Company Introduction

Company Introduction

Shenzhen Gaote High-Sensitivity Technology Co., Ltd. is a high-tech enterprise focused on the research, development, manufacturing, and sales of industrial sensors. The company’s sensor products cover high-precision position detection, precise measurement, and safety identification, and are widely used in fields such as electronics and semiconductors, CNC machine tools, automotive manufacturing, food and medical, packaging and printing, warehousing and logistics, new energy, and robotics.

The company is located in the Digital Innovation Center, Building C, Longhua District, Shenzhen, Guangdong Province, with a factory area of over 8000 square meters. It has a complete R&D center, testing center, laboratory, and intelligent production workshop, strictly following the ISO9001 quality management system to strengthen internal management. The company has strong R&D capabilities, with R&D personnel from top sensor companies in the industry, focusing on industrial sensor research for over ten years, with a deep understanding of industry technology development and product applications, accumulating rich innovation and practical experience. Optical technology, control systems, and digital algorithms are all designed independently. At the same time, the company has attracted several overseas returnees to start businesses, laying a solid foundation for the company’s products to go global.

The company adheres to the philosophy of “customer-centric, based on hard work, unity and trust, pragmatic and enterprising,” continuously developing cutting-edge products to provide users with thoughtful services and higher quality, more precise, and faster sensor solutions.

Product Matrix

Product Matrix

Photoelectric sensors, fiber optic sensors, proximity sensors, magnetic sensors, laser displacement sensors, safety light curtains

Product Applications

Product Applications

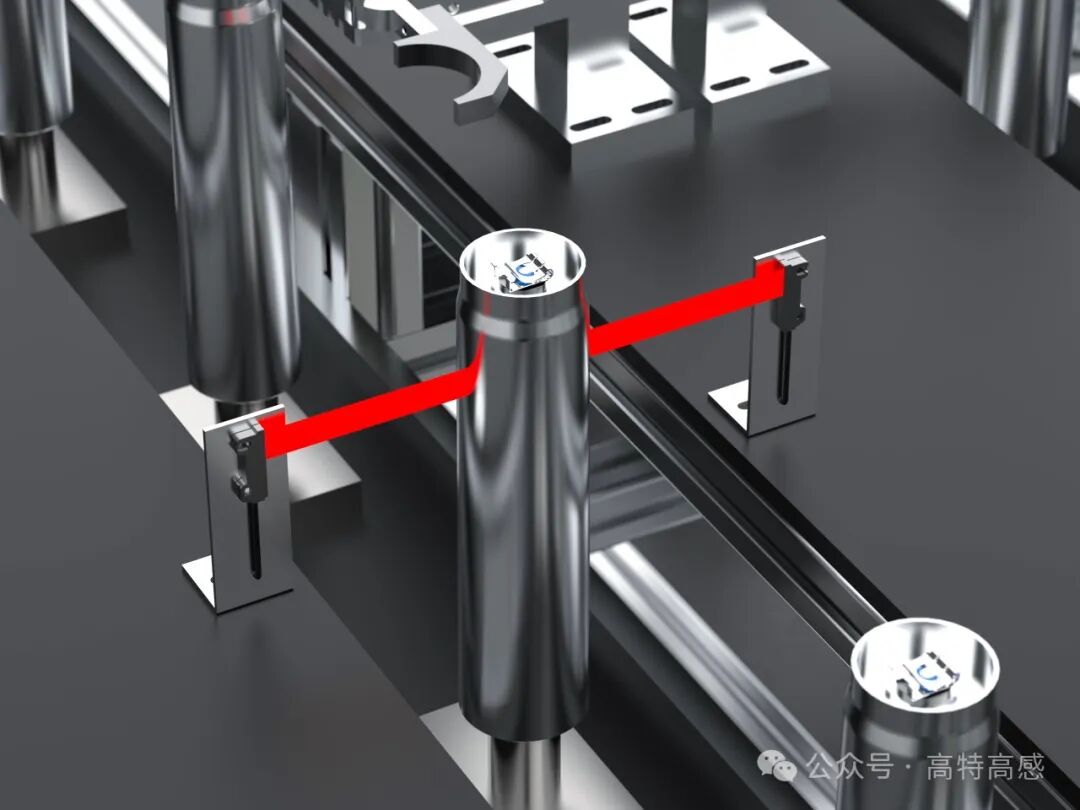

Photoelectric Sensors

Used for counting, positioning, and sorting objects. For example, in food and beverage production lines, they are used for counting and packaging positioning; in automotive manufacturing workshops, they are used for assembly positioning of parts and material transport control on production lines; in warehouse management, they detect the entry and exit of goods, achieving automated inventory counting and logistics tracking. They can also be used for position detection of goods on conveyor belts, controlling the start and stop of the conveyor belt and the diversion of goods.

Highlights:

1. Diverse light sources, including red light, infrared light, blue light, bar light, small light spots, and laser.

2. Background suppression detection principle, capable of quickly distinguishing small differences within 1mm.

3. TOFphotoelectric sensors can detect at long distances, up to 4m.

4. Excellent design for resisting co-frequency and cross-frequency interference.

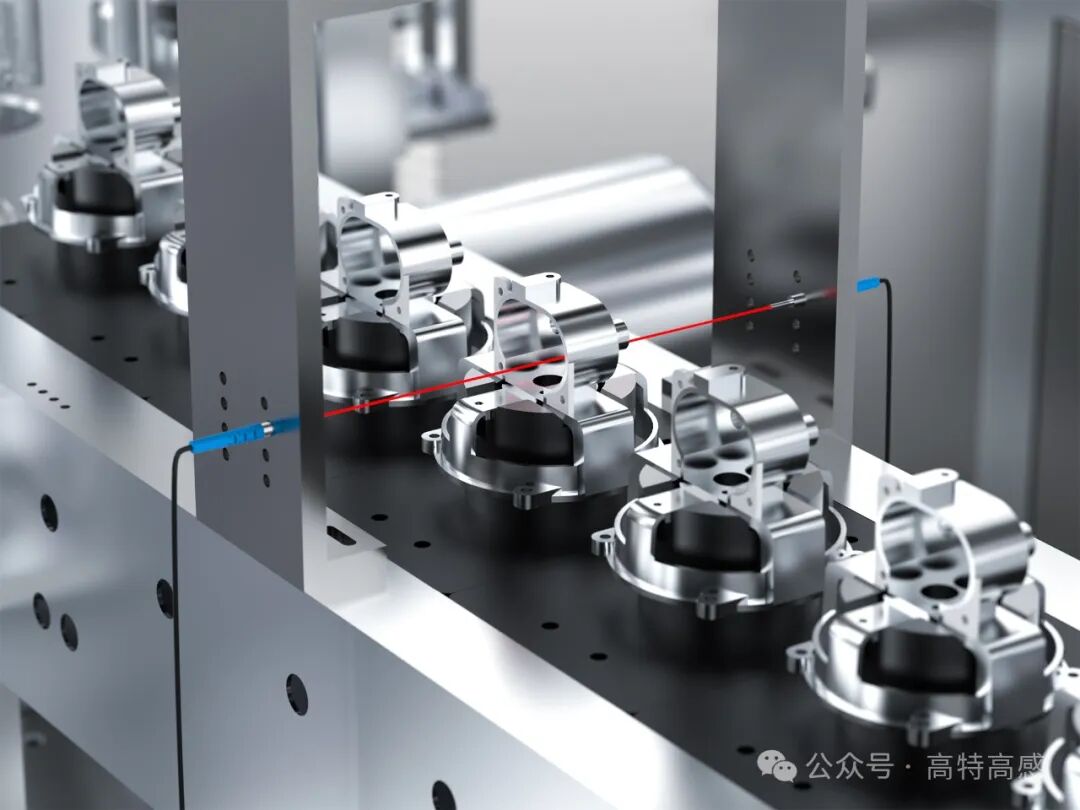

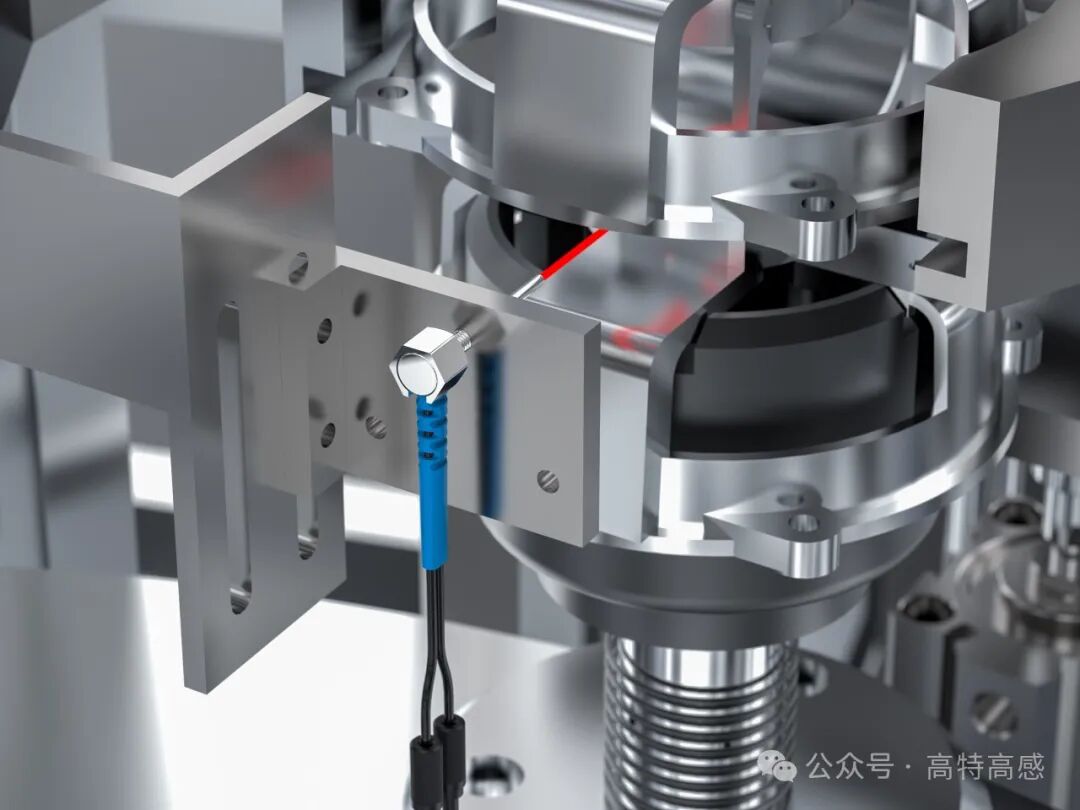

Fiber Optic Sensors

Industrial automation production lines: In the electronics manufacturing industry, they are used in SMT production lines to accurately detect the presence and position of electronic components, ensuring accurate placement. In automotive parts production lines, they can detect whether the dimensions, shapes, and assembly positions of parts are correct, achieving automated quality inspection.

Packaging industry: In packaging production lines, they are used to detect the position of packaging materials, the presence of labels, and whether products are correctly loaded into packaging. For example, in pharmaceutical packaging, they detect whether bottles are filled and whether caps are tightened.

Logistics industry: In logistics conveyor lines, they can detect the position, shape, and size of goods, achieving automatic sorting and counting.

Highlights:

1. Dual digital display in Chinese and English, stability comparable to international top brands.

2. Minimum diameter of φ1.5mm, suitable for installation in various narrow spaces.

3. Adaptable to various harsh environments such as vacuum and extreme temperatures, capable of withstanding temperatures up to 350℃.

4. Excellent resistance to co-frequency and cross-frequency interference.

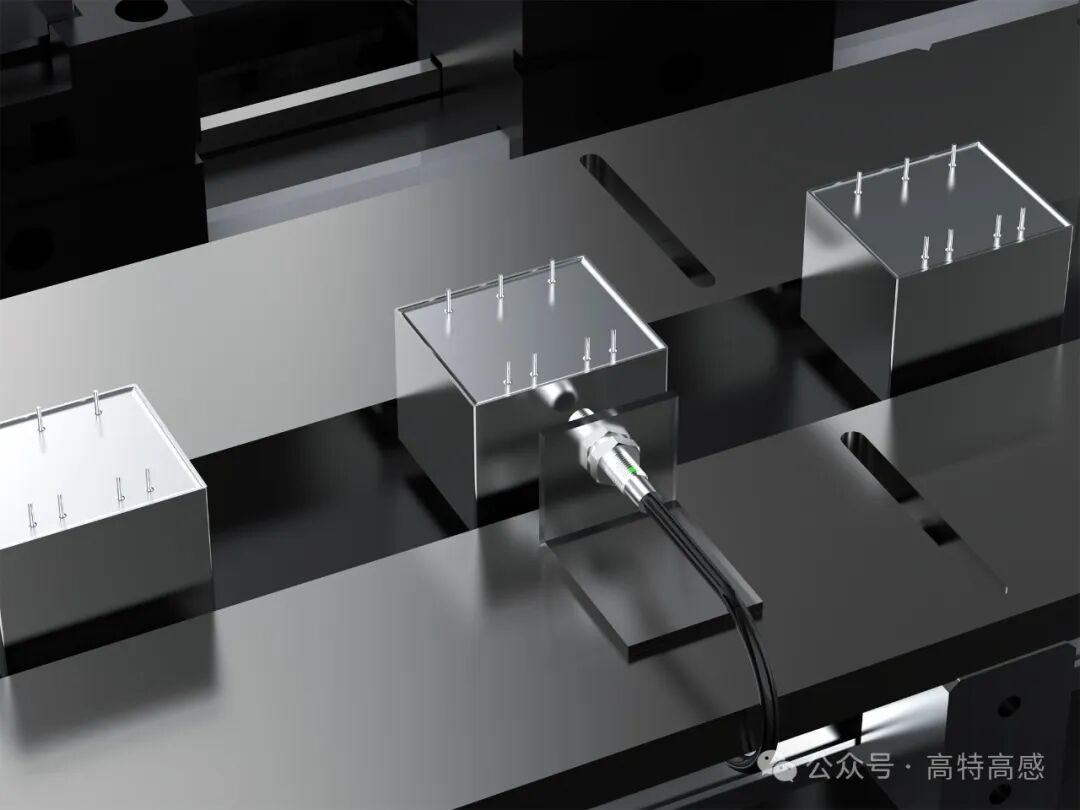

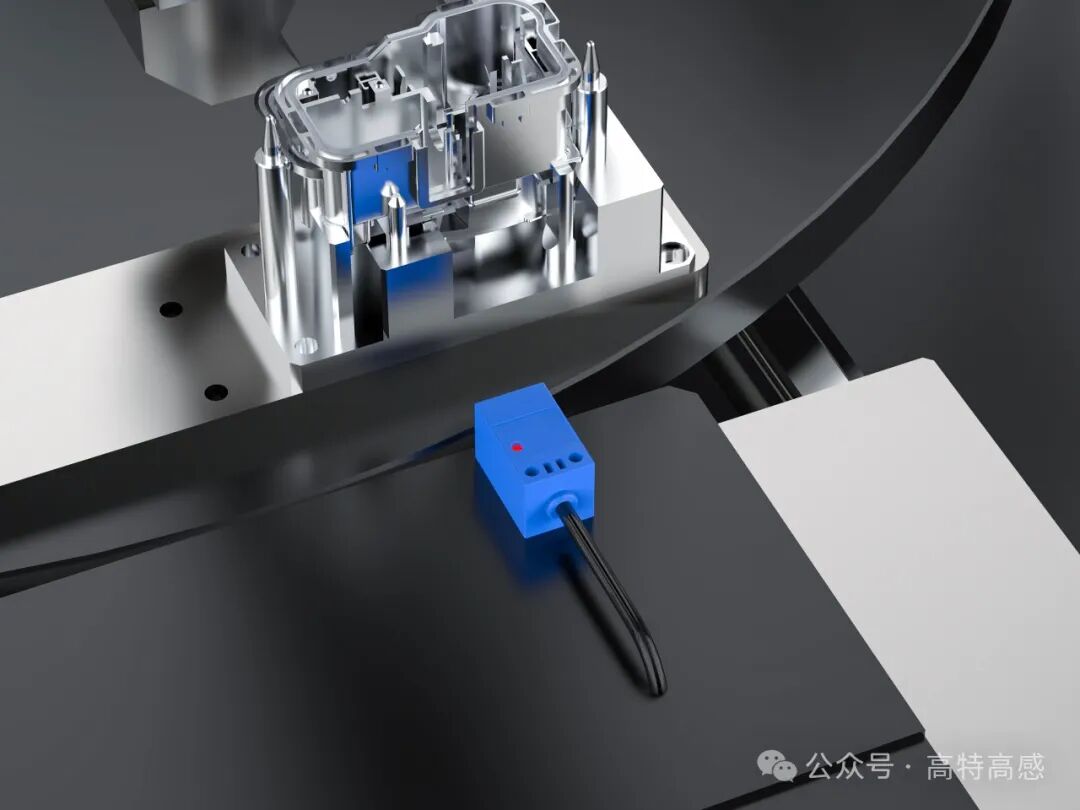

Proximity Sensors

Industrial automation control: Used for material detection on production lines, workpiece positioning, and robot motion control. For example, in automated assembly lines, they detect whether parts are in place, providing signals for subsequent assembly actions.

Machine tools: Can detect the position of tools or workpieces, achieving precise control of automatic tool changes and workpiece clamping and releasing, improving processing accuracy and efficiency.

Warehouse logistics: In warehouse shelving systems, they are used to detect whether goods are stored in designated locations, achieving automatic inventory management.

Highlights:

1. Diverse detection distances, including single, double, and triple distances.

2. Fast response, with a maximum response frequency of 3KHz.

3. Minimum diameter of φ2.8mm, suitable for split installation.

4. Highest IP68 protection level.

Magnetic Sensors

Automation production lines: Used to control various mechanical devices driven by cylinders on production lines, such as material handling and parts assembly, ensuring accurate and coordinated actions.

Robotics: Help robots precisely control the movement of cylinders in their joints and actuators, achieving accurate actions and positioning.

Highlights:

1. Minimum external dimensions of 14mm, low power consumption, and high sensitivity.

2. IP69 protection level design, suitable for use in environments with cutting fluids and oil contamination.

3. High flexibility and corrosion-resistant wiring, increasing the SR anti-bending structure.

4. Customizable for different types of cylinders.

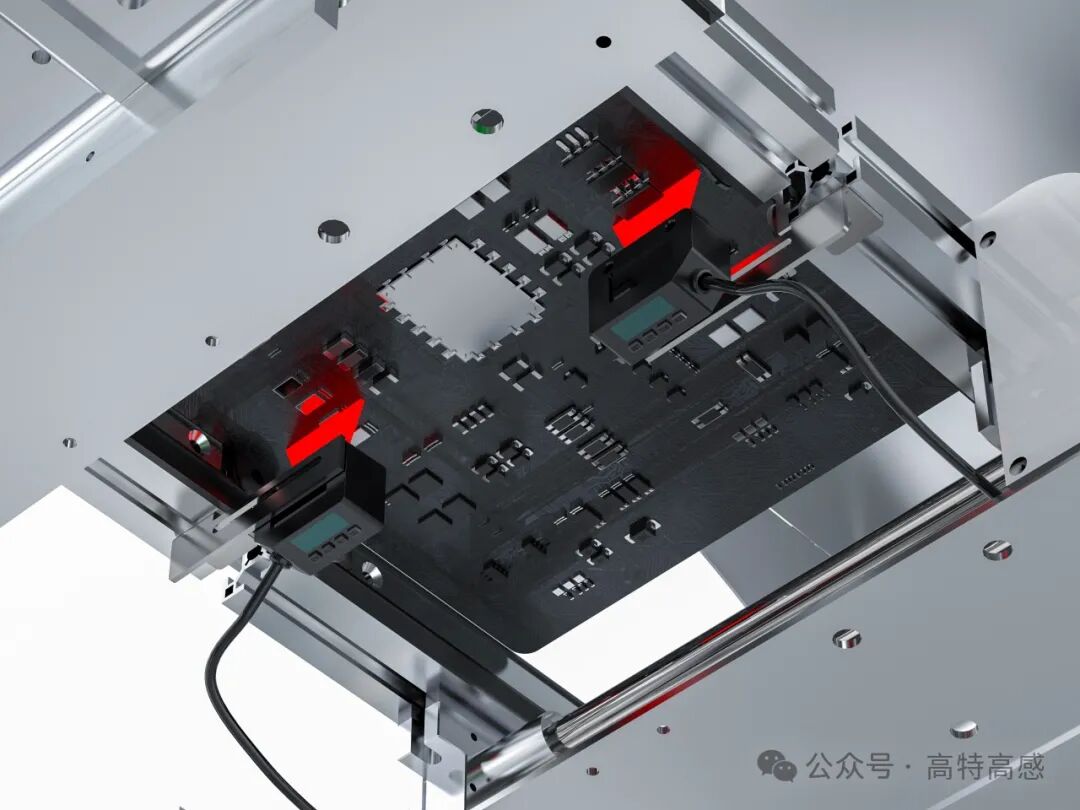

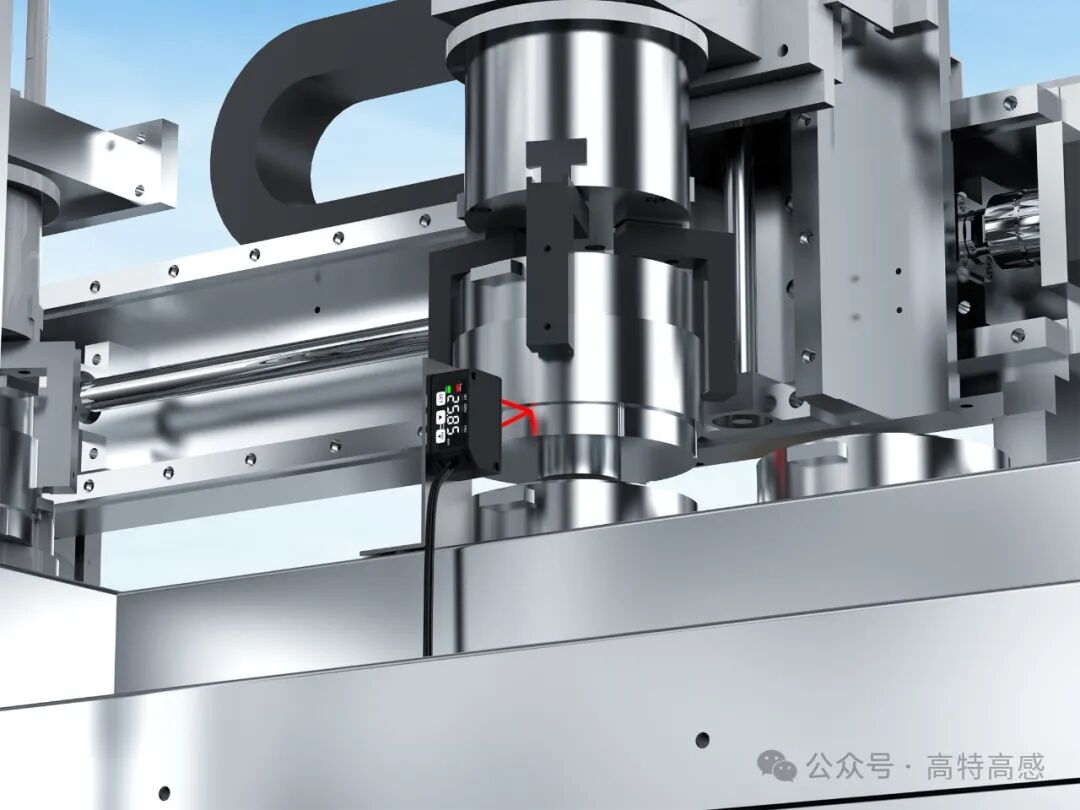

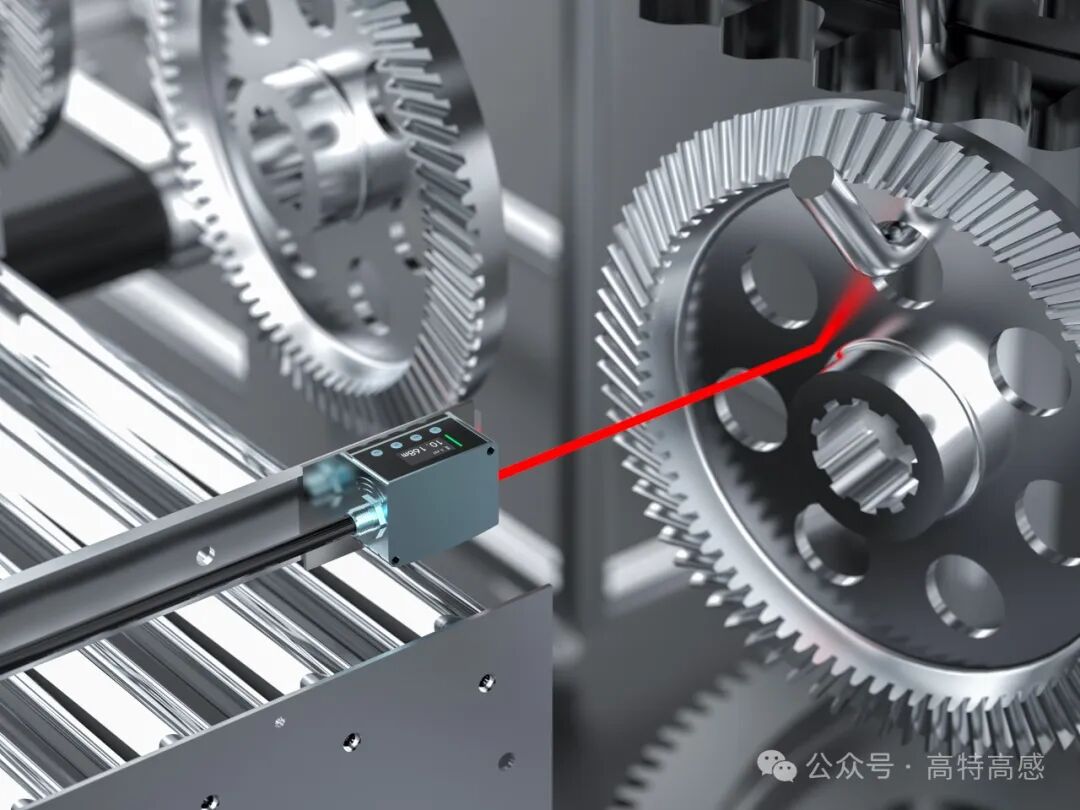

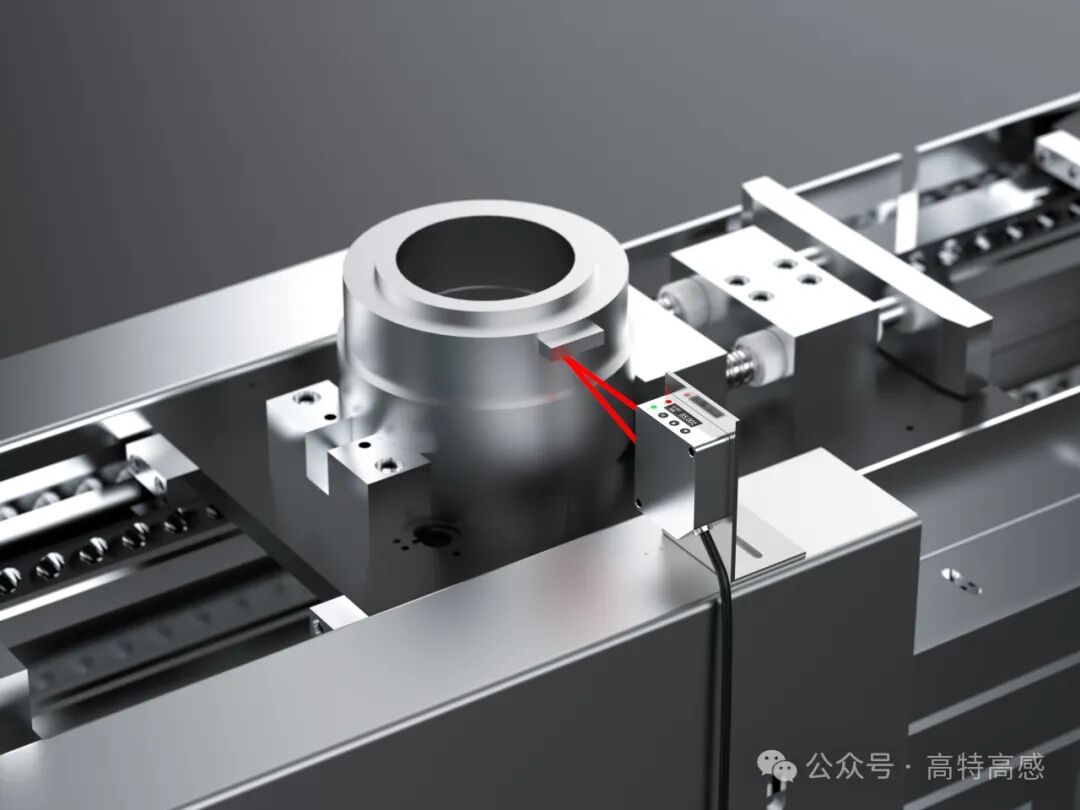

Laser Displacement Sensors

Industrial automation: Used for position detection, size measurement, and shape detection of objects on production lines, such as assembly accuracy detection of body parts in automotive manufacturing and position alignment of chip packaging in electronics manufacturing.

Logistics and warehousing: In logistics automation systems, they can be used for locating goods, measuring volume, and inventory counting, achieving intelligent warehouse management.

Robotics: Provide precise distance information for robots, used in path planning, obstacle avoidance, and object grasping tasks, improving the operational accuracy and flexibility of robots.

Highlights:

1. Capable of achieving micron-level or even higher precision measurements.

2. Measurement range covers from a few millimeters to dozens of meters or even further.

3. IP67 protection level design.

4. Chinese and English menu settings, digital tube display.

5. Customizable protocols.

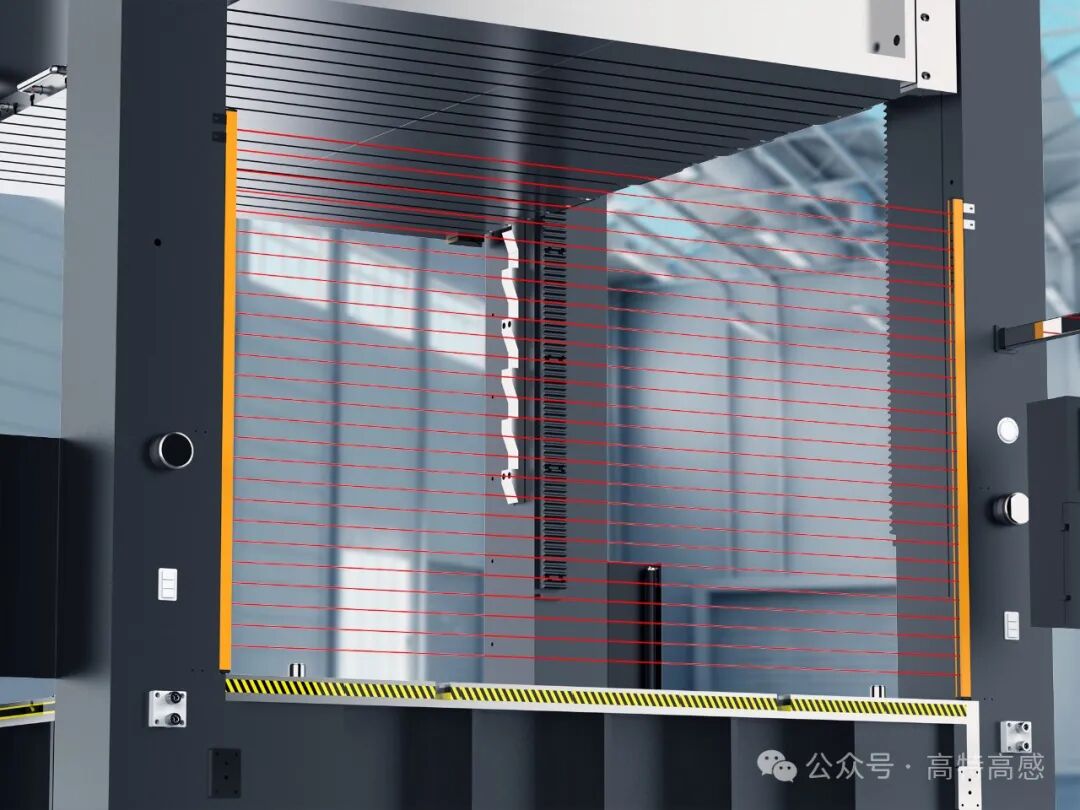

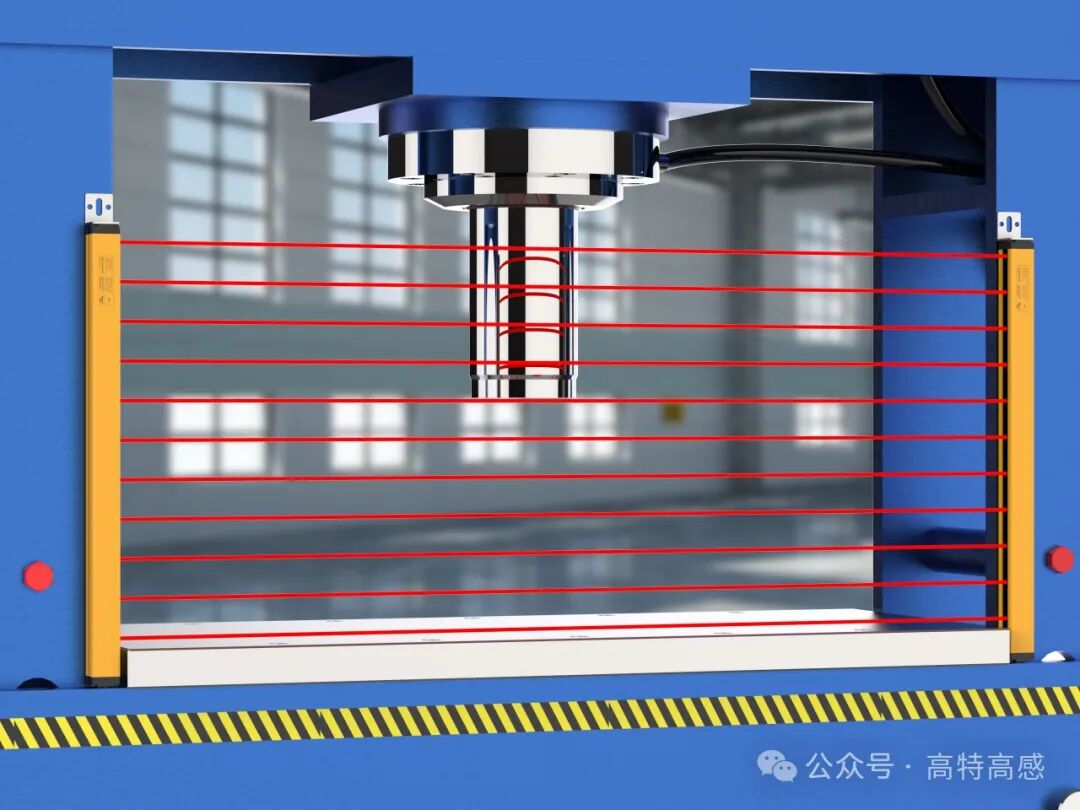

Safety Light Curtains

Industrial machinery protection: Widely used in various hazardous machines such as punching machines, shearing machines, and injection molding machines. When an object enters the light curtain protection area during equipment operation, the sensor immediately detects it, causing the equipment to stop running and preventing accidental injury to operators.

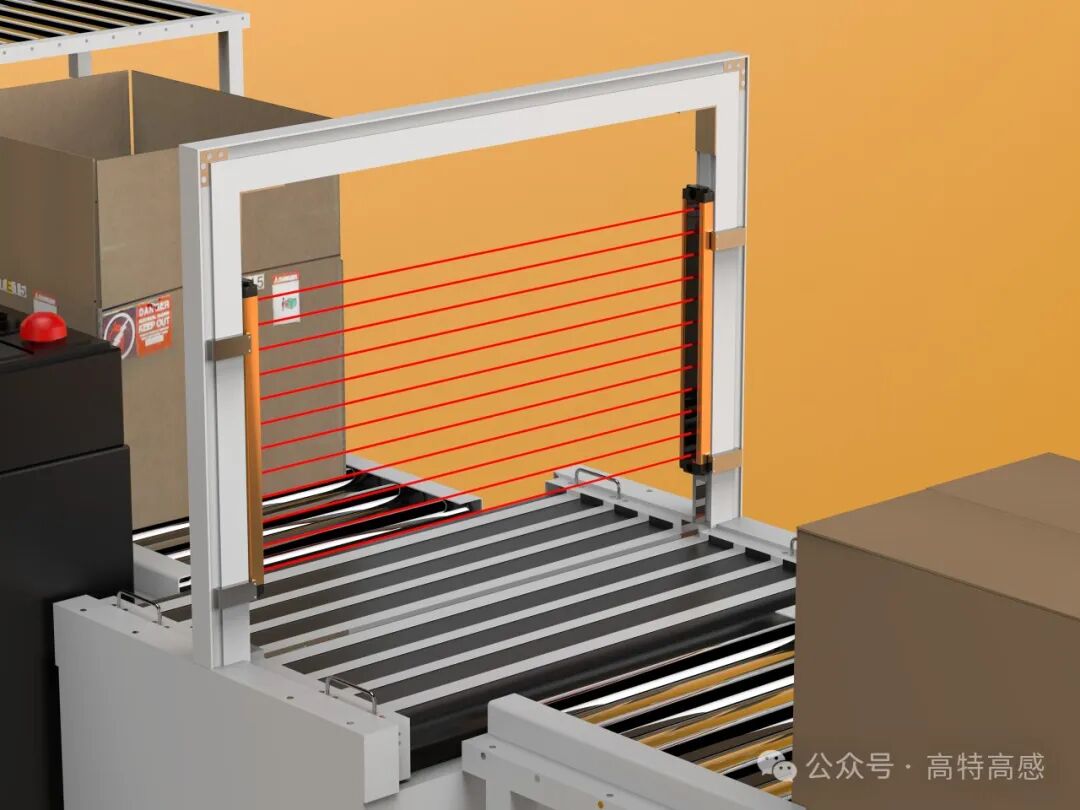

Automatic door safety protection: Installed at the entrances and exits of automatic doors, when someone or something passes through, the light curtain detects it, preventing the door from closing on people or objects, ensuring safety for personnel and items.

Logistics conveyor line safety protection: Safety light curtains are installed at intersections or areas where personnel may come into contact on logistics conveyor lines. When personnel or foreign objects enter the danger zone, the conveyor line operation is stopped in time to avoid accidents.

Highlights:

1. No blind zone design, enhancing product robustness.

2. Anti-light interference capability exceeding 10000Lux, suitable for use in arc welding scenarios.

3. Four-level safety certification, meeting various high-demand safety protection scenarios.

4. IP67 protection level design.