There are various communication methods between Siemens WINCC and Siemens PLC. Below are two commonly used communication methods.

1. Using a standard network card to communicate with the PLC via TCP/IP. The prerequisite for connecting WINCC with the PLC system through Ethernet is that the PLC system is configured with an Ethernet module or uses a PLC with a PN interface. Ethernet modules such as CP443-1 or CP343-1, and PLCs with PN interfaces such as CPU 315-2PN/DP.

Below is the communication connection using the standard network card CP443-1.

1. STEP7 Hardware Configuration

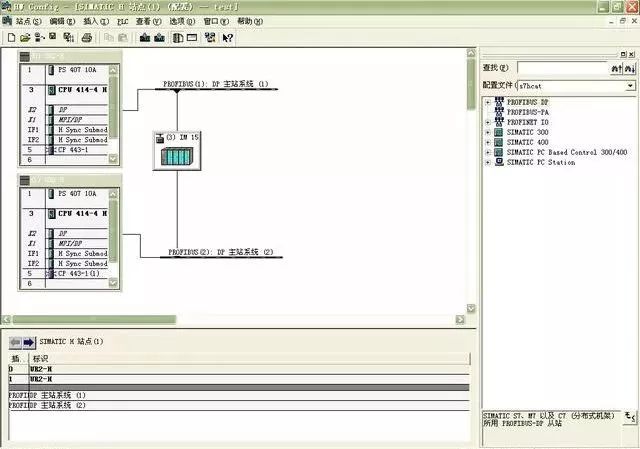

Use the STEP7 programming software to perform hardware configuration for the PLC system. Insert the actual PLC hardware in the “Hardware” configuration window, as shown in Figure 1:

Figure 1 STEP7 Hardware Configuration

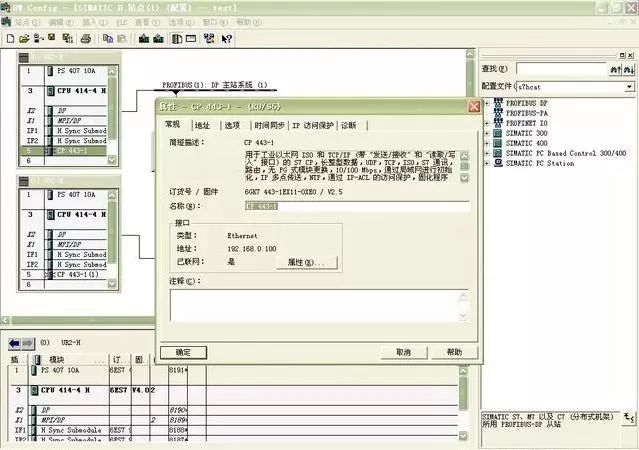

2. Double-click on the CP443-1 slot of CP443-1 to open the properties dialog box, as shown in Figure 2:

Figure 2 CP443-1 Properties Dialog Box

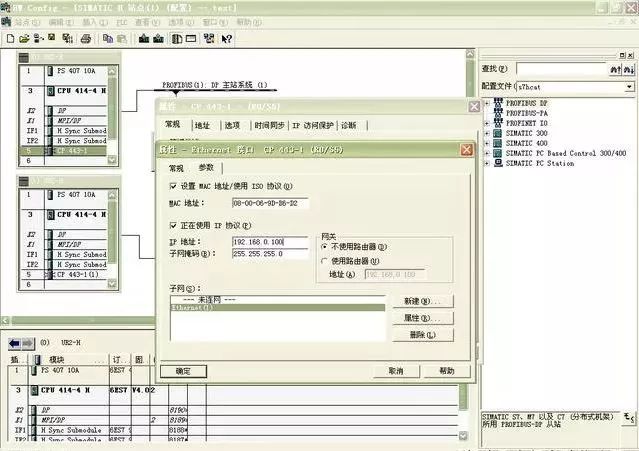

3. Click on the properties dialog box in Figure 2 to open the network parameter settings dialog box. Click the “New” button to create a new Ethernet network, input the IP address of the Ethernet module CP443-1. Generally, there is no need to enable the gateway. As shown in Figure 3:

Figure 3 Parameter Settings

Note:If using TCP/IP protocol for communication, “Using IP Protocol” must be enabled, and the configured hardware must be downloaded to the CPU, thus completing the PLC settings!

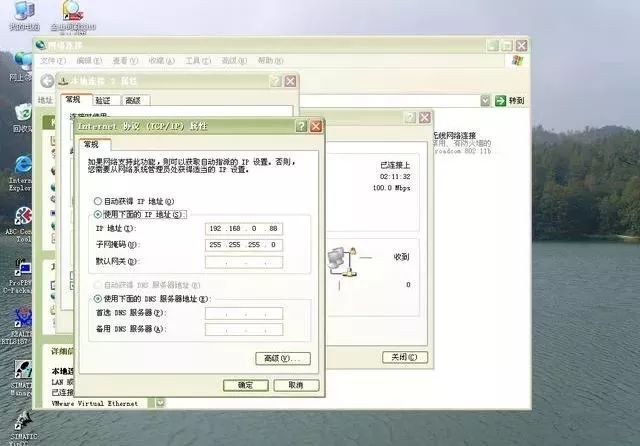

4. Set the TCP/IP parameters of the WINN (usually for Engineer Station ES and Operator Station OS) computer’s Windows operating system. Set the IP address of the WINN configuration computer to be within the same network segment as the PLC Ethernet communication module or PN interface address, as shown in Figure 4:

Figure 4 Set Computer IP Address

5. Add new drivers and set system parameters. Open the newly created project “test”, select “Variable Management” in the project management bar, right-click to select “Add New Driver”, as shown in Figure 5.

Figure 5 Add Driver

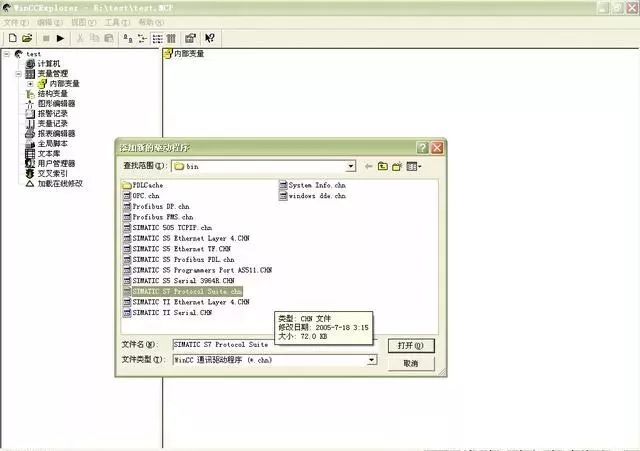

6. In the folder for adding new driver, select “SIMATIC S7 Protocol Suite.chn”, as shown in Figure 6:

Figure 6 Driver

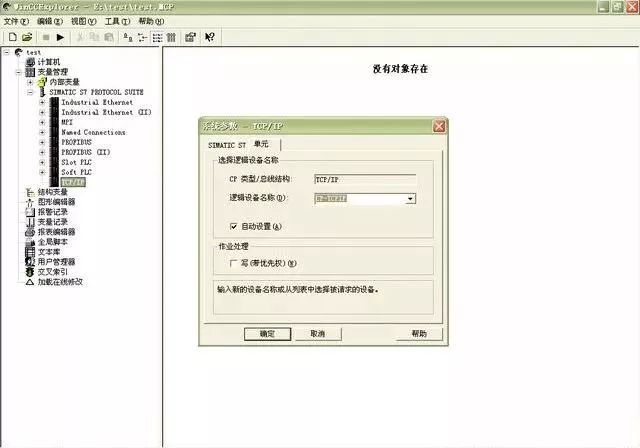

7. Right-click on TCP/IP, and in the pop-up menu click “System Parameters”, as shown in Figure 7. The “System Parameters – TCP/IP Dialog” will pop up. Select the “Unit” tab to view the “Logical Device Name”, which is generally set to CP-TCP/IP after default installation.

Figure 7 System Parameters – TCP/IP Settings

8. Add channel and connection settings

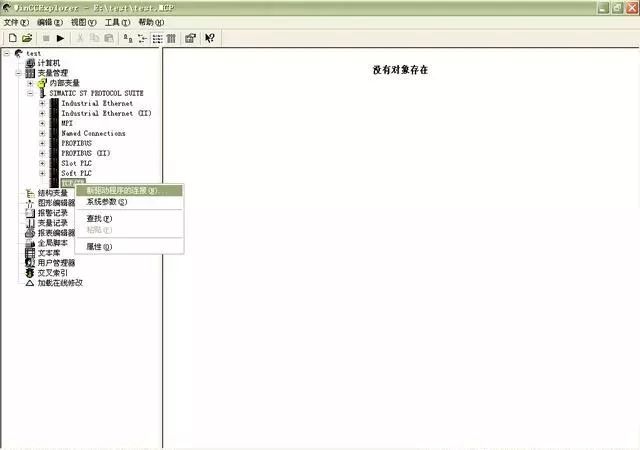

Add driver connections and set parameters. Open the WINCC6.0 project, in “Variable Management”, right-click on TCP/IP, in the drop-down menu, click “New Driver Connection (N)”, as shown in Figure 8:

Figure 8 Add Communication Connection

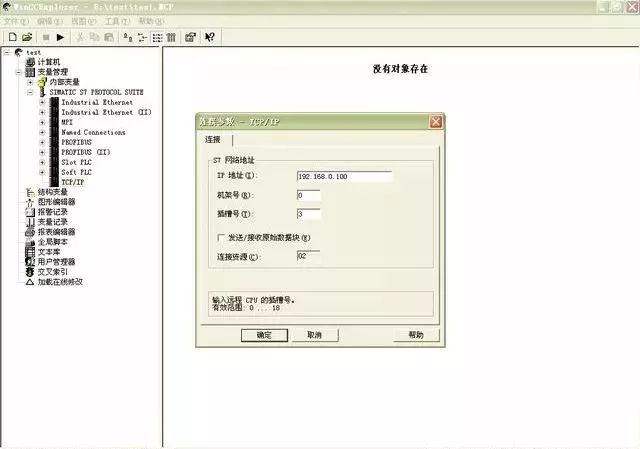

9. In the pop-up “Connection Properties” dialog box, click the “Properties” button to open the “Connection Parameters – TCP/IP Properties” dialog. Input the IP address of the Ethernet module or the CPU with PN interface that has been set in the STEP7 hardware configuration, the rack number, and the Ethernet card slot number, as shown in Figure 9:

Figure 9 TCP/IP Parameter Settings

Notes:

IP Address: The IP address of the communication module, e.g., CP443-1 is 192.168.0.100

Rack Number: The rack number of the CPU, usually filled in as 0

Slot Number: The slot number of the CPU

Note: If it is an S7-300 PLC, the slot number parameter is 2. If it is an S7-400 PLC, the slot number must be checked in the STEP7 project hardware configuration, which could be 2, 3, or 4 (mainly depending on the power supply size), otherwise communication cannot be established.

2. In WINCC6.0, Named connections are commonly used for connections with S7-400H, based on the PC station’s Configure mode. Other channels, such as MPI, PROFIBUS, and TCP/IP, are based on PG mode.

Below is the introduction on communicating with PLC through Named connections:

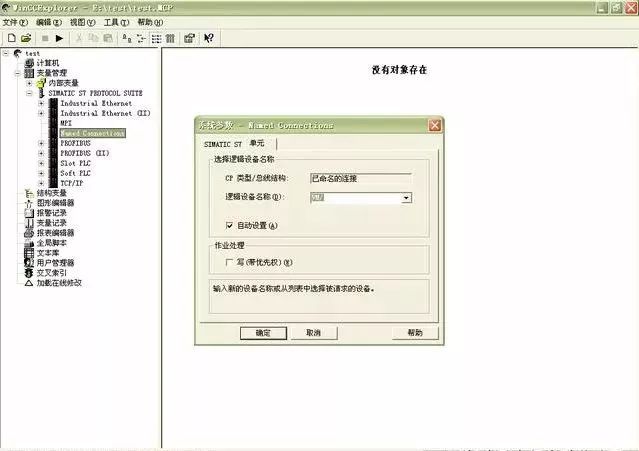

1. Right-click on Named connections, and in the pop-up menu click “System Parameters”, as shown in Figure 10. The “System Parameters – Named Connections Dialog” will pop up. Select the “Unit” tab to view the “Logical Device Name”, which is generally set to VM/ after default installation.

Figure 10 System Parameters – Named Connections Dialog

2. Add channel and connection settings

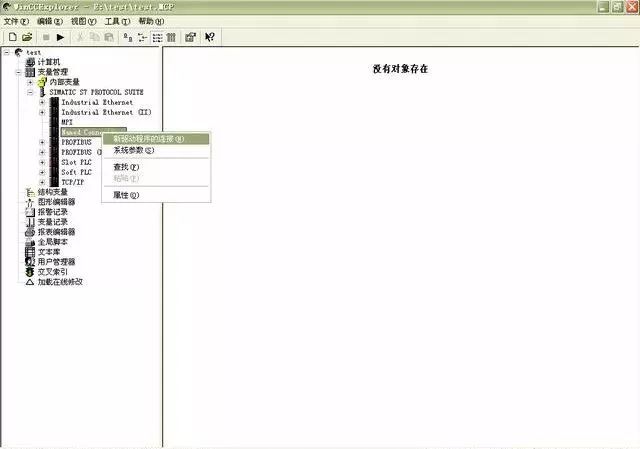

Add driver connections and set parameters. Open the WINCC6.0 project in “Variable Management”, right-click on Named connections, and in the drop-down menu, click “New Driver Connection (N)”, as shown in Figure 11:

Figure 11 Add Communication Connection

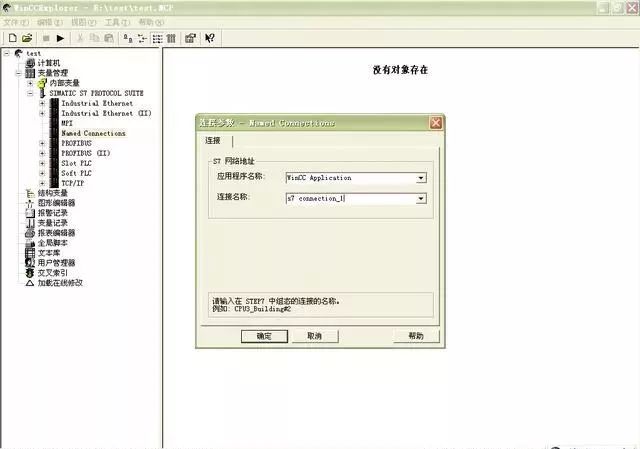

3. In the pop-up “Connection Properties” dialog box, click the “Properties” button to open the “Connection Parameters – Named Connections Properties” dialog. Input the S7 network address, specify the “Application Name” and “Connection Name”, as shown in Figure 12:

Figure 12 Connection Parameters – Named Connections Properties

Finally, click OK!

Article source: Internet, copyright belongs to the original author. If there is infringement, please contact for deletion!

2021 Junior Electrician Exam Question Bank Complete Version (Includes Answers)

Inverter Fault Query and Repair Difficulties? Just One Click!

One Click to Brush Through All Electrical Exam Questions, Don’t You Have This Artifact Yet?

Five Major Electrical Drawing Software (CAD, Eplan, CADe_simu…), Which One Do You Pick?

Latest Electrical Version CAD Drawing Software, with Super Detailed Installation Tutorial!

Latest Electrical Drawing Software EPLAN, with Super Detailed Installation Tutorial!

Common Issues for Beginners Using S7-200 SMART Programming Software (Includes Download Link)

Super Comprehensive Electrical Calculation EXCEL Sheets, Automatically Generated! No Need to Ask for Electrical Calculations!

Bluetooth Headphones, Electrician/PLC Introductory Books Available? Come and Claim Your Electrical Gifts!

Basic Skills of PLC Programming: Ladder Diagrams and Control Circuits (Includes 1164 Practical Cases of Mitsubishi PLC)

Still Can’t Understand Electrical Diagrams? Basic Electrical Diagram Reading, Simulation Software Available, Quickly Get Started with Theory and Practice!

12 Free Electrician Video Courses, 10GB Software/Ebook Materials, 30 Days of Free Electrician Live Classes!