NI partners co-creation and win-win project Season 1 activities have received customized automated testing and measurement solutions based on the NI open software platform developed by multiple partners in fields such as new energy vehicles, semiconductor mature process chips, energy storage, and high-end manufacturing.

#NI China Innovation Development Center “Co-creation and Win-win Project”# Creative solutions are being serialized, with a theme each issue to help you open new ideas for testing.

Today’s focus theme Wireless BMS (wBMS) testing solutions.

📝 Author: Shanghai Zhongzhixin Information Technology Co., Ltd. Tu Fangze

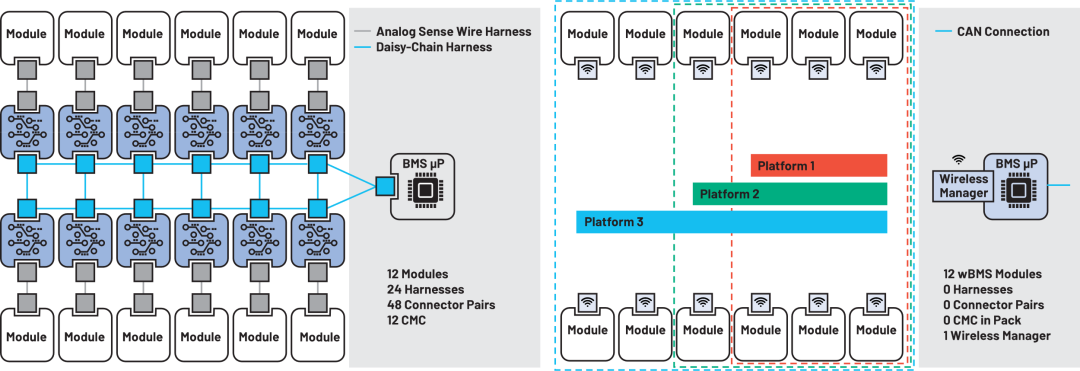

With the development of automotive electrification and intelligence, various components are accelerating the transition from mechanical systems to electronic systems. Taking the BMS (Battery Management System) field as an example, its main role is to monitor battery status information in real time by measuring voltage, current, and temperature, analyzing battery safety performance, optimizing battery energy control, and extending battery life. Currently, wired BMS architecture uses a daisy chain configuration to connect battery packs, occupying large overall space, complicated manufacturing processes, and failing to meet the demand for continuous real-time monitoring of batteries, making maintenance difficult.

At the same time, the increasing importance placed on the endurance and safety of new energy vehicles has made wireless BMS an important direction for technological research and application, replacing the traditional wired connection between battery packs and battery management systems, gradually moving from the early research and development stage to industrialization. Wireless BMS has significant advantages and potential.

Traditional BMS connects battery packs via cables, resulting in substantial space occupation and increased weight, limiting the improvement of battery energy density. In contrast, wireless BMS utilizes wireless communication modules to achieve wireless communication between the battery pack and the BMS host, thereby eliminating issues related to cables and connectors. This wireless method not only improves energy density and optimizes space but also reduces the manual input during the battery assembly phase and minimizes potential risks due to cable breakage or poor contact.

Furthermore, with the development of new technologies such as intelligent connected vehicles and the Internet of Things, BMS technology will also play a crucial role in these fields. For example, cloud-based BMS utilizes big data platforms to accumulate battery lifecycle databases, achieving higher precision algorithms and advanced warnings to reduce accident rates. The development of domain controller technology will further promote the high integration of BMS, VCU, MCU, and other functions into a single system, forming a true “system.” The market for wireless BMS is showing positive growth trends, with broad application prospects. As technology continues to innovate and advance, wireless BMS will play an increasingly important role in electric vehicles, energy storage systems, drones, and other fields, driving rapid development in these areas.

Figure 1. Wireless BMS Architecture Diagram (*Source from ADI official website)

Shanghai Zhongzhixin Information Technology Co., Ltd. (referred to as Zhongzhixin Technology) was the first to launch a wireless BMS testing solution in 2019 and completed the testing of the full lifecycle of wireless BMS in collaboration with a car manufacturer, ensuring that models equipped with wBMS modules achieve relevant verification and testing. The testing covers:

-

Wireless chip and module testing

-

Overall wireless testing of battery packs

-

Function testing based on actual external interference

Figure 2. Outdoor Testing Scene

Figure 3. Laboratory Equipment Diagram

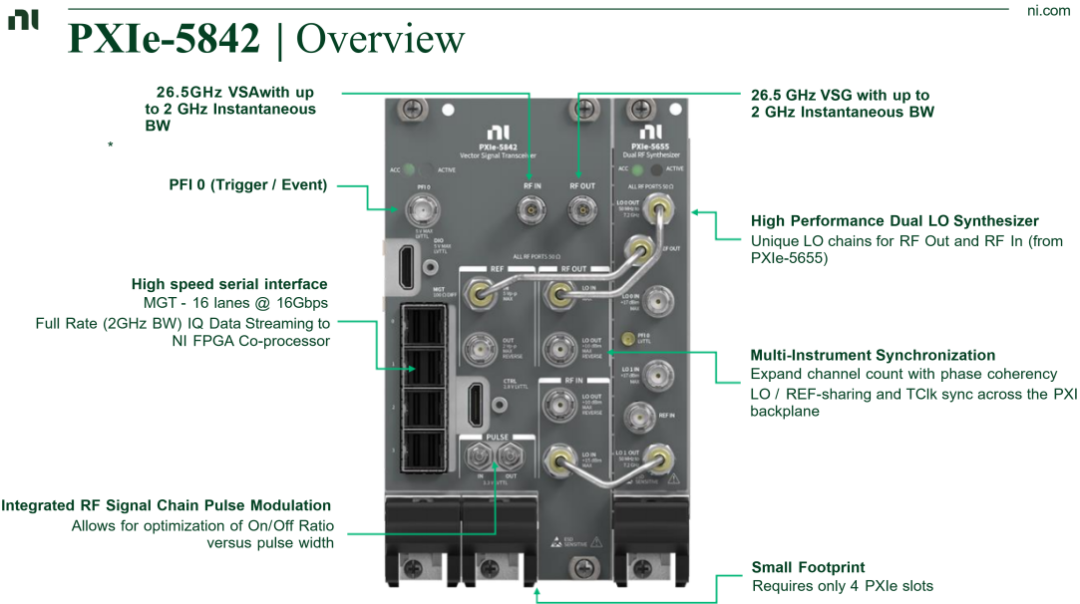

Shanghai Zhongzhixin Information Technology Co., Ltd. has launched a full lifecycle testing solution (chip-module-battery pack) for existing wBMS modules based on NI’s latest generation vector signal transceiver.NI has launched the third generation PXI vector signal transceiver PXIe-5842, which provides a continuous frequency coverage range from 30 MHz to 26.5 GHz, with instantaneous bandwidth doubled compared to previous models, reaching 2 GHz. A single device can complete all RF testing items in wBMS testing, including third-order intermodulation among others. The PXIe-5842 features four main characteristics including a wide frequency range, high instantaneous bandwidth, high-performance LO, modularity, easy synchronization, and an excellent software architecture.

Figure 4. PXIe-5842 Product Overview

Conducted Testing

Conducted testing is based on the Device Under Test (WBMS DUT), vector signal transceiver, and peripheral circuits, combined with RF analysis software. If considering signal attenuation in the channel, an attenuator or channel simulator can be configured. RF conducted testing consists of wired connections, not considering signal propagation through the air, making the testing conditions relatively simple. The reference testing items are as follows:

|

Transmitter (TX) Testing |

Receiver (RX) Testing |

|

Time Deviation Transmit Power Turn-off Power Transmit On/Off Time Template Error Vector Magnitude EVM Equalizer Spectral Flatness Carrier Frequency Offset Carrier Leakage In-band Spurious IQ Mirror Spectrum Template Additional Spectrum Template Occupied Bandwidth Out-of-band Spurious |

Reference Sensitivity Power Level Maximum Input Level In-band Blocking Out-of-band Blocking Spurious Response Intermodulation Characteristics Spurious Radiation |

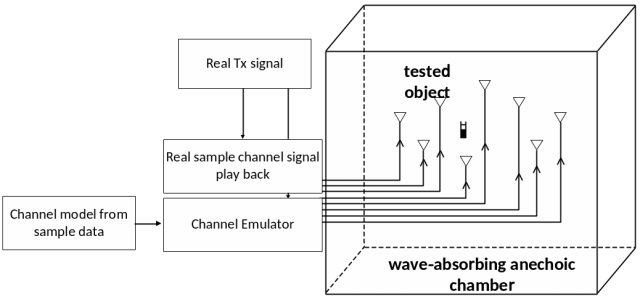

Over-the-Air (OTA) Testing

OTA testing places the testing system in an OTA chamber to better test the characteristics of the device under test in wireless air interface transmission. The testing conditions are relatively complex and require an OTA chamber or shielded room for coordination. OTA testing mainly focuses on the radiation performance of the whole machine, including transmit power and receive sensitivity. Compared with RF conducted testing, OTA testing uses an “over the air” method to connect with the testing instruments, requiring an OTA chamber and corresponding OTA system software. OTA testing can comprehensively consider internal radiation interference, product structure, antenna factors, RF chip transceiver algorithms, etc., serving as a comprehensive testing method to verify the wireless product’s air interface performance in free space. The primary focus is on the following different performance points:

-

Transmission Performance: OTA testing evaluates the transmission performance of wireless devices, including transmission speed, stability, and distance. These metrics reflect the device’s performance in actual use, especially under different network environments and signal strengths.

-

Radiation Performance: OTA testing measures the device’s radiation power and receive sensitivity to assess its radiation performance. These metrics reflect the energy consumption and signal reception capability during wireless signal transmission, which is crucial for ensuring the device’s stability and reliability in actual use.

-

Antenna Performance: OTA testing also evaluates the device’s antenna performance, including gain, efficiency, and radiation pattern parameters. These metrics reflect the radiation and reception characteristics of the device during wireless signal transmission, which is essential for ensuring communication quality and coverage range in actual use.

-

Compatibility and Interoperability: OTA testing assesses the device’s compatibility and interoperability in different network environments and with various devices. This includes communication protocol compatibility, frequency band compatibility, and data transmission stability between devices. These metrics reflect the device’s compatibility and interoperability in actual use, ensuring smooth operation in different scenarios.

The system composition block diagram and design scheme are as follows:

Figure 5. OTA Testing Block Diagram

Figure 5. OTA Testing Block Diagram

Shanghai Zhongzhixin Information Technology Co., Ltd. will work with the NI China Innovation Development Center to assist in the wireless testing application scenarios in the automotive electronics industry, helping engineers create better products and providing higher quality localized services for smart automotive companies and research institutions.