As China’s first edge computing industry promotion project, the “Edge Computing Standard Component Plan” was jointly initiated by the China Academy of Information and Communications Technology, the Industrial Internet Industry Alliance, and the Key Laboratory of Internet and Industrial Integration Innovation of the Ministry of Industry and Information Technology, aiming to form an industrial closed loop of “technology research and development, standard formulation, product testing, application demonstration, and large-scale commercialization.” This effectively assists equipment manufacturers in optimizing and iterating product capabilities and provides users with reliable and precise selection references, laying a critical foundation for promoting the large-scale deployment of edge computing. After nearly four years of development, the “Edge Computing Standard Component Plan” has completed centralized testing of four batches of products, providing testing services for more than 60 products.

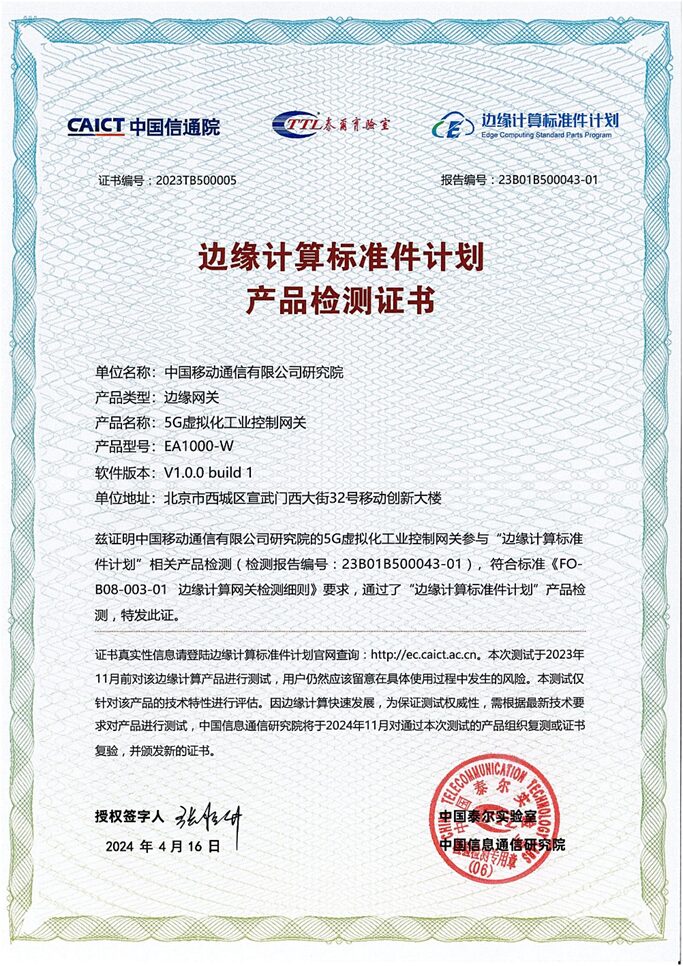

China Mobile Research Institute’s independently developed 5G virtualized industrial control gateway has successfully passed the product testing of this “Edge Computing Standard Component Plan” and has been deployed and continuously operated in various fields, assisting enterprises in upgrading applications and promoting the implementation of digital construction.

Traditional industrial networks widely use wired technology, which has complex hierarchical structures, high deployment difficulties, and insufficient flexibility. Existing industrial wireless technologies have shortcomings in communication delay, anti-interference, and stability, making it difficult to meet the stringent performance requirements for communication determinism and high reliability in industrial networks. They mainly serve data collection, video return, and mobile inspection tasks, but struggle to penetrate the core production processes of industrial control. On the other hand, industrial control architectures represented by traditional PLCs (Programmable Logic Controllers) are closed, and their vertical chimney structures result in poor scalability, high integration difficulty, and high costs. This control architecture, characterized by “computational power not going down and data not coming up,” is difficult to meet the needs of industrial internet development.

5GVirtualized Industrial Control Gateway

5G Virtualized Industrial Control Gateway

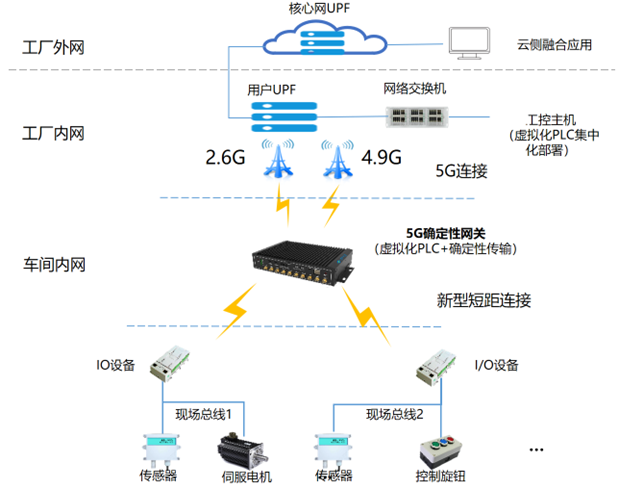

In response to the challenges faced by industrial wireless and open automation, China Mobile has developed the 5G Virtualized Industrial Control Gateway product, aiming to create a technology innovation, excellent performance, and independently controllable 5G+ industrial end-to-end high-quality control assurance technology. With the 5G industrial gateway as the anchor point, it innovates three key technologies: determinism, new short-distance communication, and virtualized PLC, addressing issues such as ensuring communication quality in interference environments, difficulty in accessing heterogeneous protocols, and expanding industrial control business.

On-site Deployment Architecture Diagram

-

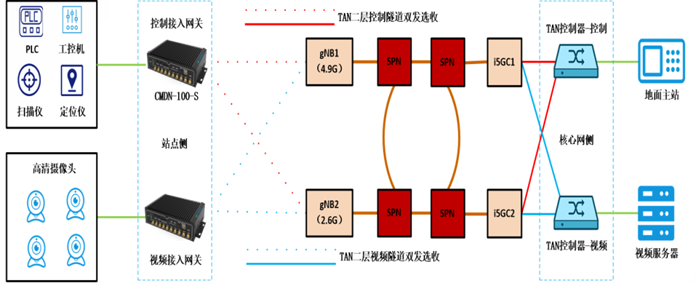

5G+TAN Achieves Deterministic Transmission to Controller

For industries with high determinism requirements, the 5G+TAN (Time-Aware Network) technology provides bounded delay jitter, high reliability, and high-precision clock synchronization through technologies such as intrinsic dual transmission selection, multi-link redundant transmission, delay threshold control, and cross-clock domain collaboration. In a 5G (R16) environment, the timing accuracy error for southbound 1588v2 is less than 500ns, software-defined delay error is less than 10 microseconds, packet loss rate is reduced by more than 40% in interference environments, and delay is reduced by more than 20%, achieving a streamlined integration of edge devices and significantly reducing costs. Currently, 5G deterministic industrial gateways and supporting deterministic controllers have been developed to achieve dual 5G transmission and seamless switching without base station awareness, ensuring stable and smooth operation of various services.

-

5G+New Short-Distance Achieves Southward Connection of the Controller

The controller typically connects to I/O using fieldbus protocols in a wired manner. In recent years, there has been an increasing demand and trend for wireless solutions. Existing wireless technologies can no longer meet the stringent requirements of some new businesses and scenarios in terms of delay, reliability, synchronization accuracy, and security. How to achieve the southward connection of the controller has always been a challenge in the industry. The Star Flash short-distance technology, based on a new air interface design, is a next-generation wireless short-distance communication technology characterized by low latency (below 100us), multi-access (over 256 devices), high reliability (over 99.999%), and independent controllability. Based on 5G+ new short-distance technology for the southward connection of the controller, it integrates wide-area communication cellular networks with short-distance networks, further expanding the coverage of cellular networks and bridging the last 100 meters of on-site connections. It can also collaborate with cellular networks to achieve deterministic transmission with dual redundancy characteristics, enhancing the reliability of data transmission and forming unique advantages.

-

5G+vPLC Achieves Unified Orchestration and Deployment of Virtualized PLC

5G+vPLC (Virtualized Controller) relies on real-time virtualization technology to build a real-time computing environment on x86/ARM general-purpose hardware. Through soft-hard decoupling, it transforms traditional PLCs into virtualized PLC control services. The virtualized PLC adopts domestic PLC software technology, meets the IEC-61131-3 standard, supports five programming languages: ST, LD, IL, SFC, and CFC, and supports virtualization access for common industrial bus protocols such as Modbus, CAN, EtherCAT, and Profinet. It also supports automatic conversion between industrial bus protocols and MQTT (Message Queuing Telemetry Transport), with a maximum task delay jitter of <150us, meeting the needs of medium to high-speed industrial control scenarios. Currently, virtualization PLC integration and deployment have been completed on several models of 5G deterministic gateways such as EA1000 and DC2000.

Certificate of the “Edge Computing Standard Component Plan”

Case1:Process Industry – Wireless Remote Control Scenario for Steel Company Cranes

China Mobile collaborated with a steel company to automate 14 cranes in its hot rolling area. The 5G deterministic industrial gateway serves as the northbound communication node for the crane-side PLC slave, achieving seamless redundant switching of China Mobile’s 5G private network 2.6GHz and 4.9GHz dual-frequency networks through multi-path redundant deterministic transmission, significantly improving the quality of on-site wireless transmission, with a packet loss rate reduced by over 50% and jitter less than 10ms, ensuring no jitter during control tasks due to cell switching.

Wireless Remote Control Architecture Diagram

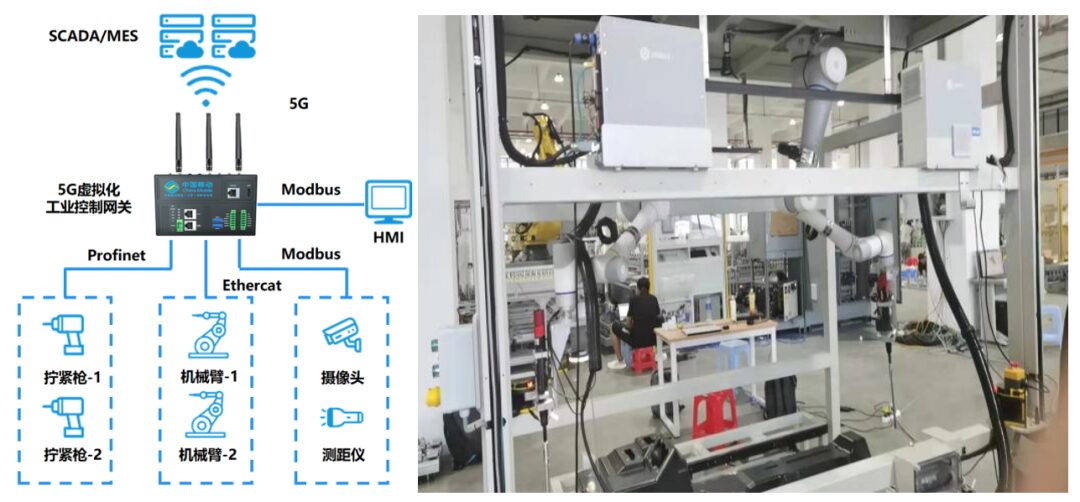

Case2:Discrete Industry – Battery Assembly Line “Control + Data Collection”

Two-in-One Replacement Scenario

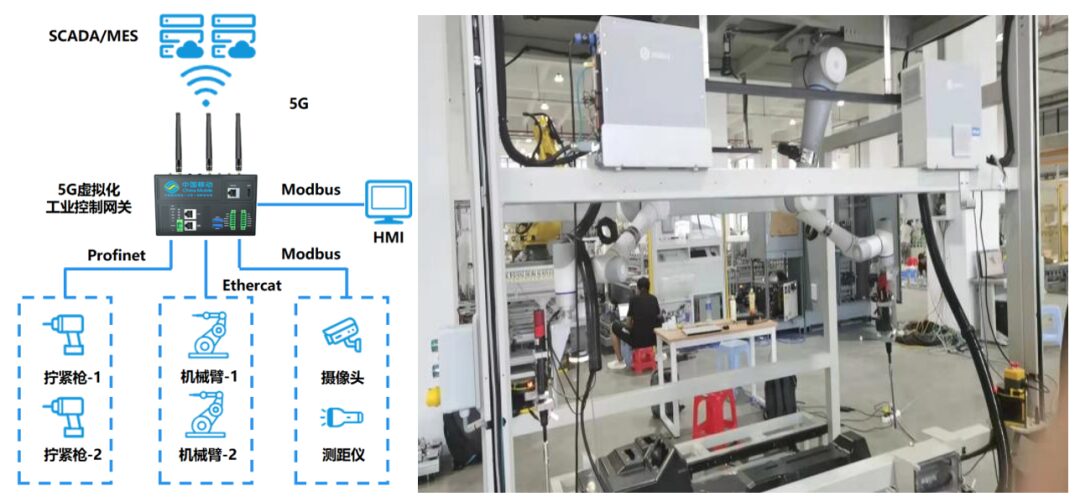

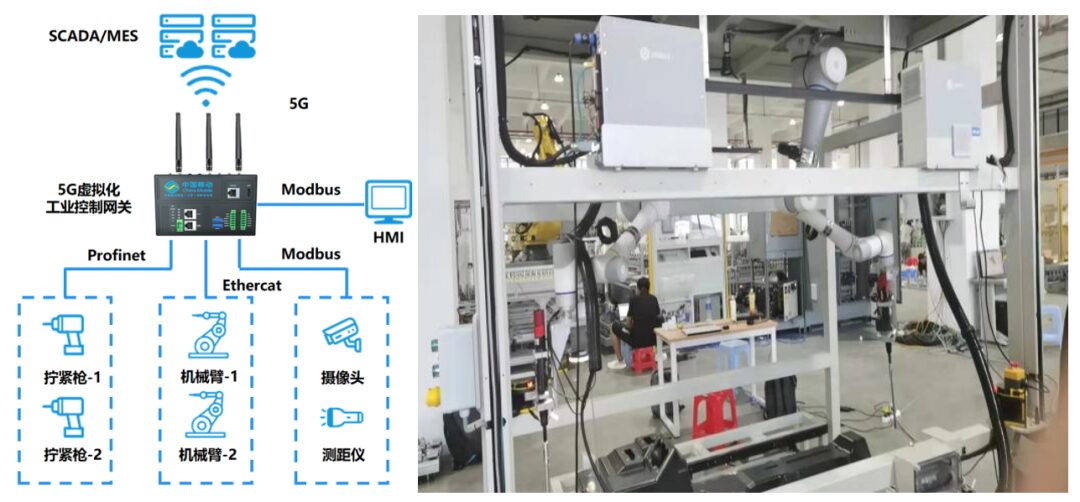

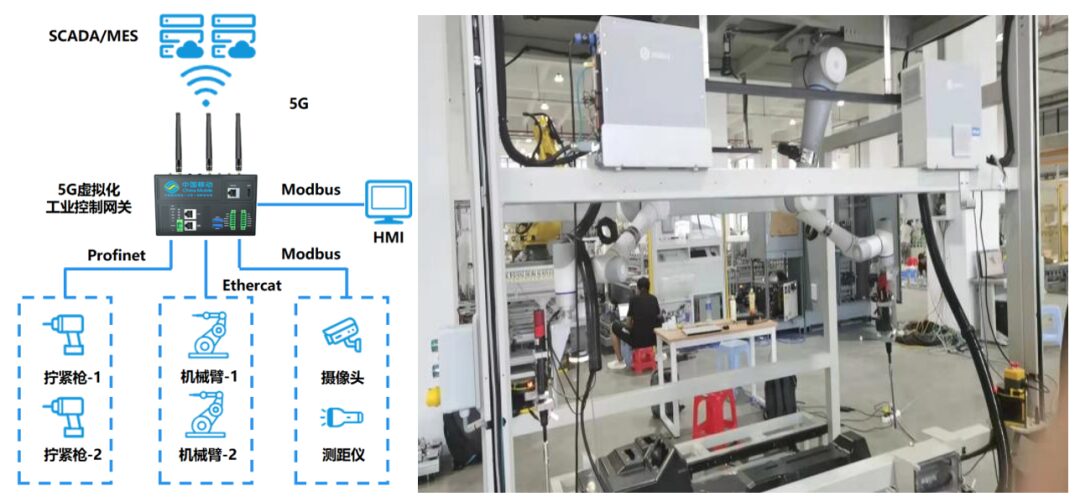

China Mobile collaborated with a domestic new energy manufacturer to complete the application verification of 5G+virtualized PLC technology on the battery assembly production line. The core solution is to use a 5G industrial control gateway with an installed virtualized PLC to achieve a two-in-one replacement of “traditional PLC + data collection gateway.” The 5G industrial control gateway first completes position calibration using a scanner and distance measuring device, then controls the robotic arm to move to the battery module position. Subsequently, the tightener on the robotic arm completes the installation and tightening of the battery module. In this case, the 5G industrial control gateway not only provides PLC real-time control services but also offers 5G data collection and remote operation and maintenance services. This compresses the traditional three-layer architecture of “on-site I/O – PLC – data collection gateway” into a flat architecture of “on-site I/O – 5G industrial control gateway,” addressing pain points such as the many control layers and specialized devices in traditional solutions, high costs, and difficulties in achieving unmanned or minimal human operations, resulting in a 50% reduction in both equipment hardware and operational costs.

Intelligent Manufacturing Architecture Diagram and On-Site Diagram for Discrete Industry

As personalized goods gradually become the mainstream consumption method, the mass production method of standardized parts on assembly lines can no longer meet existing demands. Flexible production, characterized by speed and diversity, is playing an increasingly important role in manufacturing. There is a strong demand for industrial wireless networks and open automation. The 5G deterministic industrial gateway integrates deterministic transmission, new short-distance connections, and virtualized control capabilities for the first time, achieving fully wireless, fully process, and independently controllable high-reliability industrial control applications, promoting the deep integration of 5G into core production processes, and supporting the construction of new industrialization and the integration of DOICT.

The China Mobile Research Institute was established in 2001 and is the inner-circle innovation force in China Mobile’s “One Body and Four Circles” technology innovation system. It is also the earliest, most comprehensive, and most richly developed research institution of China Mobile, concentrating high-level talents. The institute is actively implementing national science and technology innovation requirements and the company’s strategy to create a world-class “Power Mansion,” focusing on “technology innovation and industry leadership, high-end think tank for enterprises and industries, and key platform and capability research and development.” It aims to become a main force in integrating into the national science and technology innovation landscape, transforming into a world-class information service technology innovation company, and innovating the research mechanism and institutional reforms, fully supporting the company’s digital transformation and high-quality development, and bolstering the construction of a strong technological nation and high-level scientific and technological self-reliance.

Contact Person: Yang Bohan

Contact Number: 13810522535

Plenary Session丨The 24th Working Group Plenary Session of the Industrial Internet Industry Alliance was held in Baoan, Shenzhen

Plenary Session丨The 24th Working Group Plenary Session of AII successfully concluded, with various tasks progressing in an orderly manner

Welfare丨Lantern Festival Benefits are here! Come and get the 2023 AII White Paper gift package

Event丨Results Announced丨These Major Events of AII Made the List~

Call for Contributions丨”New Industrial Control Launch Action” Standard Compilation Call

Event丨The 5G Factory Innovation Development Sub-Forum was successfully held in Beijing

Little Alliance Science Popularization丨What is Industrial Intelligence?

Intelligent Manufacturing Architecture Diagram and On-Site Diagram for Discrete Industry

As personalized goods gradually become the mainstream consumption method, the mass production method of standardized parts on assembly lines can no longer meet existing demands. Flexible production, characterized by speed and diversity, is playing an increasingly important role in manufacturing. There is a strong demand for industrial wireless networks and open automation. The 5G deterministic industrial gateway integrates deterministic transmission, new short-distance connections, and virtualized control capabilities for the first time, achieving fully wireless, fully process, and independently controllable high-reliability industrial control applications, promoting the deep integration of 5G into core production processes, and supporting the construction of new industrialization and the integration of DOICT.

The China Mobile Research Institute was established in 2001 and is the inner-circle innovation force in China Mobile’s “One Body and Four Circles” technology innovation system. It is also the earliest, most comprehensive, and most richly developed research institution of China Mobile, concentrating high-level talents. The institute is actively implementing national science and technology innovation requirements and the company’s strategy to create a world-class “Power Mansion,” focusing on “technology innovation and industry leadership, high-end think tank for enterprises and industries, and key platform and capability research and development.” It aims to become a main force in integrating into the national science and technology innovation landscape, transforming into a world-class information service technology innovation company, and innovating the research mechanism and institutional reforms, fully supporting the company’s digital transformation and high-quality development, and bolstering the construction of a strong technological nation and high-level scientific and technological self-reliance.

Contact Person: Yang Bohan

Contact Number: 13810522535

Plenary Session丨The 24th Working Group Plenary Session of the Industrial Internet Industry Alliance was held in Baoan, Shenzhen

Plenary Session丨The 24th Working Group Plenary Session of AII successfully concluded, with various tasks progressing in an orderly manner

Welfare丨Lantern Festival Benefits are here! Come and get the 2023 AII White Paper gift package

Event丨Results Announced丨These Major Events of AII Made the List~

Call for Contributions丨”New Industrial Control Launch Action” Standard Compilation Call

Event丨The 5G Factory Innovation Development Sub-Forum was successfully held in Beijing

Little Alliance Science Popularization丨What is Industrial Intelligence?