Designing and building IoT hardware is always a pleasure. You can collaborate with hardware designers to create prototypes, run them with stakeholders, and develop practical, tangible products for your IoT environment.

However, what does this process require, what are the key considerations, and what should be taken into account before building hardware? This article answers all your questions.

Connected devices form the foundation of the IoT. From industrial equipment and buildings to goods transport and pipelines, these IoT devices are ubiquitous, capable of transmitting data and monitoring set metrics. Major examples of IoT devices include pressure sensors in pipelines, microchips inserted under the skin of cattle, and temperature sensors in refrigerator trailers.

Both hardware and software components are designed according to standard design protocols for IoT applications and are ultimately integrated with communication networks. Popular platforms like Arduino Uno and Raspberry Pi enable rapid prototyping without extensive custom development, thereby accelerating the time required to implement IoT configurations.

You will see that design requires determining performance requirements, necessary hardware and software, and then specifying components based on environmental considerations and the applications in which they will be used.

Hardware Design for IoT Projects

In hardware design, everything boils down to a clear understanding of the client’s business needs. You must consider the minutest details of components and data specifications, ensuring they align with the ultimate goals.

Before designing the hardware for an IoT project, ensure your team has answers to the following questions:

-

What physical signals must be measured?

-

Should sensors connect directly to the cloud or through a gateway device?

-

How often should we collect signals, and how fast should data be exchanged over the network?

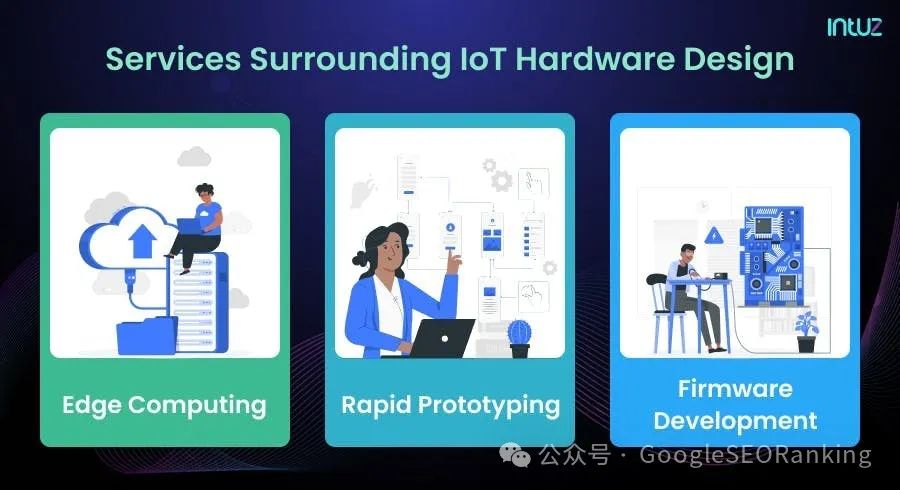

Services Around IoT Hardware Design

Whoever you designate for your IoT hardware design project should have the capability and experience to develop hardware that aligns with your core functionalities so that you can maximize the output from your IoT products.

They should be capable of handling all challenges related to integration into the existing technology stack to achieve seamless performance and complete custom IoT hardware design:

1. Edge Computing

Deploying edge computing on IoT devices rather than traditional cloud computing to achieve lower latency rates and faster offloading times. Manage access points by processing data in real-time and saving storage space, instead of collecting all data in the cloud for later analysis.

2. Rapid Prototyping

Building market-ready solutions requires time and money. Therefore, ensuring your product design and functionalities meet market expectations and requirements is crucial.

Whether you are testing whether new hardware ideas work or simply reviewing business cases, prototypes can help you understand what works and what doesn’t. Additionally, you can use 3D printed casings, dashboards, and analytics.

3. Firmware Development

Building IoT hardware devices is only a small part of the puzzle. It helps if you have microprocessors and microcontrollers for IoT devices based on IoT firmware design, development, and testing. Obtain board support packages, device drivers, network connectivity, and power management for interconnected IoT devices.

Concepts of Arduino Uno and Raspberry Pi 2

IoT hardware includes a range of devices such as bridges, sensors, routers, etc., responsible for critical tasks like system activation, detection supporting specific goals, and device security and communication.

As mentioned earlier, IoT hardware components are diverse, ranging from low-power boards to single-board processors (like Arduino Uno and Raspberry Pi 2), which are essentially smaller boards that plug into a mainboard—resulting in specific functionalities like light and heat sensors, GPS, and interactive displays. Arduino Uno is an open-source device platform that helps create compatible development boards and tools.

Device functionalities vary among different official Arduino models and dozens of third-party compatible boards. This hardware allows IoT developers to program using Python, JavaScript, and Lua. The standard approach to software running on Arduino-compatible microcontrollers is to use C++, C, and Arduino IDE.

When implementing low-level hardware functionalities (such as deep sleep modes or reading data from IoT-connected devices), you may need to rely on device-specific libraries to make your wireless devices portable. Arduino Uno is a low-cost option that supports Bluetooth and WiFi connections, making it a popular solution among IoT application developers.

On the other hand, Raspberry Pi 2 is one of the most affordable (commonly used) IoT development boards on the market. It can be used as a credit card-sized mini PC board that can also run as a personal PC. Raspberry Pi 2 offers significant enhancements in memory, speed, and multimedia processing capabilities while maintaining power consumption levels and backward compatibility.

It is also compatible with various operating systems, uses standard keyboards and mice, and supports Python, Java, and Node.js packages. It features dual-band wireless LAN, Bluetooth, WiFi, and Ethernet connectivity. Raspberry Pi 2 is used for configuring digital media systems and monitoring cameras.

Additionally, the board can boot directly from a USB-connected pen drive or hard drive—one of the key USPs of Raspberry Pi 2.

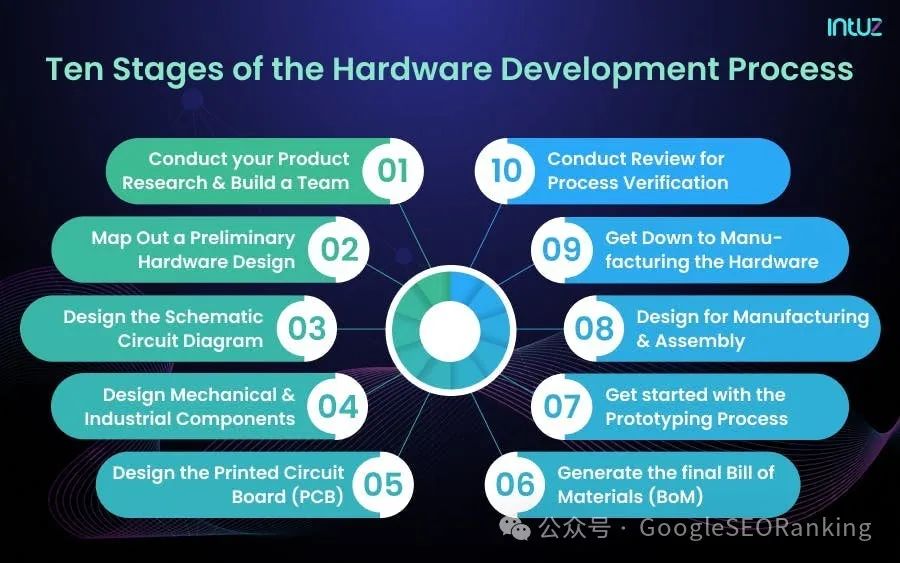

Ten Stages of the Hardware Development Process

Building hardware systems for IoT applications is itself a daunting task. Although IoT products consist of software, firmware, and hardware components, 80% of the costs and development hassles come from the latter.

Therefore, you must diligently and consciously follow this process. Don’t worry—we will detail the ten key stages in the following sections:

1. Conduct Product Research and Form a Team

First, what are you building? Include all details such as configuration, functionalities, market gaps, target customers, competing products, etc. Note the existing skills internally and the knowledge and expertise you must outsource.

Assuming you have formed a team consisting of solution designers, technical architects, and researchers. To build a Minimum Viable Product (MVP), besides listing the core product functionalities and extended features, you must clearly outline the development priorities.

The more you brainstorm with team members and talk to your target audience, the clearer your understanding of hardware development will be. Conduct thorough research and document your use cases in data sheets. Add QA resources at this stage to determine the feasibility of building test cases for IoT hardware devices.

2. Develop Preliminary Hardware Design

This is necessary to address the gap between design concepts and actual designs. Specify all electronic functionalities and how they interconnect with other functional components.

The microcontroller is the core component of any hardware product synchronized with sensors, storage chips, displays, etc. Therefore, select a microcontroller and then choose other relevant components for the hardware development process.

3. Design Schematic Circuit Diagrams

The circuit schematic primarily focuses on the product’s high-level functionalities, allowing you to consider the minutest details and components, such as sensors, microchips, and resistors.

Any mismatch in pin numbering could lead to overall product failure. Therefore, the design of the schematic must be very careful. Create a separate sub-circuit for each module for more efficient output in the hardware.

4. Design Mechanical and Industrial Components

“Computer-Aided Design and Drafting” or CAD is a technique that supports design and technical documentation to automate processes instead of manual drawing. It is used to design mechanical and industrial components.

Mechanical design follows all traditional principles to achieve fully compliant output. Depending on the type of hardware you are designing and your budget, choose CAD tools. Next, outline all design activities, including the purpose behind each design. The goal is to determine the value, functionality, and appearance of the hardware design for all components.

5. Design Printed Circuit Board (PCB)

Here are things you should never forget: the smaller the product, the more compact the components, and the more complex the creation of the PCB layout. If the product offers wireless connectivity, the design becomes even more complex. Crystal clocks, power wiring, address or data lines, etc., complicate the PCB.

To create the physical board for all electronic components, use verification tools to match the schematic with the conceived PCB process. Some well-known names include Altium Designer, Solidworks PCB, PCB Artist, etc.

6. Generate Final Bill of Materials (BoM)

The BoM is a list of all mechanical and electronic items to be procured. Whether low-cost or small components, note their quantities and specifications. Most schematic design software solutions populate the BoM.

Manually verify documentation before contacting suppliers. Finding reliable third-party suppliers is crucial since you don’t want to procure defective or poor-quality components. Make sure to choose wisely. Take time to talk to as many potential suppliers as possible.

7. Start the Prototyping Process

Prototyping connects your hardware product with the actual build that will someday hit the market. This is a critical step as it helps gauge the feasibility of the desired product. Besides saving time and effort, it ensures a fast and straightforward development process. You can prototype in-house or outsource it to skilled development agencies.

8. Design for Manufacturing and Assembly (DFMA)

Also known as DFMA, it simplifies manufacturing complexity and keeps overall costs low. DFMA helps facilitate large-scale manufacturing and minimizes the number of assembly steps for the product.

Before starting the process, consult manufacturing experts for input and analyze each component to control manufacturing costs. Follow all legitimate manufacturing processes and use standardized parts to avoid inventory complexity.

9. Start Manufacturing Hardware

Once you’ve finished your home, completed your prototype, and received stakeholder approval, you can start making hardware. Ensure you find a reliable manufacturing partner suitable for the job.

At this stage, you also need to identify and resolve any remaining issues in the design, as well as fix assembly fixtures and errors. This step often takes the longest to complete.

10. Conduct Process Validation Review

Once you have tried and tested production of 100 units in the previous stage, you can ramp up production to 100-200 units. Perform multiple build tests to assess whether your workflow is ready for mass production. You may still encounter some failures during this process. Don’t panic; instead, use this opportunity to identify and resolve all issues.

Three Building Blocks of IoT Hardware

Due to the multitude of IoT applications, it is impossible to generalize hardware architecture. However, this should not stop you from following a framework. Each IoT application consists of three standard “building blocks”:

1. Data Acquisition Module

This focuses on acquiring physical signals from “things” or “IoT assets” and converting them into digital signals that can be manipulated by computers. This hardware component includes various types of sensors such as motion, vibration, temperature, light, etc.

The signals received from sensors are converted into digital information in the computer for use. Key factors that need to be considered in the data acquisition model include the number and types of sensors that need to be measured and the accuracy of the measurements.

2. Data Processing Module

This is the “computer” that processes data acquired from IoT assets, locally stores data, performs regional analysis, and executes any other computing operations at the edge. This arrangement does not require you to be an expert in computer architecture.

Your role should be to understand the overall product goals and ask the right questions to guide your team. The main considerations for this module are processing power and the amount of local data storage.

The decisions you make here should directly relate to functionality, performance, device size, lifecycle, etc.

3. Communication Module

This refers to the circuitry that can communicate with cloud solutions. This model may include communication ports such as CAN, USB, and Modbus, as well as radio technologies for wireless communication including LoRA, 3G, 5G, ZigBee, and WiFi.

The communication module can be included within the same device as the other modules or can be a separate device specifically for communication.

Best Practices for Choosing Hardware Design for IoT Projects: A Hardware Design Guide

IoT devices are highly specialized and unique. They are designed to operate in niche environments. Of course, hardware options will also reflect the uniqueness of IoT devices. So, what are the main hardware requirements in the IoT development process? What key points should be remembered? Let’s explore:

1. Security

Clearly, your IoT devices must be the most secure devices on the planet. Therefore, even during the prototyping process, it is crucial to maintain data integrity and security of the devices. Security parameters apply to the relevant IoT devices, your communication networks, mobile and web service applications, and the cloud.

2. Power Parameters

Consider whether your device requires hardwired power or if it needs a portable power source (such as a battery). If a battery is needed, note its size, weight, and capacity requirements. Additionally, if it is a “rechargeable” type of battery, understand how often it should be charged.

3. Ease of Development

Ultimately, you want your IoT devices to start up and run quickly—without any hassle. It should capture data, communicate with other connected devices in the cloud, and become the best product for end-users. If creating IoT hardware design is painful, then that’s a problem.

4. Connectivity Requirements

This relates to wireless networks. How far do you want digital signals to transmit? How much data do you want to transmit and at what rate? Consider “fault tolerance” options. Your hardware may need upgrades to reconnect data more flexibly.

5. Data Collection, Processing, and Storage Conditions

The number of sensors connected to IoT devices, the resolution of the data captured by the connection system, and the rate at which the collected data is sampled are important components of data processing. The amount of data stored on the device depends on the frequency with which the device connects to upstream data transmission.

Conclusion

Every IoT application is different. There is no one-size-fits-all approach to hardware selection (or development) for IoT projects. Therefore, adopting standardized commodity hardware such as single-board computers and microcontrollers can save your time and money resources in the early stages of the development process.

As an IoT application development company, we are responsible for the entire development process—from conceptualizing ideas, prototyping, manufacturing design to firmware development and quality control. We provide our clients with mature IoT hardware development services.