In recent years, the term “development board” has nearly disappeared, overshadowed by countless other hardware board terms used to describe development purposes, such as “demonstration board,” “evaluation kit,” and “reference design.”

In this article, we will explain the meaning of the term “development board” (Figure 1) and show how they differ from closely related single-board computers (SBCs). We will also outline their evolution from the past to the present and discuss some trends in how they may evolve in the future.

Figure 1: An engineer working on an electronic development board.

What is a Development Board?

First, it is important to clearly define the meaning of a development board and how it differs from a single-board computer. Although development boards are now often applicable to other types of components, they are typically created by microcontroller manufacturers to highlight their features. A microcontroller is an integrated circuit that contains a processor, some RAM, flash memory, and some I/O functions, allowing it to interact with the real world. Its function is like a miniature computer implemented in a single package, designed to provide developers with a convenient way to interface and control external components (such as lights, small motors, etc.). Single-board computers also provide this functionality, with the main difference being that the CPU, RAM, and storage are contained in separate ICs on the board, and the interfaces allow it to connect to a keyboard and/or display.

The microprocessor on a single-board computer requires an operating system, while a microcontroller is managed using an integrated development environment (IDE) provided by the manufacturer. In many cases, manufacturers are now creating development boards that include microcontrollers, but the primary purpose is not to demonstrate the features of the microcontroller itself, but rather to showcase the features of sensors or other integrated circuits interfaced with it. These are referred to as “demonstration boards,” “evaluation kits,” or if they have been assembled into a collection of many components capable of performing a specific purpose, they are called “reference designs.”

Some circuit boards are not primarily intended for hardware development but rather provide software developers with real data access necessary to create and improve algorithms for applications such as artificial intelligence and machine learning. Although these may not fit the original definition and purpose of a “development board,” they are now collectively referred to as any hardware available for new electronic product hardware and software development.

The History of Development Boards

The first microcontroller development board that attracted attention in the electronics engineering community was released in 2006, when a prototype platform later known as Arduino was introduced (see Figure 1). It quickly gained adoption among many electronic designers, including hobbyists, amateur developers, and DIY engineers. Arduino laid the foundation for the commercial success of later single-board computers and microcontroller-based platforms, followed closely by the Beagleboard in 2008, which provided engineers with a low-cost, open-source community-supported development platform. The first single-board computer, the Raspberry PI, was released in 2012, and like the Beagleboard, it was considered an educational platform aimed at providing a low-cost way for students to learn how to write program code. The appeal of the Raspberry PI extended far beyond just the student demographic; it was quickly adopted by amateur developers and professional engineers.

Figure 2: Arduino single-board computer development board.

The Present of Development Boards

Today, single-board computers are primarily divided into two categories: proprietary and open-source. Proprietary SBCs are typically designed for end applications and undergo testing and quality assurance similar to other final products. They are either integrated into electronic devices or installed in rack-mounted configurations. Open-source SBCs allow users access to their hardware designs and layouts as well as any source code they use. This enables users to quickly and easily understand how the software and hardware operate, and then adopt designs that meet their requirements.

Nowadays, development boards and single-board computers can be equipped with various types of processors, including x86-based processors from the traditional PC realm (AMD and Intel) to ARM processors widely used in industrial and mobile applications, while Linux and its derivatives (Ubuntu, Fedora, Debian, etc.), Android, and Windows CE are the most commonly used operating systems on SBCs. Microcontroller development boards do not require an operating system and are programmed using the IDE provided by the manufacturer. Both microcontroller development boards and SBCs have evolved to integrate wireless connectivity (Wi-Fi, Bluetooth) as well as the latest audio and video interfaces, meaning some SBCs now possess capabilities comparable to many PCs and tablets.

The Future of Development Boards Becoming Final Products

Traditionally, manufacturers created development tools as marketing aids to improve the likelihood of selling microcontrollers to potential customers (commonly referred to in the industry as “design-in”). They aimed to minimize the workload required for design engineers to start and run components in the lab and make it easier for them to access and study their features, which would make them more likely to choose the microcontroller and auxiliary components for initial product prototype design. If the component is selected for mass production, it ultimately leads to larger product orders. For certain products, this is a cautious approach if the technical specifications between components from different suppliers are negligible. However, for manufacturers, this approach has, in some ways, become a victim of its own success. They realize they must continue to reduce the workload for engineers using their products, and development boards have become a key differentiator, especially for products that are broadly similar to competitors’ products.

Design engineers’ expectations are increasingly high; even for components with clear competitive advantages (such as power or speed), they still expect the relevant development boards to have “plug-and-play” accessibility.

Manufacturers can further enhance their value proposition by providing reference designs consisting of microcontrollers and other integrated circuits (often sensors). Initially, these reference designs were intended to provide guidance on how to interconnect devices to simulate the electrical functionality of final products, with little focus on their form factor, design dimensions, or manufacturability. However, some manufacturers have taken reference designs to a new level, allowing for the creation of mature product prototypes or even fully functional products.

Maxim Integrated (now part of Analog Devices) Health Sensor Platform (HSP) reference design serves as an example illustrating this trend of evolution. The initial version of these reference designs was a small development board equipped with various sensors for health and fitness applications (temperature, pressure, accelerometer, bio-potential, etc.) and could be configured using a microcontroller. Its next-generation products, HSP2.0 and HSP3.0, have dimensions that allow them to be worn on the wrist and look very similar to other wearable devices on the market (Figure 3).

Figure 3: Maxim Integrated’s HSP3.0.

This enables developers to evaluate the functionality of their sensors in real-world scenarios. Importantly, these designs also provide software developers with free access to sensor readings (information that is not easily obtainable from other health and fitness wearable devices). This approach aims to facilitate the development of machine learning and artificial intelligence algorithms, thereby adding value to specific applications.

By demonstrating how hardware can facilitate easy access to the required data, Maxim Integrated hopes developers will choose some (or all) of the ICs in their sensor solutions for their product designs. Maxim Integrated has extended this approach to the development of products such as the MAX Health Wrist and MAX ECG Monitor, both of which are fully designed and constructed reference designs that are completely functional wearable health devices. However, Maxim Integrated does not intend to sell directly to consumers; businesses can reach agreements with Maxim Integrated to label these products as their own in exchange for royalties.

With all development work completed, providing fully functional products in this manner is highly appealing to new clients and a broader non-technical business customer base. Nordic Semiconductor’s Thingy:91 is another example of a development platform where the hardware is almost an additional product providing developers with the data access they need to develop software and algorithms that realize the intrinsic value of the hardware (doing so conveniently makes it an obvious choice in new product designs). More manufacturers may adopt this approach in the future.

Increasing Use of Development Boards in Industrial Products

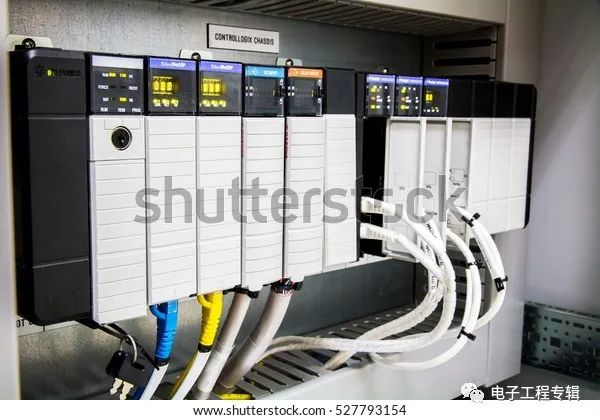

Using development boards and single-board computers for general commercial products has become commonplace, but another emerging trend is their application in smaller, yet higher-value industrial terminal products, such as programmable logic controllers, where the standards are more stringent compared to their commercial counterparts.

Figure 4: Programmable Logic Controller.

Industrial Application Testing Boards

Many SBCs today have essentially become well-validated designs, as the components they contain were initially developed for final products and have undergone testing and quality validation. Additionally, because open-source designs are constantly reviewed by a team of qualified designers and programmers, they update and assess the circuit boards and software used.

Currently, single-board computer boards are tested by high-quality design and manufacturing companies, which are subjected to the same stringent quality control as any other final product and can even obtain CE or FCC certification. This testing process can also be easily scaled to meet the requirements of industrial products.

On the other hand, microcontroller development boards provided by manufacturers or third parties, while often suitable for commercial products, typically do not undergo the rigorous testing levels required for industrial products, which means that currently, it is not recommended for manufacturers to use them in these applications (in their current form).

While some development boards include industrial-grade components, these boards are often only commercial-grade, designed to operate only at room temperature. Prototypes of development boards are typically tested at room temperature for days or weeks, depending on the manufacturer, as there are no set standards. The primary quality requirement for manufacturers is that their development boards can reliably operate at room temperature, so buyers should be aware that they are unlikely to be tested under extreme temperatures or humidity, and often have not been tested to withstand stresses such as strong vibrations or shocks.

Therefore, when considering which development board to use for an industrial application, the primary goal is to minimize risk. If a development board is chosen for industrial applications, the components must have appropriate temperature ratings. Stress testing several circuit boards at high temperatures for several days is also necessary. Similarly, if a development board is to be used in a high-humidity environment, it must be evaluated under comparable conditions. If the development board needs to be used in a high-vibration environment, it should be installed in a test frame and subjected to vibration testing.

Conclusion

Single-board computers and microcontroller development boards provide small companies with a streamlined way to bring designs to market quickly without the expense of developing new hardware. This enables them to focus on software innovation and increasingly concentrate on the development of machine learning and artificial intelligence algorithms. The functions of single-board computers and development boards have far exceeded the original scope for which they were conceived, and they have had a significant impact on the recent history of the electronics industry. Single-board computers will continue to become more powerful, smarter, and responsive, making them easily accessible for both professional engineers and electronics enthusiasts.

Author: Mark Patrick, Mouser Electronics