The Internet of Things (IoT) is a crucial component of the new generation of information technology and an important development phase in the era of “informationization”. As the name suggests, the Internet of Things refers to the internet connecting everything. This has two meanings: first, the core and foundation of the Internet of Things is still the internet, which is an extension and expansion of the network based on the internet; second, its user end extends and expands to the exchange and communication of information between any items, meaning everything is interconnected. The Internet of Things is widely applied in the integration of networks through intelligent sensing, recognition technology, and ubiquitous computing, thus being called the third wave of world information industry development following computers and the internet. The Internet of Things is an application extension of the internet; rather than saying the Internet of Things is a network, it is better to say that the Internet of Things is about business and applications. Therefore, application innovation is the core of IoT development, and innovation 2.0, centered on user experience, is the soul of IoT development.

As a pioneer in the domestic self-developed full laboratory automation pipeline, Sainomed flexibly utilizes IoT technology, integrating interdisciplinary technologies such as 5G, IoT, big data, and cloud technology into inspection laboratories, contributing to achieving a high degree of automation for more laboratories with its balanced, reliable, and personalized advantages.

Intelligent pipeline in laboratories under IoT control

The development of IoT technology has transformed the form of technological innovation. The user-centered, socially practical, and human-oriented innovation 2.0 form is emerging, and the user experience in real-life scenarios is referred to as the essence of the innovation 2.0 model. Based on IoT application innovation, the ultimate goal of laboratory automation is to replace manual operations with equipment, freeing people from low-value, highly repetitive tasks that may pose biological contamination risks. Inspection staff will transition from “operators” to “managers” and “judgers,” becoming masters of the instruments and equipment. Achieving this goal with IoT technology based on 5G is a promising path to pursue.

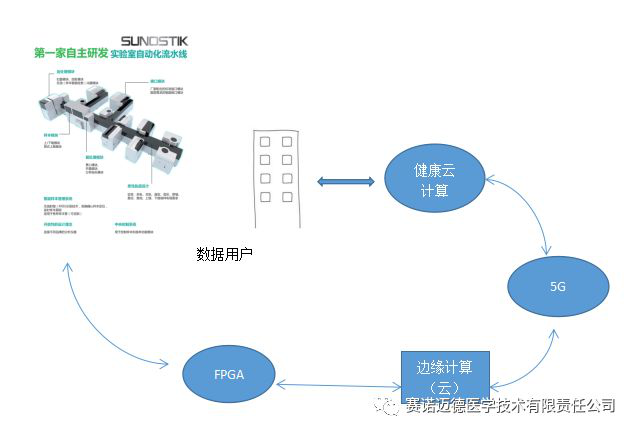

Each laboratory automation solution under IoT scenarios relies on core technologies such as sensors, RFID, FPGA, and edge computing.

Sainomed’s laboratory automation pipeline utilizes wireless radio frequency (RFID) identification technology to accurately locate various sample tubes, enabling real-time sample tracking. In terms of software, the pipeline system software is essentially a small (or micro) IoT system that integrates sample detection, scheduling, transportation, result review, equipment operation status judgment, reagent status, quality control, calibration status, data analysis, and some artificial intelligence technologies into a complex intelligent machine network in laboratory operations, achieving complex management and control without human intervention.

With the groundwork laid by technologies like 5G, IoT, and cloud, a “health data economy model” has finally formed, and the gold mine of inspection data is gradually coming into view for users. From blood collection to sample preprocessing, measurement, post-processing, logistics management, and waste disposal, the entire process is automated and generates a large amount of valuable data. By collecting and analyzing management data related to common diseases, local diseases, health check items, medical insurance, and insurance through edge computing (cloud) and inspection data cloud, scientific basis for management decisions is provided. With the arrival of the 5G era, an IoT inspection laboratory with infinite possibilities is gradually taking shape, and intelligent laboratory pipelines will enter a humanoid era.

Integrating industrial concepts to solve medical laboratory issues

The foundation of “industrialization” is “automation”. Laboratory automation inevitably relies on intelligent software systems. The Sainomed laboratory automation pipeline software encompasses database technology, logical mathematical technology of timing and rhythm, and edge computing technology for measurement processes. If the entry of 5G and IoT into laboratories applies communication technology to inspection medicine, then Sainomed’s other concept is to apply industrial automation solutions to medical laboratories and automation pipelines.

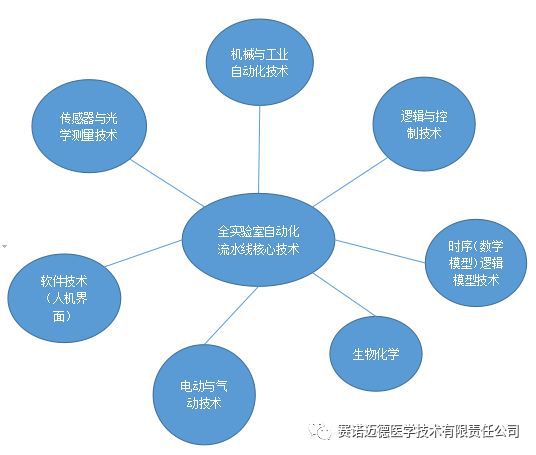

A full laboratory automation system is not merely a simple combination of tracks and modules, but a complex, dense system engineering that includes peripheral devices, processes, algorithms, and information processing, requiring balanced, reliable, and stable cooperation among information technology, automation technology, and mechanical technology across multiple disciplines. Compared to standalone products, which emphasize highlights and showcase individual advantages, complex automation and intelligent systems are similar to aerospace systems and high-speed rail systems, emphasizing cross-disciplinary integration in terms of technology. This is why there are so few manufacturers capable of producing such system products—this requires promising and passionate technical concepts, as well as a team structure and incentive system that attracts multidisciplinary technical personnel to work together for a long time.

By perfectly combining the concept of “industrialization” with inspection equipment, Sainomed stands out with an “open” model compared to foreign system integrators such as Roche, Abbott, Beckman, and Siemens. Foreign pipelines adopt a closed model, connecting specific types and models of instruments and closed reagents, while Sainomed customizes services based on user needs. Additionally, Sainomed has a significant advantage over foreign system integrators in terms of short delivery times and pricing. For pipeline manufacturers such as Beckman, IDS, and Hitachi, Sainomed’s unique “industrial technology” can achieve world-class performance indicators in sample addition accuracy, measurement accuracy, and repeatability, and can be compared with products of any brand.

When an automated intelligent system becomes complex enough, it no longer needs a single, outstanding “highlight”; rather, it requires comprehensive advantages in this niche field. This is precisely where the technical competitiveness of Sainomed’s laboratory automation pipeline system lies.

Designing automation systems for inspection departments, making automation no longer exclusive to central laboratories

Since 2012, pipelines have rapidly spread in domestic laboratories, a market that was entirely monopolized by foreign enterprises at that time. Now, domestic pipeline manufacturers have finally achieved impressive technological results, but the pipeline has long since left the era of “growth from nothing”; both domestic and foreign manufacturers are searching for new growth points.

With the continuous advancement of hierarchical diagnosis and treatment, the sample volume in hospitals at all levels and third-party inspections is increasing, leading to a strong demand for automation. In the future, large-scale (over 1000 samples) hospitals will seek laboratory automation, which will not be limited to pipelines, nor will it be confined to the automation of measurements. Transitioning from selling hardware products to software products, and then to integrated, personalized solutions, is the direction manufacturers should consider.

Therefore, Sainomed proposes the concept of being the design institute for hospital (inspection department) automation systems and the service provider for inspection department automation systems; Sainomed is the highway for laboratory operation and inspection, the ecosystem for inspection; it is a supplier and service provider in the niche field of laboratory automation systems, a technology packaging provider (trustee).

Sainomed discovers needs from the user’s perspective and the user’s point of view, strengthening communication with customers, conducting on-site service visits, selecting measurement equipment and testing items based on the actual conditions of hospitals, and planning inspection processes together with hospitals, addressing the timeliness of preprocessing, complementarity of measurements, and convenience of post-processing, ultimately achieving deeply personalized intelligent solutions.

Sainomed’s laboratory automation pipeline is not limited by space and can design structures and projects according to customer site size, existing equipment, and specialty departments, allowing large-scale top-tier hospitals to experience the convenience of intelligence, enabling third-party inspection centers to enjoy the speed of automation, and allowing smaller second-tier hospitals’ inspection departments to benefit from the convenient services of laboratory pipelines. Furthermore, the pipeline adopts an open design, allowing hospitals to freely choose measurement equipment based on needs and funding, and also providing diagnostic support, project complementarity, and automatic verification functions, reducing labor costs by 30%-40% for hospitals and by 70%-75% for third-party inspection agencies and health check centers. Such automated and intelligent products and services are applicable to hospitals at all levels that lack experience, space, manpower, and funding, and require personalized customization. In the future, the status of second-tier hospitals in the medical system will continue to rise, alleviating the pressure on third-tier hospitals and providing patients with a more convenient medical environment. The inspection laboratory empowered by 5G and IoT can not only improve inspection quality and efficiency but also connect in real-time with third-tier hospitals, achieving remote medical care and providing technical support for the development of medical alliances; at the same time, inspection data from grassroots levels will also provide strong evidence for public health and medical insurance reforms, making it even more significant.

For more details about our pipeline products, please contact:

13159609898/18686652254/18943971519 Email:[email protected]

We cordially invite everyone to visit us at Booth No. A6-T08, see you there!

Disclaimer:

① All content published by this public account, with indicated sources, is copyrighted by the original source, and does not represent the position of this public account. If there is any infringement, please contact WeChat【826699172】.

② Articles published originally by this public account require any individual, media, or website to reprint, must indicate at the beginning of the article “Reprinted from ‘CACLP In Vitro Diagnostics Information'” and credit the author.

↙Click “Read the Original” to register for the CACLP exhibition