This article provides an overview.

Traditional manufacturing is facing severe challenges in digital transformation due to rising demand and industry technological upgrades. Especially after the pandemic, uncertainties in personnel movement and epidemic control have made equipment debugging and maintenance for system integrators and operational enterprises even more challenging. More and more factories and equipment require unmanned, intelligent, and easy-to-maintain equipment control solutions.

Advantech has launched a smart production line edge control solution that integrates edge computing, machine vision, and remote device maintenance diagnostics required for intelligent equipment, effectively improving equipment production efficiency and yield rate while reducing operational management costs and energy consumption.

Advantech’s Smart Production Line Solution

System Architecture Diagram

Edge Control Platform

01

Solution Configuration

Platform Solution: Advantech Embedded Edge Controller AMAX-658 with Intel I7 Processor

I/O Module: AMAX-5000 Plug-in EtherCAT I/O Module

Software Solution: Win10 Operating System

Control Software: Advantech CODESYS Control Software

02

Solution Functions

1、 Edge-side Coordination:

2、 Automated Control:

3、 Information Integration:

In the Windows system, through Advantech MachineUnite Device Cloud Intelligence Connection System, it uploads device status data to the cloud platform, achieving remote maintenance, device status detection, and predictive maintenance.

03

Product Advantages

1

Diverse Buses

Advantech edge controllers support various industrial buses, integrating multiple peripherals and actuators from different manufacturers to solve integration issues;

2

Rapid Project Implementation

It supports PLC programming languages familiar to automation engineers and also supports languages familiar to IT engineers such as C/C#, MATLAB, Labview, Python, etc., facilitating collaboration among engineering teams and reducing project construction time;

3

Improved Stability

Compared to traditional solutions that require multiple devices to be connected via cables, the AMAX-658 integrates IPC and PLC functions into a single controller, effectively reducing the number of network ports on-site, thus enhancing hardware stability. The multi-core, multi-system architecture also combines IPC’s information processing capabilities with PLC’s real-time safety features;

4

Increased Processing Rhythm

By quickly exchanging information through internal bus protocols, it improves information exchange speed and overall processing rhythm of the equipment.

5

Intelligence

The entire solution integrates automation control with information transmission and analysis, truly achieving unmanned processing. It supports WIFI and 4G functions, enabling remote maintenance of devices and facilitating quick upgrades.

Machine Vision Positioning and Inspection

Visual inspection data such as capacity, production efficiency, and yield rate are uploaded after statistics, combined with the Advantech MachineUnite Device Cloud Intelligence Connection System for intelligent analysis and management.

First Station: Unordered Loading

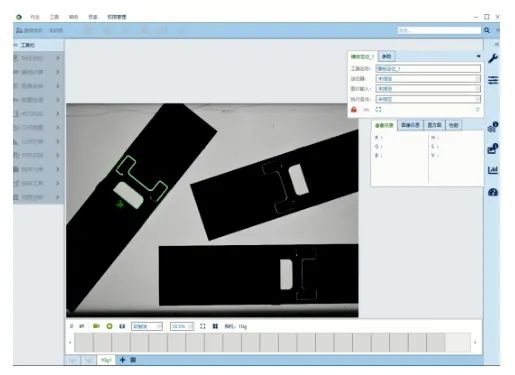

In conjunction with robotic control, the intelligent vision software VisionNavi can upload product position information to the vision control platform after recognizing the product, allowing the control platform to issue commands for the robot to automatically grab and load. The entire process requires no human intervention, and materials can be placed randomly without prior manual sorting, significantly reducing labor requirements.

Unordered grabbing software interface

Product Configuration:

Vision System: Advantech Smart Vision Software VisionNavi;

Camera: QCAM Series 10 Gigabit Industrial Camera (25 million pixels);

Light Source: Backlight;

Vision Control Platform: Advantech Machine Vision Controller AIIS-3410

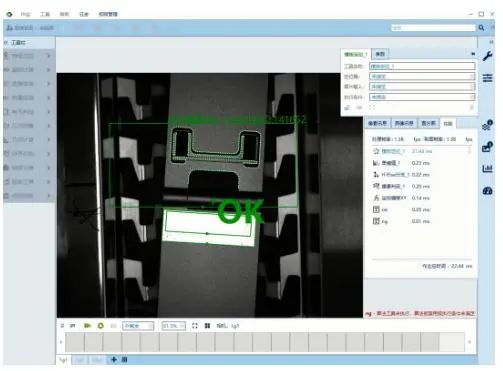

Second Station: Incoming Product Quality Inspection and Visual Positioning

This station inspects the quality of products before processing, avoiding the influx of defective products from previous processes, which would lead to waste of materials and labor in the processing stage. Due to the high precision required for product processing, visual calculations for position positioning must be performed before loading, sending back the offset position information to the control platform to provide the position data needed for subsequent laser processing.

Incoming Quality Inspection detects OK products, guiding the robot to pick them up to the good product discharge area, while NG products are guided to the defective product discharge area.

Incoming inspection and position correction (OK)

Incoming inspection and position correction (NG)

Product Configuration:

Vision System: Advantech Smart Vision Software VisionNavi;

Camera: QCAM Series Gigabit Industrial Camera (5 million pixels);

Light Source: Backlight;

Vision Control Platform: Advantech Machine Vision Controller AIIS-3410

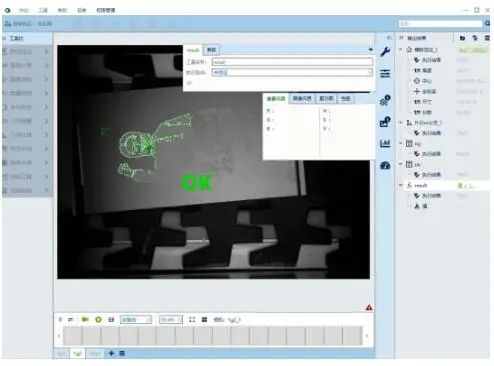

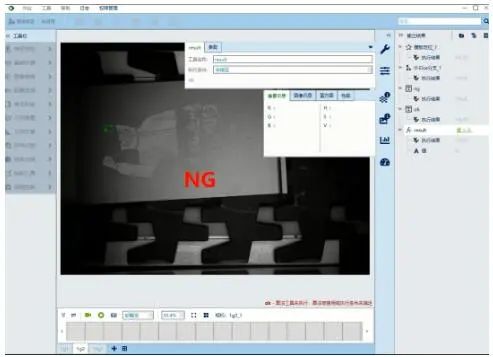

Third Station: Finished Product Quality Inspection

After laser processing, this station performs defect inspection on the products, sorting out qualified products from defects such as misprints, missed prints, and position offsets during production, and uploads the inspection results to the control platform. The control platform, based on the returned data, controls the robot to visually sort the qualified and defective products.

Finished product quality inspection (OK)

Finished product quality inspection (NG)

Advantages of Smart Vision Software VisionNavi

01

Quick Configuration

Quickly configure visual solutions, saving development time for visual projects;

02

Template Matching

Excellent template matching solutions effectively address issues such as product unevenness and shadows;

03

Greater Product Compatibility

VisionNavi can establish multiple different templates for classification and detection of different products.

04

Faster Detection Speed

VisionNavi employs multi-threaded synchronous parallel processing, providing stable detection results while improving speed;

05

Richer Output Methods

VisionNavi supports TCP/IP, IO, RS232, and other output methods, allowing direct communication with PLCs from Siemens, Mitsubishi, etc.;

06

Simpler Calibration Methods

VisionNavi offers multiple calibration methods, with tool-based operations allowing for one-click calibration, QR code calibration board calibration, etc.

Remote Device Maintenance

Advantech MachineUnite Device Cloud Intelligence Connection System

System Advantages

01

Global Monitoring

It can monitor device UPH, energy consumption, and device faults;

02

Preventive Maintenance

Achieves lifespan management for critical components – laser heads based on planning. Enhances equipment lifespan.

03

Data Analysis

Establishes energy-saving suggestion models, failure predictions, and process improvements;

04

Remote Maintenance

Remote troubleshooting, maintenance, and formula upgrades via VPN.