3D printing technology reference notes that the second article related to 3D printing technology in Nature was published on April 23, 2025. Researchers from Princeton University published an article titled “Modular chiral origami metamaterials (模块化手性折纸超材料)”. The core content of this research is to develop a modular chiral origami metamaterial with multimodal deformation mechanisms using 3D printing technology, which shows great application potential in various fields such as mechanics, thermodynamics, and optics, achieving groundbreaking progress.This research’s first author is Zhao Tuo, who studied at Dalian University of Technology for his undergraduate degree and is currently a postdoctoral researcher at Princeton University. Research Background

Research Background

Mechanical metamaterials are artificial materials designed through special structural designs, capable of exhibiting extraordinary properties beyond ordinary materials like “Transformers”. Traditional designs use unit structures such as rigidly connected octahedral trusses and Kelvin lattices, which are valuable in lightweight characteristics, impact resistance, and fracture studies, but these structures have relatively single deformation modes, similar to LEGO blocks that can only be assembled in a straight line.

In contrast, the upgraded origami metamaterials borrow from the principles of origami and paper cutting, using flexible hinges for connections, allowing materials to achieve free deformation in three-dimensional space, like foldable origami works. This design not only breaks through the limitations of traditional linear deformation but also achieves coupling effects of twisting and stretching through chiral structures.However, the multi-degree-of-freedom deformation introduced by geometric nonlinearity still requires integrated control or external excitation to drive. Additionally, existing research often focuses on limited physical properties under uniaxial loading.

Research Breakthrough

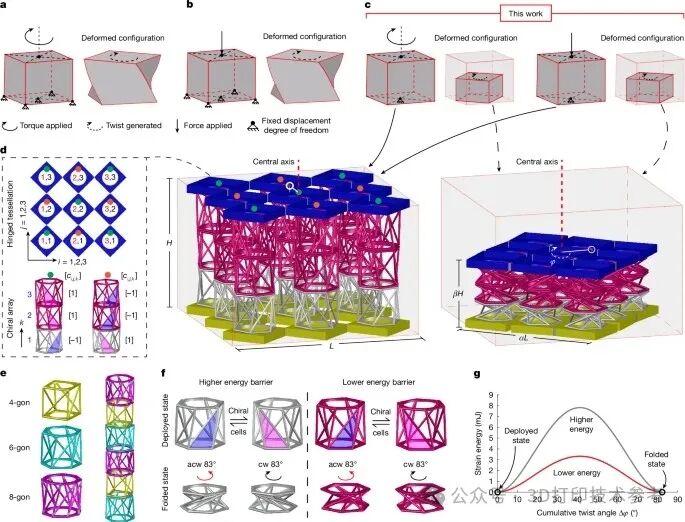

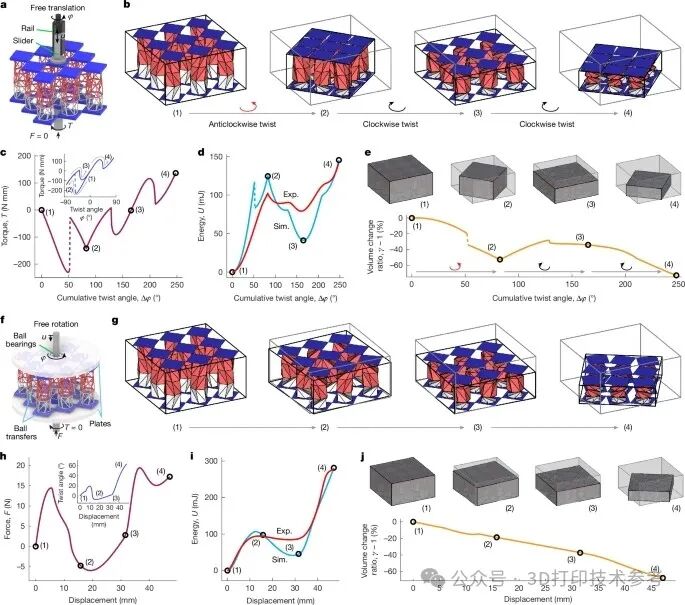

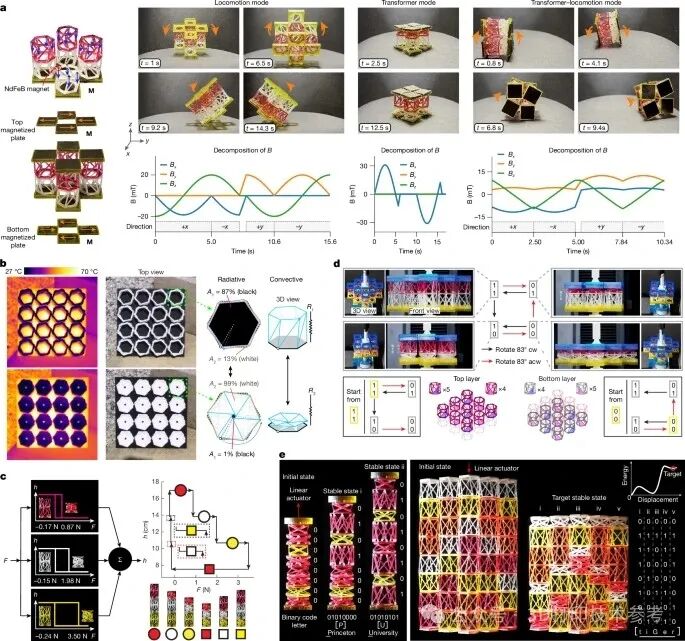

Zhao Tuo and others have developed a metamaterial that can achieve combined motion of translation + twisting with a single control, and can freely expand and contract in three directions.

The design inspiration for this material comes from origami art, integrating two special structures: chiral helical arrays (like the DNA double helix determining the direction of twisting) and stretchable tessellated structures (which become thicker when stretched like a honeycomb). Its innovation lies in the modular assembly method, allowing components to be freely replaced like LEGO blocks: it can adjust to achieve near-zero/negative Poisson’s ratio and other special properties, while also presetting multiple stable states. By optimizing the module shapes, chiral features, and material properties, it is like programming the material, allowing precise control over the mechanical response of the structure, such as setting different energy barriers.

This “programmable metamaterial” has enormous application potential, capable of creating seismic buffer devices; after cross-disciplinary integration of magnetic/thermal/optical functions, it can create robots that can deform and move, as well as develop smart temperature-controlled buildings. The entire design breaks the limitations of traditional materials’ single functionality, making it possible for single control to achieve multimodal motion, truly realizing the deep integration of materials and intelligent systems.

Application of 3D Printing in Modular Chiral Origami

Metamaterial Manufacturing

3D printing technology reference notes that this modular chiral origami metamaterial consists of unit cells, hinge-connected tessellated structures, and assembly plates. These structures are all manufactured using PolyJet 3D printing technology, which is characterized by high precision and the ability to integrate multiple materials, meeting the complex geometric shapes and different mechanical performance requirements of metamaterials.

Multimodal metamaterials composed of lattice units inspired by hinged tessellation and chiral origami

The unit cells consist of rods and soft joints. During the manufacturing process, rods used four materials with similar elastic moduli, approximately 2.2 GPa; soft joints mixed various materials during printing, achieving elastic moduli of 1.7 MPa, 2.7 MPa, and 3.9 MPa depending on the material combinations. This multi-material 3D printing approach allows different parts of the metamaterial to possess different mechanical properties, thus achieving the desired multimodal deformation behavior.

3D printing technology can accurately construct various complex geometric structures of modular chiral origami metamaterials. Taking hexagonal unit cells as an example, their expanded height is 28.3 mm, folded height is 12.6 mm, and polygon radius is 16.8 mm. These precise dimensional parameters are crucial for ensuring the stability and repeatability of the unit cells during the deformation process. Furthermore, 3D printing can achieve the transition from shell-based origami to rod-based lattice units, providing greater flexibility for the geometric design of metamaterials. Through 3D printing, researchers can easily combine various regular polygons as the top and bottom faces of the unit cells, creating metamaterial modules with different geometric characteristics and deformation performances, such as quadrilateral, hexagonal, and octagonal unit cells.

The manufacturing process of modular chiral origami metamaterials is highly modular. Each unit cell can be individually 3D printed and tested, and then assembled as needed to form larger-scale metamaterial structures. This modular assembly method not only improves manufacturing efficiency but also facilitates the optimization and adjustment of the metamaterial’s performance. Researchers can quickly manufacture metamaterial modules with different mechanical responses by changing the geometric shapes of the unit cells, chiral assignments, and material combinations, and evaluate their performance through experimental and simulation analyses, thus achieving precise control over the overall performance of the metamaterial. At the same time, modular assembly also makes the maintenance and replacement of metamaterials much simpler, as only the problematic modules need to be replaced, without the need to remanufacture the entire structure.

ENDIn summary, 3D printing technology plays a key role in the manufacturing process of this metamaterial, achieving precise construction of complex geometric structures while integrating multiple materials into 3D printing, providing critical manufacturing technology for creating metamaterials with integrated mechanical properties.This research’s metamaterials are based on highly modular assembly, allowing for the reprogramming of instability and local chirality control, with adjustable load-bearing capacity and scalability. It provides pathways for multimodal, multi-stability, and reprogrammable machines, applicable to robotic transformers, thermal regulation, mechanical memory in hysteresis loops, non-exchange state transitions, and plug-and-play functional components for energy absorption and information encryption.Note:This article is created by 3D printing technology reference, and unauthorized reproduction is prohibited..Welcome to share

ENDIn summary, 3D printing technology plays a key role in the manufacturing process of this metamaterial, achieving precise construction of complex geometric structures while integrating multiple materials into 3D printing, providing critical manufacturing technology for creating metamaterials with integrated mechanical properties.This research’s metamaterials are based on highly modular assembly, allowing for the reprogramming of instability and local chirality control, with adjustable load-bearing capacity and scalability. It provides pathways for multimodal, multi-stability, and reprogrammable machines, applicable to robotic transformers, thermal regulation, mechanical memory in hysteresis loops, non-exchange state transitions, and plug-and-play functional components for energy absorption and information encryption.Note:This article is created by 3D printing technology reference, and unauthorized reproduction is prohibited..Welcome to share

Welcome to join the PhD and Master exchangeQ group:248112776

Further Reading:

1. The first additive Nature article in 2025: New breakthroughs in 3D printing material research and process control!

2. Latest Nature overview on volumetric 3D printing

3. The third additive Science article in 2025: Breakthroughs in 3D printing materials and applications, with a Chinese scholar as the first author!

4. The first additive Science article in 2025: More powerful structural materials for 3D printing—PAMs!