Many embedded systems that cannot connect to the mains power often rely on battery power. However, when the battery runs out, the maintenance cost of replacing the battery is relatively high and causes considerable inconvenience. If energy harvesting technology can be used to provide perpetual power to the system, this problem can be solved. This article will introduce how to use energy harvesting technology to establish a permanently operating embedded system, as well as related solutions introduced by Silicon Labs.

Pursuing a Perpetual Energy Harvesting System

Energy harvesting technology is rapidly becoming a viable power choice for embedded system designers, enabling wireless sensors to be used in applications that were previously unachievable with traditional battery-powered designs. For example, energy harvesting power allows system designers to easily build ultra-thin wireless sensors with a range of over 100 meters and a lifespan of over 20 years.

The ultimate goal of energy harvesting systems is to achieve perpetual operation. Energy harvesting systems can achieve perpetual operation by ensuring that the collected energy meets or exceeds the energy consumed by the system during operation. Energy management is a key aspect of designing energy harvesting systems. The first step is to determine the available power output of the harvester, which can convert solar energy, mechanical energy, or thermal energy into electrical energy. Solar harvesters have the highest power density, capable of harvesting 15 mW/cm2 of surface area, maximizing the output power of the energy harvester, which is crucial for building a robust energy harvesting system.

When designing energy harvesting systems, it is most important to provide sufficient functionality while minimizing the power consumption of the embedded system. By selecting components with low leakage specifications and using ultra-low power microcontrollers (MCU) (such as Silicon Labs‘s Si10xx wireless MCU), low power consumption can be achieved. Most technologies used to achieve low power operation in battery-powered systems can also be applied to minimize power consumption in energy harvesting systems.

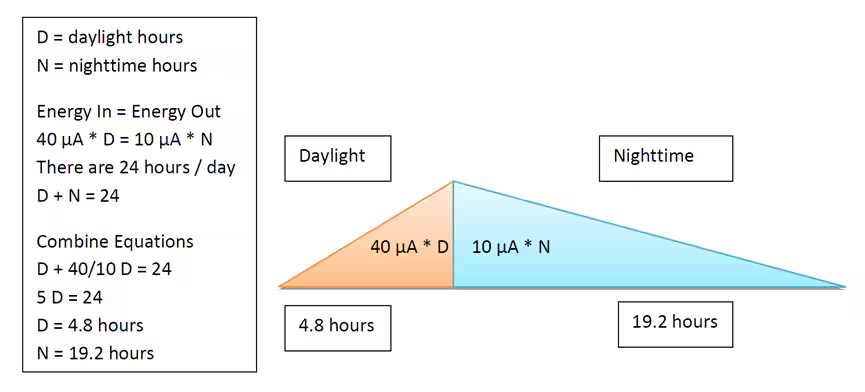

Let’s look at an example of a solar wireless sensor node, which transmits data at an average current of 10 µA every 20 minutes. This system is equipped with a solar panel that provides a continuous current of 50 µA during the day. The net current available for charging the battery during the day is 40 µA, while the battery discharges at a rate of 10 µA at night. As long as the system is exposed to at least 4.8 hours of sunlight each day, the energy harvesting system can achieve perpetual operation.

Thin Film Batteries Balance Harvesting and Consumption of Average Power

There are two types of energy harvesting systems capable of achieving perpetual operation, each with different energy storage mechanisms. The first type requires long periods of energy collection and accumulation, using low leakage, high-capacity energy containers, such as thin film batteries. Perpetual operation is achieved by balancing the average harvested energy and the average power consumed. Such energy harvesting systems are the most flexible and typically experience bursts of high power consumption for short durations. These systems spend most of their time in low power sleep mode, always powered on and continuously harvesting energy. An example of such a system is a solar wireless sensor node.

The second type of energy harvesting system remains powered off until an energy pulse is detected, collects energy, and stores it in a low-impedance energy container (such as a capacitor). After a brief power-up reset, the system uses the limited energy collected from the energy pulse to perform necessary system functions. Perpetual operation is achieved by balancing the total energy consumed during task execution and the energy harvested from a single pulse. An example of such a system is a wireless light switch that uses energy generated by a mechanical switch to transmit RF signals to a receiver located at the light fixture.

Traditional batteries such as button cells, AA lithium batteries, and lithium thionyl chloride batteries have been used for many years in embedded systems requiring long lifespans. The introduction of thin film batteries creates a new option for system designers to balance cost, size, and safety. As developers continually face pressure to reduce system costs, economical button cells seem to be the best solution for lowering manufacturing costs and quickly bringing products to market. However, replacing button batteries incurs hidden costs.

If you think the total lifespan storage capacity of a thin film battery exceeds 30 CR2032 button cells, you will quickly conclude that the initial cost of thin film batteries is negligible compared to the cost of replacing 30 button batteries, often exceeding multiples of the embedded system’s lifecycle.

When considering battery size, thin film batteries have the thinnest profiles of all battery types (as thin as 0.17 mm). The total lifespan capacity of thin film batteries is equivalent to four lithium “AA” batteries or one “C” type lithium thionyl chloride battery, making thin film batteries ideal for space-constrained embedded systems requiring ultra-thin profiles and long battery life.

Moreover, thin film batteries do not present safety issues associated with large traditional batteries, such as flammability and explosion hazards. Since thin film batteries are rechargeable, they only store a portion of their total lifespan capacity at any given time. If the battery accidentally shorts or is exposed to extreme heat or open flames, this makes the battery safer. The waste produced by thin film batteries is also significantly less than that of large traditional batteries, which typically end up in landfills rather than being recycled.

Energy Harvesting Reference Designs Accelerate Product Development

The power consumption of battery-powered IoT devices has always been a critical issue affecting the operation of IoT devices. Various organizations behind wireless standards are dedicated to helping meet consumer expectations for lower power consumption in this field. Zigbee Green Power is a good example of considering energy harvesting when designing wireless communication.

Silicon Labs and Arrow Electronics jointly developed an energy harvesting reference design based on the Silicon Labs EFR32MG22 system-on-chip (SoC), which pairs Zigbee Green Power light switches with energy harvesting power management. MG22 is designed for the Zigbee protocol, compact in size and equipped with advanced security features, making it an ideal choice for ultra-low power endpoint devices. Silicon Labs also offers energy-efficient power management ICs like EFP0111 to provide better power management capabilities. Silicon Labs also provides MCUs, wireless starter kits, and the Simplicity Studio that provides a robust development and debugging environment to assist customers in quickly developing energy harvesting systems.

The core component of this design is the energy harvesting generator, which adopts a monostable generator module from ZF. This is a bidirectional switch generator, meaning energy is generated when the switch is pressed and released. The switch has magnets with two poles, and pushing down the switch generates a magnetic field that passes through the core and returns to the other pole. Then, when the user releases the switch, the magnetic field changes and passes through the core in the opposite direction, and this changing magnetic field generates a current, which is the energy we can harvest. When the ZF generator is pressed or released, it generates an alternating voltage, and the system can use this energy generated from mechanical energy to turn on the light fixture, with the ultimate goal of being able to turn the light on and off without wiring between the switch and the fixture.

Powering IoT devices is an energy-intensive task, and innovative battery-free powering methods will simplify development and help create a cleaner environment. For example, the energy required to make an LED blink once is sufficient to transmit multiple RF signals. Low-power silicon chip designs combined with networks optimized for low-power applications will lay the foundation for a new era of power management and significantly reduce costs and waste for manufacturers and consumers.

High-Performance, Low-Power Power Management Solutions

Silicon Labs launched the EFR32MG22 (MG22) series SoC, optimized for Zigbee solutions, bringing industry-leading energy efficiency to IoT applications such as smart home sensors, lighting control, and building and industrial automation.

The EFR32MG22 and EFR32MG22E Zigbee SoC solutions are part of the Wireless Gecko Series 2 platform. MG22 series provides optimized Zigbee SoC solutions that integrate high-performance, low-power 76.8 MHz ARM® Cortex® -M33 cores with TrustZone. MG22 enables you to create energy-efficient applications, while MG22E (“E” stands for energy-saving) further enhances the energy-saving advantages by extending battery life and supporting completely battery-free designs. MG22 SoC combines ultra-low transmission and reception power (+6 dBm at 8.2 mA TX, 3.9 mA RX), 1.4 µA deep sleep mode power, and low-power peripherals to provide industry-leading energy-saving solutions for applications using the Zigbee protocol (including Green Power).

Silicon Labs’s EFP0111GM20 energy-efficient power management IC (PMIC) is a flexible, efficient, multi-output power management IC that provides complete system power for EFR32 and EFM32 devices, three output voltage rails, and main battery charge measurement capabilities. EFP0111 boost converter PMIC operates within a voltage range of 1.7 to 5.2, with a static current as low as 150 nA. EFP0111GM20 supports multiple battery technologies from 1.5 to 5.5 volts, providing flexibility for various battery technologies while improving the power efficiency of EFR32 and EFM32.

Silicon Labs’s Si10xx Sub-GHz wireless MCU combines high-performance wireless connectivity with ultra-low power microcontroller processing in a small package of 5 x 6 mm. The device supports a frequency range of 142 to 1050 MHz, including an integrated advanced packet processing engine with a link budget of up to 146 dB. By reducing the current for TX, RX, active, and sleep modes, and supporting fast wake-up times, the device is optimized to reduce power consumption in battery-supported applications. Si106x MCU is pin-compatible with Si108x devices, with flash memory capacity adjustable between 8 and 64 kB, and provides robust analog and digital peripherals including ADC, dual comparators, timers, and GPIO. All devices are designed to comply with the 802.15.4g smart metering standard and support global regulatory standards including FCC, ETSI, and ARIB regulations.

Conclusion

Energy harvesting technology has become quite popular, and due to the numerous benefits it offers for embedded system design, it is expected to become even more prevalent in the coming years. Once properly designed, an energy harvesting system can achieve perpetual operation after overcoming the initial power-up reset. With careful system design, the lifespan of energy harvesting systems can be extended to over 20 years. Thin film batteries are commonly used in energy harvesting systems due to their ultra-thin profile and low leakage characteristics, eliminating the need for a main power supply or traditional replaceable batteries, allowing for flexible embedded system designs that create new application possibilities and open up new areas for embedded system development. Silicon Labs’s MG22 series Zigbee SoC solutions, EFP0111GM20 energy-efficient power management IC, and Si10xx Sub-GHz wireless MCU will be able to provide excellent energy management capabilities for energy harvesting systems, ensuring that embedded systems can operate for extended periods without the hassle of battery replacement.

This article is also published on the Arrow Electronics website, original link:https://www.arrow.com/zh-cn/research-and-events/articles/designing-perpetual-power-for-embedded-systems-using-energy-harvesting-technology

Scan the QR code below to follow Silicon Labs’ social media platforms