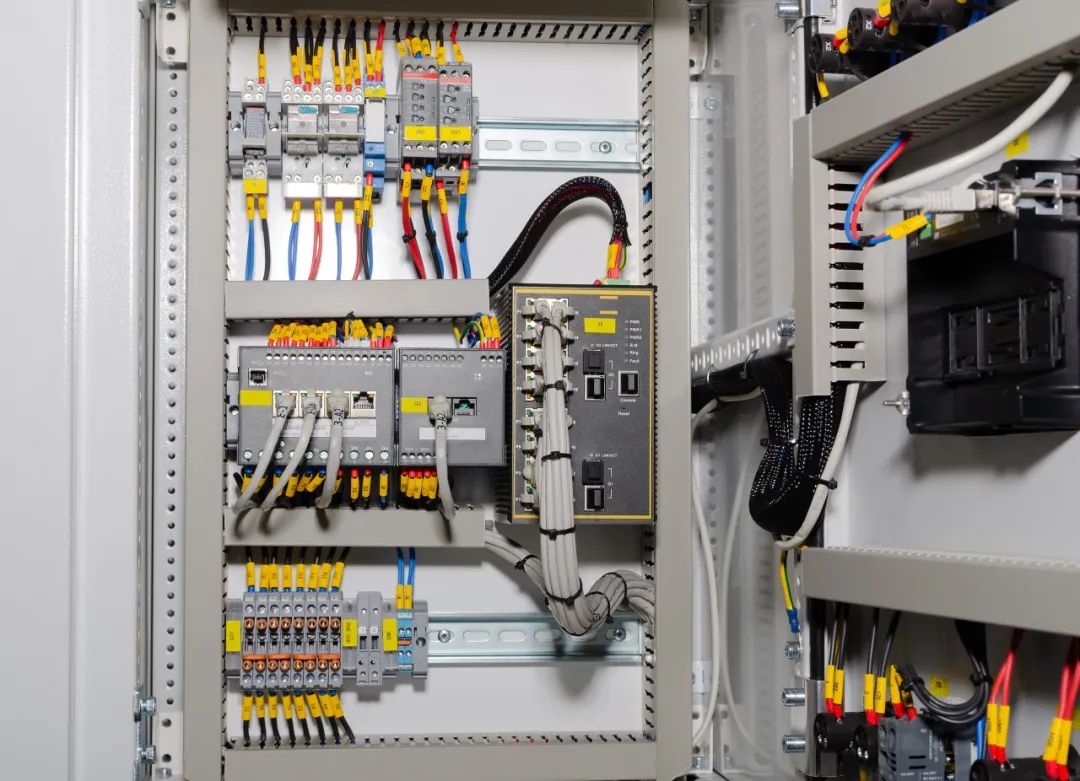

PLC is a computer specifically designed for industrial control. It controls various devices and apparatus in the industrial production process by writing programs. A PLC mainly consists of input modules, a central processing unit, and output modules. It collects and processes input signals and then controls output signals based on preset logic programs, thereby achieving precise control of devices.

Advantages of PLC Programming

Compared to traditional hardwired control systems, PLC programming has the following advantages:

1. High Flexibility: PLC programming can be modified and adjusted at any time according to actual needs, adapting to changes in the requirements of different production scenarios.

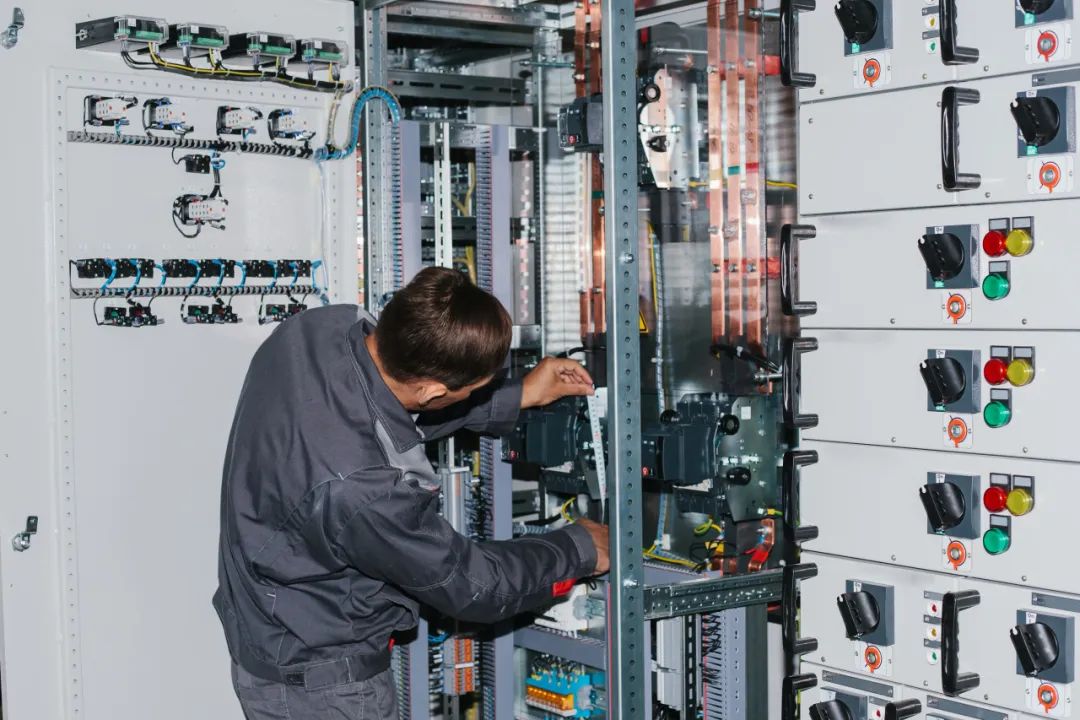

2. High Reliability: PLC systems are designed with a modular approach, resulting in a low failure rate and ensuring stable operation of production lines.

3. Easy Maintenance: The structure of PLC programming is clear, making it easy to maintain and troubleshoot, significantly reducing repair and downtime.

Application Areas of PLC Programming

PLC is widely used in various industrial scenarios, including manufacturing, energy, transportation, etc. Through PLC programming, industrial production lines can achieve automation and precise control, improve production efficiency, reduce energy consumption, and ensure product quality.

In the era of industrial intelligence, PLC programming, as a core technology of industrial automation, is playing an increasingly important role. Mastering PLC programming skills not only enhances the competitiveness of engineers but also brings greater production efficiency and competitive advantages to enterprises. Let us jointly embrace the challenges of industrial intelligence and support the transformation of Chinese manufacturing into intelligent manufacturing!