At the recently concluded CES 2016, major chip manufacturers and device manufacturers engaged in a fierce competition in the air, making drones a hot new product. The reason is that if drones are positioned solely as consumer products, their market capacity is quite limited, and manufacturers’ enthusiasm would not be so high. However, as demand for drones in agriculture, logistics, and other application scenarios continues to be explored, a frenzy that sweeps through the entire industry chain naturally follows. The theme related to drones was everywhere at this year’s CES, and we can proudly say that domestic companies like DJI and Ehang seized the opportunity due to their keen market insight, allowing domestic manufacturers to shine in this market and gain significant influence in the industry chain.

However, looking at the upstream chip suppliers in the drone market, especially the main control chips, they are still dominated by European, American, and Korean manufacturers. We have compiled the current mainstream 8 major drone main control chips for your reference:

-

1. STMicroelectronicsSTM32 Series

Currently, STMicroelectronics’ STM32 series is a widely adopted main control chip for drones in China. STMicroelectronics has a smart approach by sponsoring the National University Student Electronic Design Competition early on, where the recommended main control chip for drone projects is STM32. As students become familiar with this main control platform, they naturally choose it when working on drones after graduation.

The STM32 series includes multiple product lines such as STM32 F0/F1/F2/F3/F4/F7/L0/L1/L4, among which the STM32 F4 series is widely used in drones.

Based on the ARM Cortex-M4, the STM32F4 series MCU uses STMicroelectronics’ NVM technology and ART Accelerator, achieving processing performance of 225 DMIPS/608 CoreMark at a working frequency of up to 180 MHz when executing from flash memory, which is the highest benchmark score achieved by any microcontroller product based on the Cortex-M core to date.

Due to the dynamic power adjustment feature, the current consumption range when executing from flash memory is from 89 µA/MHz for the STM32F410 to 260 µA/MHz for the STM32F439.

The STM32F4 series includes eight mutually compatible Digital Signal Controller (DSC) product lines, perfectly combining MCU real-time control functions with DSP signal processing capabilities:

-

High-end Series• STM32F469/479 – 180 MHz CPU/225 DMIPS, up to 2 MB dual-bank flash, with SDRAM and QSPI interfaces, Chrom-ART Accelerator™, LCD-TFT controller, and MPI-DSI interface• STM32F429/439 – 180 MHz CPU/225 DMIPS, up to 2MB dual-bank flash, with SDRAM interface, Chrom-ART Accelerator™, and LCD-TFT controller• STM32F427/437 – 180 MHz CPU/225 DMIPS, up to 2 MB dual-bank flash, with SDRAM interface, Chrom-ART Accelerator™, serial audio interface, higher performance, and lower static power consumption

-

Basic Series• STM32F446 – 180 MHz/225 DMIPS, up to 512 KB Flash, with Dual Quad SPI and SDRAM interfaces• STM32F407/417 – 168 MHz CPU/210 DMIPS, up to 1MB Flash, with added Ethernet MAC and camera interface• STM32F405/415 – 168 MHz CPU/210 DMIPS, up to 1MB Flash, with advanced connectivity and encryption features

-

Basic Type Series• STM32F411 – 100 MHz CPU/125 DMIPS, with excellent power efficiency, larger SRAM, and new smart DMA, optimized for data batch processing power consumption (Dynamic Efficiency Series with batch collection mode)• STM32F410 – 100 MHz CPU/125 DMIPS, setting a new milestone for outstanding power efficiency performance (89 µA/MHz in sleep mode and 6 µA), using new smart DMA, optimized for data batch processing power consumption (Dynamic Efficiency™ series), equipped with true random number generator, low-power timer, and DAC• STM32F401 – 84 MHz CPU/105 DMIPS, the smallest and lowest cost solution, with excellent power efficiency (Dynamic Efficiency series)

-

2. QualcommSnapdragon Flight Platform

At CES 2016, Qualcomm Incorporated’s subsidiary Qualcomm Technologies, Tencent, and Zero Degree Intelligent Control released and showcased a commercial drone YING based on the Qualcomm Snapdragon Flight platform, which is expected to be launched globally in the first half of 2016.

Snapdragon Flight is a highly optimized 58x40mm development board specifically designed for consumer drones and robotic applications. It includes a Snapdragon 801 SoC (composed of four cores at 2.26GHz), supports GPS, 4K video recording, strong connectivity, and advanced drone software and development tools, with dual-channel Wi-Fi and Bluetooth modules, supporting real-time flight control systems, equipped with Global Navigation Satellite System (GNSS) receivers, supporting 4K video processing, and quick charging technology, all integrated into a credit card-sized motherboard. This brings cutting-edge mobile technology to create a new level of consumer drones.

This chip can reduce the average price of 4K drones from around 7791 RMB to approximately 1948-2597 RMB, extending the flight time from 20 minutes to 45-60 minutes, making it feel very practical.

The Snapdragon Flight platform has advanced processing capabilities, relying on Qualcomm’s Hexagon DSP for real-time flight control, built-in Qualcomm 2×2 Wi-Fi and Bluetooth connectivity, and optimized leading GNSS for highly accurate positioning. The purpose of the Snapdragon Flight platform is to meet the advanced features that drone consumers want most, including:

-

4K Video—supports 4K HD imaging, graphics optimization, and video processing capabilities, as well as synchronous 720p decoding

-

Advanced Communication and Navigation—dual-channel 2*2 802.11n WiFi, Bluetooth 4.0, and 5Hz GNSS positioning features, as well as real-time flight control based on Hexagon DSP

-

Robust Imaging and Sensing—4K stereo VGA, optical flow camera, Inertial Measurement Unit (IMU), barometric sensor, and additional sensor support and ports

-

Qualcomm Quick Charge Technology—supports fast charging between video/images

The Snapdragon 801 processor supports some of the hottest smartphones in the world, including a 2.26GHz quad-core Qualcomm Krait CPU, Qualcomm Adreno 330 GPU, Hexagon DSP, and optional video decoding engine and dual image signal processors (ISP).

These functional components constitute an asynchronous computing platform that supports the development of advanced drone features such as obstacle avoidance and video stability.

-

3. Intel Atom Processor

At CES 2016, Intel showcased the Yuneec Typhoon H, which employs Intel’s RealSense technology in the UAV field. This device features collision avoidance, easy takeoff, equipped with a 4K camera and a 360-degree gimbal, as well as a remote control with a built-in display, allowing sports enthusiasts to capture themselves in action. Yuneec plans to market this device in the first half of 2016.

It is equipped with up to six Intel “RealSense” 3D cameras and uses a quad-core Intel Atom processor on a PCI-express custom card to process real-time information about distance and how to avoid close obstacles.

Intel promotes drones as a new emerging application for its processor products, but from the promotional effort, it seems that Intel is more eager to see breakthroughs in its RealSense technology, which it has been focusing on for the past two years, in the application of 3D cameras in drones. We know a lot about Intel’s processors, so here we will focus on introducing Intel’s RealSense 3D camera.

-

– From the hardware aspect, it is a 3D camera that supports Intel RealSense computing;

-

– From the software aspect, it is the SDK for Intel’s “RealSense” computing;

Intel’s 3D cameras are divided into two types, one for short distances with higher precision for front 3D cameras, and another for longer distances with slightly lower precision for rear 3D cameras.

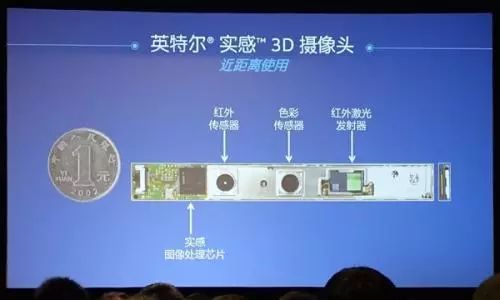

The front RealSense 3D camera, like Kinect, operates on the principle of “structured light”. For specifics on the structure, please see the following image:

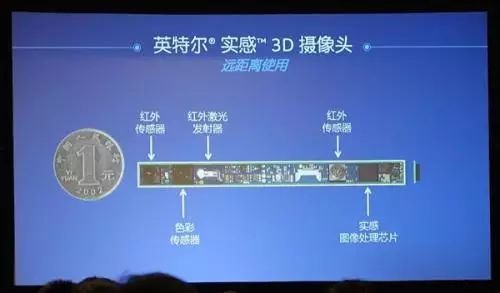

As for the long-distance 3D camera, Intel uses the “active stereo imaging principle,” mimicking the “parallax” principle of human eyes by emitting a beam of infrared light to track the position of this beam with left and right infrared sensors, then calculating the “depth” information in the 3D image using triangulation.

This is its structure:

Intel’s RealSense 3D cameras can be categorized into R series and F series based on their placement in devices (front/rear). The rear camera model used in the Dell Venue 8 7840 is the Snapshot R100, and the same series also includes R200. The front cameras typically used in traditional computers, laptops, and all-in-one PCs are referred to as the F series, with current devices being F200.

R200 is mainly targeted for tablet use, with primary applications including 3D scanning, home decoration, immersive fitting, image and video processing, and gaming applications. In comparison, R100 is much simpler in functionality, primarily supporting RealSense. Additionally, the main uses of F200 include capturing and scanning 3D data, gesture control, and immersive collaboration.

-

4. Samsung Artik Chip

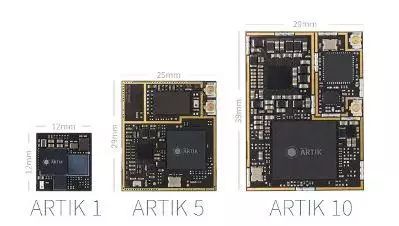

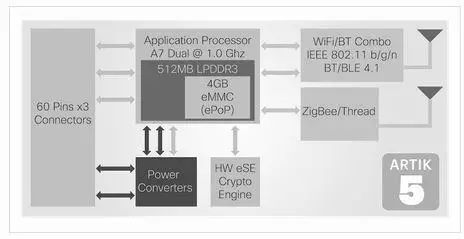

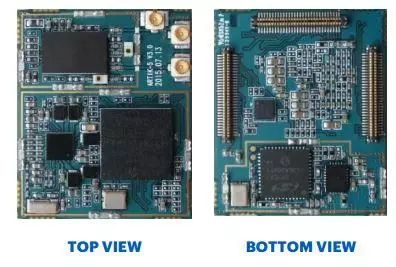

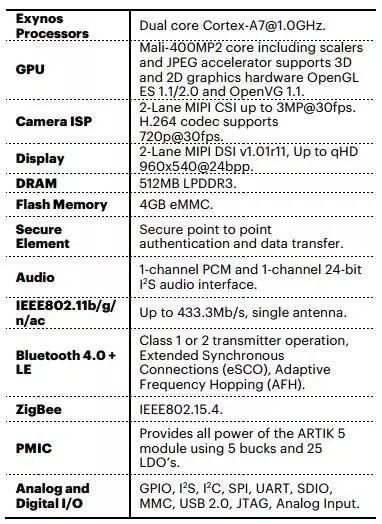

Samsung’s Artik chip has three models, among which the main one used in drones is the Artik 5. The Artik 5 measures 29x25mm and is equipped with a 1GHz ARM dual-core processor (Mali 400 MP2 GPU), along with 512MB LPDDR3 memory and 4GB eMMC flash storage. It supports Wi-Fi, low-power Bluetooth, and 802.11 b/g/n. Additionally, this chip can decode H.264 formatted 720p 30fps video and provides TrustZone.

ARTIK 5 uses Samsung’s next-generation ePoP packaging technology, providing the best combination of computing power and storage capacity for a wide range of devices and applications, achieving a balance between performance and power consumption. It integrates the industry’s best security features.

ARTIK 5 module is a highly integrated system module, using Exynos architecture dual-core ARM Cortex-A7 processor, integrating DRAM and flash storage, a secure element (SE), and providing various standard digital control interfaces to support external sensors and high-performance peripheral devices, expanding module functionality.

-

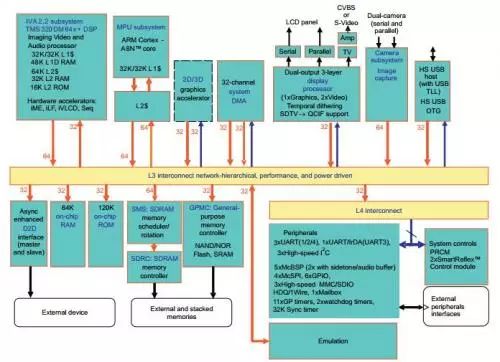

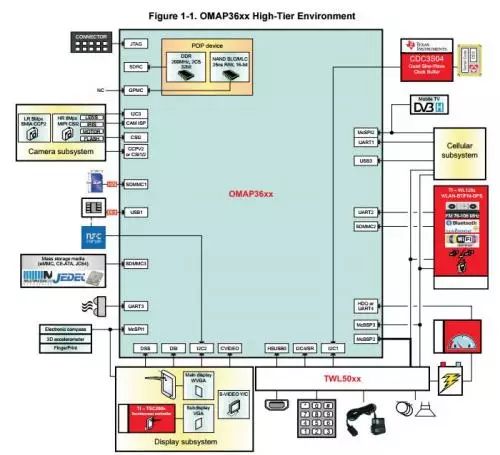

5. Texas Instruments OMAP3630

Texas Instruments’ OMAP3630 once shone in the single-core era of smartphones, but as multi-core became mainstream and Texas Instruments gradually withdrew from consumer electronics, the OMAP3630’s battlefield has shifted to emerging markets like drones.

-

6. Atmel Mega2560 Chip

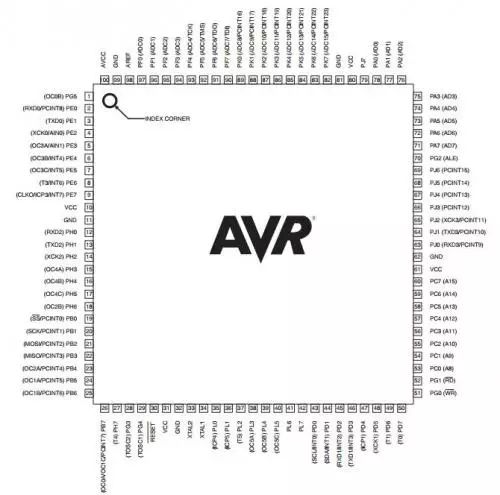

Atmel’s AVR processor chip is widely adopted in drones abroad, but STMicroelectronics occupies most of the market domestically. Its characteristics include: Core Processor: AVR Core Bit Width: 8-bit Speed: 16MHz Connectivity: EBI/EMI, I2C, SPI, UART/USART Peripheral Devices: Under-voltage detection/reset, POR, PWM, WDT Input/Output Count: 86 Program Memory Capacity: 256KB (256K x 8) Program Memory Type: FLASH EEPROM Size: 4K x 8 RAM Capacity: 8K x 8 Voltage – Power Supply (Vcc/Vdd): 4.5 V ~ 5.5 V Data Converter: A/D 16x10b Oscillator Type: Internal Operating Temperature: -40°C ~ 85°C Package/Shell: 100-TQFP, 100-VQFP

-

7. XMOS XCORE Multi-core Microcontroller

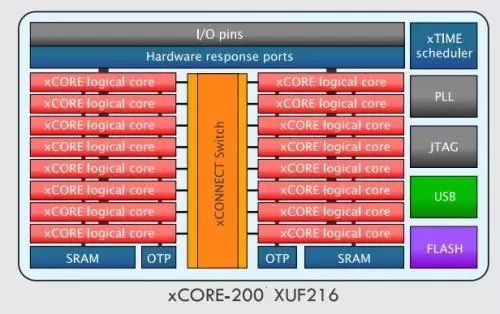

Multi-rotor aircraft require four to six brushless motors to drive the drone’s rotors. The motor driver controller is used to control the speed and direction of the drone. In principle, one motor requires one 8-bit MCU for control, but there are also solutions where one MCU controls multiple BLDC motors.

The European processor manufacturer XMOS, active in the robotics market, has also entered the drone field. Currently, XMOS’s xCORE multi-core microcontroller series has been adopted by some OEM customers of drones/multi-rotor aircraft. In these systems, the XMOS multi-core microcontroller is used for both flight control and internal MCU communication.

xCORE multi-core microcontrollers have between 8 to 32 high-frequency 32-bit RISC cores operating at up to 500MHz. The xCORE devices also feature Hardware Response I/O interfaces, providing hardware real-time I/O performance with very low latency. The multi-core solution supports completely independent execution of system control and communication tasks without any real-time operating system (RTOS) overhead. The hardware real-time performance of xCORE microcontrollers allows customers to implement precise control algorithms without jitter in the system.

-

8. Nuvoton MINI 51 Series

Although from Taiwan, there is finally a domestic processor available.

Mini51 is a Cortex-M0 32-bit microcontroller series characterized by a wide voltage operating range of 2.5V to 5.5V and an operating temperature of -40℃ ~ 105℃, built-in 22.1184 MHz high-precision RC oscillator (±1% accuracy at 25℃ 5V), and built-in Data Flash, under-voltage detection, rich peripherals, integrated serial transmission interfaces, high anti-interference capability (8KV ESD/4KV EFT), supporting online system updates (ISP), online circuit updates (ICP), and online application updates (IAP), available in TSSOP20, QFN33 (4mm*4mm and 5mm*5mm), and LQFP48 packages.

Key Features:

• Core – Cortex®-M0 32-bit microprocessor – Operating frequency up to 24 MHz – Operating voltage: 2.5V to 5.5V – Operating temperature: -40℃ ~ 105℃• Memory – 16 KB application – Built-in 2 KB SRAM – Configurable Data Flash – Online system updates ISP (In-System Programming) – Online circuit updates ICP (In-Circuit Programming) – Online application updates IAP (In-Application Programming)• Analog to Digital Converter (ADC) – Provides 8 channels – 10-bit resolution – Sampling rate up to 250kSPS – PWM output can trigger A/D conversion

• Pulse Width Modulation (PWM)

– Up to 6-channel PWM output or 3-channel complementary PWM output – PWM time and period can trigger A/D conversion

• Communication Interfaces – One set of SPI (up to 24 MHz) – One set of I²C (up to 400 kHz) – One set of UART• Clock Control – External crystal 4 to 24MHz – Built-in 22.1184 MHz high-precision RC oscillator, ±1% error at room temperature 5V (source: drone)

About Us: EPTC

Welcome to follow EPTC

WeChat ID: china-eptc