Introduction(Written by “Industrial Internet of Things Technology and Applications” (Authors: Yin Zhouping et al.); WeChat Public Account: Smart Manufacturing Garden)

A typical Internet of Things (IoT) system architecture consists of three layers. The first is the perception layer, which utilizes Radio Frequency Identification (RFID), sensors, QR codes, etc., to obtain information about objects anytime and anywhere; the second is the network layer, which integrates telecommunications networks and the Internet to transmit object information accurately and in real-time; the third is the application layer, which processes the information obtained from the perception layer to achieve intelligent recognition, positioning, tracking, monitoring, and management applications.

In industrial applications, the Industrial Internet of Things faces two main differences compared to traditional IoT system architectures: first, in the perception layer, most industrial control commands and sensor data uploads require real-time capabilities. In traditional IoT architectures, data must be transmitted from the perception layer to the application layer via the network layer, where it is processed before decisions are made. For control commands issued, they must again pass through the network layer to the perception layer for execution. Since the network layer typically uses Ethernet or telecommunications networks, which lack guarantees for real-time transmission, traditional IoT architectures are not suitable for high-speed data acquisition or real-time control in industrial applications. Second, in existing industrial systems, different enterprises have their own data acquisition and supervisory control systems (Supervisory Control and Data Acquisition, SCADA), which implement data collection and monitoring within the factory. SCADA systems may overlap with the application layer of IoT in certain functions. How to integrate existing SCADA systems with IoT technology, such as which data needs to be transmitted to the application layer for analysis, which data should be stored in the local SCADA database, and which data should not reach the application layer (often involving critical sensor data or key system information that should only be processed internally within the factory) is a significant challenge.

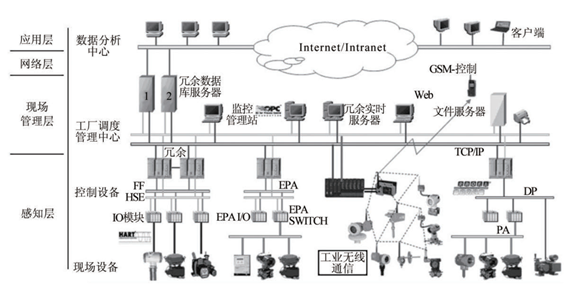

The system architecture of the Industrial Internet of Things needs to add a field management layer on top of the traditional IoT architecture. Its role is similar to that of a sub-application layer, allowing for data preprocessing at a lower level, which is essential for achieving real-time control, real-time alarms, and real-time data recording in industrial applications, as shown in Figure 1.

Figure 1: Architecture of the Industrial Internet of Things

1. Perception Layer

The main function of the perception layer is to identify objects, collect information, and perform automatic control. It is the source of object recognition and information collection in the IoT; it consists of a data acquisition sub-layer, short-range communication technologies, and a collaborative information processing sub-layer. The data acquisition sub-layer collects physical events and data information occurring in the physical world through various types of sensors, such as various physical quantities, identifiers, and audio-video multimedia data. IoT data acquisition involves technologies such as sensors, RFID, multimedia information collection, QR codes, and real-time positioning. The short-range communication technology and collaborative information processing sub-layer process the collected data locally to improve information accuracy, reduce information redundancy, and connect to wide-area networks through self-organizing short-range sensor networks. Middleware technology in the perception layer aims to solve compatibility issues between perception layer data and various application platforms, including code management, service management, state management, device management, time synchronization, and positioning. In some applications, actuators or other intelligent terminals may need to respond to perception results to achieve intelligent control. While technologies such as RFID, short-range communication, and industrial buses are relatively mature, many IoT-specific technical standards still need to be developed.

The perception layer consists of field devices and control devices, primarily responsible for sensing industrial machine information and issuing control commands. Field devices mainly include temperature sensors, humidity sensors, pressure sensors, RFID, electric valves, transmitters, etc., which are directly connected to industrial machines and serve as the terminal mechanisms for the sensing control process. Control devices mainly refer to controllers such as PLCs, which are used in industrial systems to achieve high-speed real-time control functions, particularly important for industrial control. Control devices and field devices form the fieldbus control network, such as commonly used CAN bus networks and Profibus networks. It is worth mentioning that Industrial Wireless Sensor Networks (WISN), as an important component of IoT technology, can coexist with existing fieldbus networks through gateways. WISN is widely used in the implementation of the perception layer due to its high reliability, low cost, and easy scalability, playing a significant role in environmental data sensing and industrial process control.

2. Field Management Layer

The field management layer mainly refers to the local scheduling management center of the factory, which is the SCADA system mentioned above. The scheduling management center acts as the local manager of the industrial system and the provider of external interfaces for industrial data, generally including industrial database servers, monitoring servers, file servers, and web servers. As a layer distinct from traditional IoT system architectures, the field management layer plays an important role in industrial IoT systems. The field management layer integrates existing industrial monitoring systems, allowing for timely recording and processing of critical industrial data from the perception layer. For some lower-level process control commands that require real-time response, it can quickly respond and make timely control decisions. On the other hand, the field management layer provides external data interfaces, allowing the scheduling management center to publish data from within the factory to the application layer through database servers and web servers, enabling the application layer to transparently access sensing information from different industrial machines, which is crucial for further data analysis.

3. Network Layer

The network layer consists of the Internet, telecommunications networks, etc., responsible for information transmission, routing, and control. The network layer transmits various types of information from the perception layer to the application layer through the underlying carrying networks, including mobile communication networks, the Internet, satellite networks, broadcasting networks, industry-specific networks, and the resulting integrated networks. Depending on application requirements, it can serve as a transparent network layer or be upgraded to meet future transmission requirements for different content. After more than a decade of rapid development, technologies such as mobile communication and the Internet have matured and can generally meet the data transmission needs in the early stages of IoT. The network layer mainly focuses on the transmission issues of data from the perception layer that has undergone preliminary processing through various networks. This involves intelligent routers, interoperability of different network transmission protocols, self-organizing communication, and various network technologies. Global identification resolution will be completed at this layer. Aside from global identification resolution, other technologies are relatively mature, primarily adopting existing standards.

4. Application Layer

The application layer implements application services for the sensed information, including information processing, massive data storage, data mining and analysis, artificial intelligence, and other technologies.

The application layer is the ultimate value embodiment of the Industrial Internet of Things. It deeply integrates with industry-specific technologies based on the demands of industrial applications, utilizing big data processing technologies to analyze data from the perception layer, primarily including monitoring production processes, tracking the operational status of industrial machines, and recording, ultimately producing results that guide enterprise and industry development, such as optimizing production processes, guiding production management, improving operational efficiency, and predicting industry development, achieving widespread intelligence. Different enterprises can share the results of big data analysis, which plays a significant role in promoting collaborative production and overall productivity among enterprises.

The application layer mainly includes a service support layer and an application subset layer. The core function of the IoT is to collect, develop, and utilize information resources, making this part very important. The main function of the service support layer is to form a dynamic data resource library that is updated in real-time and adapted to business needs based on the data collected from the lower layers. This part will employ metadata registration, metadata discovery, information resource directories, interoperability meta-models, classification coding, parallel computing, data mining, data harvesting, intelligent search, and other technologies, urgently requiring the development of IoT data models, metadata, ontologies, services, and other standards, as well as the technical planning and maintenance of IoT data architecture and information resource libraries. Various business scenarios can develop corresponding data resource management based on the characteristics of business needs. The business architecture layer’s main function is to develop IoT business architecture, application architecture, IT architecture, data architecture, technical reference models, and business operation view designs based on IoT business needs using modeling, enterprise architecture, SOA, and other design methods. The IoT encompasses a wide range of applications, including various business needs, operational models, application systems, technical systems, information needs, and product forms, necessitating a unified and systematic business architecture to meet the demands for comprehensive real-time perception, multi-objective business, and heterogeneous technology integration. Various business application fields can subdivide business types, including green agriculture, industrial monitoring, public safety, urban management, remote healthcare, smart homes, smart transportation, and environmental monitoring, tailoring technologies related to business, services, data resources, common support, networks, and perception layers to form different solutions. This part can also undertake some presentation and human-computer interaction functions. The application layer will provide unified information resource support for various businesses, establishing and updating a reusable information resource library and application service resource library in real-time, allowing various business services to be combined according to user needs, significantly improving the adaptability of IoT application systems to business. This layer can enhance the reusability of application system resources, laying the foundation for rapidly constructing new IoT applications and meeting the complex and variable network resource application and service demands in IoT environments. This part involves data resources, architecture, and business process domains, which are key to the effectiveness of the IoT, and there are few applicable universal information technology standards, thus requiring the development of many standards.

In addition, the IoT also requires public technical support for information security, IoT management, service quality management, etc., primarily adopting existing standards. Information is not transmitted unidirectionally between layers; there is interaction, control, etc., and the transmitted information is diverse, with the most critical being around item information, completing massive data collection, identification resolution, transmission, intelligent processing, and other links, integrating with applications in various business fields to complete various business functions. Therefore, the system architecture and standard system of the IoT are a closely related whole, guiding the direction and fields of IoT research.