In digital signal processing (DSP) systems, noise issues often arise. To ensure signal quality and improve system performance, many engineers opt for hardware noise reduction techniques. So, do you know how this hardware noise reduction is implemented?

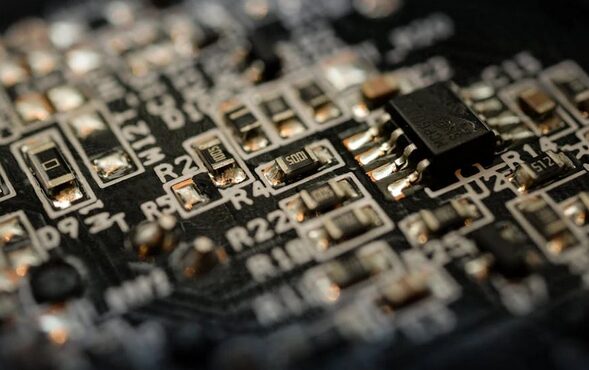

1. Board Structure Domain Line Layout Optimization

Use a large area ground plane with the power supply: ensure a low impedance path for power decoupling.

Narrow trace design: use 4 to 8 mil traces to enhance high-frequency damping and reduce capacitive coupling.

Partitioned layout: strictly separate digital, analog, receiving, and transmitting/power lines, separating circuits by frequency and type.

Avoid PCB notches: reduce unwanted loop generation.

Stacked structure design: control impedance to form a stable transmission line structure, sealing traces between the power and ground layers.

Minimize loop area: especially for clock signals, to reduce electromagnetic radiation.

Direct connection for high-speed lines: shorten and connect directly to reduce noise coupling.

Avoid parallel high-noise traces: keep sensitive traces away from high-speed switching signal lines.

No floating digital inputs: prevent unnecessary switching noise.

Parallel wiring: arrange power, ground, and signal lines in parallel to eliminate noise.

2. Application of Filtering Technology

High-frequency low-inductance capacitor decoupling: use appropriate capacitance ceramic capacitors at each IC pin (e.g., 0.1uF for 14MHz, >0.01uF for >15MHz).

Bypass for analog circuits: all power and reference voltage pins need to be bypassed.

Bypass for fast switching devices: reduce switching noise.

Multi-stage filtering: attenuate power supply noise across multiple frequency bands.

Crystal oscillator embedding and grounding: reduce radiation and coupling.

Local shielding: add shielding around critical areas or high noise sources.

Adjacent ground line layout: enhance electric field shielding effect.

Decoupling line driver/receiver: place close to I/O interfaces to reduce coupling and radiation.

Shielding and twisted leads: process interference leads to eliminate coupling on the PCB.

Inductive load protection: add clamp diodes to suppress transient voltages.

This article is an original piece by Yiy Education. Please indicate the source when reprinting!