Overview of MQTT Protocol

MQTT is a standard messaging protocol for the Internet of Things (IoT). It is designed as a very lightweight publish/subscribe messaging transport, making it ideal for connecting remote devices with minimal code footprint and network bandwidth. The MQTT protocol has the following characteristics:

-

Lightweight and Efficient: The MQTT client is very small and requires minimal device resources. The MQTT message header is small, optimizing network bandwidth.

-

Bi-Directional Communication: MQTT allows messaging between devices and the cloud, as well as from the cloud to devices.

-

Reliable Messaging: MQTT has three defined quality of service levels: 0 – at most once, 1 – at least once, and 2 – exactly once, ensuring message delivery reliability based on business scenarios.

-

Support for Unreliable Networks: Many IoT devices connect through unreliable cellular networks. MQTT’s support for persistent sessions reduces the time to reconnect clients to the broker.

-

Security: MQTT allows for easy encryption of messages using TLS and authenticating clients with modern authentication protocols (e.g., OAuth).

Today, MQTT is widely used in industries such as automotive, manufacturing, telecommunications, and oil and gas.

This series of articles will provide a detailed analysis of how the MQTT protocol functions in practical application scenarios across various industries.

IoT Business in the Oil Industry

With the rapid development of IoT technology, new information sensing devices and various wired and wireless network technologies are gradually being adopted in oil exploration, production, and transportation environments. Oil and petrochemical companies aim to leverage IoT technology for remote management of oilfield terminal devices, optimizing the efficiency, safety, and scalability of IoT data storage.

In the context of oil production and transportation storage, converting traditional industrial bus protocols and PLC protocols into IoT MQTT protocols through industrial edge gateways allows real-time data from the field to be transmitted to data centers, enabling remote data collection and centralized management of field data. This is currently one of the key directions for production monitoring technology transformation in oil and petrochemical companies.

Pain Points in Traditional Oil Production Data Acquisition Scenarios

Traditional oil fields transmit real-time data such as oil pressure, oil temperature, load, and power from oil wells to RTUs or PLCs via dedicated wireless or wired networks, and then aggregate this data through local SCADA systems for storage in the databases of production operation areas or control rooms at joint stations. The central machine room of the plant needs to periodically synchronize data from the control room’s database to aggregate data from multiple operation areas.

As enterprises increasingly demand real-time data consumption, the access frequency to edge databases has also risen, gradually exposing the following issues during actual operations:

-

Hardware and software for data collection at the site are aging, with high update costs;

-

As the volume of collected data continues to increase, overall performance begins to fail to meet the growing data demands;

-

The plant cannot obtain real-time data, leading to insufficient real-time management and monitoring capabilities;

-

On-site technical maintenance personnel face high workloads and labor costs.

MQTT-Based Oil Production Data Acquisition Solution

Thanks to the widespread adoption of network technology in the oil industry, network connectivity between oilfield operation areas and plants has been largely achieved, providing the foundational network conditions for the introduction of IoT technology. Various production data can also be collected and aggregated through the MQTT protocol for further processing, fully realizing its value.

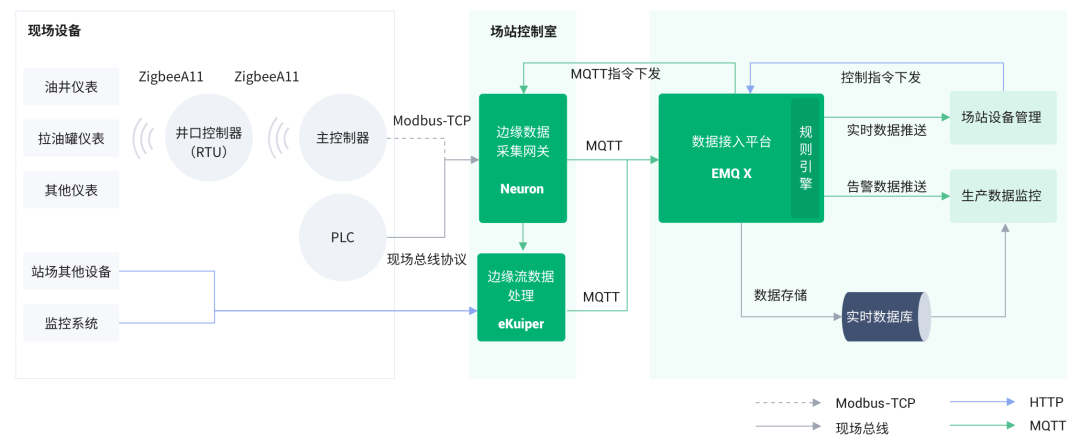

For example, the EMQ cloud-edge data acquisition solution:

1. Converting Various Industrial Protocols to MQTT for Unified Access

At the site, through the industrial data acquisition gateway Neuron (https://www.emqx.cn/products/neuron), data from instruments using Modbus-RTU and Modbus-TCP protocols is converted into a highly reliable and lightweight MQTT protocol, and real-time data is then pushed to the data access platform EMQ X in the central machine room of the plant via a dedicated network;

2. Filtering and Processing Data Before Pushing

Some redundant data or data from other systems can be filtered and processed using lightweight data processing software eKuiper (https://github.com/lf-edge/ekuiper) deployed at the site, pushing meaningful data to the data access platform EMQ X in the central machine room;

3. Real-Time Movement of Collected Data to Databases for Business Applications

The data access platform EMQ X in the central machine room stores the unified real-time data in the central machine room’s database, allowing various business applications to interface with the database to pull relevant business data;

4. Real-Time Push of Alarm Information via MQTT Protocol

Data requiring real-time processing, such as production equipment alarms and site access control alarms, can be pushed to the alarm processing business system by the data access platform EMQ X via the MQTT protocol, enabling rapid processing of real-time data;

5. Real-Time Monitoring of Equipment Using MQTT Protocol

The data center platform of the plant can also achieve remote control and management of on-site equipment through MQTT messages.

What Has MQTT Protocol Brought?

1. Improved Business Real-Time Performance

The lightweight and highly reliable QoS characteristics of the MQTT protocol allow a large number of devices and system data from production operation areas to be reported in real-time to the plant’s data center, significantly enhancing business real-time performance;

2. Reduced Hardware and Software Costs

The lightweight design of MQTT greatly reduces the hardware requirements from client to server. In the EMQ cloud-edge data acquisition solution, the high-availability MQTT message server EMQ X in the central machine room and the lightweight edge industrial gateway Neuron used for business operations replace the expensive SCADA systems and data acquisition storage servers on the site, reducing overall hardware and software costs by over 50%;

3. Labor Cost Savings

By adopting a lightweight front-end and heavy back-end architecture, the number and complexity of on-site devices are greatly reduced, leading to a reduction in on-site operational load and personnel costs by over 70%.

Through the MQTT protocol-based data acquisition architecture, the plant’s data center can obtain various real-time data from the site, enabling new business applications such as remote equipment operation, optimization analysis of well placement, monitoring of operational environment control emissions, and remote assistance for repairs, achieving cost reduction and efficiency improvement as well as business innovation for oil enterprises.

Click “Read the original text” to learn more.

↓↓↓