Hardware manufacturers are currently in the midst of the fourth industrial revolution driven by the Internet of Things (IoT). To keep pace with new technological developments, they must advance towards “smart” objectives. This article details three ways to benefit from connected devices and ten considerations for software-centric models.

To profit from the transformation to software business models, device manufacturers’ systems must be ready to maximize the returns on software investments and leverage intellectual property to protect those investments. Hardware manufacturers must rethink their traditional business models and consider the role of certification and licensing management in maximizing revenue potential. What does a software-centric business model look like?

Adopting a software-centric model means manufacturers must redesign products from fixed-function, non-connected devices to flexible, seamlessly connected systems. A software-centric model simplifies and streamlines all aspects of the supply chain.

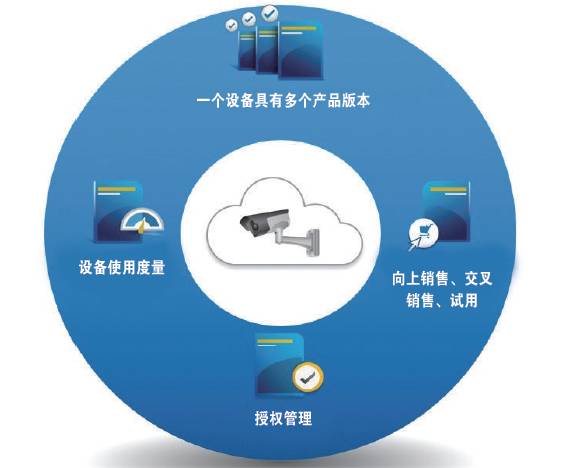

For example, a telecommunications company developed a “connected” commercial video surveillance camera with ten features. Using a software license-driven model, the telecommunications company only needs to manufacture one physical model. By leveraging software and licensing, the device manufacturer can simply enable features 1 to 3 for sale as a “basic” model. Then, features 1 to 6 can be enabled for sale as a “high-end” model, or all remaining features can be enabled for sale as a “platinum” model. Previously, three models required three manufacturing supply chains, but now it has been reduced to one.

Moreover, this software-centric model increases adaptability and flexibility, allowing manufacturers to quickly configure products to take advantage of emerging market trends without changing their physical supply chains. For instance, if software features 1, 4, 5, and 9 are more favored by Chinese users, rapid licensing reconfiguration can optimize the model for the Chinese market.

A connected product with a backend licensing management system also allows device manufacturers to easily generate new revenue streams from cameras. For example, a user of a “basic” model camera can log into the device’s portal and purchase a 30-day trial of the “high-end” model product. Once credit card information is provided, the system unlocks the high-end features on the camera without delay, giving the user an upgraded device while generating new revenue for the manufacturer from the additional purchase. Depending on the trial’s settings, at the end of 30 days, the user may pay the full upgrade fee, thus fully upgrading the camera. Alternatively, through the licensing management system, the camera can automatically revert to the basic model.

The same principle applies to IoT manufacturers across the industrial sector. The market is changing; if construction, telecommunications, and gaming can benefit from adopting a software-centric model, then manufacturers of oil and gas equipment, test and measurement equipment, and medical devices can do so as well.

While producing these devices is a major part of manufacturers’ work, installing software, connecting these devices, and ensuring performance is still crucial. An important consideration in designing a connected device is to implement security measures from the outset. In this regard, manufacturers must ensure that applications use tamper-proof licensing codes to help reduce hacking risks. If additional protection is needed, companies must invest time in reverse engineering the software embedded in the devices and making modifications at the machine level.

Connected systems and a software-centric model will benefit manufacturers. Image source: Flexera Software

This type of embedded licensing model has been successfully used in many devices: mobile phones with unlockable GPS features, routers sold by tier based on the number of supported ports, and cameras with different signal processing algorithms based on available licenses.

Using automated licensing and authorization management systems to monetize internet-connected devices can bring many benefits to businesses, including:

1. Reduced Manufacturing and Distribution Costs: By embedding software control, internet-connected devices significantly reduce manufacturing costs. Companies control product features, capacity, configuration, and production volume through software, licensing, and authorization management, reducing the variety of product models they must manufacture, allowing them to build once and package in multiple functional forms. Product configuration can be delayed until customers clarify their specific needs. This manufacturing flexibility means manufacturers, distributors, and retailers need minimal inventory, greatly improving supply chain efficiency.

2. New Markets and Revenue Streams: IoT can create entirely new revenue streams and help businesses expand their existing customer base. For instance, using a software licensing model, manufacturers can easily offer enhanced features through software upgrades and charge for enhanced functionalities based on software maintenance and upgrades. There is an opportunity to charge for new software support while providing customers with a better experience. Moreover, because software supports flexible product configurations, manufacturers can quickly, easily, and cost-effectively package and price devices to meet emerging or niche market demands. Additional data generated by smart, connected devices can also be transformed into intelligence to identify new potential markets and opportunities.

3. Extended Product Lifespan: Licensing and authorization management extend the lifespan of devices. Most device functionalities are managed and controlled through software rather than hard-coded into the physical components. As a result, product upgrades and feature enhancements can be performed via software instructions sent to the device over the internet. This allows customers to derive more value from the devices over a longer period with minimal disruption. This is also beneficial for manufacturers, as it provides more upselling opportunities at the lowest cost and effort.

Licensing and authorization management software helps smart device manufacturers offer personalized products and services without needing to manufacture multiple models by connecting products to the internet.

By making simple modifications to the device software, manufacturers can provide personalized products based on customer needs by managing how the devices operate. For example, by enabling or disabling certain features, setting device capacity, and controlling product operation. This greatly simplifies product lifecycle management and aids in supply chain management.

Data provided by software-controlled devices can also reveal how customers use the hardware, what software they use most frequently, and what new services may be created. Furthermore, product usage information can help manufacturers make informed choices when packaging products and services for customers and markets, balancing cost and service value.

When rapidly adopting a software-centric model, smart device manufacturers should consider ten key points.

1. Provide secure business support for the transformation. This is broader than engineering or product management and requires coordination across business groups.

2. Understand traditional software licensing methods and their approval pathways, and whether they can be leveraged in the smart device environment.

3. Identify appropriate software licensing policies and enforcement mechanisms among the wide variety of available options, and estimate the flexibility needed for future modifications as business environments change.

4. Understand the differences between delivering hardware and digital goods; distribution mechanisms can be coordinated or unique.

5. Understand the software value lifecycle, which is a continuous process increasingly based on subscriptions, as opposed to a one-time hardware transaction.

6. Create business processes to support the software value cycle.

7. Reserve self-service portals for customers, which can reduce production costs and increase customer acceptance of software.

8. Define and execute a product management and marketing strategy.

9. Complete sales training and compensation policies; sales are not just about selling a quantity of hardware devices but selling “value”.

10. Continuously fine-tune product development, delivery, and implementation strategies to optimize revenue and profit.

By using licensing and authorization management, manufacturers create connected devices that unlock new revenue streams, protect intellectual property, and enable order-based configurations while significantly reducing inventory, helping to better respond to changing markets.

Author: Steven Schmidt