Today, we will discuss a very important topic—encryption protection for PLC programs. PLCs (Programmable Logic Controllers) are the core devices in industrial automation, and the PLC program acts as its brain, controlling the entire system’s operation. To prevent programs from being maliciously cracked or copied, encryption protection is particularly important.

The goal today is to help you understand the core principles of PLC program encryption and learn practical methods to protect industrial secrets.

What is PLC Program Encryption?

In simple terms, PLC program encryption is like putting a “protective suit” on the program to prevent unauthorized access, copying, or tampering. There are many ways to implement encryption protection, including password protection, hardware binding, encryption algorithms, and program compilation protection.

For example:

-

If the PLC program is a house, encryption is like installing a password lock on the house; without the key, no one can enter.

-

More advanced encryption methods, such as hardware binding, are like a lock that not only requires a key but also needs to be opened with a specific key in conjunction with facial recognition.

Why is PLC Program Encryption Necessary?

In industrial production, PLC programs often contain core control logic and technical secrets. If these programs are cracked or copied, it may lead to the following issues:

-

Technical Leakage: Competitors may steal your technical secrets, resulting in immeasurable losses.

-

Safety Hazards: Unauthorized modifications may cause equipment to operate abnormally, leading to safety accidents.

-

Difficulties in Rights Protection: Without protective measures, once a program is misappropriated, it is challenging to prove that the program is your original work.

Common Methods and Principles of PLC Encryption

Next, I will explain several common PLC encryption methods in simple and understandable language, combined with practical examples.

1. Password Protection: The Most Basic Firewall

Concept: By setting a password, access to the PLC program is restricted. Only those who know the password can view or modify the program. Siemens PLCs typically support multi-level password protection (e.g., 4-level password protection for S7-200).

Application Scenario: Suitable for scenarios where there are basic requirements for program access, such as preventing unauthorized technicians from modifying the program.

Example: Suppose you have developed an automated assembly line control program; you can restrict the following operations by setting passwords:

-

Level 1 Password: Allows monitoring of program running status but does not permit modifications.

-

Level 4 Password: Completely prohibits program upload, even if the password is known, the program cannot be copied.

Notes:

-

The password should be complex enough to avoid being cracked (e.g., avoid weak passwords like “12345”).

-

Regularly change passwords to prevent long-term use leading to leakage.

2. Hardware Binding: The “Exclusive Marriage” of Program and Device

Concept: By binding the program to a specific hardware device (such as the CPU’s serial number, EEPROM chip, etc.), even if the program is copied to another device, it cannot run.

Application Scenario: Suitable for scenarios requiring absolute security, such as high-value equipment or protection of commercial secrets.

Example: A common hardware protection method used by German engineers binds the program to the PLC’s CPU serial number. This is like your car key can only start your own car; changing to another car key will render it ineffective.

Notes:

-

Ensure that the hardware-bound program matches the device to avoid operational errors that prevent the program from running.

-

If the device needs to be replaced, remember to unbind it; otherwise, the new device cannot use the original program.

3. Compilation Protection: Turning the Program into a “Riddle”

Concept: By compiling or obfuscating the program, the logic of the program becomes difficult to understand, preventing it from being cracked. Siemens’ “KNOWHOW” function is a common compilation protection technology.

Application Scenario: Suitable for scenarios where part of the program needs to be delivered to customers for maintenance, but the core secrets need to be retained.

Example: If you design a complex recipe control system, you can encrypt the core logic using the “KNOWHOW” function, allowing customers to see only the peripheral parts of the program while being unable to access the core content.

Notes:

-

Encrypted program blocks should be separated from unencrypted blocks to avoid affecting normal program maintenance.

-

Select appropriate encryption methods to avoid impacting program performance.

4. Communication Encryption: The “Invisible Transmission” of Data

Concept: Data exchange is achieved through the PLC’s communication function without directly exposing the control logic. Imitators can only see communication data and cannot crack the specific logic of the program.

Application Scenario: Suitable for scenarios where multiple PLCs or PLCs are connected to third-party devices.

Example: If you design a servo system controlled by a PLC, you can control the servo motor’s operation through communication methods (such as MODBUS protocol). Even if imitators obtain the program, it is difficult to crack the specific logic of the communication data.

Notes:

-

Set reasonable communication parameters (such as baud rate, station number) to avoid default parameters being guessed.

-

Encrypt communication data to prevent data packets from being intercepted and analyzed.

5. Program Logic Traps: Making Imitators “Step on Mines”

Concept: Embed hidden protection logic in the program; if the program is tampered with or copied, it will trigger a “mine,” causing the system to fail to operate normally.

Example: An engineer embedded a detection logic in the program: if the PLC’s CPU serial number does not match the original device, it will trigger an alarm and stop the program from running.

Notes:

-

The mine logic should be hidden and reasonable to avoid being easily discovered.

-

When embedding mines, ensure thorough testing to avoid false triggers.

Practical Case: How to Protect an Assembly Line Control System?

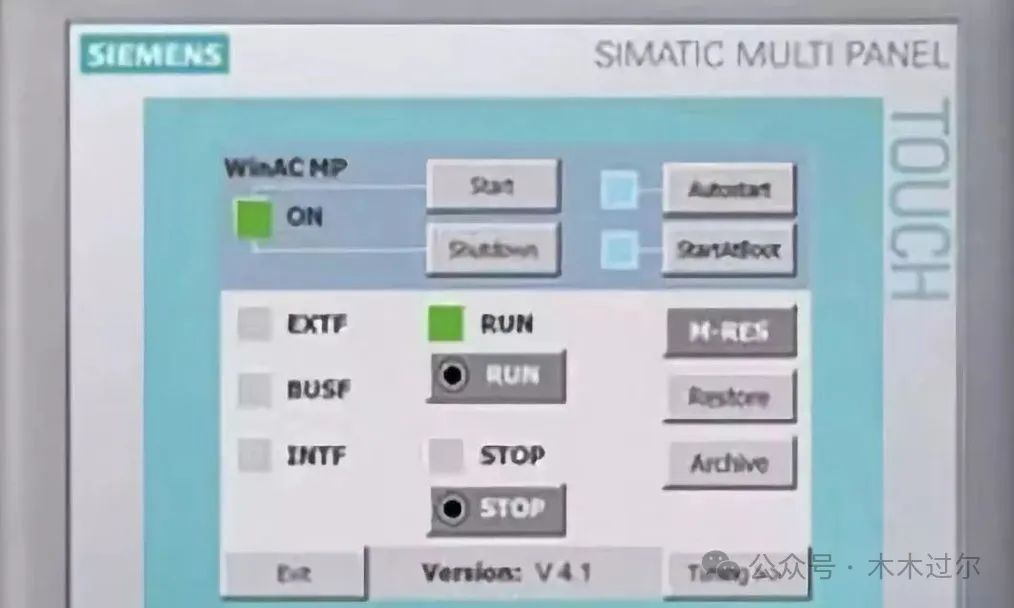

Suppose you have designed an automated assembly line control system, including PLC, HMI (Human-Machine Interface), and servo drives. Here is a complete encryption protection plan:

-

PLC Program Encryption: Use Siemens’ KNOWHOW function to encrypt core program blocks to prevent customer access.

-

HMI Program Protection: Bind the HMI source program to the PLC and add vendor identification on the screen to prevent imitation.

-

Communication Encryption: Use the MODBUS protocol for data exchange between the PLC and servo drives, and encrypt the communication data.

-

Hardware Binding: Bind the PLC program to the CPU serial number to ensure the program can only run on the specified device.

-

Logic Traps: Embed a “mine” in the program; if tampering is detected, it will stop the assembly line from running.

Common Questions and Solutions

Question 1: Why is the PLC output not functioning?

Solution: Check if the output load is too large or if the program logic is correct.

Question 2: The program cannot run after encryption?

Solution: Confirm whether the encryption settings have affected the program logic or if the hardware binding is mismatched.

Question 3: Communication data intercepted?

Solution: Enable communication encryption to prevent data packets from being tampered with.

Notes

-

Hardware Debugging: Always check voltage levels before wiring to prevent burning out the PLC module.

-

Program Testing: Ensure the program logic is correct before encryption to avoid difficulties in debugging afterward.

-

Backup Original Code: Keep an unencrypted original program before encryption for future maintenance.

Conclusion

PLC program encryption is an important means of protecting industrial secrets. From password protection to hardware binding, to communication encryption and logic traps, each method has its unique application scenarios. As engineers, we need to flexibly combine these methods based on actual needs to create a fortress-like program protection system.

The final suggestion: When learning and practicing PLC encryption, start with simple password protection and gradually try more advanced encryption technologies. Only through continuous exploration and summarization can we truly master this skill and ensure the safety of industrial automation systems!

Ak, looking forward to our next technical exchange!

Like and share

Let money and love flow to you