April 2025 (Issue No. 16)

Authors: Wang Yiwei, Mao Yu, Zhai Meng’en, Ma Yanyan, Li Lanlan, Liu Yang, Yang Jian

////////////////////////////////////////

Introduction: Transcatheter mitral valve “valve-in-ring” replacement surgery (TMViR) is an emerging alternative treatment method for patients with mitral regurgitation (MR) due to previous failed mitral valve repair. However, this procedure may still face common problems and complications during surgery, necessitating further exploration of solutions.

Professor Yang Jian’s team at Xijing Hospital reported the world’s first TMViR surgery using the Mi-thos system (developed by Shanghai Niupai Medical Technology Co., Ltd.) via the apical approach in the Journal of Cardiovascular Development and Disease. This case involved a 67-year-old male patient who had undergone mitral valve repair and tricuspid valve annuloplasty seven years ago and recently experienced severe recurrent mitral regurgitation (NYHA class IV). Given the high risk of re-thoracotomy, Professor Yang Jian’s team opted for the apical approach and successfully performed TMViR surgery using an innovative dedicated device—the Mi-thos system. To mitigate potential intraoperative risks, a personalized 3D printed model of the patient was used for simulation and guidance prior to surgery, which was completed smoothly, and the patient’s symptoms significantly improved postoperatively.Research Background Recurrent mitral regurgitation (MR) following failed annuloplasty can lead to adverse clinical outcomes and affect long-term prognosis. For patients unsuitable for high-risk reoperation, interventional treatment for postoperative recurrent MR can serve as an alternative treatment option. However, most devices available for percutaneous intervention are often used for “off-label” indications, and there are still certain limitations when applied to the “valve-in-ring” strategy. Given the anatomical complexity of the mitral valve structure and the risk of intraoperative complications, comprehensive preoperative assessment and simulation are urgently needed to determine the suitability of the devices and ensure surgical success. In recent years, the application of cardiovascular three-dimensional (3D) printing technology has shown significant advantages in preoperative precise assessment and operational guidance for structural heart disease interventions. This report describes for the first time a case of TMViR performed via the apical approach using the innovative Mi-thos system (developed by Shanghai Niupai Medical Technology Co., Ltd.). The Mi-thos system is specifically designed for transcatheter mitral valve replacement (TMVR). To optimize the surgical strategy and assess potential intraoperative and postoperative risks, Professor Yang Jian’s team constructed a personalized 3D printed model based on preoperative imaging data to simulate key operational steps during the surgery.Case Introduction

Professor Yang Jian’s team at Xijing Hospital reported the world’s first TMViR surgery using the Mi-thos system (developed by Shanghai Niupai Medical Technology Co., Ltd.) via the apical approach in the Journal of Cardiovascular Development and Disease. This case involved a 67-year-old male patient who had undergone mitral valve repair and tricuspid valve annuloplasty seven years ago and recently experienced severe recurrent mitral regurgitation (NYHA class IV). Given the high risk of re-thoracotomy, Professor Yang Jian’s team opted for the apical approach and successfully performed TMViR surgery using an innovative dedicated device—the Mi-thos system. To mitigate potential intraoperative risks, a personalized 3D printed model of the patient was used for simulation and guidance prior to surgery, which was completed smoothly, and the patient’s symptoms significantly improved postoperatively.Research Background Recurrent mitral regurgitation (MR) following failed annuloplasty can lead to adverse clinical outcomes and affect long-term prognosis. For patients unsuitable for high-risk reoperation, interventional treatment for postoperative recurrent MR can serve as an alternative treatment option. However, most devices available for percutaneous intervention are often used for “off-label” indications, and there are still certain limitations when applied to the “valve-in-ring” strategy. Given the anatomical complexity of the mitral valve structure and the risk of intraoperative complications, comprehensive preoperative assessment and simulation are urgently needed to determine the suitability of the devices and ensure surgical success. In recent years, the application of cardiovascular three-dimensional (3D) printing technology has shown significant advantages in preoperative precise assessment and operational guidance for structural heart disease interventions. This report describes for the first time a case of TMViR performed via the apical approach using the innovative Mi-thos system (developed by Shanghai Niupai Medical Technology Co., Ltd.). The Mi-thos system is specifically designed for transcatheter mitral valve replacement (TMVR). To optimize the surgical strategy and assess potential intraoperative and postoperative risks, Professor Yang Jian’s team constructed a personalized 3D printed model based on preoperative imaging data to simulate key operational steps during the surgery.Case Introduction

The patient is a 67-year-old male with severe MR and moderate tricuspid regurgitation, who had previously undergone surgical mitral valve repair and tricuspid annuloplasty, with a 36 mm Edwards Physio ring implanted. Three months ago, the patient was readmitted due to fatigue, chest tightness, and dyspnea on exertion (NYHA class IV), and echocardiography indicated recurrent mitral regurgitation with severe regurgitation (regurgitant volume 36.0 mL; Vmax = 167 cm/s), a maximum transvalvular pressure gradient of 13 mmHg, left ventricular enlargement, and an ejection fraction of 46%.

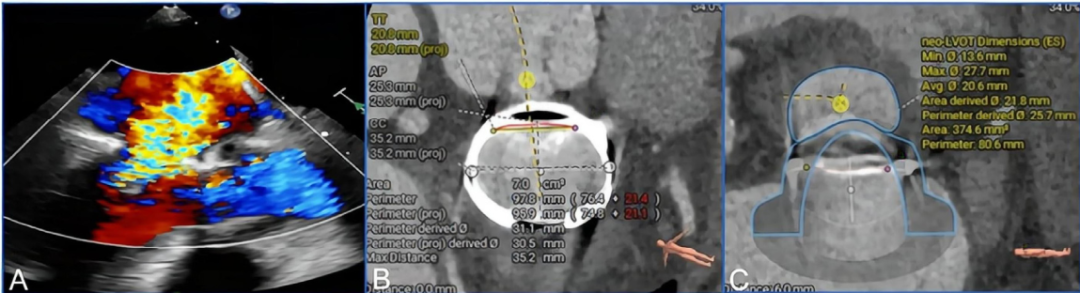

Professor Yang Jian’s team at Xijing Hospital conducted a detailed assessment of the patient’s transesophageal echocardiography (TEE) and CTA images, considering the patient’s significant symptoms and the extremely high risk of re-thoracotomy (STS score 11.192%; EuroSCORE II score 8.3%), ultimately deciding to perform TMViR (see Figure 1A–E).

Figure 1. (A-E) Preoperative imaging assessment.(A) Preoperative echocardiography indicated severe mitral regurgitation. (B–E) Preoperative CTA was used to assess the mitral valve annulus and left ventricular outflow tract structure. (B) The area of the mitral valve repair ring was 7.0 cm². (C, D) After simulating the implantation of the Mi-thos biological valve, the new left ventricular outflow tract area was 374.6 cm², with no obstruction observed. (E) The projection angle for valve implantation during surgery was RAO 46°, CAU 22°.

Preoperative 3D Printing Model and Simulation

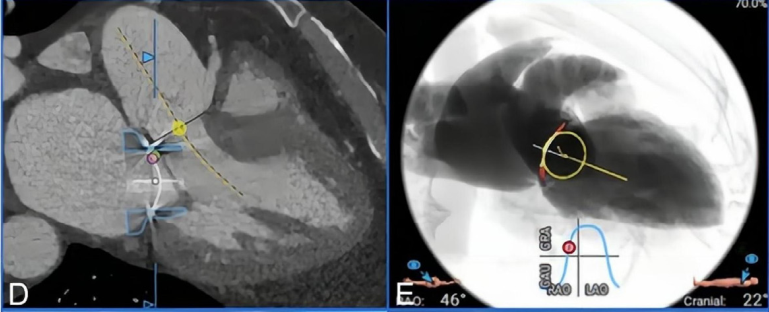

To achieve precise assessment, Professor Yang Jian’s team constructed a personalized 3D printed model of the patient based on CTA data. First, DICOM format images were imported into Materialise Mimics 21.0 software (Leuven, Belgium), where image segmentation was completed and exported as STL files. Subsequently, the STL files were post-processed using Materialise 3-Matic 14.0. Finally, the model was imported into the Polyjet 850 multi-material full-color 3D printer (Stratasys, Eden Prairie, Minnesota, USA) for printing. This printer uses materials of varying softness to accurately replicate the real texture of different structures such as the valve ring and myocardial tissue (Figure 1F–H).

Preoperatively, the model was used for bench testing, clearly observing the deployment of the released biological valve, which helped predict major complications that may occur during the perioperative period. Given that the area of the 36 mm Physio ring is 7.0 cm² and it is a D-shaped semi-rigid structure, using the conventional “valve-in-valve” technique carries a high risk of complications, thus the apical approach for implanting the Mi-thos valve system was ultimately chosen (Figure 1I).

Figure 1. (F-I) Preoperative 3D printing model used for surgical planning.(F) Three-dimensional reconstruction and landing zone structure calculation based on CTA data. (G, H) Preoperative 3D printed model from the left atrial and ventricular perspectives. (I) The Mi-thos valve system adopts a D-shaped design, which fits well with the saddle-shaped mitral valve annulus.Surgical Steps

Figure 1. (F-I) Preoperative 3D printing model used for surgical planning.(F) Three-dimensional reconstruction and landing zone structure calculation based on CTA data. (G, H) Preoperative 3D printed model from the left atrial and ventricular perspectives. (I) The Mi-thos valve system adopts a D-shaped design, which fits well with the saddle-shaped mitral valve annulus.Surgical Steps

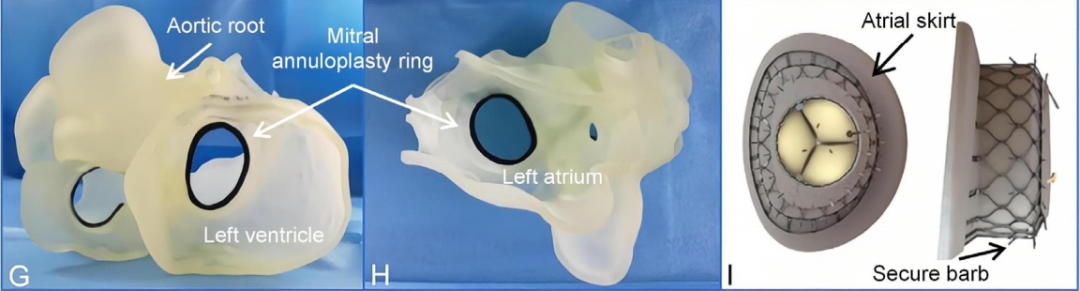

1. The surgery was performed under general anesthesia and mechanical ventilation, with fluoroscopy and TEE guidance during the procedure. A 4 cm small incision was made in the left anterior chest to establish a puncture channel through the apex. A 6F sheath was inserted via the right femoral artery and vein, and a temporary pacing electrode was introduced into the right ventricle through the venous sheath. Simultaneously, a 6F pig-tail catheter was placed into the left ventricle via the right femoral artery.

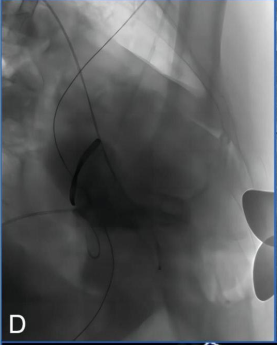

2. After successfully establishing the standard apical channel and securing the puncture site with a hexagonal suture technique, the angle was adjusted to a cranial right anterior oblique position for clearer visualization of the left ventricle and left atrium structures. Angiography was performed to assess the mitral regurgitation (Figure D), left ventricular morphology, and annulus structure.

Figure D: Intraoperative angiography indicated severe mitral regurgitation.

3. Based on the preoperative 3D printing model simulated assessment created from the patient’s individual CTA data (Figure A–C).

Figure A-C: Preoperative simulation using 3D printing (A) Adjusting the valve release position and its coaxial alignment with the annulus. (B, C) The biological valve fully deployed, observable from both left atrial and left ventricular perspectives.

4. The 33 mm Mi-thos biological valve was assembled with the delivery system in vitro, and then a puncture was completed at the apex, followed by the insertion of a 6F sheath, which was then advanced through the 6F pig-tail catheter and J-tip 0.035 inch guidewire across the surgically repaired mitral valve annulus into the left atrium. Subsequently, a 260 cm Lunderquist super stiff guidewire (Cook Medical, Bloomington, Indiana, USA) was exchanged.

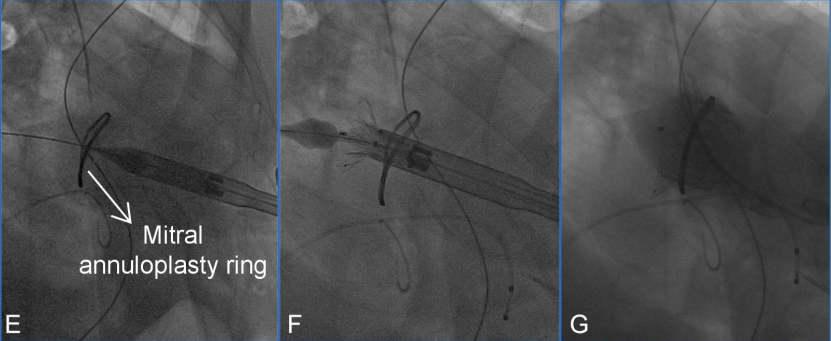

5. The delivery system was then advanced retrogradely through the apical approach across the mitral valve repair ring into the left atrium along the guidewire. By retracting the outer sheath of the delivery system, the atrial skirt designed to fit the D-shaped mitral valve annulus was precisely covered over the original annulus and repair ring under the guidance of TEE and angiography, while the ventricular portion of the valve remained partially retained in the sheath.

Figure E-G: Main surgical steps of transcatheter mitral “valve-in-ring” replacement surgery. (E) The delivery system was successfully delivered via the apical approach. (F) The biological valve was released. (G) Angiography indicated appropriate valve positioning.

Figure E-G: Main surgical steps of transcatheter mitral “valve-in-ring” replacement surgery. (E) The delivery system was successfully delivered via the apical approach. (F) The biological valve was released. (G) Angiography indicated appropriate valve positioning.

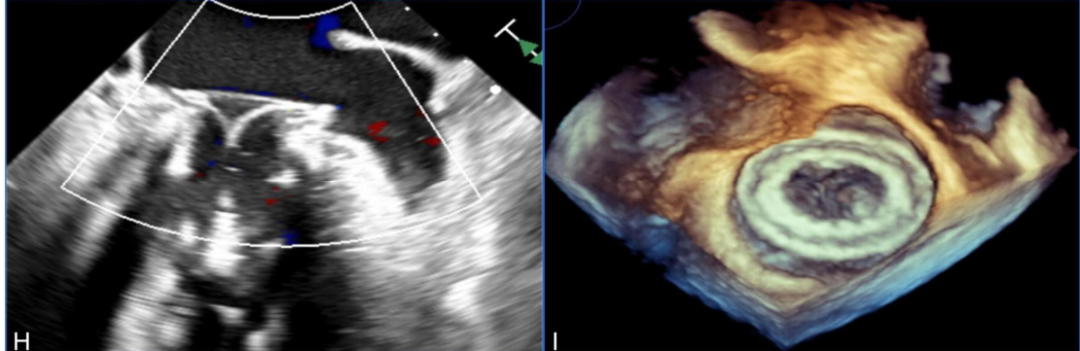

Figure H-I: Post-release TEE examination indicated stable valve position, good function, and no paravalvular leak.

6. After confirming the position and alignment of the Mi-thos valve, the delivery system was slowly retracted to accurately position it on the annulus. Subsequently, the ventricular portion of the valve was released under rapid pacing at 140 beats per minute, and it was firmly anchored in the native mitral valve position using its built-in fixation barbs.

7. Intraoperative left ventricular angiography immediately showed that the Mi-thos biological valve was well positioned and shaped, with no intravalvular regurgitation, paravalvular leak (PVL), or left ventricular outflow tract obstruction (LVOTO) observed (the new left ventricular outflow tract area was 374.6 cm²); TEE further assessed the valve position and function, showing an average transvalvular pressure gradient of 3 mmHg.

8. Finally, the delivery system was smoothly removed through the apical incision, and hemostasis was successfully achieved using pre-placed apex sutures. After closing the incision, the patient was successfully weaned off the ventilator and transferred to the cardiac intensive care unit.

Postoperative Recovery

The patient’s postoperative recovery was smooth, and on the fifth day post-surgery, the patient was discharged in good general condition. Pre-discharge transthoracic echocardiography indicated that the valve position and function were good, with no significant intravalvular or paravalvular regurgitation, nor LVOTO observed; the maximum and average transvalvular pressure gradients were 6 mmHg and 2 mmHg, respectively. The patient’s symptoms significantly improved compared to pre-surgery, now classified as NYHA class II.

This case report demonstrates the feasibility and safety of the Mi-thos system in patients with mitral regurgitation following annuloplasty failure, performing TMVR via the apical approach. This device is easy to operate and can effectively stabilize the patient’s condition during surgery, showing great potential for minimally invasive treatment in specific patients. Its structural design advantages can effectively reduce common TMVR complications, while the application of 3D printing technology in preoperative assessment and simulation further enhances the feasibility and safety of TMViR, providing strong support for developing precise and personalized surgical strategies.

Expert Introduction

Yang Jian

Xijing Hospital, Air Force Military Medical University(Click to enter the expert’s personal homepage)

Swipe up to read

Director of the Cardiovascular Surgery Ward 1 at Xijing Hospital, doctoral supervisor. Fellow of the American Heart Association (FAHA), Fellow of the American College of Cardiology (FACC). Appointed as a leading talent in scientific and technological innovation for young and middle-aged people in Shaanxi Province, leader of the Shaanxi Provincial Science and Technology Innovation Team, and recipient of the Shaanxi Provincial Outstanding Youth Science Fund project. Clinically proficient in transcatheter minimally invasive interventions for various structural heart diseases such as mitral and aortic valve diseases, awarded the fourth “National Famous Doctor” title. Has made significant contributions to the development of minimally invasive cardiovascular devices, clinical translation, and multimodal imaging assessment primarily using 3D printing. Has published over 50 SCI papers as the first or corresponding author in international journals such as Eur Heart J and JACC, and has undertaken more than 10 projects including the National Key Research and Development Program and the National Natural Science Foundation, with funding exceeding 10 million yuan. Has received the second prize for National Scientific and Technological Progress and the first prize for Chinese Medical Science and Technology. Holds over 30 national patents. Chief editor of five monographs including “Cardiovascular 3D Printing Technology,” “Cardiovascular 3D Printing (English Edition),” “3D Printing Technology in Transcatheter Aortic Valve Replacement—Application and Practice,” and “Transcatheter Aortic Valve Replacement Operation Guide Manual.”

Liu Yang

Xijing Hospital, First Affiliated Hospital of Air Force Military Medical University (Click to enter the expert’s personal homepage)

Swipe up to read

Doctor of Cardiovascular Surgery, Associate Chief Physician, Associate Professor, Master’s Supervisor. Leader of the minimally invasive structural heart disease group and ECMO group. Postdoctoral fellow at the University of Maryland School of Medicine. Member of the Minimally Invasive Cardiovascular Surgery Professional Committee of the National Cardiovascular Disease Expert Committee. Focused on minimally invasive treatment of cardiovascular diseases. Has developed several new techniques for minimally invasive treatment of cardiovascular diseases, including minimally invasive interventional valve repair and replacement, paravalvular leak closure after valve replacement, and coronary leak closure. Has published over 70 research articles, including 28 SCI articles; has led one major military special sub-project, one National Natural Science Foundation project, and three military and provincial-level projects; has participated in 13 projects including the “863” key project and major national science and technology special projects during the 12th and 13th Five-Year Plans. Holds 11 national patents; chief editor of one monograph, associate editor of three monographs, and contributor to eight monographs. Has received a provincial-level first prize for scientific and technological progress and has been awarded the ASAIO Young Physician Award, Euro-ELSO Young Researcher Award, Chinese Medical Association Cardiovascular Surgery Branch Xinglin Award, Shulan Excellent Engineering Young Physician Funding Program, and the Lillehei Scholarship and Elbaken Scholarship from the Chinese Medical Association’s Thoracic and Cardiovascular Surgery Branch.

Further Reading

Swipe up to read

Discussion on the Structure Literature of Xijing|Professor Yang Jian of Xijing Hospital: Deep Learning and 3D Printing-Assisted TAVR Prediction of Coronary Risk

Discussion on the Structure Literature of Xijing|3D Bioprinting Aortic Valve Intracellular Proteomics and Extracellular Vesicle Proteomics as Metrics for Disease Restoration

Discussion on the Structure Literature of Xijing|Single-Center Experience of Transcatheter Paravalvular Leak Closure

Discussion on the Structure Literature of Xijing|The Impact of Mechanical Circulatory Support on Mortality After Transcatheter Aortic Valve Replacement: A Landmark Analysis StudyDiscussion on the Structure Literature of Xijing|Gender Differences in TAVR Prognosis

Discussion on the Structure Literature of Xijing|A Retrospective Study Comparing the Effectiveness of Transcatheter Tricuspid Valve Replacement and Medical Therapy in Symptomatic Severe Tricuspid Regurgitation Patients

Discussion on the Structure Literature of Xijing|The Impact of Tricuspid Regurgitation and Right Ventricular Volume Overload on HFpEF Patients

Discussion on the Structure Literature of Xijing|Physical and Computational Modeling of Transcatheter Interventions for Structural Heart DiseaseDiscussion on the Structure Literature of Xijing|Application of Personalized 3D Printed Aortic Root Models with Built-in Sensors in TAVR SurgeryDiscussion on the Structure Literature of Xijing|Preparation of Sodium Alginate Hydrogel Scaffolds for Cardiac Valve Tissue EngineeringDiscussion on the Structure Literature of Xijing|Cardiac Valve Tissue Engineering: Applying Melt Electrospinning 3D Printing Technology to Manufacture Spatially Heterogeneous ScaffoldsDiscussion on the Structure Literature of Xijing|Translating Medical Imaging into Cardiovascular 3D Printing Models—A Systematic Review of Applications, Technologies, and ValidationDiscussion on the Structure Literature of Xijing|Revisiting the “Youthful” TAVR TechnologyDiscussion on the Structure Literature of Xijing|Hydrogel Bioprinting Simulating Cardiac Valves with Complex Shapes and High Fatigue Resistance—Progress and ProspectsDiscussion on the Structure Literature of Xijing|Prospects for the Application of 3D Printing, Computer Modeling, and Artificial Intelligence in Structural Heart DiseaseDiscussion on the Structure Literature of Xijing|Applications of 3D Printing, Computer Modeling, and Artificial Intelligence in Structural Heart Disease

· END ·

Copyright and Disclaimer:The Yandao Medical Voice Network aims to build a platform for academic dissemination and media expression. The copyright of the information in the text belongs to the holder, and we only provide it for information transmission purposes. If there is any infringement, please contact us for deletion.

Click “Read the original text” to learn more about cutting-edge technology news and enter the “Yang Fan Yuan Hang” column