With the advancement of technology and the development of artificial intelligence, humanoid robots are gradually coming into people’s view as an important track for future industries. Recently, the China Academy of Information and Communications Technology’s TIER System Laboratory released the “Research Report on the Development of the Humanoid Robot Industry (2024)”, which deeply analyzes the current status of humanoid robots, future development paths, and market forecasts, pointing out significant trends that are forming in this field.

See the end of the article for the complete report download method!

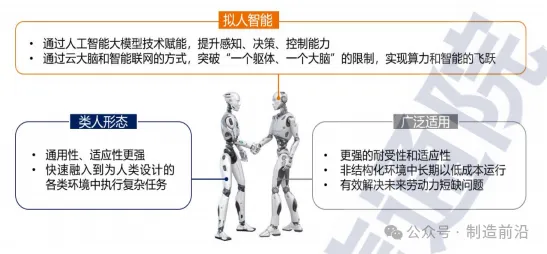

1. Imitation of Human Appearance and Behavior: Humanoid robots are designed to imitate human form and behavior, equipped with a high level of intelligence.

2. Human-like Features:

– Human-like Intelligence: Humanoid robots achieve human-like perception, decision-making, and control capabilities through the empowerment of artificial intelligence large model technology. They can choose to break through the limitations of a single body through a cloud-based “brain” and intelligent networking, achieving leaps in computing power and intelligence.

– Human-like Form: The high simulation of human form allows humanoid robots to quickly integrate into various environments designed for humans to perform complex tasks, possessing greater versatility and adaptability.

– Wide Applicability: Humanoid robots have stronger tolerance and adaptability than humans, capable of operating in unstructured environments for long periods at low cost, effectively addressing future labor shortages, and will be widely applied in industrial production, public services, special operations, and other fields.

By Form Classification

1. Wheeled Humanoid Robots:

– Mainly use wheeled drive, emphasizing tactile sensors and dexterous hand operation functions.

2. Half-body Bipedal Humanoid Robots:

– Emphasizes the leg movement capabilities of the robot, with the hands primarily used for balance.

3. All-round Humanoid Robots:

– Equipped with bipedal, bimanual, and various perception and artificial intelligence functions, adaptable to multitasking in open environments.

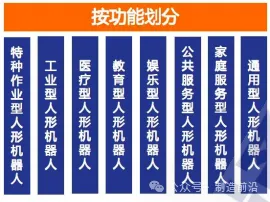

By Function Classification

1. Special Operations Humanoid Robots:

– Used for tasks such as patrolling, inspection, disaster rescue, and hazardous operations.

2. Industrial Humanoid Robots:

– Used in industrial production and logistics fields, such as cargo handling and manufacturing.

3. Medical Humanoid Robots:

– Assist doctors in surgery, diagnosis, rehabilitation, and other tasks.

4. Educational Humanoid Robots:

– Serve as teaching aids, providing interactive learning content.

5. Entertainment Humanoid Robots:

– Interact with humans, providing companionship and entertainment functions.

6. Public Service Humanoid Robots:

– Provide public services in hotels, restaurants, shopping malls, etc.

7. Household Service Humanoid Robots:

– Used for household elderly care, childcare, chores, etc.

8. General-purpose Humanoid Robots:

– Applicable in multiple fields including industrial, service, education, and medical.

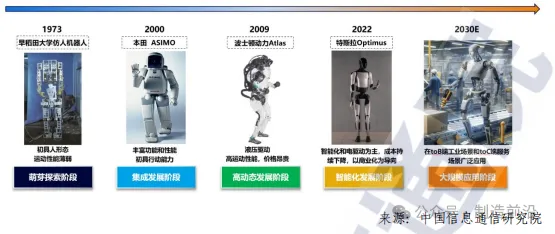

1. Budding Exploration Stage (Late 1960s to 1990s):

– Aimed primarily at achieving basic bipedal walking functionality.

– Represented by Waseda University in Japan, which developed a series of robots, such as WAP, WL, WABIAN, and WABOT.

– Features: Basic achievement of bipedal walking functions and control capabilities, initially possessing a humanoid structure, but overall movement capabilities were weak.

2. Integrated Development Stage (Early 2000s to 2010):

– Characterized by the integration of perception and intelligent control.

– Honda’s ASIMO series of humanoid robots represented significant progress during this stage.

– Features: Through the integration of perception and intelligent control technologies, robots possessed a preliminary perception system, capable of sensing basic information about the surrounding environment and making simple judgments based on perception inputs to adjust actions.

3. High-Dynamic Development Stage (2010 to 2022):

– Advances in control theory and technology enhanced the cognitive abilities of robots.

– Robots could independently and stably perform complex actions, and during this stage, humanoid robots possessed strong movement capabilities.

– Representative products include Honda’s upgraded ASIMO robot and Boston Dynamics’ ATLAS robot.

– Features: Capable of precisely completing delicate tasks such as grasping objects and pouring liquids, as well as maintaining balance and achieving high dynamic movements in challenging scenarios.

4. Intelligent Development Stage (2022—):

– Empowered by artificial intelligence technology, robots possess more intelligent perception, interaction, and decision-making capabilities.

– Electric drive has become the mainstream technology route for “limbs,” achieving more precise walking and operation, and increasing the speed of R&D iteration.

– Representative products include Tesla’s Optimus robot.

– Features: Based on artificial intelligence technology and self-developed FSD (Full Self-Driving) chips, achieving task-level and action-level decision-making through end-to-end neural network models, as well as recognizing objects, faces, and gestures in complex environments.

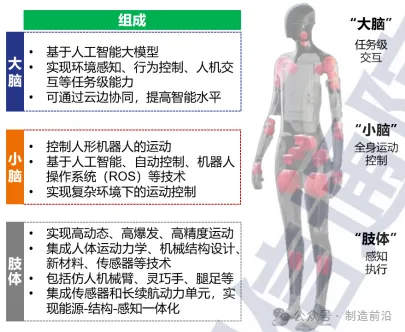

1. High Degree of Technology Integration, Multi-Angle Imitation of Humans

– Humanoid robot technology integrates innovations from artificial intelligence, mechanical engineering, electronic engineering, and other fields, achieving imitation of humans, including three main parts: “brain,” “cerebellum,” and “limbs.”

– The “brain” is responsible for environmental perception, behavior control, and human-machine interaction tasks.

– The “cerebellum” is responsible for motion control, achieving motion control in complex environments.

– The “limbs” are responsible for achieving high dynamics, high explosiveness, and high precision movements, integrating technologies such as human motion mechanics, mechanical structure design, new materials, and sensors.

2. Accelerated Development of Whole Machines, Continuous Innovation of Products

– Globally, companies like Tesla, Figure AI, and Boston Dynamics have become the first tier of humanoid robot complete machine products, launching products with high levels of intelligence and comprehensive performance.

3. Parallel Exploration of “Brain” Technology Routes, Initial Human-Like Intelligence

– The “brain” technology of humanoid robots centers on large models, providing task-level interaction, environmental perception, task planning, and decision-making capabilities.

– Technology routes include LLM (Large Language Model) + VFM (Visual Foundation Model), VLM (Visual-Language Model), VLA (Visual-Language-Action Model), and multi-modal large models, etc.

– The “brain” of humanoid robots is evolving towards higher levels of intelligence and autonomy, requiring breakthroughs in perception modes, instruction generation speed and complexity, generalization ability enhancement, and model architecture optimization.

4. “Cerebellum” Loads Artificial Intelligence Technology, More Human-Like Motion Methods

– The motion control of the “cerebellum” includes two main categories: model-based control methods and learning-based control methods.

– Model-based control methods rely on precise dynamic models, while learning-based control methods use end-to-end artificial intelligence technology to reduce development difficulty and improve iteration speed.

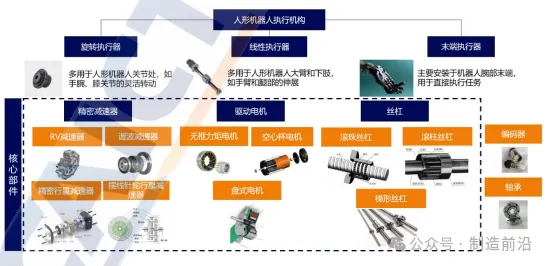

5. Multi-Technology Fusion Development of “Limbs,” Gradual Convergence of Technology Routes

– The core driving technology route of the “limb” execution mechanism has fully shifted from traditional hydraulic drive methods to electric drive.

– Execution mechanisms include rotary actuators, linear actuators, and end-effectors.

– In terms of chip technology, processor chips are the core of functionality realization, with the mainstream technology route being CPU + GPU solutions.

– In terms of sensor technology, humanoid robots require various types of sensors, such as six-dimensional force sensors, joint torque sensors, etc.

– In terms of power supply technology, high-performance power supplies provide lasting power, with lithium-ion batteries being mainstream.

– In terms of new materials technology, lightweight materials such as carbon fiber and engineering plastics are used to enhance the robot’s maneuverability and safety.

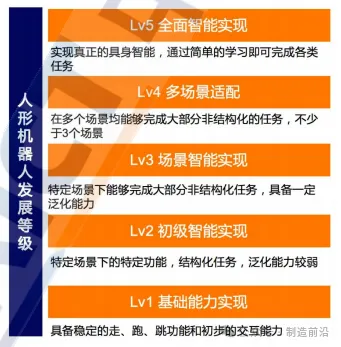

The capability levels of humanoid robots can be divided into the following five levels:

1. Level 1 (Lv1) Basic Capability Realization:

– Humanoid robots possess stable walking, running, and jumping functions and initial interaction capabilities.

2. Level 2 (Lv2) Initial Intelligence Realization:

– Humanoid robots can achieve specific functions in specific scenarios, executing structured tasks, but with weak generalization abilities.

3. Level 3 (Lv3) Scenario Intelligence Realization:

– Humanoid robots can complete most unstructured tasks in specific scenarios, possessing certain generalization abilities.

4. Level 4 (Lv4) Multi-Scenario Adaptation:

– Humanoid robots can complete most unstructured tasks in multiple scenarios, involving no less than 3 scenarios.

5. Level 5 (Lv5) Comprehensive Intelligence Realization:

– Humanoid robots can achieve true embodied intelligence, completing various tasks through simple learning.

Humanoid robots are in the early stages of development, with a vast market potential in the future. Currently, the vast majority of all-round humanoid robot products are at Lv1 level, while a small number of leading companies’ latest products and other forms of humanoid robots are gradually exploring Lv2 level.

Considering the overall technological progress and demand-side situation, it is expected that from now until 2028, all-round humanoid robots will remain at Lv1 level, primarily landing in scientific research scenarios, with customers mainly being research teams from universities and companies engaged in humanoid robot-related hardware and software research, while other forms of humanoid robots will accelerate their evolution towards Lv2 level. The market scale for complete machines in our country is approximately 2 to 5 billion yuan. From 2028 to 2035, humanoid robots will generally enter Lv2 level, focusing on special scenario applications, with industrial scenarios gradually materializing, and the complete machine market scale reaching about 5 to 50 billion yuan. From 2035 to 2040, humanoid robots will generally enter Lv3 level, forming scale in industrial scenarios, with service scenarios gradually materializing, and the complete machine market scale reaching about 100 to 300 billion yuan. From 2040 to 2045, humanoid robots will generally enter Lv4 level, achieving large-scale applications in industrial and service scenarios, with the complete machine market scale reaching about 500 to 1 trillion yuan. After 2045, humanoid robots will generally enter Lv5 level, with humanoid robots exceeding 100 million units in various industries, and the complete machine market scale potentially reaching around 10 trillion yuan.

1. Production Manufacturing:

– Industrial Production: Such as agricultural harvesting, automotive and 3C manufacturing.

– Precision Assembly and Operation: Performing precise assembly tasks such as circuit board soldering, screen installation, and battery securing.

– Flexible Production Line Operations: Adapting to different production line layouts and station requirements, achieving rapid adjustments and reorganization of the production line.

– In-Plant Material Flow and Management: Carrying out tasks such as material handling and inventory counting.

– Quality Inspection and Maintenance: Executing quality control tasks such as appearance inspection and functional testing of products.

2. Logistics:

– Warehouse Management and Picking: In large e-commerce warehouses, completing sorting and packaging tasks based on order information.

– Handling and Loading: Carrying heavy objects and performing loading and unloading tasks in complex environments.

– Autonomous Navigation and Scheduling: Achieving autonomous path planning and obstacle avoidance in complex warehouse environments.

– Last Mile Delivery: Delivering packages directly to consumers.

3. Household and Commercial Services:

– Household Services and Companionship: Providing various services such as housekeeping, education, and entertainment.

– Commercial Services: Providing reception, guided tours, and other services in exhibition halls, supermarkets, hotels, and other venues.

– Scientific Research and Education: Serving as teaching assistants in classrooms, realizing functions such as research assistance and teaching demonstrations.

4. Medical Health:

– Assisting in surgeries, rehabilitation nursing, etc.: Helping healthcare personnel with daily tasks, reducing workload and burden.

5. Security Patrol:

– Conducting patrol monitoring in areas such as parks, factories, and warehouses.

6. Hazardous Operations:

– In fields such as petroleum, nuclear energy, mining, chemical, fire-fighting, etc.: Replacing humans in hazardous environments.

7. Disaster Rescue:

– After disasters such as earthquakes, fires, and floods, helping rescuers quickly locate victims and improve rescue efficiency.

These application scenarios cover the potential roles of humanoid robots in various fields including industry, services, education, healthcare, and security, demonstrating the broad applicability of humanoid robot technology and its significant impact on future society.

The article is organized and edited by the Manufacturing Frontier public account.

The Manufacturing Frontier analyzes the humanoid robot industry chain as follows:

Upstream: Raw Materials and Components

1. Reducer:

– Precision reducers are key components of robots, especially RV reducers and harmonic reducers, which can provide high torque and precise motion control.

– The technical difficulty lies in improving precision and lifespan while reducing costs.

2. Motors:

– Including frameless torque motors and hollow cup motors, they need to have high torque density and fast response characteristics.

– The efficiency and control precision of the motor directly affect the performance of the robot.

3. Screws and Guides:

– Used to achieve precise linear motion, requiring high precision and wear resistance.

– Technological development focuses on improving load capacity and reducing friction.

4. Controllers:

– The controller is the “brain” of the robot, responsible for processing sensor information and sending control commands.

– It requires strong computing power and real-time processing capabilities.

5. Sensors:

– Including various sensors such as vision, touch, and force, used for environmental perception and interaction.

– The technical challenge lies in improving the precision, response speed, and environmental adaptability of the sensors.

Midstream: R&D, Design, and Manufacturing of Robot Bodies

1. Body Design:

– The design needs to consider the stability, flexibility, and safety of the mechanical structure.

– It is necessary to integrate artificial intelligence algorithms into the design to achieve autonomous decision-making and motion control.

2. Manufacturing and Integration:

– Involves precision machining, electronic assembly, and software integration.

– Quality must be strictly controlled during manufacturing to ensure product reliability and consistency.

3. Software and Hardware Integration:

– Closely combine hardware platforms with software algorithms to realize complex control and interaction functions.

– Compatibility and collaborative work issues between software and hardware need to be resolved.

Downstream: End Applications

1. Industrial Manufacturing:

– Robots need to possess precise operational capabilities and compatibility with existing production lines.

– The technical challenge lies in achieving seamless integration with human workers and automated production lines.

2. Logistics:

– Robots need to have efficient material handling capabilities and autonomous navigation abilities.

– The technical challenge lies in improving the load capacity of robots and reducing charging time.

3. Household and Commercial Services:

– Robots need to have high interaction capabilities and flexibility.

– The technical challenge lies in improving the intelligence level of robots and adapting to different environments.

4. Medical Health:

– Robots need to possess precise operational capabilities and adaptability to sterile operating environments.

– The technical challenge lies in ensuring the safety and accuracy of medical operations.

5. Security Patrol and Hazardous Operations:

– Robots need to have the ability to work in harsh environments and autonomous decision-making capabilities.

– The technical challenge lies in improving the durability of robots and adapting to extreme conditions.

From the iteration path, the B2B market is an essential stage for the development of humanoid robots, while the B2C market will become a key direction in the long term. From a technological perspective, the “brain” and “cerebellum” belong to the ICT field, while the “limbs” belong to the industrial equipment field, and the two fields should work together for integrated development. However, the focus of efforts varies at different stages. In the early stages of industry landing, when application scales are small, the key factor for humanoid robots to land is their level of intelligence, which should be emphasized in the ICT field to accelerate the development of “brain” and “cerebellum” technologies while simultaneously addressing the shortcomings of components. In the large-scale application stage, cost becomes the core issue. The most basic requirement for using humanoid robots in industrial scenarios is that their comprehensive usage costs (including purchase, depreciation, and maintenance) must be less than labor costs, while B2C users in service scenarios are more price-sensitive. Currently, the release prices of humanoid robots still range from hundreds of thousands to millions, requiring a focus on reducing costs in the industrial equipment field.

Commercial Landing Path

– Phase One (2024—2030): Policy guidance, deeply exploring high-value scenarios such as hazardous operations and extreme environments, selecting a batch of typical needs that can be landed and promoted. The government bridges the gap, promoting the connection between supply and demand for special application scenarios, and developing a batch of products for landing applications.

– Phase Two (2030—2035): Accelerating exploration of large-scale application scenarios related to industrial manufacturing and logistics, starting from “replacing relatively simple and repetitive labor,” maturing one generation of applications at a time, accelerating technology maturity, reducing unit costs, and enhancing overall performance, gradually increasing penetration rates in manufacturing scenarios.

– Phase Three (Post-2035): Strengthening the integrated innovation of artificial intelligence and humanoid robots, achieving higher levels of embodied intelligence, and promoting humanoid robots into service industry scenarios such as hospitals, schools, shopping malls, and restaurants, ultimately entering thousands of households.

Source: Industry Information Headline