With the rapid development of industrial technology, distributed control systems and field control systems have emerged. The three major control systems in industrial process control are PLC, DCS, and FCS. Some believe that FCS is developed from PLC, while others think it is derived from DCS. FCS has a close relationship with both PLC and DCS, yet there are some differences.

PLC controllers are electronic systems designed for digital computation operations specifically for applications in industrial environments. They use a type of programmable memory to internally store programs, execute logical operations, sequential control, timing, counting, and arithmetic operations, and control various types of machinery or production processes through digital or analog inputs and outputs.

DCS, or Distributed Control System, is a computer-based control system that rapidly developed in the mid-1970s. It integrates control technology, computer technology, image display technology, and communication technology, also known as 4C technology, to monitor, control, and manage production processes. It breaks the limitations of conventional control instruments and effectively addresses the risks associated with early computer systems, which were overly centralized in information, management, and control.

The core of the FCS fieldbus control system is the bus protocol, based on digital intelligent field devices, fundamentally focusing on localized information processing.

The Basic Characteristics of Process Control Systems Composed of Large PLCs

(1) The structure is top-down; PLC can function as an independent DCS or as a subsystem of DCS.

(2) PID is placed in the control station, enabling various functions such as continuous PID control.

(3) A PC can serve as the master station with multiple identical PLCs as slave stations; alternatively, a single PLC can act as the master with multiple identical PLCs as slaves, forming a PLC network.

(4) It is mainly used for sequential control in industrial automation, while new PLCs also incorporate closed-loop control functions.

The Basic Characteristics of DCS Control Systems

(1) A top-down tree structure where communication is key.

(2) PID is in the controller, linking the computer with field instruments.

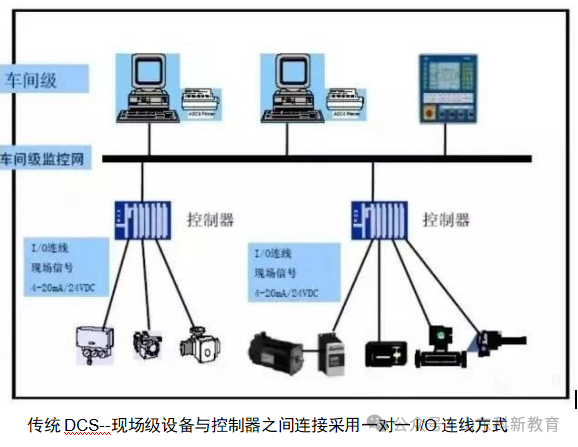

(3) It features a tree topology and parallel continuous link structure, with many cables running from relay stations to field instruments in parallel.

(4) The signal system includes both digital and analog signals.

(5) DCS generally consists of a field instrument layer, control device unit layer, factory (workshop) layer, and enterprise management layer.

The Basic Characteristics of FCS Control Systems

(1) FCS integrates 3C technology. It is suitable for intrinsically safe, hazardous areas, variable processes, and extremely challenging environments.

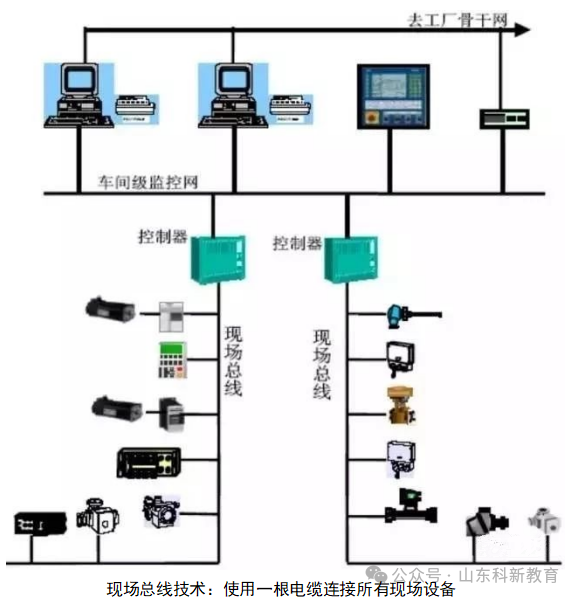

(2) Field devices are highly intelligent, providing all-digital signals; a single bus connects all devices.

(3) The bidirectional digital communication bus from the control room to field devices is interconnected, bidirectional, serial multi-node, and an open digital communication system that replaces the one-way, single-point, parallel, closed analog systems.

(4) Control functions are completely decentralized.

Comparison Between DCS and PLC Control Systems

DCS is a “distributed control system,” while PLC is merely a control “device”; the difference lies in “system” versus “device.” A system can perform and coordinate the functions of any device, whereas a PLC device only implements the functions of its unit. In terms of networking, the network is the central nervous system of the control system.

The DCS system, such as the HOLLiAS MACS system, is divided into two levels: system network and control network. The system network interconnects the field control station with the system operator station, while the control network facilitates communication between the field control station and intelligent I/O units, ensuring real-time and reliable information transfer.

In contrast, PLCs typically operate individually, and when communicating with other PLCs or upper-level computers, they usually employ a single network structure. In terms of network security, PLCs lack robust protective measures.

DCS design includes numerous expandable interfaces, making it easy to connect external or extended systems, whereas once a PLC system is established, adding or removing operator stations is quite challenging. To ensure the safety and reliability of DCS control devices, DCS employs dual redundant control units. When a critical control unit fails, a corresponding redundant unit switches to active duty without disruption, ensuring the system’s overall safety and reliability.

PLC systems generally do not incorporate redundancy, making it difficult to implement redundant control strategies. Especially when a PLC unit fails, the entire system must be halted for replacement and reprogramming. Thus, DCS systems are considered one level safer and more reliable than PLCs. The hardware reliability of DCS and PLC is quite similar. PLCs excel in software, utilizing a sequential scanning mechanism, and dominate in high-speed sequential control. The cycle time for PLC is around 10 ms, while DCS control stations operate around 500 ms.

In terms of sequential interlocking functions, DCS is at a disadvantage compared to PLCs, and the logic execution speed does not match that of PLCs. Relatively, systems based on PLCs are more cost-effective. DCS field control stations typically adopt centralized control; although they support remote distributed I/O, they are rarely used due to cost constraints. In contrast, PLCs, based on fieldbus technology, offer smaller, more flexible, and user-friendly remote distributed I/O, effectively saving wiring costs.

Comparison Between FCS and DCS Control Systems

FCS can be said to combine the characteristics of both DCS and PLC, making a revolutionary step forward.

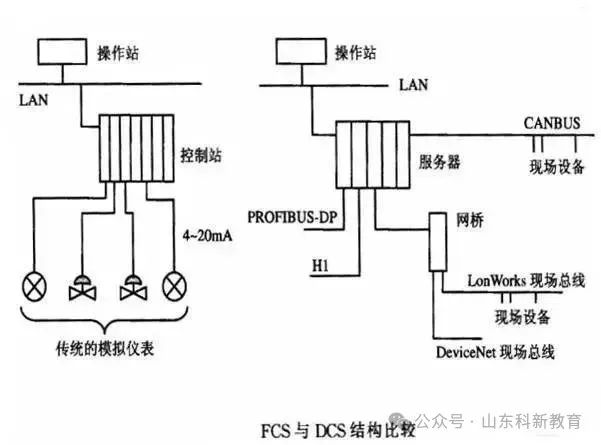

(1) FCS is an open system with fully open technical standards; its field devices are interoperable and compatible with different manufacturers and brands, allowing users to achieve optimal system integration. In contrast, DCS systems are closed, with products from different manufacturers being incompatible.

(2) FCS achieves fully digital signal transmission, with communication extending from the lowest level sensors and actuators to the highest level, providing strong support for MES and ERP systems; more importantly, it allows for remote diagnostics, maintenance, and configuration of field devices. DCS communication capabilities are significantly limited; while it can connect to the Internet, it cannot reach the lower levels and offers limited information, lacking the ability for remote operations on field devices.

(3) FCS features a fully decentralized structure, eliminating the I/O units and control stations present in DCS, delegating control functions to field devices, thus achieving complete decentralization and making system expansion straightforward; DCS only decentralizes to the controller level, emphasizing the controller’s functions, with the data highway being critical.

(4) FCS achieves high precision in control systems, reaching ±0.1%; whereas DCS signal systems are binary or analog, requiring A/D and D/A conversion, resulting in a precision of ±0.5%.

(5) FCS can place PID closed-loop functions directly in field transmitters or actuators, along with digital communication, thus shortening sampling and control cycles, currently improving from DCS’s 2-5 times per second to 10-20 times per second, enhancing regulation performance.

(6) By eliminating a significant amount of hardware, cables, and installation aids, FCS saves substantial installation and debugging costs, resulting in a much lower price compared to DCS.

FCS is an open, fully distributed, intelligent control system. However, traditional DCS and PLC systems have been in use for decades, evolving into practical and highly reliable systems. As they develop, there is a trend for them to converge; for instance, new DCS systems now have strong sequential control capabilities, while new PLCs are also competitive in closed-loop control, and both can form large control networks.

Source: This article is reprinted from the internet, copyright belongs to the original author. If there are copyright issues, please contact us in time for deletion. Thank you!

Scan to Follow

WeChat ID|13615417996

Follow the QR code on the left to get free

[Siemens Data Collection]