Skip to content

Optimizing Sensor Network Design for IoT

Author: Mark Beecham, MCU and Sensor Product Manager at Silicon Labs

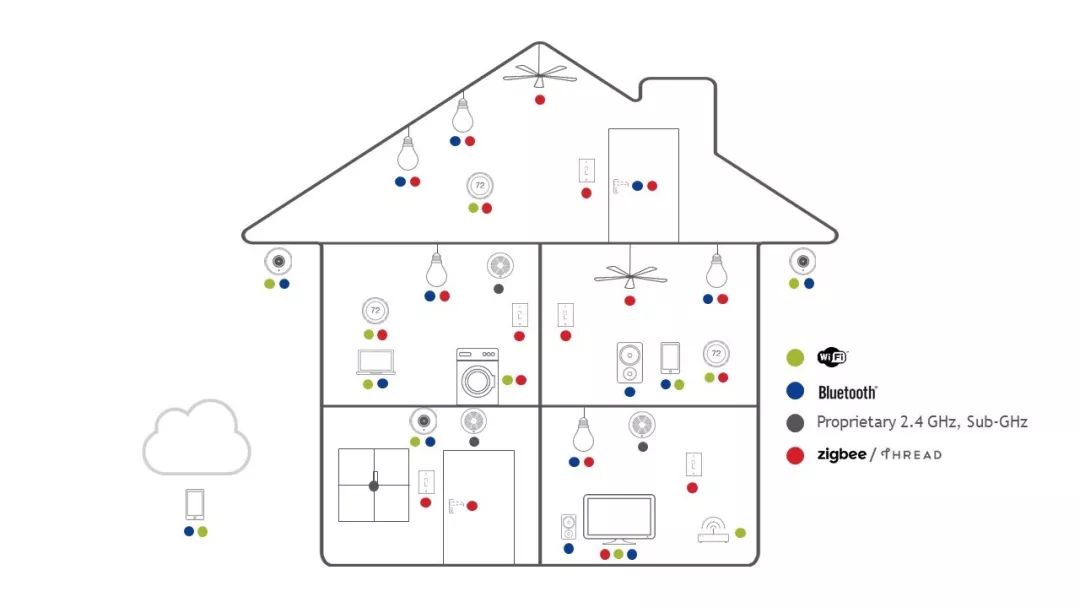

When developing the next wireless sensor network application, it is worthwhile to adopt the optimal number of sensors to optimize the network while considering key design variables such as network medium, wall power or battery supply, wireless protocol options, and network configuration.

With the rise of IoT, we have noticed a growing trend of collecting and aggregating sensor data from various smart home, industrial, green energy, transportation, and smart city applications. The industry generally believes that the more data sent to the cloud or local control systems, the better.

Much of this sensor data takes the form of physical sensing for personnel detection, object detection, temperature, humidity, light, sound, and vibration, among others. Over time, developers have realized the difficulties of deploying large sensor networks, and many cloud computing companies have concluded that if you cannot make decisions based on data, accessing large amounts of data does not necessarily add value.

In today’s cost-sensitive environment, every deployed sensing device or network must strike a balance between development and deployment complexity and the value provided to IoT service providers, cloud computing companies, and end-users. The trend we now see in deployed sensor networks is to simplify the network and only measure those aspects that can assist in cost savings and/or enhance the end-user experience.

Sensor Network Trends and Examples

Let us consider two examples: retail stores and commercial office buildings. They showcase a new trend regarding the optimal number of sensors required for deploying IoT applications.

The most valuable real estate in a store is its product shelves, with the key metric being customer conversion rates. Most large retailers would benefit from a sensor network that can measure occupancy, customer and item locations, inventory levels, etc. Ideally, the system would use sensor data to increase the likelihood of customer purchases.

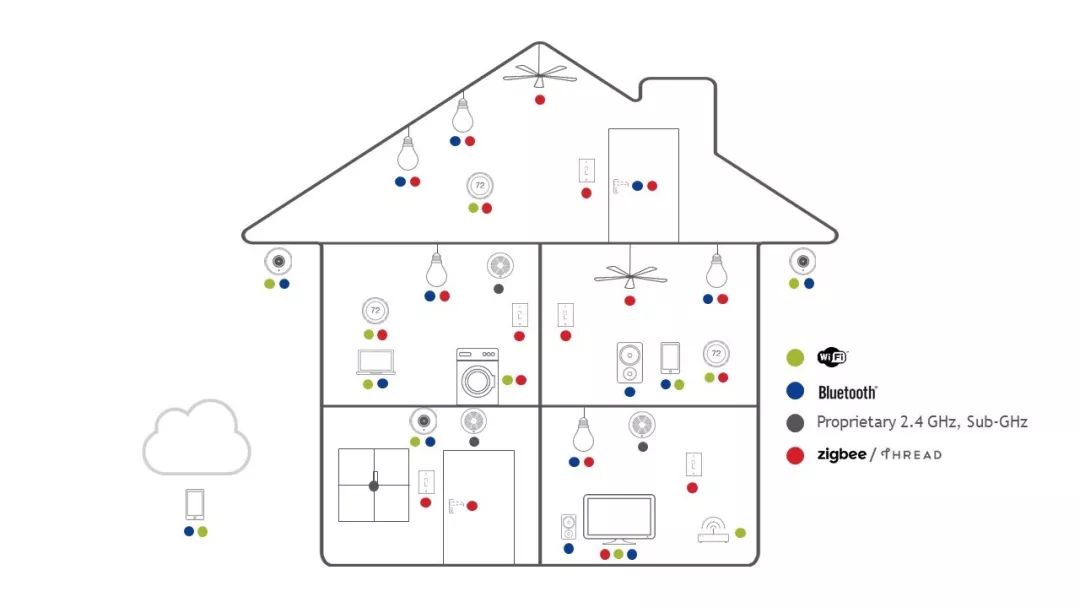

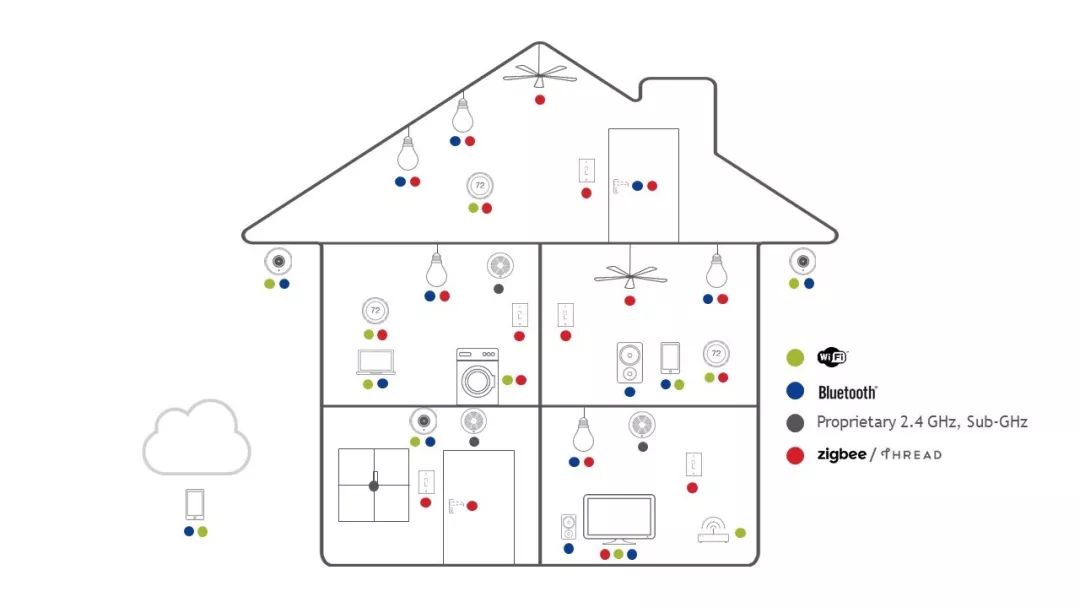

Sensors can utilize new Bluetooth tracking technologies, such as Angle of Arrival (AoA) and Angle of Departure (AoD) along with Received Signal Strength Indicator (RSSI) or distance phase shift. These AoX (see AoD positioning system in Figure 1) and ranging technologies enable the network to triangulate the location of customers’ smartphones or devices embedded in shopping baskets/carts to detect customer positioning and determine where shoppers spend more time in the store. This data, combined with facial recognition technology or smartphone identification, can assign a purchase profile to each shopper, predicting the items they are most likely to buy and providing in-store sales or bundling promotions to incentivize them to purchase, or targeted marketing campaigns after their in-store visit.

Figure 1 Bluetooth 5.1 supported AoA and AoD (AoX) technology enhances the development of indoor positioning systems

An optimized sensor network can also provide store managers with insights into purchasing decisions for various product types. For example, the sensor network may reveal that certain customers spend a lot of time comparing toothpaste brands while quickly selecting shampoo from brands they know. This information allows stores to stock items that customers are more likely to purchase more intelligently, enhancing store efficiency and profitability.

Transforming office buildings into smart buildings equipped with sensors can reduce maintenance and operational costs while enhancing the safety, comfort, and convenience of its occupants. Temperature control is a major cost factor in facility management. A typical 100,000 square foot building may spend over $50,000 per month to adequately cool or heat. Investing $300,000 in a smart sensor network that reduces this cost by 15% would be a wise investment that could pay off in a few years. Another added value is an optimized sensor network designed to prevent damage. Being able to sense threats such as leaks, flooding, smoke, and fire and respond swiftly can save significant repair costs while protecting occupants and even saving lives. Reducing threats through sensor networks may also lower insurance premiums.

While these two sensor network examples directly increase the revenue and net profit of deployers, two key challenges must be considered when implementing sensor networks: the physical medium for deploying sensors and how to process sensor data.

The configuration of each sensor network varies depending on application requirements and physical environment. For instance, some networks can be deployed in retail environments with uniform coverage, while others must be implemented in corporate offices with differently sized rooms. Some networks need to operate 24/7, while others run only part-time on certain days. Factories plagued by electromagnetic noise from motors can pose a challenging environment for sensor networks, making certain types of sensing or communication technologies unavailable, but each situation requires the best sensing solution.

Consider the example of commercial buildings. The common goal is to reduce energy consumption and costs for lighting and HVAC systems. There are two options: minimize lighting and HVAC usage in areas that are rarely used or implement energy-efficient lighting and environmental controls. In either case, necessary sensor types must be deployed, such as detecting occupancy, light levels, and temperature sensors. Additional humidity or pressure sensors can ensure occupants have greater comfort by optimizing lighting and temperature control.

To deploy the optimal sensor network, developers must make some decisions in advance:

“Will the sensing nodes be battery-powered or wired?”

Wireless sensor nodes powered by batteries are easier to install due to the lack of wiring constraints. However, changing batteries every few years can negatively impact ROI. Using wired power (wall power or Power over Ethernet) may also incur high upfront costs, and local regulatory compatibility varies by region. Deploying low-voltage systems like PoE is more cost-effective than delivering 110V or 220V to each sensor node. Another economical option is to install low-voltage LED lighting and sensor networks to make energy savings easier.

“Will the sensing nodes use wired or wireless communication?”

Solutions must weigh the trade-offs of using “wired power and wired data communication” versus “battery power and wireless data.” Wireless is cost-effective because it eliminates the need to deploy data lines throughout the building, but other upfront engineering costs and complexities must be considered when deploying wireless networks. For new buildings, deploying CAT5 cables is straightforward, enabling data and power delivery to each node. Using CAT5 cables, data rates are typically less than a typical 1 Gbps, allowing transmission over 100 meters. However, in some building renovations, deploying cables to hard-to-reach areas (such as ceiling spaces) can be nearly impossible. In such cases, wireless connections may be the best choice.

When implementing wireless networks, developers must consider which media and protocols to use. Wi-Fi is attractive due to its ease of use characteristics such as widely deployed infrastructure and familiarity with IP data packets, but Wi-Fi supports a limited number of terminal nodes and access points and has significant power consumption compared to other short-range wireless transmission technology options. While Zigbee addresses the power consumption issue, developing a Zigbee network can be challenging for developers lacking mesh expertise. Deployers need to evaluate the pros and cons of each protocol choice to determine the best path; however, there is no perfect solution, and the best wireless choice is to achieve optimal application goals with acceptable trade-offs.

“Where will decisions based on sensor data be processed?”

Depending on the requirements of the commercial building or home, decisions to turn HVAC systems on or off can be made locally by HVAC controllers in the building. Alternatively, sensor data can be sent to the cloud for processing, enabling remote control of HVAC systems.

This choice between local or remote data processing and control depends on many factors, including the complexity of computation required to make decisions, the amount of data that must be processed, and whether post-processing or remote monitoring is needed. For smart homes with limited data requirements, local processing and control may be feasible. However, managing HVAC systems for buildings with many rooms may require a gateway to transmit data to the cloud.

Processing the data generated by hundreds of sensor nodes is a barrier for many developers attempting to deploy large-scale sensor networks. Setting up a few nodes in a lab and getting them to communicate with a host or the cloud is relatively simple, but as the number of nodes increases, the difficulty of network design rises exponentially.

Applications that collect local or cloud data must identify all data and timestamp it to build an accurate model of blocks. For smart offices, the host system will receive data from hundreds of sensors. This can be an impractical, costly, and challenging issue. While each sensor at the endpoint may only cost $0.50, the overhead requirements for mesh networks and cloud computing may far exceed the cost of the sensors. Experienced sensor network deployers now only add what is absolutely necessary at each endpoint. This streamlined optimization approach can reduce data overhead and lower endpoint power consumption, saving battery replacement costs.

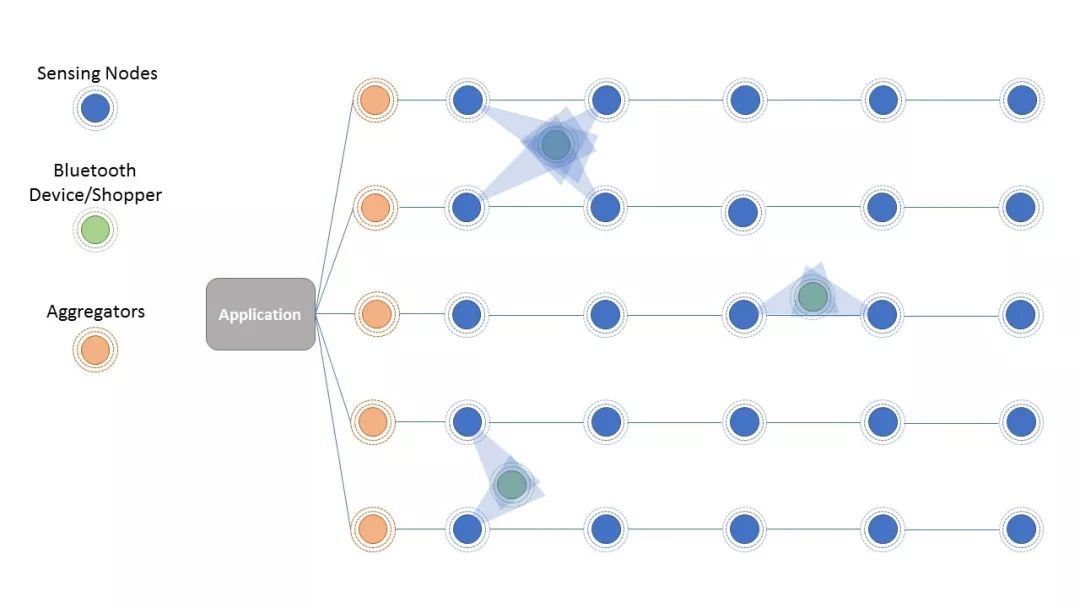

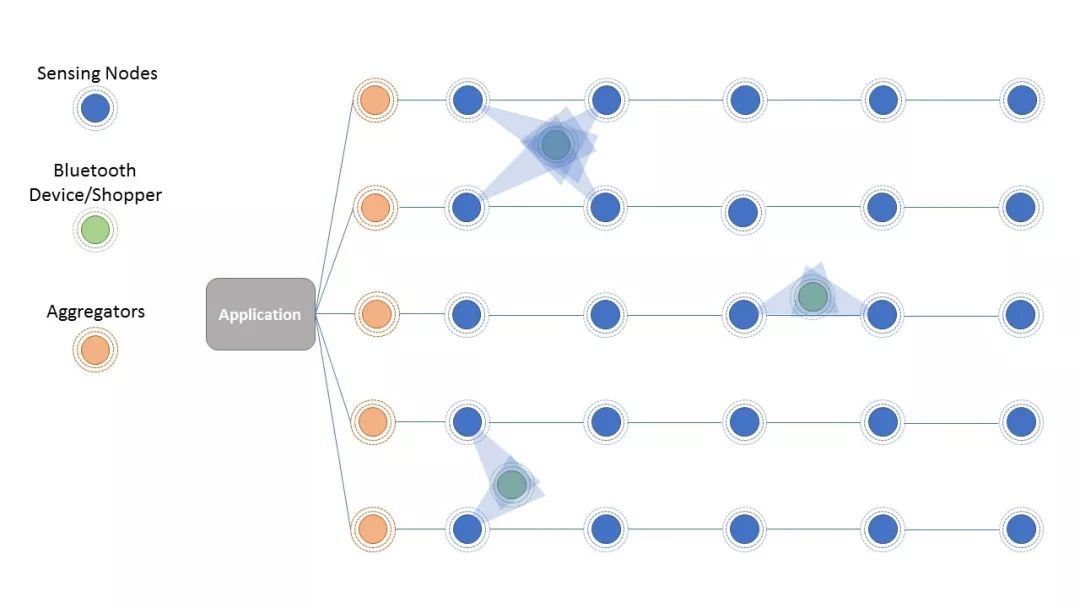

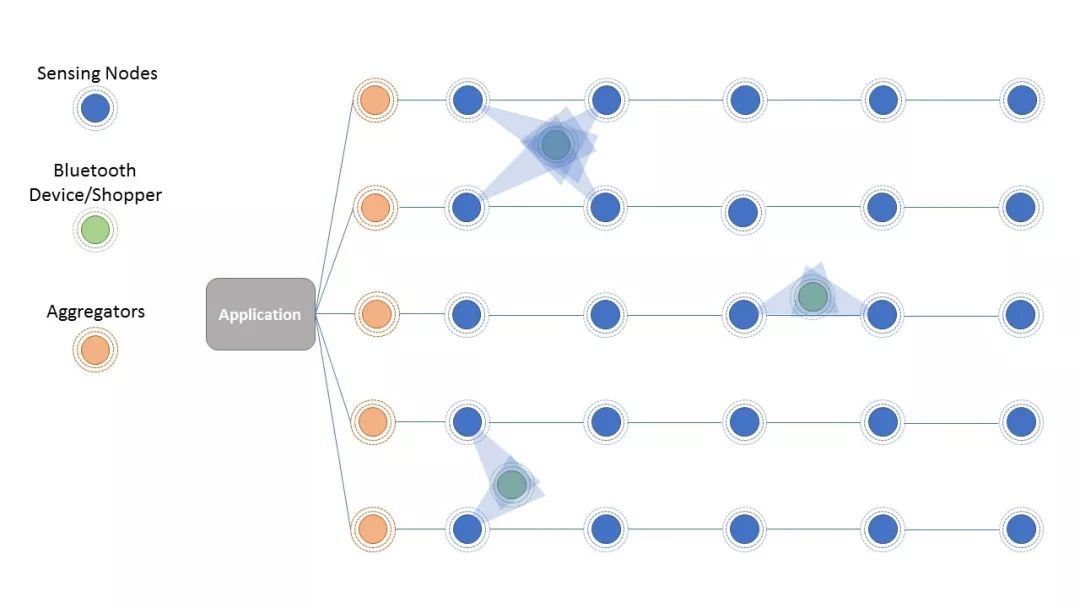

Network topology is a multivariable problem. The trend in solutions is to use a hybrid topology that combines mesh networks, bus, or tree topologies. For example, in smart offices, deploying many smaller sensor mesh networks that can utilize each other to relay messages to a hub or access point (as shown in Figure 2) makes sense. This access point can be part of another mesh network that is just a step away from the host or contains the host and other hubs. By sharing the workload between the hub and the host, using these “intermediate” nodes simplifies this challenge.

Figure 2 Smart offices can deploy smaller sensor mesh networks that utilize each other to relay messages to a hub or access point

By using a hybrid topology, the cloud can receive combined data, reducing the burden on cloud applications and achieving a more scalable network. Cloud applications are likely tailored for specific tasks and must be created or authorized to provide monitoring capabilities for the building.

The current trend is to implement this application through Software as a Service (SaaS). For example, insurance companies looking to reduce HVAC costs often lack the core capabilities to develop this application themselves. This application provides feedback and configurations that facility managers can customize to control their building environment according to their preferences.

Deploying sensor networks is a challenge. No single sensor network layout or measurement combination fits every IoT application. One network may focus on tracking assets or personnel, while another prioritizes sensing environmental changes to reduce costs or avoid disasters. Regardless of the chosen sensor network approach, it must deliver value that offsets the costs and complexities of deploying physical media and processing data to ultimately make decisions.

From battery-powered endpoints to large-scale cloud-based applications, sensor network deployment must be carefully planned. When deploying or designing sensor networks, all aspects must be considered, as even the slightest oversight can lead to difficult trade-offs. Considerations include how to power each sensor node, how to transmit data, and the path to the host application, as well as how to service or expand the network over time. Sensor networks are beginning to achieve optimal cost-effectiveness, and more businesses will deploy them to reduce costs, gain intelligence, and stand out from the competition.

Mark Beecham, MCU and Sensor Product Manager at Silicon Labs

Mark Beecham is a product marketing engineer responsible for supporting and defining Silicon Labs’ 8-bit and 32-bit microcontrollers and sensor products. Mark focuses on embedded systems and sensors and joined Silicon Labs in 2015, previously working at IBM and Texas Instruments. He also holds a Bachelor’s degree in Electrical Engineering from Texas A&M University.

You can also scan the following QR code to follow Silicon Labs on social media platforms