Previous Article

Starting from this issue, the author will discuss the three main stages of the body design and development process in three parts: upper, middle, and lower. This will identify the key work focuses of each stage and share experiences and lessons learned in development management with readers.

Body design and development is a part of the overall vehicle development project. Due to the special nature of the load-bearing body, the technical integration of body design and development is high, the workload is large, and many professionals and personnel are involved. The external interfaces are complex, and the requirements for concurrent engineering are strict; therefore, we will discuss it independently.

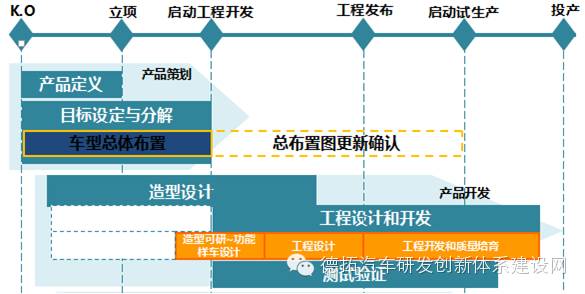

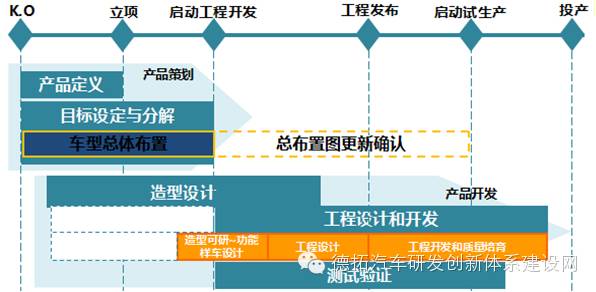

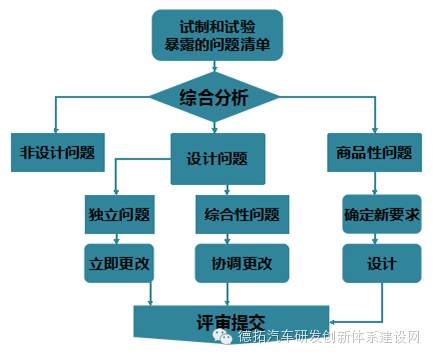

We divide the design and development of sedan bodies into the following three main stages (see Figure 1):

● Feasibility study of styling, engineering feasibility study, design of functional prototypes;

● Engineering design;

● Engineering development and quality cultivation.

Figure 1 Overall Vehicle Product Development Process

Figure 1 Overall Vehicle Product Development Process

Next, we will enter the discussion of the first stage, “Feasibility Study of Styling, Engineering Feasibility Study, Design of Functional Prototypes”:

1. Feasibility Study of Styling

When the overall layout provides a preliminary control point diagram, and the styling provides the internal and external CAS surfaces (3D digital surfaces), the body must conduct a feasibility study on styling (referred to as styling feasibility study).

In the industry, stylists are referred to as Designers—they are the true proposers of concepts and ideas, thus enjoying the highest authority in development.

However, the creativity of the stylist needs to be realized through engineering. Therefore, as its technical support, the body department must first analyze the overall and partial realization methods and costs of the idea, i.e., feasibility; this work is the styling feasibility study.

This stage mainly involves geometric drawing and analysis of the body:

— Selecting the structural form of relevant components (which is also the creativity and concept of body components);

— Drawing the cross-sections of components, determining connection relationships, and further refining the spatial layout, i.e., making a layout;

— Placing the main cross-sections of the white body between the internal and external CAS surfaces to determine whether the main cross-sections are guaranteed;

— Conducting regulatory compliance analysis.

For insufficient geometric space, excessively high costs of implementing styling elements, and regulatory non-compliance, negotiations and adjustments need to be made with the styling department.

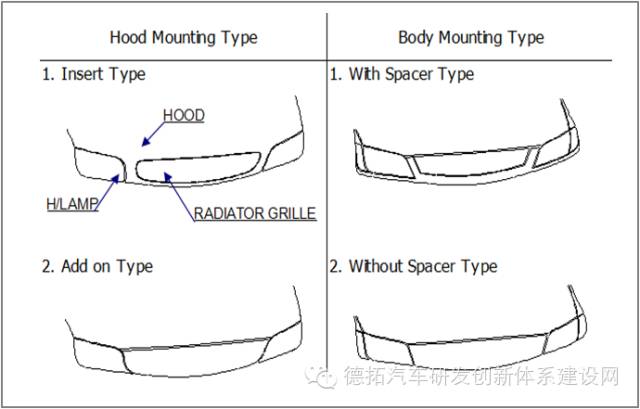

Taking structural selection as an example:

Figure 2 shows a comparative diagram of the installation schemes for the front grille. Some are installed on the engine hood, while others are installed on the bumper or the body. Among those installed on the hood, there are embedded and metal plate-connected types. The aesthetic effects, structural weights, and manufacturing costs of these schemes differ. Therefore, similar structural schemes must be finalized with styling to ensure that aesthetics can be realized and to lock down the seam lines, allowing the body to determine the general structure and installation relationships, project approval costs, and product competitiveness.

Figure 2 Front Grille Installation Methods

Figure 2 Front Grille Installation Methods

For a mature body design team with ample experience, the structural selection process is very simple. If the styling is clearly expressed in the renderings, and the body and related departments clarify that it is a structure reused from a previous vehicle, it is considered finalized. For new structures, analysis is required.

For a young team, this type of structure needs to be carefully discussed together, compared laterally, and ultimately selected.

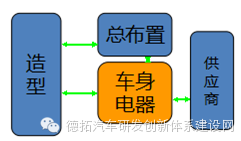

The styling feasibility study period is a collaborative process involving multiple specialties. Their general interface relationships are shown in Figure 3:

Figure 3 Analysis Transfer Window of Styling Feasibility Study

Figure 3 Analysis Transfer Window of Styling Feasibility Study

During this period, the overall layout mainly controls and coordinates hard points, while the body electrical department develops structural concepts and geometric layouts to support the realization of styling. For some issues at the technical boundary, support from suppliers with strong technical capabilities is also needed.

The completion of the styling feasibility study is marked by reaching a consensus on the feasibility of internal and external styling elements and profiles, the basic completion of the body structure concept, meeting the overall layout requirements, and freezing the clay model.

2. Engineering Feasibility Study

The engineering feasibility study mainly accomplishes two tasks:

● Preliminary analysis and virtual verification of body performance;

● Feasibility of manufacturing and assembly.

After completing the styling feasibility study (geometric feasibility), the body proceeds with the preliminary 3D drawing of the white body and opening parts, design of interior and exterior trim and equipment components, and installation layout of parts. The parts are assigned material definitions, and the resulting 3D can be subjected to simulation analyses for weight, strength, stiffness, passive safety, NVH, etc., against target requirements to determine the performance of the body and components. If standards cannot be met, repeated optimizations are necessary.

At the same time, the 3D data is handed over to the manufacturing department for process analysis:

— Stamping forming analysis

— Welding sequence, welding gun accessibility, welding strength analysis

— Paint drainage analysis

— Overall assembly process analysis

— Dimensional engineering analysis

It should be noted that the selection of important new processes and new structures has been determined beforehand, but it does not exclude final discussions and decisions during this stage.

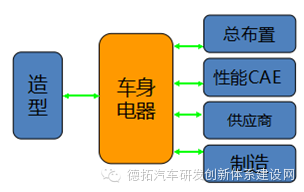

The engineering feasibility study is also a process of multi-interface transfer and multiple rounds of modification and optimization, as shown in Figure 4:

Figure 4 Interfaces of Engineering Feasibility Study

Figure 4 Interfaces of Engineering Feasibility Study

Just for performance simulation, for a single indicator such as the overall mode of the body or local mode, multiple adjustments of the 3D model are often required. When the indicator meets the standard, other performances still need to be verified to ensure that modifications do not weaken them.

Modifications proposed due to process issues also need to trace back and evaluate whether other performances and functions are affected.

3. Design of Functional Prototypes

Currently, at the general design level in China, the development of basic vehicle models still requires the production of functional prototypes to verify the geometric quality of the design (no static or dynamic interference), manufacturing process feasibility, overall vehicle quality, etc. The product department also needs physical vehicles for competitive capability evaluation.

The cost of prototype manufacturing is high, and it requires a certain period. Moreover, the interior and exterior trim can only be made into rapid prototyping parts, thus the verification of prototypes can only be limited to functionality and partial performance. The prototype plan must be strictly compiled according to the needs that can be met. Due to off-site production, sometimes metal materials must be replaced.

Additionally, this stage may not necessarily produce all the defined models according to the configuration requirements of product planning. Therefore, the design of trial prototypes and the BOM definition only represents a portion of the representative models that must be verified at this stage.

The condition for designing functional prototypes is that the styling A surface is frozen, and the 3D files after meeting the targets of the engineering feasibility study are completed. The output of prototype design is based on the engineering feasibility study, completing all installations such as powertrains and pipelines, chassis pipelines, electrical components and harness layouts, and handling all installation connection details of body parts themselves. Due to time constraints, 2D drawings may not be fully completed.

In summary, we can see that in sedan development, due to the adoption of concurrent engineering, the entire body design and development process accompanying styling design is highly integrated, with many design interfaces and complex threads. This requires a strong project department to coordinate all parties.

We often encounter the following situations: the plan is arranged, and all parties have no objections, but in actual work, the interfaces of all parties cannot be in place on time. It’s like a performance where the curtain has been raised, one character’s lines are halfway through, and the other character has not appeared, making it impossible to continue. Or someone appears, but the lines do not match, and the heart is not in place.

Therefore, in modern sedan project development, several guarantees must be obtained:

● Internal Organizational Assurance

Not only must sufficient human resources be obtained in a timely manner, but the qualifications of core personnel must also be ensured. Some companies have insufficient core personnel, assigning the same person to every project, resulting in these personnel having to attend every project meeting. A large number of pending matters are recorded in their notebooks, but they have no time to address them, causing project delays.

● Suppliers with Development Strength in Place

It should be acknowledged that many suppliers are at a higher level than the OEMs in their professional fields. This is the result of social specialization. For the same component, the OEM may only experience it once every 1-2 years, while the supplier may experience it several times in a year, thus their accumulation and improvement conditions are better than those of the OEM.

For the project, whether suppliers can timely complete work directly affects the quality and progress. However, whether the identity of the suppliers is confirmed also involves the agreement on component prices. When the definition of a component is not clear, the price is uncertain. Without a quote, there is no supplier identity, and without an identity, they cannot participate in definition and development, leading to a vicious cycle, causing project delays.

● New Structures and New Processes

New structures and processes involved must be proposed and researched to reach a unified opinion in advance. All new things will have many unknown factors, requiring a process of understanding and mastering. Even if a decision is made to adopt them, continuous tracking is needed to ensure synchronization with other mature technologies.

There are also factors that can affect the progress of body development. The project department must have a general assessment in advance, make good plans, and control the project process.

The development process described in this article is based on the specific practices of certain companies and is not adopted by all companies. For a non-fully forward project, the styling feasibility study and engineering feasibility study do not necessarily have to be distinctly separated, as some feasibility is implicit within.

For some relatively stable model changes, when the enterprise’s virtual verification capability is strong, prototypes are no longer made. In summary, the choice of design and development process is determined by the level of the enterprise and the difficulty of the project. The project department of the enterprise must choose a development process that suits itself, carefully track the project, and control the review of each node to avoid the project progressing with problems, ultimately achieving full compliance with project standards.

Middle Part

In the previous article in the product development series of the system construction network, the author introduced that according to the upper, middle, and lower parts, the key work focuses of the development process and the lessons learned from body development will be discussed in three main stages of sedan body design and development:

First Stage: Feasibility Study of Styling, Engineering Feasibility Study, Design of Functional Prototypes

Second Stage: Engineering Design

Third Stage: Engineering Development and Quality Cultivation

In the previous article, we discussed the feasibility study of styling, engineering feasibility study, and design of functional prototypes. This article will summarize the key work focuses and difficulties of the engineering design stage (as shown in Figure 5).

Figure 5 Overall Vehicle Product Development Process

Figure 5 Overall Vehicle Product Development Process

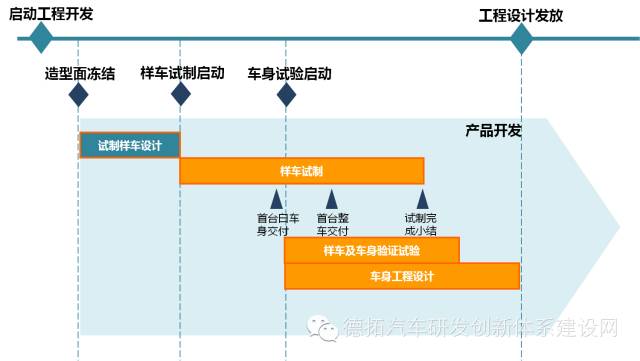

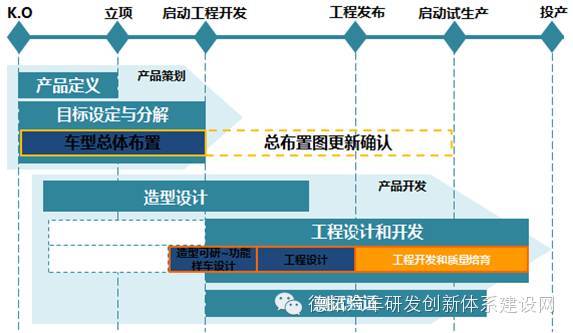

For basic models, the engineering design stage generally includes the trial production of PROTOTYPE functional prototypes, validation tests for prototypes and components, engineering design, and engineering design release. Although prototype trial production and testing are not operated by the body department, they still constitute a whole with engineering design (as shown in Figure 6).

Figure 6 Engineering Design Stage

Figure 6 Engineering Design Stage

For modern design and development, verification work accompanies the entire design process and gradually replaces full vehicle road tests with bench tests, and CAE simulation analysis gradually replaces physical verification. However, for long-cycle projects such as sedan design and development, although the development cycle is repeatedly compressed, some physical verifications still cannot or cannot be completely eliminated. Therefore, most companies still produce soft molds and conduct prototype trials primarily using metal bodies for the development of basic models, while non-metal components mostly use rapid prototyping.

Despite adopting such a process, various issues may still arise if caution is not exercised, hindering the normal operation of the project. Therefore, the author wants to share experiences and lessons based on some companies’ actual operations. Due to space limitations, the article cannot elaborate on the design process but will focus more on highlighting some key points and difficulties in body engineering design from the perspective of verification and confirmation.

1. Verification Needs and Trial Production of Prototypes

The trial production and verification of prototypes can mainly solve the following issues and avoid major risks:

● Through trial production, the geometric quality, stamping formability, and welding feasibility of the design can be verified;

● Through the main performance tests of the white body and opening parts, the performance of the body can be confirmed;

● Through collision tests of the entire vehicle, the passive safety level of the basic body can be grasped; if there are issues, adjustments can be made promptly;

● Through the assembly and functionality verification of the entire vehicle, basic confirmation of assembly feasibility and overall vehicle functionality can be achieved; at the same time, the product department can promptly conduct product evaluations and propose adjustment suggestions if necessary.

Once engineering development begins, a large amount of funding and human resources are invested, which means the entire project is irreversible. The success or failure of the project hinges on this, so many companies still conduct the above trials and verifications, referring to this process as functional prototype trial production and testing, i.e., Function Trial.

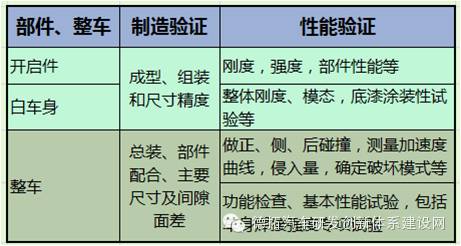

The arrangement and workload of prototype trial production depend entirely on the verification needs. Generally, there will be:

Table 1 Functional Prototype Testing

Table 1 Functional Prototype Testing

Table 1 lists the main contents of verification during the functional prototype stage. Under the current rapid advancement of CAE simulation technology, most verifications have undergone analysis and optimization during the engineering feasibility study stage, with the scope of analysis often far exceeding the above items, including NVH, flow fields, thermal dynamics, durability, etc. However, since CAE analysis is mostly in the development and improvement stage, to avoid errors, most companies still confirm through physical vehicle verification.

The table also shows that the output of prototype trials is not only the complete vehicle but also white bodies and opening parts. These needs come not only from the OEM but also from suppliers and, in special cases, from regulatory departments. Therefore:

● Prototypes and samples must first have a demand plan, which includes all necessary testing and verification items, submission times, quantities, and special requirements;

● Prototypes must have specific design definition documents, including 3D, necessary 2D, and BOM. The design definition documents must reflect all the above needs, i.e., the required parts and vehicles, and also serve as the basis for transitioning to engineering design;

● The trial production of prototypes and samples must have detailed plans to facilitate the trial production, ordering, assembly, acceptance of parts, and also facilitate the coordination with subsequent departments, including preparation of testing devices and personnel.

Due to the extremely high cost of prototype trial production, the quantity of prototypes needed must be discussed repeatedly, and usage must be arranged comprehensively. Moreover, some trial-produced parts may not necessarily meet the final definition, and their representativeness for verification needs to be recognized by the demand department.

2. Body Engineering Design

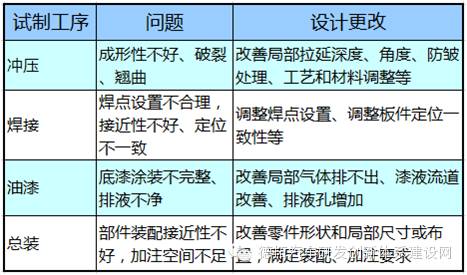

The engineering design stage mainly involves continuous modifications and improvements to the prototype design. Starting from the trial production of body parts, various problems begin to emerge, primarily the major design issues and handling solutions (as shown in Table 2):

Table 2 Common Issues During Trial Production Verification

Table 2 Common Issues During Trial Production Verification

Some independent issues can be immediately modified by the body department. For comprehensive issues, multi-department research and resolution are required. For enterprises with rich experience, adequate reviews, and high simulation levels, not all of the above issues may occur. However, special situations, especially with new organizations, new materials, and new components, often present more issues, which aligns with the process of human understanding of things.

Here, the author can share some frequently encountered problems:

1. During trial production, some issues are often found, but operators modify them on their own during assembly, which is not reflected in the problem records, leading to the same issues during the next assembly. This modification may seem to speed up trial production, but it contradicts the purpose of trial production: to expose design issues. All problems encountered during the production and assembly process must be recorded and described in detail for analysis and improvement by the design department and tracking by the project management department. It should never be understood that just assembling a few vehicles for testing completes the task.

2. Some amusing problems often arise during development, such as: after completing a test, a list of failures and failure modes is submitted, but someone in the design department says that some components were installed incorrectly and do not meet our definition. This leads to wasted manpower, process time, and costs for the trial production testing department. Therefore, the components used for testing must meet the definition and have representativeness; all trial parts must also be recognized and meet necessary quality standards.

3. After receiving feedback on failure issues, the design department promptly begins to modify the design, which is indeed a very good attitude. However, whether the failure phenomenon is clear, whether the cause of the failure is found, whether it is a design issue or related to process, materials, management, etc. is critical. Rushing to modify without identifying the root cause of the problem may lead to continuous modifications in the future. I once experienced this in an internationally advanced automotive company: after less than 2000km of testing, the gearbox gear broke. The head of the testing department fed back the issue, and I casually replied, “We have a spare part.” The head of the testing department, looking serious, asked me: “The problem is not found; what happens when this spare part goes in again after 2000km?”

In the engineering design stage, as more personnel are involved, the complexity of problems increases, making project control more difficult. Therefore, during the verification process, a rigorous attitude is needed for problem management. Additionally, a comprehensive inventory and analysis of problems is required, and centralized decisions and change plans must be made. Furthermore, more issues will continue to emerge during the testing of the body and complete vehicle. Besides receiving clearly defined issues, there will also be some performance or functionality problems that are not clearly defined. Some of these issues need to be elevated to the product level for decision-making, thus forming the basis for design changes. The engineering design change management process is shown in Figure 7:

Figure 7 Engineering Design Change Process

Figure 7 Engineering Design Change Process

Generally, the design after changes requires simulation confirmation and design review. Designers should conduct thorough self-checks before design release, using tools such as CHECKLIST and problem prevention checklists. These two documents are the technical accumulation of the enterprise.

The issuance of engineering design documents should be based on the maturity of parts, the ease of changes, and the actual planning of human resources, and requires full-process management and control. Considering the actual needs of the development cycle, long-cycle parts are often released first, followed by medium and short-cycle parts. The issued engineering design documents should meet the following conditions:

● Define all vehicle models in the product planning;

● Complete 2D, 3D, and BOM files, with accurate reflection of relevant manufacturing information;

● Confirmation and issuance of supplier drawings, ensuring all installation boundary conditions are locked and all testing items and acceptance conditions are clarified;

● Product definition documents are generally issued through a carrier document. For documents issued for engineering design (i.e., for engineering development), the carrier document must specify that they can be used for tooling and mold development.

In summary, the key points and difficulties of management work in the engineering design stage are to effectively manage the issuance of engineering design documents, control the process of prototype trial production and testing verification, and manage engineering design changes. The control points can be summarized as follows:

1. The verification needs of this stage should have a detailed checklist, be reviewed, and form a trial production plan, testing verification plan, supported by design definition documents;

2. All components entering trial production must comply with design definitions and have qualified inspection reports;

3. Problems during the trial production process must be recorded in detail, and temporary solutions must be recognized and documented;

4. Design issues and testing failures must be recorded in detail and compiled into a unified checklist, undergoing professional analysis and classification, determining the true cause before proceeding with design changes.

Lower Part

Combining the previous two articles from the system construction network, the author has discussed the three main stages of sedan body design and development according to the upper, middle, and lower parts:

First Stage: Feasibility Study of Styling, Engineering Feasibility Study, Design of Functional Prototypes

Second Stage: Engineering Design

Third Stage: Engineering Development and Quality Cultivation

In the previous article, the author summarized the key work focuses and difficulties of the engineering design stage. Next, we will elaborate on the process of the third stage, “Engineering Development and Quality Cultivation” (as shown in Figure 8).

Figure 8 Overall Vehicle Product Development Process

Figure 8 Overall Vehicle Product Development Process

In general terms, by the time of the engineering development stage, the main work has shifted to the manufacturing system, led by the manufacturing department (suppliers are external manufacturing departments, and their management is part of engineering development). As the design department, the internal work during this stage involves explaining product definitions and tracking improvement work, while externally participating in supplier development management, thus the workload is also heavy.

Without undergoing this process, it is impossible to handle various quality issues that arise during this stage and become a mature product design engineer. This may also be the reason why some design companies are gradually eliminated.

Many companies still refer to engineering development as production preparation, which is merely a matter of terminology. The key is the pull of high acceptance standards, a series of new technologies, and methods being applied. Production preparation encompasses more than just process design and production line layout; it must reflect the planning of the initial quality plan (APQP), ensuring that the process fully meets quality requirements, and also needs to control the quality of outputs at each stage, ultimately passing the sample approval process (PPAP). In other words, the goal of this stage is not just to produce products but to ensure that products meeting quality standards are produced.

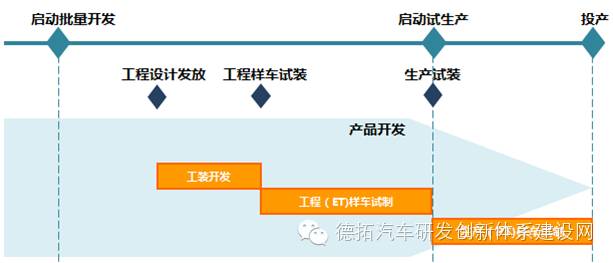

Although the overall product development work has fully returned to the complete vehicle level at this time, we will still discuss the work and common problems encountered in this stage from the perspective of body development. As shown in Figure 9, the main work during the engineering development and quality cultivation stage includes: tooling development, engineering prototype trial production, and production prototype trial production.

Figure 9 Engineering Development Stage Process Flowchart

Figure 9 Engineering Development Stage Process Flowchart

1. Tooling Development

This refers specifically to tooling development. In fact, the manufacturing technology department (including suppliers) has already completed the basic scheme of the process and feasibility analysis during the synchronization process. When the functional prototype design documents are issued, the selection of major tooling and mold suppliers and their development plans, as well as the preliminary design of tooling for component suppliers, have already been conducted. Here, based on the final definitions of engineering design, the production of tooling and molds (including those for supplier parts) is approved and initiated.

For component suppliers, they can be roughly divided into three categories:

● Suppliers with strong technical capabilities, whose assurance systems and delivery times are reliable. The OEM’s work mainly involves ensuring that design definitions are clear and that design changes are communicated promptly;

● Basic suppliers, who require acknowledgment of their initial quality plans in addition to the above two points, and their development processes need to be tracked, ensuring acceptance in the later stages;

● Weaker suppliers, of which there may be a number, whose systems and development controls require guidance and monitoring from the OEM, essentially needing the OEM’s assistance to improve.

Therefore, the design, quality, and procurement departments of the OEM must allocate sufficient human resources to manage the latter two categories, especially the third category of suppliers, to ensure that work at each stage does not lag behind.

The development of in-house manufactured components is led by the manufacturing department, with tooling and molds outsourced to qualified suppliers. The key points for controlling the quality of body manufacturing are:

● For stamping large and high-strength material parts, the focus is on controlling forming quality, ensuring no tearing, wrinkling, or springback occurs;

● For welding, it is essential to control the geometric quality of subassemblies and assemblies, selecting appropriate fixtures for positioning, support, and clamping consistency to ensure final geometric precision.

Typically, the precision goals for the metal body frame and installation points are determined during the early stages of development, which also guarantees the subsequent appearance quality and gap surface differences.

2. Engineering Prototype Trial Production (ET)

The engineering prototype trial production (also known as out-of-line tooling prototype trial production) can assess and promote the quality of component development, enhancing the overall vehicle integration quality, while also providing prototypes for more precise calibration, adjustment, reliability, and durability testing during the overall vehicle development. Since many design quality issues will also be discovered during this stage, design adjustments and optimizations will occur (at a local level), and depending on the project difficulty and quality status, engineering trial production may not be limited to just one round. Due to the need for prototype verification, intermediate design changes must be reflected in subsequent prototypes, so the assembly plan for prototypes depends on the timely provision of new sample parts, and the definition of sample parts must be closely tracked.

Like functional (FT) prototypes, engineering prototypes (ET) also have meticulous plans based on verification needs. At this point, the sample parts are essentially tooling samples, and the cost of trial production vehicles is much lower, with the quality status of prototypes being better (when adjustments are relatively mature) than that of functional prototypes. Therefore, the number of engineering prototypes produced is relatively high, primarily used for passive safety calibration, powertrain and chassis tuning, electrical testing (including interference resistance), and overall vehicle durability tests.

As with all quality issues, the quality of engineering prototypes depends on development control and design and technical standards.

When it comes to supplier components, once geometric and functional issues are resolved, many problems arise from technical standards and acceptance conditions. For mature OEMs and suppliers, complete technical standards should be established for components, enabling comprehensive control over their functions and performances. For different target sales regions, these standards need to be supplemented and adjusted to better fit the conditions and user habits of the regions, thus forming acceptance conditions. These technical standards are a long-term accumulation process and need to be balanced across systems and components. Therefore, this is also foundational work that emerging enterprises, including independent brands, need to invest significant effort into.

The production and submission of samples must strictly follow management procedures. Suppliers must first implement development according to the OEM’s recognized initial quality plan (APQP), and during the sample submission phase, they must work according to the sample approval process (PPQP).

Geometric inspections, verification tests, and appearance assessments of the submitted samples must be conducted strictly according to standards, with original records maintained, such as: the equipment and gauges for geometric measurement should be specified in the agreed technical conditions, measurement control points; the methods, equipment, and values for testing; conditions for assessing appearance and comparison samples, etc.

Submitted samples must have accompanying records of verification compliance. During the rapid development phase of the automotive industry as a whole, it is not uncommon for some suppliers to begin development without detailed analysis of technical conditions, leading to incomplete compliance with technical conditions during subsequent verification. They may submit samples without declaration, hoping that the OEM’s tests will identify any issues, which often leads to frequent quality problems later (of course, this does not exclude the factor of insufficient experience accumulation on the OEM’s part). Therefore, the OEM needs to invest more engineers to track the supplier’s development process, jointly analyze quality issues and countermeasures, and promote the rapid maturity of the supplier’s component quality.

Identified quality issues should also be managed according to the design change process introduced in “Body Design and Development (Middle Part).”

3. Production Prototype Trial Production (PT)

The production prototype trial production occurs on the production line. At this stage, the single-piece production quality of the OEM and supplier components should be problem-free, focusing on assessing and enhancing the quality stability of the continuous production process, synchronizing rhythms (production capacity), and managing related packaging, transportation, and logistics issues, as well as the proficiency of manufacturing personnel. Meanwhile, this stage still has overall vehicle integration quality issues and individual component issues, some of which require design optimization.

Production prototypes generally meet commercialization conditions and can be sold. However, the first few batches of vehicles are still used extensively for various tests, including test drives conducted by some non-professional drivers within the company and external users, to identify and raise their driving experiences and dissatisfaction issues as a basis for further improvements and assessments of competitive capabilities before launch.

4. Quality Cultivation During the Engineering Development Stage

The quality of vehicles during the engineering development stage is a continuous improvement process.

In the past, some companies were accustomed to referring to the issues and handling that arose during this stage as “quality tackling.” At that time, both the development concept and methods were relatively outdated. Insufficient human input in the early design phase led to inadequate work, resulting in numerous quality issues emerging just before production, some of which were even fatal. Consequently, specialized teams were organized for urgent tackling, attempting to quickly meet sales conditions. This not only incurred high labor and cost expenses but also delayed the launch, and quality issues were not necessarily resolved adequately.

Modern development concepts are completely different.

It is first recognized that the quality of the complete vehicle product is a gradually improving and maturing process. Therefore, various means are employed to address major issues and risks during the early development stages, including benchmarking, simulation, mule vehicle development, risk assessment and countermeasure handling, and tracking control of new technologies and components.

In the later stages, the focus shifts to:

● Calibration, improvement, and acceptance of each system;

● Continuous rectification of customer-perceived quality defects and dissatisfaction issues.

Numerous system calibrations must be performed on engineering prototypes, such as NVH, passive safety, handling stability, powertrain and emissions, and active safety. For passive safety, for example:

● After measuring the basic conditions of collision (acceleration curves and intrusion amounts) on functional prototypes, suppliers will comprehensively develop the safety restraint systems, including: airbag deployment timing, airbag deployment direction and timing, airbag exhaust control; seatbelt tightening timing, seatbelt force-limiting detection, etc.

● Upon receiving engineering prototypes, all relevant collision tests and misfire prevention tests will be conducted, and after aggregating the test results, NCAP ratings will be evaluated and calibrated until preset standards (such as five-star collision safety) are achieved.

For parts that cannot meet standards, local design adjustments are required, and verification will be conducted in the next round of prototypes.

For these performance calibrations, the OEM must have a professional team capable of evaluation and acceptance to ensure that the enterprise can confirm whether performance meets standards, rather than just taking the supplier’s word for it.

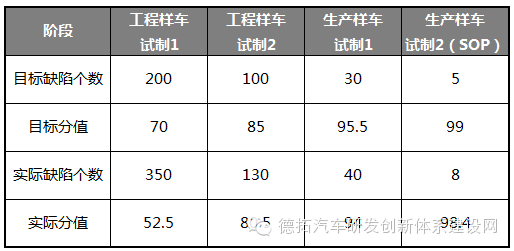

Regarding customer-perceived quality defects and dissatisfaction issues, most enterprises adopt sample evaluations and scoring methods to determine the quality status of the current batch of prototypes and the gap between acceptance standards, then achieve targets in stages, as shown in Table 3:

Table 3 Quality Targets and Actual Status at Each Stage

Table 3 Quality Targets and Actual Status at Each Stage

Table 1 assumes that both engineering and production prototypes undergo two rounds (the production trial production of the second stage is the same as SOP). The defect and score targets for each round of prototypes are pre-defined. Each round may have more than one prototype, and their defects and average scores are recorded. When the score deviates from the target value by a certain degree (e.g., ±3%), the stage node cannot pass, and trial production work must be halted for rectification. It is not excluded that a small number of non-serious issues can be postponed for improvement in the next stage (excluding the final SOP prototypes).

All gaps and surface differences of opening parts, the handling feel of all operating components, and any discomfort during driving and riding will be resolved during this stage.

Establishing a quality cultivation system can be summarized as follows:

● There must be a complete set of operable evaluation methods and a relatively stable team of evaluators with high skill levels;

● Early-stage quality achievement targets for each phase should be established;

● Gradual improvements in product quality must be made rhythmically, enhancing product quality maturity;

● When necessary, the quality department has the power to veto, halting projects for rectification;

● Quality records should have traceability for this vehicle model and serve to prevent recurrence for subsequent models.

The key control points for the design team during the engineering development (i.e., production preparation) stage include:

● Besides graphic files, all technical conditions must also be complete;

● When defining changes, confirmation with all parties (including suppliers) must be in place;

● The objectives, definition documents, and sample statuses for each round of prototypes must be aligned;

● The quality status of all components entering assembly must be clear and stage-qualified, with final assembly components fully meeting standards;

● Maintain good communication with suppliers (it is not advisable to adopt an overly harsh attitude towards suppliers; high-pressure situations only foster deception and cultivate incompetence in certain departments of the OEM). For quality issues with third-category suppliers, a joint analysis should be conducted, striving for a one-time resolution without leaving any doubts.

Conclusion

The entire process of body design and development runs through the main line of new product development for the complete vehicle and has a decisive impact on the final outcome of the vehicle product and project:

1. Due to the special nature of load-bearing bodies, other system components must be installed on top of the body, so the quality of the body is the foundation of overall vehicle integration quality;

2. The number of components in the body is very large, so the investment in body mold development accounts for a significant proportion of overall vehicle investment;

3. The technical integration level of body development is very high, the design workload is substantial, the number of professionals and personnel involved in the development process is the most, the internal and external interfaces are the most complex, and the requirements for concurrent engineering are very high. Therefore, the body design and development cycle of new models usually falls on the critical path of the overall vehicle development project plan, and the scope of body development largely determines the length of the overall vehicle product development cycle.

Therefore, managing the entire process of body design and development well will play a crucial role in achieving the QCD goals of the overall vehicle product development project.