By | Sensor Technology (WW_CGQJS)

MEMS sensors are key devices for obtaining information and play a significant role in the miniaturization of various sensing devices. They have been widely used in fields such as space satellites, launch vehicles, aerospace equipment, aircraft, various vehicles, biomedical applications, and consumer electronics.

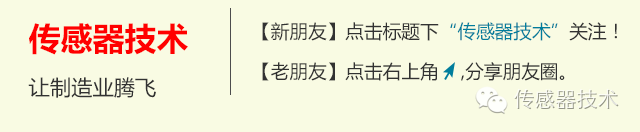

MEMS pressure sensors are the most widely used sensors in automobiles, with at least 18 automotive application fields driving the growth of pressure sensors, including: tire pressure, brake sensors in electronic stability control systems, side airbags, engine control related to increasingly stringent emission standards, atmospheric pressure, and exhaust gas recirculation pressure. These sensors use single crystal silicon as the material, employing MEMS technology to create force-sensitive membranes within the material, then doping impurities on the membrane to form four strain gauges, which are connected in a circuit using a Wheatstone bridge to achieve high sensitivity. Automotive MEMS pressure sensors come in several common forms, including capacitive, piezoresistive, differential transformer, and surface acoustic wave types.

The principle of MEMS accelerometers is based on Newton’s classical mechanics, typically consisting of a suspension system and a sensing mass. They detect acceleration through the displacement of a micro-silicon mass block and are mainly used in automotive airbag systems, anti-slip systems, automotive navigation systems, and anti-theft systems. In addition to capacitive and piezoresistive types, MEMS accelerometers also come in piezoelectric, tunneling current, resonant, and thermocouple types. Among these, capacitive MEMS accelerometers have high sensitivity and are minimally affected by temperature, making them the mainstream product in MEMS micro-accelerometers.

Micro gyroscopes are angular rate sensors mainly used for GPS signal compensation in automotive navigation and chassis control systems. They come in several types, including vibrating and rotor types. The most commonly used is the vibrating gyroscope, which utilizes the Coriolis effect generated when a vibrating mass block made of single crystal or polycrystalline silicon is rotated by a base to sense angular velocity. For example, when a car turns, the system uses the gyroscope to measure angular velocity to indicate whether the steering wheel is turned correctly, actively applying appropriate braking to the inner or outer wheels to prevent the car from leaving the lane. Typically, it forms an active control system with low accelerometers.

MEMS flow sensors are based on traditional thermal membrane anemometer principles, utilizing advanced membrane technology to process stable thin-film resistors onto a membrane. Due to MEMS processing, the sensor’s response time is shortened, and the front and back bridge circuits allow for the determination of fluid flow direction, enabling further measurement of backflow volume.

To prevent temperature changes from affecting measurement accuracy, the sensor employs two thermistors for temperature compensation on the front and back bridges. Flow sensors are mainly used to detect the air intake and fuel injection amounts in engines, thus controlling the air-fuel ratio near optimal values. Additionally, flow sensors are widely used in exhaust recirculation, anti-slip driving, brake anti-lock systems, and electronic suspension systems.

In terms of sales revenue, the top five automotive MEMS applications ranked in descending order are: ESC, airbags, manifold absolute pressure (MAP), TPMS, and rollover detection.

With the rapid development of the consumer electronics field and continuous product innovation, particularly benefiting from the fast growth of smartphones and tablets, consumer electronics have replaced the automotive field as the largest application market for MEMS. MEMS sensors in smartphones and tablets account for nearly 90% of the consumer electronics MEMS sensor market.

Applications of MEMS sensors in consumer electronics include motion/fall detection, navigation data compensation, gaming/human-machine interface, power management, GPS enhancement/blind spot elimination, speed/distance counting, etc. These MEMS technologies have significantly improved user experience.

The hard disk drive drop protection in end devices is one of the historically significant representative applications of MEMS motion sensors in the consumer electronics market. The three-axis accelerometer in laptops can monitor acceleration; due to its specific functions and data processing circuits, it can detect unexpected drops of the hard disk drive and promptly command the read/write head to retract to a safe position, preventing damage to the read/write head when the computer ultimately falls to the floor.

Smartphones

are the largest application field for MEMS in consumer products. They include MEMS microphones, 3D accelerometers, RF passive and active components, camera stabilization and GPS gyroscopes, small fuel cells, and biochemical chips. The most commonly used sensors are accelerometers, gyroscopes, and MEMS silicon microphones, with accelerometers being the top application product in this market. Recently, the rapid growth of gyroscopes has made them the second largest application product after accelerometers.

Sales of MEMS microphones surpassed $1 billion in 2015, and a global industry research report from IHS indicates that the global MEMS microphone market will maintain an 18% compound annual growth rate (CAGR) for the next five years. Some MEMS sensors are just entering the market, such as magnetometers, fingerprint sensors, environmental sensors, and MEMS phone cameras. The scale and diversity of MEMS sensors in mobile applications continue to grow rapidly.

Apple first applied MEMS accelerometers in the iPhone in 2007, initiating a sensor revolution in the mobile industry. The iPhone 6 Plus uses accelerometers, gyroscopes, electronic compasses, barometers, fingerprint sensors, proximity and ambient light sensors, MEMS microphones, and image sensors. To date, Apple has over 350 patents related to sensors, covering touch, imaging, motion, vibration sensing, data processing, drop detection, and brightness sensing.

Game Consoles

are prominent representatives of motion tracking and gesture recognition applications. Taking the revolutionary Nintendo Wii game console as an example, it uses a MEMS three-axis accelerometer to capture any subtle movements of the player, immersing them in a real gaming experience by integrating different actions into the game, such as mimicking a real tennis match, an engaging golf game, a tense boxing match, or a relaxing fishing competition.

High-efficiency, low-cost micro MEMS sensors have fundamentally changed the way people interact with mobile devices. In various mobile devices, game consoles, remote controls, and other equipment, MEMS sensors can achieve advanced functions and exciting user interfaces, allowing users’ gestures and touches to activate corresponding functions. This marks a milestone in the “upgrade and replacement” of consumer electronics.

Smart Wearables

are currently the hottest emerging products, and the sensing components they use must meet more stringent requirements in terms of size, power consumption, sensing sensitivity, and component reliability. The most successful component cases are inertial sensors and MEMS microphones, with well-known companies like Google, Apple, Microsoft, and Motorola integrating these two components into their wearable device products, making them standard sensor configurations.

The two main functional projects of smart wearable devices are quantifying life (Quantified Self) and personal environmental safety monitoring. The sensing functions required can generally be categorized into four major types: activity sensing, image sensing, environmental sensing, and physiological sensing. The application demands for MEMS components in wearable devices are aimed at achieving miniaturization, low power consumption, high performance, and multifunctional integration.

Fitness and health monitoring are representative applications of MEMS sensors in smart wearable devices. Pedometers or step counters utilize three-axis MEMS accelerometers; under specific conditions, the sensors can accurately measure the acceleration acting on the system during walking and running. By processing the acceleration data, the pedometer displays the user’s steps, speed, and calories burned during physical activity.

MEMS sensors used in aerospace applications must adapt to different space environments, including: vacuum, electromagnetic radiation, high-energy particle radiation, plasma, micro-meteoroids, planetary atmospheres, magnetic fields, and gravitational fields, as well as induced environments generated by spacecraft systems during operation or under space conditions, such as vibrations caused by ignition of orbital control thrusters and the deployment of solar panel wings; the induced magnetic fields generated by the movement of magnetic materials and current circuits in the spacecraft within the space magnetic field; and molecular contamination caused by the deposition of organic material effluents from the spacecraft on other surfaces.

Therefore, aerospace sensors are mainly divided into state sensors and environmental sensors. The former includes various instantaneous position sensors for moving parts, such as flap and aileron positions, nozzle sizes, throttle positions, landing gear retraction positions, aircraft state sensors, such as angle of attack, sideslip angle sensors, aircraft attitude sensors, etc., as well as various parameters such as hydraulic pressure, oil pressure, engine vibration, oil metal debris, various consumables such as remaining fuel quantity, consumption rate, etc., along with ice detection sensors, fire alarm sensors, limit sensors, overload sensors, life sensors, and various redundant system automatic switch sensors.

Environmental sensors mainly consist of temperature sensors, humidity sensors, oxygen sensors, pressure sensors, flow sensors, etc.

MEMS sensors in aerospace applications have five main uses:

① Provide operational information about spacecraft, facilitating fault diagnosis;

② Assess the coordination of operations among subsystems, verifying design schemes;

③ Provide information necessary for system self-checks, offering a basis for commanders’ decision-making;

④ Provide internal detection parameters for subsystems and the entire machine, verifying design correctness;

⑤ Monitor the internal and external environment of the spacecraft, providing necessary living conditions for pilots and astronauts, ensuring normal flight parameters.

Electronic Devices Composed of MEMS Sensors

MEMS sensors have important applications in electronic devices in aircraft, aircraft design, and micro-satellite technologies. The onboard distributed atmospheric data computer is directly composed of a multifunctional micro-atmospheric data probe (also known as a combined pitot tube), micro pressure sensors (static, differential, and dynamic pressure), and a signal processing unit, all encapsulated in a housing, forming a micro-electromechanical system.

MEMS Inertial Navigation Systems

Micro inertial navigation systems integrate micro gyroscopes, micro accelerometers, and their signal processing units. This system is primarily made of silicon materials and manufactured using MEMS processing technology, with volume and mass reduced by at least 2 to 3 orders of magnitude compared to conventional inertial navigation systems.

Micro Inertial Measurement Units (MIMUs) made with MEMS technology have no moving parts and greatly outperform conventional inertial instruments in terms of lifespan, reliability, cost, size, and mass. The standardized, high-performance spacecraft attitude measurement instruments produced have better performance, lower prices, and can be used across various aerospace platforms. Using MIMU devices significantly reduces the weight of the equipment.

MEMS Accelerometers

Accelerometers are used in aerospace applications for attitude and heading reference systems; strapdown inertial measurement units; aircraft navigation systems; flight control systems; including structural tests during flight such as flutter testing; health system testing; stability testing; ground vibration testing (wind tunnel testing); modal testing; engine control systems, guidance systems, etc.

MEMS Chemical Sensors

This high-temperature sensor array, similar to an electronic nose, is used to detect and control emissions from aerospace and automotive engines. By analyzing the signals generated by the electronic nose, the composition of the exhaust gases in the emission system can be determined.

MEMS Pressure Sensors

Aerospace sensors are commonly used in flight, flight testing, engine testing, structural strength testing, wind tunnel testing, and during the manufacturing process of equipment. The characteristics of pressure measurement include a wide variety of measured pressures, extensive coverage, multiple measurement points, and high measurement accuracy requirements.

Aerospace combines advanced manufacturing technology, information technology, and materials technology, leading to increasingly higher requirements for sensors. The development direction of MEMS sensors is towards multifunctionality, miniaturization, intelligence, and integration. As product reliability improves and prices drop, and as manufacturing technology matures, the application of MEMS sensors in aerospace will increasingly replace traditional sensors.

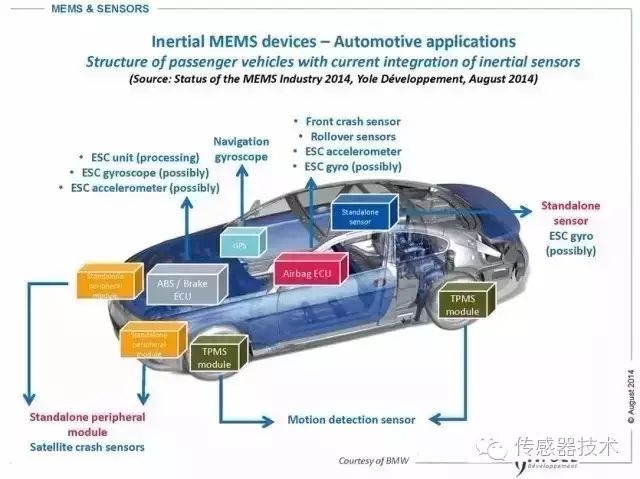

The breakthroughs in MEMS sensor technology have brought unprecedented convenience and experiences to medical applications. With the aging population, healthcare issues have become increasingly important. Fields such as in vitro diagnostics, drug research, patient monitoring, drug delivery methods, and implantable medical devices are continuously evolving, and system integrators need innovative technologies to rapidly enhance product performance, reduce product costs, and minimize product sizes.

Implantable Sensors

Must be small in size, lightweight, and compatible with the body, while also requiring very low power consumption. More importantly, they must not degrade over time.

Since these sensors belong to Class III medical devices, they require approval from the Food and Drug Administration (FDA) before use. Generally speaking, these sensors are very expensive and require experts to perform surgical implantation. Power requirements are one of the main challenges faced by implantable sensors to function normally. Sensors that operate without power are the ideal solution.

Piezoelectric Polymer Sensors

These sensors are small in size, highly reliable, do not require external power, and can operate continuously for long periods. They can be applied in monitoring patient activity through pacemakers, allowing real-time monitoring of heart rate changes. For example, if a large aneurysm develops in the abdomen, requiring the removal of a portion of a weak artery and replacing it with a synthetic tubular organ, a sensor can be implanted during surgery to monitor pressure leakage at the surgical site.

Pacemakers

Whenever a patient moves, the sensor generates a signal. The pacemaker receives these signals and causes the heart to beat accordingly. If the patient is at rest, the signal is zero, and the pacemaker will make the heart beat at a normal frequency, such as about 70 beats per minute. The sensor can distinguish various activities, such as walking, running, or other physical activities. The sensor’s output is proportional to the amount of movement.

MEMS Accelerometers

A non-invasive fetal heart detection method is proposed, developing a simple, intuitive, and accurate medical auxiliary instrument for clinical diagnosis and self-examination of pregnant women, positioned between fetal heart stethoscopes and Doppler fetal monitors.

By using accelerometers to convert fetal heart rates into analog voltage signals, a pre-amplifier is used to achieve differential amplification. Then, a series of intermediate signal processing steps, including filtering, convert the analog voltage signal into a digital signal. The data is analyzed and processed by a microcontroller, and the processed results are output.

Based on MEMS accelerometers, the fetal heart rate detection device can be improved to serve as a remote fetal heart monitoring system. The central signal acquisition and analysis monitoring host at the hospital provides automatic analysis results, and doctors diagnose based on these results, notifying pregnant women to visit the hospital promptly if any issues arise. This technology allows pregnant women to check the fetus’s condition at any time, ensuring the health of both the fetus and the mother.

Biological Sensors

Everything is connected, and intelligent sensing is at the forefront. With the rapid development of communication technology, the application of MEMS sensor technology enables all smart objects to interact with the real world, driving the development of the Internet of Things (IoT).

The Internet of Things (IoT) connects any object to the Internet for information exchange and communication, achieving intelligent identification, positioning, tracking, monitoring, and management. In short, the IoT is the “Internet of Everything”.

From a network structure perspective, the IoT can be divided into three layers: the perception layer, network layer, and application layer. The perception layer, located at the bottom of the three-layer structure of the IoT, is the core foundation of the IoT. Sensors, as an important component of the perception layer, convert physical quantities, chemical quantities, and biological quantities from the real world into digital signals that can be processed, forming the basis and premise for realizing the IoT.

The vigorous promotion of the IoT and the widespread application of smart terminals have significantly increased the demand for sensor products, gradually shifting focus towards the high-tech MEMS sensor field. MEMS technology is widely applied in the IoT, covering various sub-fields such as wearable devices, smart homes, healthcare, Industry 4.0, smart vehicles, and smart cities.

Humanity communicates and shares information through a giant intelligent network infrastructure shared by billions of people globally, achieving comprehensive community interaction and information sharing, linking physical objects and virtual analytics to achieve ubiquitous sensing, identification, control, and service.

In a future world of infinite sensing and interconnectedness, a variety of intelligent technologies abound: unmanned vehicles will drive automatically, making driving safer; smart appliances will provide convenient and comfortable living management and security services; plant factories will precisely control crop production processes and solve food shortages caused by climate change; Industry 4.0 will achieve safe and efficient human-machine collaboration, enhancing product yield and quality; telemedicine networks will bring better and more convenient healthcare services; and smart grids will improve energy efficiency in cities, drive economic growth, and mitigate global warming. For individuals, mobile and wearable devices will provide ubiquitous information services and life care. Additionally, traditional industrial applications, such as healthcare, navigation, military, aerospace, seismic exploration, and process control, are utilizing MEMS sensing technology to form a new type of industrial IoT.

MEMS sensor technology, characterized by low power consumption, high precision, and small size, meets the needs of an intelligent world interconnected by everything. The development and market introduction of new MEMS sensors make a rich variety of IoT applications possible, enhancing the vibrancy of our lives.