Introduction

In the context of a profound adjustment in the global industrial chain and a new round of technological revolution, China’s manufacturing industry is undergoing a critical transformation from scale expansion to quality improvement. Equipment upgrades, as the core lever of this process, are essentially driven by intelligent and digital technologies to systematically upgrade production equipment, processes, and supporting systems, thereby enhancing industrial efficiency, optimizing resource allocation, and reshaping competitive advantages. This encompasses not only the iteration of hardware facilities but also the collaborative reconstruction of technical standards, management models, and spatial carriers. From a practical perspective, equipment upgrades need to focus on three major aspects: first, the technical aspect, achieving intelligent transformation of equipment through the integration of technologies such as artificial intelligence and the Internet of Things; second, the industrial aspect, promoting collaborative upgrades along the industrial chain and value chain integration; and third, the spatial aspect, relying on urban planning to optimize resource allocation and provide suitable carriers for technology applications.

The necessity of equipment upgrades for industrial upgrading has reached a broad consensus. On one hand, the traditional manufacturing model, which relies on low-cost factor-driven approaches, is becoming unsustainable, with aging equipment leading to high energy consumption and low efficiency, necessitating technological iteration to break through development bottlenecks; on the other hand, global industrial chain competition is shifting towards technology-intensive fields, with intelligent manufacturing becoming the core path to enhance international division of labor status. The 2025 government work report clearly states that large-scale equipment upgrades are a key measure to eliminate backward production capacity and optimize industrial structure, and are also a strategic pivot for constructing a new development pattern of “dual circulation”. International experience shows that Germany’s “Industry 4.0” and the United States’ “Advanced Manufacturing Partnership” both regard equipment intelligence and spatial layout optimization as the cornerstones of industrial upgrading, confirming the inseparability of technological innovation and spatial adaptation.

It is important to emphasize that equipment upgrades are not isolated technical actions but are a system engineering deeply coupled with urban planning. Intelligent manufacturing imposes higher requirements on spatial carriers: industrial spaces need to possess flexible adaptability to accommodate technological iterations, infrastructure networks must form synergistic effects with intelligent devices, and green low-carbon goals must be realized through spatial optimization. For example, the intensive layout of industrial land can shorten the technology conversion cycle, and city planning empowered by digital twin technology can dynamically respond to changes in industrial demand. This “technology-space-institution” linkage mechanism allows equipment upgrades to transcend single production link transformations, evolving into a comprehensive reconstruction process of production factors.

Current practices further validate the bidirectional empowerment relationship between equipment upgrades and spatial restructuring. For instance: Kunshan has designated industrial R&D land protection lines to guide the geographical clustering of high-end manufacturing and R&D institutions, reducing technology conversion costs; Xiong’an New Area relies on digital twin technology to achieve intelligent collaboration between industry and city, providing dynamic adaptive space for emerging industries such as autonomous driving; Shenzhen Bay Ecological Park combines land development intensity with energy efficiency through a “vertical city” design, breaking resource constraints. These cases demonstrate that spatial planning not only provides a physical carrier for equipment upgrades but also stimulates the scale effect of technology applications through institutional innovations (such as carbon quota linkage and floor area ratio rewards).

▼Source: Network

The core logic of China’s manufacturing industry’s leap to “intelligent manufacturing” lies in achieving a systematic transformation through four dimensions: regional industrial positioning, infrastructure collaboration, green low-carbon optimization, and industry-city integration innovation, realizing the deep coupling of technological iteration and spatial reconstruction. Regional industrial positioning guides vertical integration and horizontal collaboration of the industrial chain through functional zoning, avoiding resource misallocation; infrastructure collaboration supports the landing of technology application scenarios with intelligence and proactive layout, reducing systemic costs; green low-carbon optimization transforms ecological constraints into competitive advantages through spatial intensive use and clean technology integration; and industry-city integration innovation relies on mixed-function spaces and digital services to build an innovation ecosystem that promotes mutual growth between people, industry, and cities. These four paths collectively reveal the underlying logic of “planning-driven + intelligent manufacturing leap”: spatial reconstruction not only provides a physical carrier for equipment upgrades but also amplifies the localized effects of technological upgrades into the competitiveness of the entire industrial chain through institutional design and factor allocation, ultimately empowering China’s manufacturing industry to achieve both efficiency leaps and sustainable development goals.

Planning Coordination of Regional Industrial Positioning and Functional Zoning

The planning coordination of regional industrial positioning and functional zoning is an important spatial strategy for achieving the transformation of “China Intelligent Manufacturing”. Scientific spatial layout can not only optimize resource allocation but also form differentiated regional competitive advantages through vertical integration and horizontal collaboration of the industrial chain.

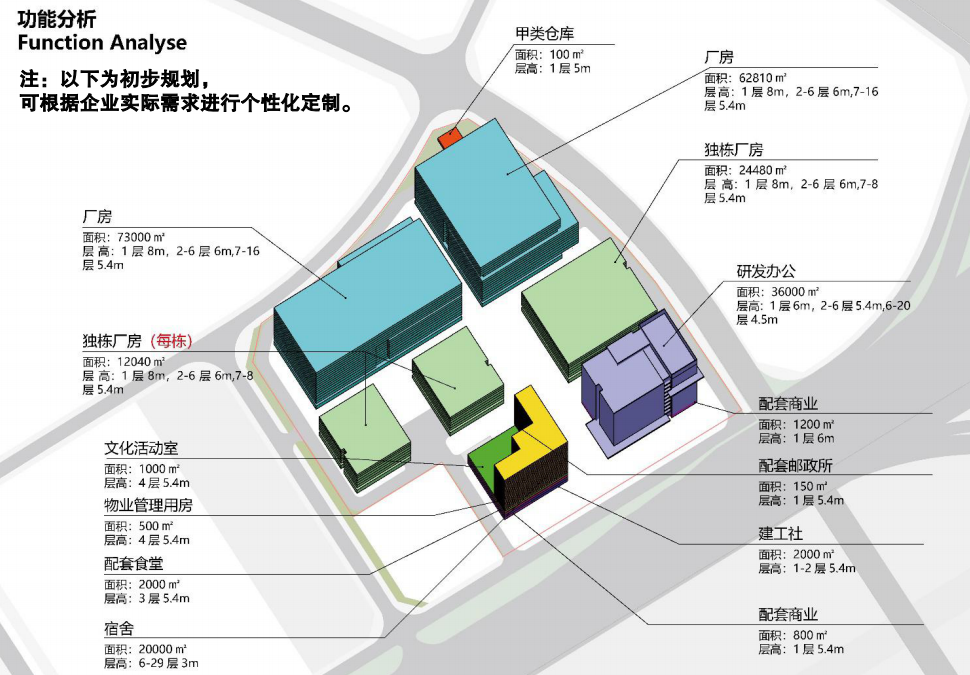

For example, in the practice of Kunshan Huacheng Intelligent Manufacturing Technology Industrial Park, by designating industrial and productive R&D land protection lines, clarifying industrial clustering boundaries, and guiding high-end manufacturing and R&D institutions to concentrate in the park. This strategy not only avoids the fragmentation of land resources but also innovates through the “industrial neighborhood center” model, integrating production and living service functions—intensive layouts of public transport stations, commercial facilities, and rental housing significantly shorten commuting distances, forming a 15-minute living circle centered around industry, effectively alleviating the “pendulum effect” of population flow in traditional industrial parks, and providing a stable living and innovation environment for technical workers and R&D talents.

Jinjiang City adopts a “reservation-customization” strategy in land spatial planning, prioritizing the land needs of major projects and constructing industrial chain clusters around leading enterprises. Taking the Chip Intelligent Manufacturing Industrial Park as an example, relying on leading integrated circuit enterprises such as Jinhua and Quliang, it has introduced 15 upstream and downstream enterprises to form a complete industrial chain closed loop from chip design, packaging testing to terminal applications. This “leading enterprise + park” model not only reduces logistics and collaboration costs between enterprises but also accelerates industrial upgrading through technological spillover effects. More importantly, the reserved flexible space in the planning provides a carrier for future technological iterations, such as the reserved land for 5G communication base stations, which provides expansion interfaces for the research and development of next-generation semiconductor materials.

The planning of Xiong’an New Area represents the future direction of deep empowerment by digital technology. Through “digital twin” technology, the physical city and virtual space are synchronized in planning and dynamically interact, achieving precise matching of industrial resources and urban functions. In the planning of the starting area, innovation resources are concentrated in the core areas of digital economy and artificial intelligence, while special functional sections for intelligent manufacturing and green energy are delineated through spatial zoning, forming an “one core multiple poles” innovation network. This planning model that combines virtual and real allows the city to respond in real-time to changes in industrial demand— for example, when the demand for autonomous driving testing surges, the digital twin system can quickly simulate road network adjustment plans and simultaneously implement dedicated testing roads in physical space, greatly enhancing industrial adaptation efficiency.

These practices reveal the core logic of functional zoning: achieving deep integration and dynamic optimization of the industrial chain through spatial planning. In the vertical dimension, Kunshan’s land protection line ensures the geographical proximity of manufacturing and R&D links, shortening the technology conversion cycle; in the horizontal dimension, Jinjiang’s industrial cluster model reduces innovation costs through resource sharing among enterprises; while Xiong’an’s digital planning provides a “programmable” spatial carrier for technological iterations.

All three point to a common goal—breaking the functional singularity of traditional industrial parks and constructing a composite industrial space with flexible adaptability. This planning thinking aligns closely with the “optimization of land space development and protection pattern” proposed in the 2025 government work report, providing full-chain support for “China Intelligent Manufacturing” from land supply to innovation ecology.

▼Source: Network

Coordinated Upgrading of Infrastructure and Intelligent Manufacturing Technologies

The coordinated upgrading of infrastructure and technology applications is the key technical support for the transformation of “China Intelligent Manufacturing”, with the core being to deeply integrate intelligent devices with urban infrastructure to build a technological ecosystem that adapts to future industrial needs. This process not only requires the large-scale application of cutting-edge technologies such as the Internet of Things and artificial intelligence but also relies on the forward-looking layout and dynamic optimization mechanisms of urban planning for infrastructure functions.

In the field of municipal infrastructure, intelligent upgrading has shifted from single equipment updates to systematic capability reconstruction. Taking urban lifeline projects as an example, the State Council’s “Implementation Plan for Promoting the Update of Construction and Municipal Infrastructure Equipment” clearly requires embedding intelligent sensing devices in key nodes such as gas, bridges, and tunnels, transforming safety prevention and control from passive response to proactive intervention through real-time data collection and risk prediction models. A coastal city has improved the intelligent monitoring coverage of its pipeline network to 98% by deploying a three-dimensional visualization urban lifeline platform, and using machine learning algorithms to provide millisecond-level early warnings for underground pipeline leakage risks, reducing accident response times by over 60%. This technological integration not only enhances urban safety resilience but also provides precise control interfaces for key parameters such as industrial water and energy supply for intelligent manufacturing enterprises through data sharing mechanisms.

The intelligent transformation of transportation infrastructure demonstrates the industrial empowerment effect of “vehicle-city collaboration”. The construction of the country’s first intelligent connected industry integration demonstration zone achieves real-time interaction between autonomous driving logistics vehicles and urban traffic signals through AI sensing devices and V2X communication units covering the entire area. This system improves the average traffic efficiency of logistics vehicles by 35%, while also providing high-precision map updates and scenario simulation testing services for vehicle manufacturers through collaborative computing between roadside units (RSU) and cloud platforms, directly promoting the clustering of six autonomous driving industry chain enterprises in the surrounding area. Another major city has reduced core area intersection delays by 20% through a smart traffic signal optimization system, and combined with dynamic traffic flow data, provides scientific basis for the layout of new energy vehicle charging piles and battery swap stations, forming a deep coupling between transportation infrastructure and the new energy industry.

This coordinated upgrading follows the principle of “demand-oriented, moderately advanced”, addressing current industrial pain points while reserving expansion space for technological iterations. In practical terms, innovative models such as the co-pole deployment of 5G base stations and smart streetlights, and the integrated design of edge computing nodes and substations, reflect the multiple service attributes of infrastructure—meeting the needs of intelligent manufacturing enterprises for low-latency networks and stable power supply, while also supporting seamless access to future technologies such as 6G communication and distributed energy through modular architectures. A national-level new area has taken the lead in planning by adopting the “Infrastructure as a Service” (IaaS) concept, synchronously constructing new infrastructure such as computing power centers and industrial internet platforms with traditional road networks and pipelines, enabling park enterprises to call upon computing resources and data services as needed, significantly lowering the threshold for digital transformation.

Policy guidance and the improvement of the standard system further strengthen this synergistic effect. The “Three-Year Action Plan for New Infrastructure Construction” clearly proposes establishing a “technology-scenario-standard” linkage mechanism, requiring urban planning departments to embed intelligent device installation standards in land transfer conditions, such as mandating new industrial parks to be equipped with environmental monitoring sensors and energy management systems. This institutional design has enabled an ecological industrial park in Shenzhen to achieve a 30% reduction in building energy consumption during the initial construction phase, and form a green supply chain closed loop with surrounding manufacturing enterprises through carbon emission data interfaces.

Current practices indicate that the intelligent upgrading of infrastructure has transcended mere technological addition, but rather reconstructs industrial service capabilities through spatial carrier innovation. From Weihai’s urban lifeline platform to Guangzhou’s “vehicle-road-cloud integration” system, these explorations not only validate the feasibility of technology applications but also reveal the core role of urban planning in equipment upgrades—guiding the direction of technological integration through spatial resource allocation, ensuring sustained innovation momentum through institutional design, ultimately building a solid technical foundation and ecological support for “China Intelligent Manufacturing”.

▼Source: Network

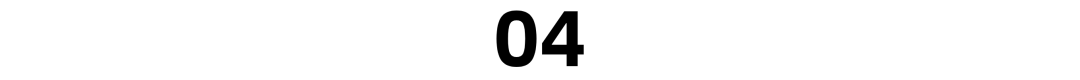

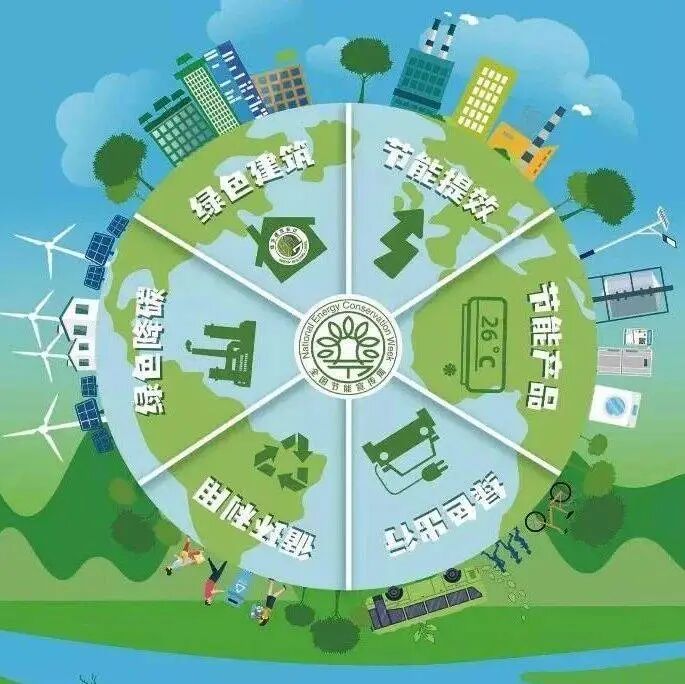

Bidirectional Empowerment of Green Low-Carbon and Spatial Optimization

The green low-carbon transition and spatial resource optimization are the core paths for “China Intelligent Manufacturing” to achieve sustainable development, essentially through the collaborative design of industrial layout and spatial planning, transforming clean technology applications and resource intensive use into systematic competitive advantages. The policy orientation of “eliminating polluting production capacity and introducing green production capacity” proposed in the 2025 Two Sessions report not only requires the equipment upgrades of the manufacturing industry to tilt towards green technologies but also necessitates urban planning to provide physical carriers and institutional guarantees for low-carbon transitions through spatial resource allocation.

The practice of Xiong’an New Area provides a systematic model for this. As a national-level new area, its planning incorporates the principle of ecological priority: through large-scale afforestation and wetland restoration, the forest coverage rate has increased to 70%, creating an ecological safety barrier covering the entire area; at the urban construction level, the “narrow road dense network” concept optimizes the road network structure, increasing the proportion of non-motorized vehicles and public transport to 80%, and achieving over 60% coverage of photovoltaic building integration through an intelligent power supply system. This “ecological foundation + green infrastructure” model has reduced the energy consumption per unit of GDP in the new area by 45% compared to traditional industrial cities, while providing emission reduction benefits for resident enterprises through a carbon sink trading mechanism, forming a bidirectional transformation of ecological value and economic value.

The transformation of Taopu Intelligent Innovation City focuses on the low-carbon update of existing spaces. Through the AI Park smart management platform, integrating building energy consumption monitoring, renewable energy scheduling, and microgrid control, dynamic energy consumption management is implemented for 32 buildings in the park. The system predicts peak office loads through machine learning, automatically adjusts the charging and discharging strategies of photovoltaic energy storage systems, and links air conditioning and lighting equipment for time-zone control, ultimately reducing the comprehensive energy consumption of buildings by 30%. The breakthrough of this technical path lies in upgrading originally dispersed energy management units into a “perception-analysis-optimization” closed-loop system, providing replicable technical standards for the green update of old industrial areas.

At the industrial level, new energy equipment upgrade policies achieve precise implementation through spatial planning. Taking Shenzhen Bay Ecological Park as an example, its “vertical city” design breaks the traditional flat functional zoning model, stacking R&D laboratories, intelligent manufacturing pilot platforms, and commercial service facilities vertically, increasing land development intensity to a floor area ratio of 6.0 while shortening commuting distances to within 500 meters through vertical transportation cores and corridor systems. This spatial intensive strategy has reduced the energy consumption per unit of output in the park by 28% and fostered an industrial collaboration model of “R&D upstairs, pilot testing downstairs”. Emerging fields such as offshore wind power have also received development support through spatial reservation mechanisms: a coastal city has designated a 200 square kilometer exclusive functional area in its land spatial planning, constructing supporting operation and maintenance mother ports and high-voltage transmission corridors, shortening the construction cycle of a single wind turbine by 40%, and forming a complete industrial chain cluster from equipment manufacturing to operation and maintenance services.

Innovations in policy tools further strengthen the guiding role of spatial planning in green transitions. The “Action Plan for Clean Production Transformation in Key Industries” clearly requires new industrial parks to reserve 15% of land for carbon capture and storage facilities, this rigid constraint has led Suzhou Industrial Park to establish the country’s first CCUS (carbon capture, utilization, and storage) demonstration project, with an annual carbon dioxide storage of 100,000 tons. The linkage of carbon emission trading systems and spatial regulation is even more groundbreaking: Beijing Economic-Technological Development Area links enterprise carbon quotas with land scale, granting floor area ratio rewards to enterprises that exceed emission reduction targets, prompting a semiconductor company to reduce the carbon intensity of its products by 52% through process innovation and additionally obtain 3,000 square meters of R&D land indicators.

These practices indicate that the success of the green low-carbon transition relies on spatial planning shifting from passive adaptation to proactive leadership. Xiong’an New Area constructs a system performance reduction for urban operation through ecological foundations, Taopu Intelligent Innovation City activates the energy efficiency potential of existing spaces through digital means, and Shenzhen Bay Ecological Park breaks land resource constraints through three-dimensional development models, all revealing the threefold mechanism of “spatial optimization-technology application-institutional innovation”. This systematic thinking aligns closely with the requirements of “comprehensive and all-factor green transition” proposed in the 2025 government work report, providing a complete solution for “China Intelligent Manufacturing” from single equipment upgrades to regional ecological reconstruction.

▼Source: Network

Innovation Ecosystem of Industry-City Integration and Talent Aggregation

The innovation ecosystem of industry-city integration and talent aggregation is the core social foundation for “China Intelligent Manufacturing” to achieve sustainable innovation, essentially constructing a virtuous cycle system of “industry attracting talent, talent feeding back to industry” through spatial functional complexity and service supply optimization. This process requires not only the mixed-use design of physical space but also the precise response of digital technologies to talent needs and the continuous activation of factor flow through institutional innovation.

The “industrial neighborhood center” model in Kunshan solves the imbalance between work and residence in traditional industrial parks through spatial reconstruction. Within a radius of 1 kilometer, production R&D areas, rental housing communities, and comprehensive service hubs are concentrated, with affordable rental housing accounting for 40%, and provided to technical workers and R&D personnel at 30% below market rent. The accompanying community canteens, skills training centers, and 24-hour convenience stores reduce living service costs by 25%, while an integrated public transport system achieves 8-minute commuting coverage. This model has reduced the employee turnover rate in the park from an annual average of 18% to 5%, and attracted three vocational colleges to establish training bases nearby, forming an integrated ecosystem of “residence-employment-skill enhancement”.

The “Internet + Park” strategy of Guangzhou Development Zone focuses on the digital upgrade of public services. By integrating government, business, and life service entry points, an online and offline integrated platform is constructed: enterprises can apply for policy subsidies and reserve laboratory equipment with one click through an APP, while talents can check apartment listings, medical appointments, and school enrollment information in real-time. Within two years of platform operation, administrative efficiency for enterprises improved by 50%, and talent service satisfaction reached 92%. Additionally, the park guides 32 enterprises to transform their production lines intelligently through an energy consumption data sharing mechanism, reducing energy consumption per unit of output by 15%, and incubating five industrial internet service providers, forming a chain reaction of “service optimization-energy efficiency improvement-industrial upgrading”.

Xiong’an New Area systematically introduces high-end innovation factors by accommodating the decongestion of non-capital functions from Beijing. The planned university park has introduced four “Double First-Class” university research institutes, along with the construction of international hospitals and scientist communities, providing a combination of policies including “talent housing + relocation subsidies + research start-up funds”. This strategy has increased the proportion of R&D personnel in the new area from 3% in 2020 to 15% in 2025, and formed 12 industry-university-research joint laboratories in fields such as digital transportation and green buildings. More critically, through the integrated planning of “campus-community-park”, the testing cycle for research results has been shortened by 40%, with a certain new energy materials project taking only 11 months from laboratory to mass production, creating a typical case of “Xiong’an speed”.

Hefei City constructs a talent attraction field of “hard technology-strong platform-optimal ecology” through the future industry pilot zone. In the quantum information pilot zone, six 6G communication laboratories, nurturing bases (including scientist apartments and venture capital centers), and pilot production lines are constructed simultaneously, achieving full-chain coverage of “basic research-technology transfer-industry incubation”. This area has attracted 23 top teams through the “ranking system” mechanism, with the flexible display team overcoming the folding screen technology challenge, driving an additional output value of 8 billion yuan for upstream and downstream enterprises. The accompanying “Jianghuai Talent Plan” provides housing subsidies, individual income tax refunds, and other policies, making the net inflow rate of high-end talents rank among the top three in the country for three consecutive years.

The deep application of digital twin technology further strengthens the precision and dynamism of industry-city integration. Shenzhen Bay Ecological Park uses the CIM (City Information Model) digital base to integrate real-time data from 12 categories such as energy consumption, traffic, and security, providing personalized services for talents: the system automatically adjusts office lighting and temperature based on the working habits of researchers, optimizes shuttle bus routes according to commuting preferences, and links surrounding commercial entities to push targeted consumption discounts. Chengdu Unicorn Island Park utilizes digital twins to achieve full-cycle management of “planning-construction-operation”, simulating the economic benefits and energy consumption of different industrial combinations in virtual space, ultimately determining a dual-leading industrial layout of “artificial intelligence + biomedicine”, enhancing the matching degree of park investment attraction by 37% and reducing operating costs by 22%.

Policy innovation provides institutional guarantees for this ecosystem. The “Industry-City Integration Development Plan (2025-2030)” clearly requires new industrial parks to construct no less than 30% mixed-function space and establish a special fund for talent services. Suzhou Industrial Park has built the country’s first “Industry-City-People” integration development index system based on this, incorporating 12 indicators such as talent satisfaction and enterprise R&D intensity into land transfer evaluations, prompting a certain biopharmaceutical park to optimize the per capita office area for R&D personnel from 15 square meters to 10 square meters, while also adding shared laboratories and other composite spaces, increasing the density of patent output by 2.3 times.

These practices reveal the threefold progressive logic of industry-city integration: Kunshan achieves basic talent stability through spatial intensification and cost control, Guangzhou enhances service efficiency to activate existing talent potential through digital platforms, Xiong’an and Hefei break through innovation talent bottlenecks by introducing high-end factors, while Shenzhen and Chengdu leverage digital technologies to achieve precise matching of talent needs. This gradient evolution path aligns deeply with the “Talent-Driven Development” strategy proposed in “Made in China 2025”, constructing a multi-level talent support system from skilled workers to scientists for “China Intelligent Manufacturing”, ultimately generating sustained innovation momentum through the deep integration of “people-industry-city”.

▼Source: Network

Conclusion

The leap from “Made in China” to “Intelligent Manufacturing in China” is essentially a systematic transformation driven by the synergy of technological revolution and spatial reconstruction. This process requires not only industrial technological iteration with equipment upgrades as a lever but also the precise allocation of production factors and the continuous cultivation of innovation ecology through urban planning. The “large-scale equipment upgrade” policy proposed in the 2025 government work report provides a key opportunity for industrial upgrading, but its effectiveness relies on the deep participation of urban planning in spatial carrier supply, institutional design optimization, and multi-party collaboration.

Summarizing the practical paths reveals that the core logic of intelligent manufacturing transformation lies in the deep coupling of four dimensions: first, regional industrial positioning achieves efficient aggregation of resources through functional zoning, as evidenced by Kunshan’s designation of industrial R&D land protection lines and Jinjiang’s construction of “leading enterprise + park” industrial chain clusters, indicating that spatial planning can guide vertical integration and horizontal collaboration of the industrial chain, avoiding homogenized competition while reserving flexible space for technological iteration; second, infrastructure upgrades adhere to the principles of intelligence and proactivity, as demonstrated by Weihai’s real-time monitoring system for urban lifeline projects and Jinan’s intelligent connected demonstration zone’s vehicle-road collaboration system, validating the supporting role of dynamic adaptation of infrastructure to industrial needs for technology implementation; third, green low-carbon transitions are empowered by spatial optimization and technological innovation, as shown by Xiong’an New Area’s 70% forest coverage ecological foundation and Shenzhen Bay’s vertical city design leading to a 28% reduction in energy consumption, revealing the amplifying effect of spatial intensive use on clean production; fourth, industry-city integration activates innovation momentum through talent aggregation, with Kunshan’s 8-minute commuting circle and Hefei’s future industry pilot zone’s “ranking system” mechanism constructing a multi-level talent ecology from skilled workers to scientists.

The key to the success of this transformation lies in the collaborative innovation of the “technology-space-institution” triple mechanism. On the technological level, the application of tools such as the Internet of Things and digital twins shifts urban planning from static blueprints to dynamic response systems— Xiong’an’s digital twin city optimizes industrial spatial allocation in real-time, and Shenzhen Bay’s CIM platform precisely matches talent needs, both reflecting the innovative planning paradigm empowered by technology. On the spatial level, from Kunshan’s 1-kilometer living circle to Chengdu Unicorn Island’s “planning-construction-operation” integrated management, the functional complexity design of spatial carriers significantly enhances factor allocation efficiency. On the institutional level, policies such as the “Three-Year Action Plan for New Infrastructure Construction” and the “Industry-City Integration Development Plan” transform industrial upgrading goals into actionable spatial control indicators through tools such as floor area ratio rewards and carbon quota linkages, with Suzhou Industrial Park’s “Industry-City-People” index system quantifying R&D density as a typical case.

Looking ahead, the development of China’s intelligent manufacturing needs to continue breakthroughs in three directions: first, strengthening the foresight and scientific nature of planning, establishing a linkage mechanism between “industrial technology roadmap-spatial demand forecasting”, reserving interfaces for next-generation technologies such as 6G communication and quantum computing in planning for 5G base station co-pole deployment and computing power center siting; second, deepening the synergistic effects of “equipment upgrades-spatial updates”, combining the renovation of old factories with new infrastructure implantation, and learning from the AI Park model of Taopu Intelligent Innovation City to activate the value of existing spaces through energy management platforms; third, improving the collaborative governance system of “policy-market-society”, promoting innovative systems such as carbon quota exchange for floor area ratio in Beijing Economic Development Zone and Hefei Talent Plan, constructing an innovation ecology co-built and shared by multiple parties.

As the world’s largest manufacturing economy, China’s transformation practice provides important insights for latecomer countries: intelligent manufacturing is not only a process of technological substitution but also a systematic engineering that re-encodes production factors into sustainable competitiveness through spatial reconstruction and institutional innovation. In the bidirectional interaction between equipment upgrades and urban planning, China is exploring a distinctive path that combines efficiency enhancement with inclusive growth, which is not only a strategic choice to respond to the global industrial chain restructuring but also an important breakthrough for achieving high-quality development.

Source

Source | New Land Planning Person – Smart Media Group

Image Source | Network

Editing and Typesetting

China Planning and Construction Industry Urban Planning Design Institute Information Center

CONTACT US

Cooperation/Submission/Reprint please contact