Since 2019, influenced by the economic environment and the Sino-US trade war, except for the photovoltaic, LED, and lithium battery markets which remained relatively stable, the 3C, automotive manufacturing, and semiconductor industries have shown significant downward trends, and the domestic automation market has not been “spared”, with market trends nearly bottoming out. However, with the arrival of emerging technologies such as 5G and the Internet of Things, along with the continuous development of the new energy vehicle industry, signals of rebound have begun to emerge, and it is expected that the manufacturing industry will see some recovery next year. Amidst the ongoing market downturn, Advantech’s revenue in China in the first half of 2019 was also affected to some extent, resulting in a slowdown in growth, but it remained basically flat or slightly grew compared to the same period last year. From the overall revenue perspective of Advantech globally, it still achieved double-digit growth.

Advantech Technology Intelligent Device Division Business Development Director Li Guozhong

Advantech Technology Intelligent Device Division Business Development Director Li GuozhongIn Advantech’s view, everything has two sides; crises are opportunities for transformation. Only in the face of crises will enterprises seek change and breakthroughs, thus gaining new development opportunities. In response to market challenges, Advantech remained calm in 2019, focusing on internal capabilities, leveraging strengths, and innovating to develop controllers, industrial software, vision products, and industry solutions based on industrial IoT applications; at the same time, closely following market development trends, focusing on the future, and upgrading products, technologies, and services to prepare for a strong entry into the new technology era.

Focus on Strengths

Develop IoT-Based Intelligent Controllers

With the arrival of the Internet of Things and cloud computing era, the new demands created by industrial interconnectivity and the continuous expansion of the global market are constantly extending. As a company with a significant influence in IoT, automation, and embedded computing, Advantech’s positioning is gradually transforming from a hardware developer to an IoT service provider, making IoT development planning a top strategic priority, with all business groups, including Advantech’s Intelligent Device Division, moving in this direction. Among them, the Intelligent Device Division will focus on IoT-centered intelligent applications as its core research direction, gradually deepening the research on control systems for intelligent equipment and smart factories.

Currently, manufacturing enterprises are in a transformation and upgrade phase in the era of the Internet of Everything, with the collection and analysis of production and equipment data becoming the core driving force for digital transformation. However, traditional digital upgrade solutions require the combination of PLCs, PCs, gateways, SCADA software, and other products with different functions across multiple fields, achieving industrial IoT solutions through system integration, which generally has a complex system architecture. Enterprises face challenges such as operational difficulties, high development and maintenance costs, and high security risks. To address this, Advantech has launched the next-generation industrial IoT WISE-5000 series edge controllers, breaking down the connection barriers between devices and between devices and the cloud, achieving efficient operation and interconnectivity of machines.

WISE-5000 series edge controllers are based on the Advantech WISE-PaaS platform, replacing the traditional IPC+PLC solution, achieving IT and OT integration through a modular system architecture that can run multiple functions such as high-speed data collection, motion control, machine vision, logic control, predictive maintenance, and device networking on the same platform; at the same time, data analysis and optimization control data can be directly connected to the industrial cloud platform, enabling intelligent production line control in collaboration with the remote industrial cloud platform. Its compact size saves installation space, making it easier for equipment manufacturers to integrate IT and OT applications.

Moreover, the WISE-5000 series edge controllers adopt EtherCAT I/O and PCI Express interface designs, providing a variety of I/O and communication modules that can be flexibly expanded; equipped with Intel’s sixth-generation Skylake Core i processor, they offer fast transmission speeds; meeting users’ diverse needs and high mechanical efficiency requirements. Currently, the efficient application of the WISE-5000 series controllers in intelligent equipment and smart factories has received high praise from users.

Combining Software and Hardware

Driving Industrial Acceleration and Upgrading

“In the era of the digital economy, with the support of new-generation information technologies such as the Internet of Things, artificial intelligence, big data, and cloud computing, hardware reshapes the infrastructure, and software implements intelligent decision-making. The combination of the two, ‘soft and hard’, stimulates new momentum and more effectively drives the accelerated transformation and upgrading of the manufacturing industry,” said Li Guozhong, Business Development Director of Advantech Technology Intelligent Device Division,through the integration of software and hardware, and collaboration with equipment manufacturers to develop systematic solutions, to enhance the automation level of machines, is also one of Advantech’s current key R&D goals.

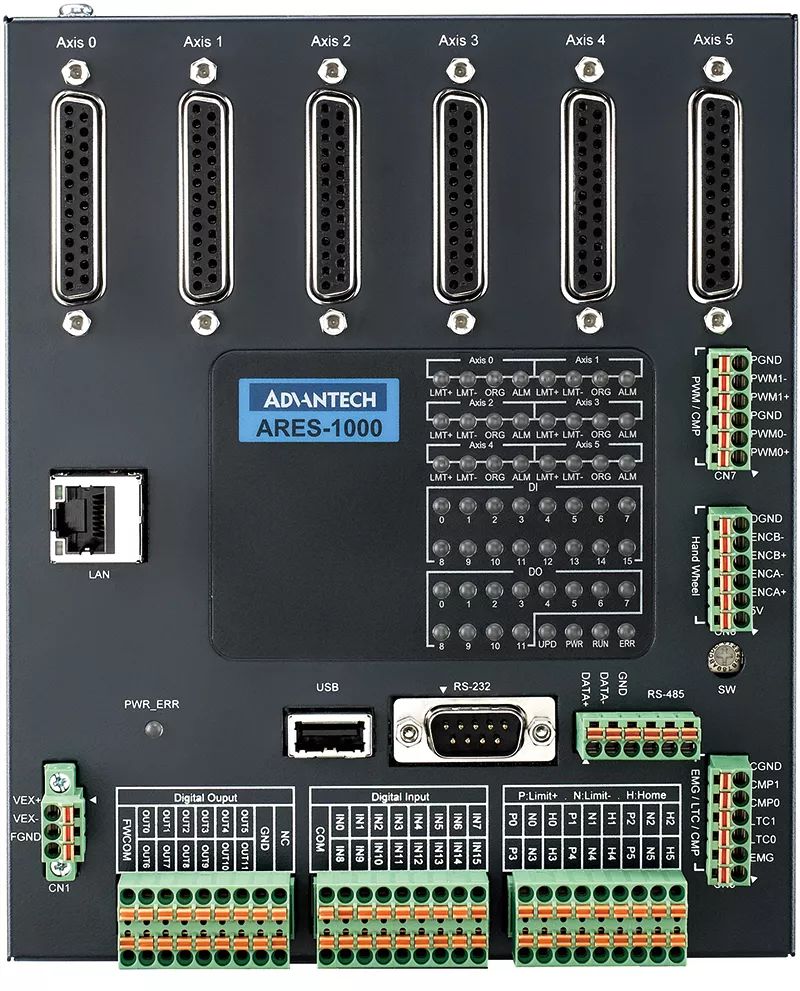

Taking Advantech’s first launched ARM-based ARES-1000 standalone motion controller as an example, it has significant advantages in the integration with industrial software. The ARES-1000 standalone motion controller features a high-precision and robust 6-axis synchronous motion control system, with an integrated compact design that combines motion and I/O control, and uses an ARM processor supporting real-time control, greatly improving the system’s operational efficiency and reliability.

In terms of software, the ARES-1000 is built with a Softmotion motion core, supporting multi-axis synchronous motion and high-precision trajectory planning; it also provides the ARES Developer software development environment, allowing for BASIC programming language design, shortening and simplifying the program development process. Through the integration of software and hardware, the ARES-1000 meets high precision, trajectory planning, and high-speed application needs while significantly reducing development costs and time, providing a cost-effective motion control solution for users in niche industries such as laser cutting and 3C dispensing.

For instance, in providing a 3D dispensing solution for the mobile phone industry, the ARES-1000 standalone motion controller uses 5-axis automation control, offers the ARES Developer software development environment, and a dedicated industry instruction module for 3D dispensing, supporting BASIC simple programming language and various motion trajectories and path planning. While meeting strict requirements for precision, accuracy, and speed, it achieves precise fluid transfer along the edges of the phone and the sides of components by adjusting the phone’s tilt to the optimal dispensing angle, thus addressing the issues of insufficient adhesion and poor sealing of traditional planar dispensing solutions, and shortening the project development time.

Facing the Future

Focusing on Integrated IoT Solutions

At the forum held this year on “Industrial IoT, Path to Industry Ecosystem Development”, Advantech Chairman Liu Kezhen pointed out that the industrial IoT is currently facing the dilemma of integrated applications, and industrial APPs tailored for different niche industry applications—industrial IoT system solutions—will be the breakthrough to solve the existing IoT dilemmas. Advantech is decoupling and restructuring its self-developed WISE-PaaS industrial IoT cloud platform, making it modular and microservice-oriented, allowing industry system integration partners to more easily extract some functional modules, further co-create complete services with Advantech, expand business opportunities, and construct a new industrial IoT value chain.

In this regard, Li Guozhong also mentioned that in the past, Advantech primarily developed products in the industrial control field in the form of “control cards”; now, surrounding the WISE-PaaS platform, Advantech provides a complete set of solutions including controllers + software, along with co-creation collaborations with specialized development teams in various niche fields,which has now formed a diversified SRP (Solution Ready Packages) industry solution on the WISE-PaaS platform, allowing end-users to directly procure and deploy.

For example, Advantech’s MAS controller integrates a Softmotion core to achieve complex motion control and, through its PC-Based open characteristics, runs third-party Windows vision software. Meanwhile, through Advantech’s MotionStudio software’s open interface and communication, it provides graphical development modules and a wealth of craft instructions, assisting users in quickly developing automation equipment within a limited time. This solution integrates the device’s “brain,” “eyes,” and “hands,” combining motion control, machine vision, MO control, and massive data access, allowing seamless connection of equipment with Industry 4.0, simplifying architecture, shortening development time, reducing costs, and offering flexible scalability.

To further advance the integrated IoT solutions systematically and comprehensively, the field of machine vision is also a significant focus for Advantech. Machine vision is not only a hot topic in the current IoT field but is also developing rapidly; with the continuous acceleration of smart manufacturing processes, the development of machine vision is gradually entering the “deep water zone.” The deep integration of AI and machine vision has endowed industrial equipment with “eagle-eyed” capabilities, empowering traditional machine vision with training, inference, and retraining capabilities through deep learning, which is the current focus of research and development in the field of machine vision. As a result, Advantech has quickly gathered existing technical teams and product organizations to focus on R&D and is now capable of providing comprehensive AI-based deep learning machine vision solutions for specific industry applications.

Currently, Advantech’s deep learning machine vision solutions essentially include industrial servers for training (4U rack-mounted GPU server SKY-6400, Intel Xeon processors), accelerators with powerful and scalable edge inference engines (including smart cameras ICAM-7000, modular industrial computers MIC-7000/UNO-3000), and Intel OpenVino SDK toolkits, greatly simplifying the development and deployment of deep learning models. This allows users to benefit from a higher degree of automation, intelligence, precision, and efficiency in production lines through intelligent machine vision systems, enjoying efficiency and cost advantages.

For instance, in the digital production process in factories, OCR is mainly used to recognize and read alphanumeric texts on labels, materials, parts, and finished products, which is crucial for ensuring the traceability of products throughout their lifecycle. Advantech’s deep learning-based OCR solution greatly reduces the complexity of recognition through image labeling, training, and inference processes, being more accurate and intelligent compared to traditional OCR solutions; additionally, Advantech’s deep learning-based defect detection solution continuously accumulates experience in various defect types through training, inference, and retraining processes, enhancing the precise identification of defect types and solving the problems of missed and false detections that may occur in traditional automatic optical inspection (AOI) systems.

The development of industrial IoT has become an important driving force for the transformation and upgrading of the manufacturing industry, Advantech is following the development plan set by the enterprise, keeping up with market development trends, and continuously innovating to strengthen visibility in vertical markets. In the future, Advantech will continue to collaborate with equipment manufacturers to focus on in-depth research in various fields such as buses, controllers, software integration, deep integration of AI and machine vision, cloud computing, and promote integrated IoT solutions as the main development axis, targeting niche fields such as renewable energy, photovoltaics, semiconductors, automotive parts inspection, and laser processing. At the same time, Advantech will always be customer-value-oriented, using pre-sales “pain point” analysis + post-sales problem tracking as the team’s operational approach to provide high-quality one-stop services for customers.

It is worth mentioning that Advantech will continue to strengthen the value of WISE-PaaS through its self-built industrial IoT cloud platform, integrating internal and external resources, collaborating with upstream and downstream partners in the IoT industry chain to implement industrial IoT applications across various industries, and jointly creating an open, integrated, and symbiotic IoT ecosystem.

End

Previous Highlights

Why Can’t We Compete with Japan on Gear Reducer Principles?

PID Three-Loop Control Can Also Solve Vibration Issues This Way

Basic Principles of Servo Motor Steering Control

What Are High and Low Inertia in Servo Motors, and How to Match Them?

What Mechanical Transmission Ratio Is Most Suitable for Motion Control Systems?