Industry is the cornerstone of the prosperity and development of the national economy, and industrial software is the wing for the industry’s takeoff. Looking ahead, with the deep integration of IT/OT/CT (Information, Operation, Communication Technology) and manufacturing, the future of industry will develop towards flexibility, intelligence, customization, and service orientation. Industrial robots, as one of the important indicators of a country’s manufacturing and technological level, are leading the transformation and upgrading of the manufacturing industry. The development of industrial embedded operating systems is one of the key paths to promote the digitalization and intelligence of industrial robots.

Recently, the Industrial Software Industry Development Center (hereinafter referred to as “National Innovation Center”) under the Greater Bay Area National Innovation Center and the well-known publicly listed industrial robot company Guangdong TuoSiDa Technology Co., Ltd. (hereinafter referred to as “TuoSiDa”) reached an important milestone in joint innovation on basic software platform technology—TuoSiDa has adopted the National Innovation Center’s embedded operating system, targeting industrial robots, injection molding machines, and surrounding automation application scenarios, to create a new generation of integrated intelligent motion control platform.

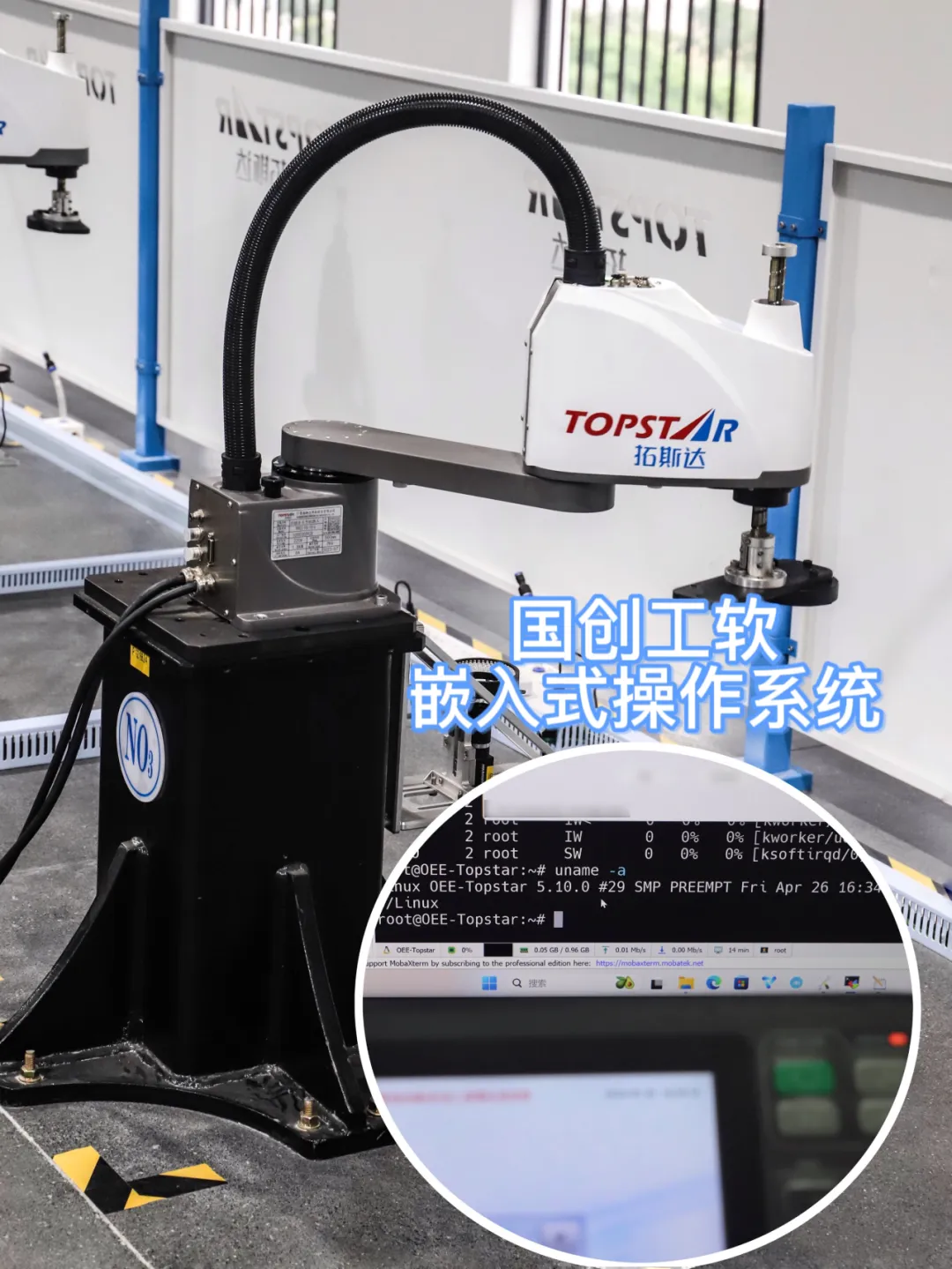

Successful application of TuoSiDa’s new generation motion controller platform in industrial robot scenarios

After on-site verification by TuoSiDa, the National Innovation Center’s embedded operating system has performed well in overall functionality, performance, stability, reliability, and safety, and will soon begin joint market promotion.

The industrial robot industry calls for a self-controllable, high-performance embedded operating system

Over the past few decades, the widespread application of industrial automation technology has improved production efficiency and saved labor costs for enterprises. As an important force driving intelligent manufacturing and automation processes, industrial robots face a series of problems and challenges during their vigorous development:

-

Most industrial equipment relies on foreign chips and operating systems, with core underlying technologies being controlled by others, facing the risk of “bottlenecking”;

-

The acceleration of intelligent manufacturing in domestic industries has led to a surge in the industrial robot market scale, attracting a large number of manufacturers to join, resulting in fierce industry competition and continuously squeezed profit margins, necessitating cost reduction and efficiency improvement;

-

The integration of new technologies such as AI, 5G, big data, and cloud computing has raised higher requirements for the advancement, stability, intelligence, and networking levels of industrial robots.

In response, the National Innovation Center’s embedded operating system team has launched an embedded operating system solution for industrial robot scenarios, assisting enterprises in improving quality and efficiency, and driving business towards high-end manufacturing.

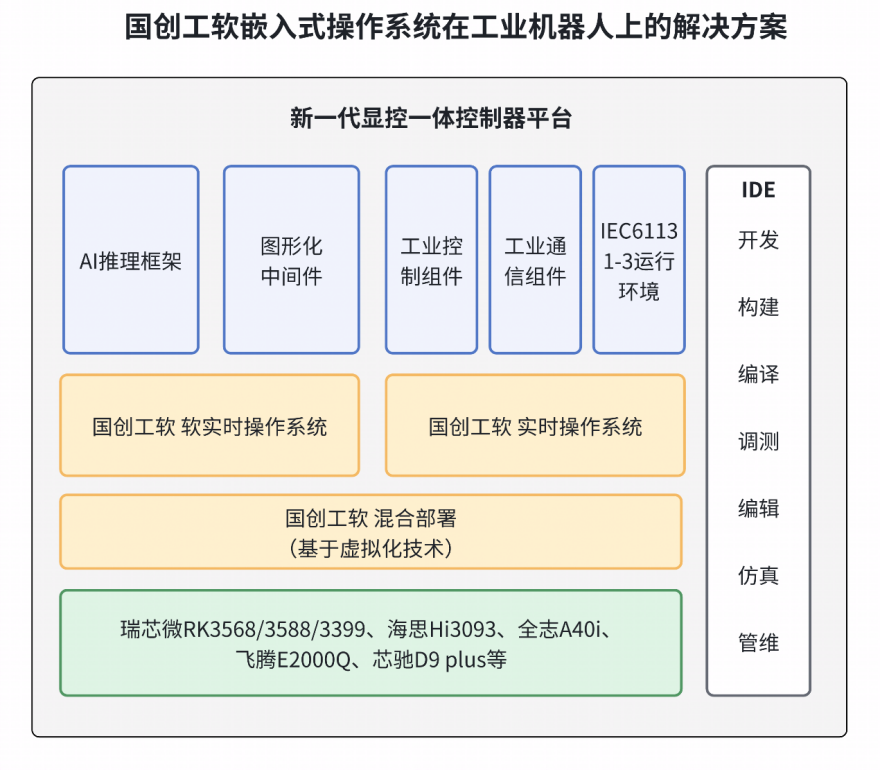

Solution schematic diagram

This operating system adopts a hybrid deployment of key bases, real-time virtualization technology, and “soft real-time + hard real-time” multi-system cross-concurrency, flexibly meeting industrial application scenarios, and is compatible with mainstream domestic chips (Rockchip RK3568/3588/3399, HiSilicon Hi3093, Allwinner A40i, Phytium E2000Q, and Xinchip D9 plus, etc.).

Among them, the soft real-time operating system is based on the openEuler community, supporting graphical display, AI, databases, and other non-real-time applications; the hard real-time operating system exhibits high real-time, high reliability, and high security characteristics, meeting the microsecond-level periodic task requirements for multi-axis robot motion control and five-axis CNC high-speed precision machining; both soft real-time and hard real-time operating systems support various industrial field buses and communication protocols (EtherCAT, ModBus, CANopen, OPC UA, MQTT, etc.), and are compatible with various mainstream industrial ecosystems (PLC, HMI); providing developers with integrated development tools (IDE) for the operating system, constructing a high-security, high-reliability, high-performance embedded operating system solution aimed at high-end industrial equipment, leading industry development.

Core Value

1. Built a full-stack domestic ecosystem from chip operating systems to various industrial middleware, helping enterprises solve self-controllable issues;

2. Multi-business hybrid deployment on the same hardware increases integration, helping enterprises reduce costs by more than 30%;

3. Optimization of real-time performance and assurance of reliability, reducing control task cycle jitter by more than 50%, helping enterprises upgrade high-end businesses and break through bottlenecks;

4. Supports AI engines and various communication protocols, assisting enterprises in digital and intelligent transformation;

5. Provides a simple and easy-to-use, end-to-cloud integrated, open collaboration, co-construction, and sharing integrated development environment, helping developers improve development efficiency, save human resources, and accelerate business iteration.

As the global industry enters a critical stage of accelerated conversion of old and new driving forces, industrial software has been widely applied in the core links of the industrial field, with operating systems serving as the foundational base of industrial software, playing a crucial role in industrial development.National Innovation Center will continue to expand the application of operating systems in more industrial scenarios, forming typical application demonstrations, achieving self-controllable domestic software and hardware, promoting the transformation and upgrading of the manufacturing industry, supporting our country in transitioning from a major manufacturing nation to a strong manufacturing nation, and assisting in high-quality development.

Article source from the WeChat public account of the Greater Bay Area National Technology Innovation Center: Original link