PLC Equipment Fault Warning: An Intelligent System for Early Problem Prevention

Relay Failure: A production line at an automotive factory was halted for 4 hours due to contactor oxidation, resulting in a direct loss of 1.2 million.

Valve Sticking: A chemical plant’s reactor valve seized due to insufficient lubrication, causing high-temperature material leakage, with repair costs reaching 3 million.

Sensor Malfunction: A cement plant’s belt scale experienced signal interference, leading to an imbalance in the mixing ratio and resulting in 1.5 million in wasted products.

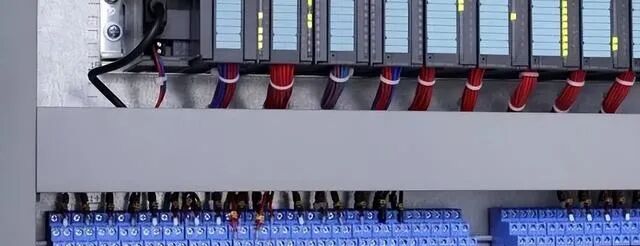

1. Hardware Layer: Dual Insurance of Safety PLC

Redundant Design: Dual processors cross-checking, any inconsistency leads to immediate shutdown.

Three-State Input: Can detect sensor disconnections, improving reliability by 90% compared to ordinary PLCs.

Output Line Detection: Millisecond-level pulse detection circuits to prevent contact sticking.

2. Data Layer: Edge Computing + Digital Twin

Sensor Network: Real-time collection of over 20 parameters such as vibration, temperature, and current.

Digital Twin: Virtual models that map equipment status in real-time, predicting failures in advance.

LSTM Neural Network: Trained on historical data, achieving a prediction accuracy of 98%.

3. Communication Layer: The “Highway” of 5G + TSN

5G Low Latency: Data transmission speed increased by 10 times, response time < 1ms.

TSN Time-Sensitive Networking: Ensures multi-device synchronization accuracy at the nanosecond level.

4. Decision Layer: Automated Work Order Generation System

Three-Level Warning: Yellow (Abnormal) → Orange (Potential Fault) → Red (Immediate Shutdown).

Knowledge Base: Built-in 300+ fault resolution solutions, improving maintenance efficiency by 70%.

3. Comparison of Scene-Specific Solutions

4. Technical Pitfall Guide

❗ Pitfall 1: Incorrect Grounding

Case: A factory experienced downtime due to PLC and inverter sharing a ground, causing interference and a loss of 500,000.

Solution: Single-point grounding + 50MΩ insulation resistance.

❗ Pitfall 2: Interference from Inter-Wire Capacitance

Case: Excessively long cables caused false signal triggers, leading to 3 production line malfunctions per day.

Solution: Twisted cables + shorten length + shielded wires.

❗ Pitfall 3: Incompatible Protocols

Case: Mixing old and new equipment caused communication interruptions, resulting in 2 hours of downtime.

Solution: Protocol gateway (e.g., Modbus to Profibus).

5. ROI Justification: Investment to Output Ratio of 1:20

6. Implementation Roadmap

Risk Assessment: Scan existing equipment failure rates to identify high-risk points.

Solution Selection: Choose hardware + algorithm combinations based on scenarios.

Pilot Testing: Deploy on 3 production lines to validate effectiveness.

Full Rollout: Cover the entire factory within 6 months.

7. Interactive Q&A

Has your factory ever encountered sudden equipment shutdown issues?

Want to know how to use AI to predict PLC failures?

Like the TOP3 to receive “Industrial Protocol Secrets”!

Final Quote: Prevention is always more cost-effective than repair! An intelligent warning system acts like “insurance” for PLCs, transforming equipment from “emergency rescue” to “preventive care”. Follow me for the next reveal on the “black technology” of industrial protocol conversion!