Blueflite is a visionary company founded in 2018, dedicated to transforming the last-mile delivery in industries such as healthcare, retail, and industrial logistics. They utilize HP Multi Jet Fusion (MJF) 3D printing technology to create advanced cargo drones, providing faster and more efficient solutions for time-sensitive deliveries.

Overcoming design challenges to create drones that balance lightweight and high durability has been a significant challenge for Blueflite. Early efforts relied on traditional technologies such as carbon fiber structures and FDM printing. While carbon fiber is strong, it is slow to produce and cumbersome, leading to delays in design adjustments. Initial 3D printing methods were also disappointing—FDM printing resulted in visible layer lines, making it unsuitable for creating streamlined aircraft; SLA printing produced brittle parts; and SLS printing resulted in overly heavy components.

Technological Breakthrough

The disruptive technology of HP Multi Jet Fusion has brought about a breakthrough. This 3D printing technology can produce parts with higher material strength, finer surface details, and more consistent quality. This marks a turning point in the production of Blueflite drones.

Now,each drone contains 48 components manufactured through MJF, including the shell, electronic device mounting brackets, landing gear, and battery housings.Blueflite has chosen HP’s Nylon 12, a material praised for its lightweight properties and strong strength-to-weight ratio, making it an ideal choice for efficient drones. Under HP’s technical guidance, they have improved designs by incorporating elements such as reinforcements and complex lattice patterns.

The significant performance advantages translate into impressive results from HP MJF technology:

Lighter structure: The drone body has reduced weight by 25%, enhancing flight efficiency and range.

Faster development: Design time has been shortened from weeks to hours, allowing Blueflite to quickly test 2-10 iterations of each component and refine their builds.

Smooth surfaces: The precision of MJF printing gives parts a smooth, professional appearance, enhancing the visual appeal of the drones.

Flexible customization: The rapid prototyping capability allows Blueflite to quickly adapt to different customer needs.

The transition to MJF not only makes the drones lighter, stronger, and more reliable but also raises industry standards.It surpasses traditional composite manufacturing processes, reduces labor requirements, and provides customers with the flexibility to easily adjust designs.The drones’ exceptional quality and refined appearance have captured the attention of customers.

Blueflite’s adoption of this technology highlights the impact of modern manufacturing on unmanned systems. Their work is not just about assembling drones; it is about reshaping the way goods reach their destinations. The company aims to go further by utilizing 3D printing technology to manufacture larger and more complex drone components, further refining their craft. With HP MJF as a cornerstone, Blueflite is poised to dominate the U.S. cargo drone market and drive ongoing advancements in the field.

Scan to follow us

Scan to follow

Follow me

— Previous Highlights —

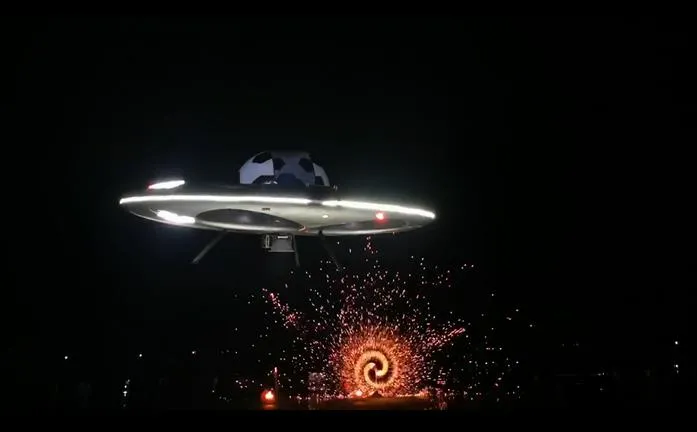

Zhihang Flying Saucer Leads New Trends in Low-altitude Advertising, Illuminating the Beibu Gulf Opening Festival

CCTV Focus! Promoting the Low-altitude Economy to ‘Fly’ into New Tracks—Xihe Aviation

Peak Collaboration! Yingfei Technology & Tianfeng Innovation Join Forces to Create a Model of Strategic Cooperation