In yesterday’sAnalysis of Difficulties in the Development of Equipment Industry Software, several difficult issues in the development of industrial software were discussed. It is not right to only mention the problems without discussing solutions. Therefore, in this article, we will briefly discuss how to effectively develop industrial software.

1. Guiding Principles for High-Quality Development

In 2020, the country proposed the industrial development guideline of “high-quality development” and has been continuously strengthening support for the real economy. The introduction of this guideline is certainly based on a summary of the existing problems and stages in our industry, as well as guidance for future development transformations.

This guideline is proposed based on an understanding of China’s manufacturing industry itself and can be explained from multiple dimensions to illustrate its significant importance.

1. The market has entered a stage of demand for high-end products

After more than 40 years of reform and opening up, it must be acknowledged that everyone’s living standards have improved, and the demand for high-quality products is also significant. This summer, while visiting friends working at JinJia Group in Shenzhen, he excitedly introduced several directions of product R&D in soft packaging that made me have a new understanding of this traditionally understood industry. Due to the upgrade of consumption, there is a higher demand for higher-quality packaging materials and processes. For consumers, how to make packaging more user-friendly, preservative, safe to use, and environmentally friendly has led to many innovative demands in soft packaging.

2. We are facing development difficulties

Even without the boring suppression from the United States, our industry itself needs high-quality development from the perspective of domestic demand or global competitiveness, shifting from extensive reliance on cheap labor costs to high-quality development.

3. Cross-border innovation is the way to truly enter new tracks

Cross-border innovation is inevitable. Recently, I also communicated with experts in the printing machinery field. Printing, even as a seemingly traditional industry, has extended its usage to emerging material fields. For example, coating processes for lithium batteries, screen/laser transfer for photovoltaics, flexible hybrid electronic printing, digital printing for textiles, digital printing, 3D printing, and plastic films are also beginning to meet the rapid growth demand like that in the lithium battery industry. BFS has also been applied to the plastic industry’s extrusion and blowing processes in the pharmaceutical industry.

Many experts I have encountered in the lithium battery field are also very concerned about cross-border technologies. In the process of developing lithium battery equipment, they place great importance on the application of cross-industry technologies. For example, tension control, temperature control, cutting, and coating processes in the printing industry, as well as the reference and integration of digitalization with the pharmaceutical, photovoltaic, and semiconductor fields in application and standardization.

Additionally, the MBA center at Shanghai University has integrated electrical engineering and management to establish an MBA focused on intelligent manufacturing. Professor Chen Bing from Huazhong University of Science and Technology also discussed how to integrate IE knowledge systems into the training of electrical engineering talents, enabling students to build a recognition of quality, cost, and delivery capabilities in manufacturing processes to cultivate talents from multiple dimensions.

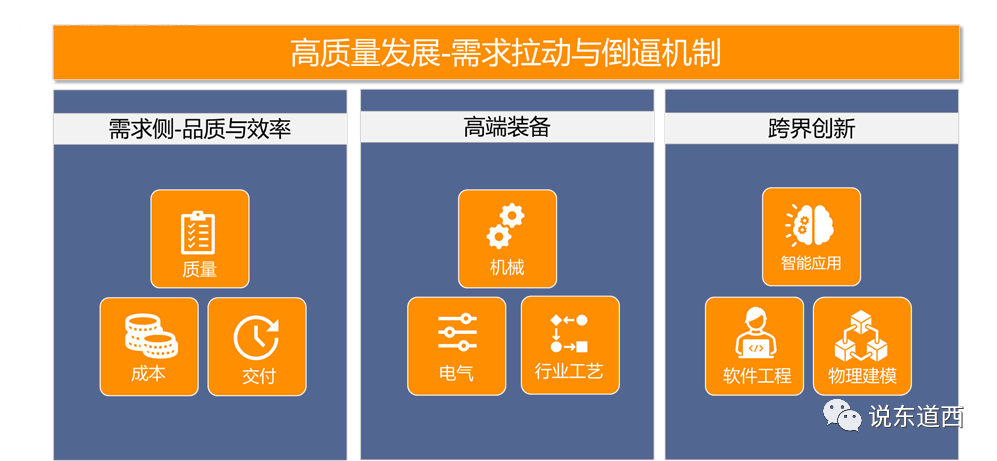

Figure 1: Demand-side Pull and Cross-border Integration for High-Quality Development

As shown in Figure 1, high-quality development relies on demand-side pull and cross-border innovation, and its foundation lies in the development of high-end equipment. Here, “high-end” does not refer to what we usually call high-speed trains or large installations; the meaning of “high-end” here refers to high performance compared to the same standards, rather than a specific industry.High-quality products and globally competitive products all require high-end equipment for production, and to truly win competitiveness, it must be supported by one’s own capabilities.

4. Industrial software is at the best time

Industrial software is becoming a hot topic, which is a good phenomenon because, as I discussed with Ms. Su Meiping from the Transmission Network a few days ago, in the past few years, whether in various conferences, forums, or gatherings in various industry circles, everyone has been discussing how to develop and learn from each other.

In this sense, we have reached the best stage, increasingly clearly recognizing the existing problems in development and gradually clarifying how we should develop. Industry elites have also realized this issue.

Therefore, industrial software can definitely develop well because our path is becoming clearer.

2. Development Perspective—Transformation Towards Forward Design

More and more people are realizing the importance of “forward design,” which is reflected in many aspects. We need to see that industrial software is essentially about the reuse of knowledge, formed through multi-level modeling.

Figure 2 is a diagram I drew this summer for MBA students at Shanghai University, analyzing the presence of modeling at every stage from multiple dimensions:

Figure 2: Industrial Software, Ubiquitous Modeling

First, it is clear that high-quality development and the transformation of enterprises depend on how to obtain differentiated competitiveness, core technology control with independent intellectual property rights, and soft power to respond to changing markets. This requires changing the existing development model of imitation and copying to forward design and independent research and development, focusing on long-termism.

1. Communication—Information Modeling

Information modeling can reduce costs in engineering integration, equipment design, and operations, as well as collaboration among various software. If these information modeling standards are not followed, then different manufacturers and types of equipment will incur significant coding and engineering debugging costs during collaboration in the manufacturing site. Furthermore, it makes the project non-reproducible—this is also a common phenomenon in the current development of the industrial internet.

2. Control Modeling

This is a necessary breakthrough for industrial software, based on platform software to achieve self-knowledge encapsulation. Moreover, this encapsulation belongs to one’s own Know-How, and the benefit of software is that it is independent of the platform. Knowledge is a capability that does not depend on the platform.

For example, Beckhoff’s Automation Studio and SIEMENS’ Portal are designed for these industrial embedded applications. Additionally, these platforms are often based on open architectures to allow users to encapsulate processes, which can use C/C++, or even Python, Java, etc., to encapsulate computational task models, knowledge, analysis software, etc.

3. Digital Twin

Digital twins also need to be based on models, but they emphasize more on the needs of “dynamic interaction” and “whole lifecycle”.

4. Strategy Models for Edge Computing

At the level of manufacturing lines and workshops, there are usually scheduling issues such as AGV scheduling, logistics scheduling, in-process logistics scheduling, equipment scheduling, planning, paths, etc., which are also components of industrial software because they need to obtain data from on-site equipment, analyze it, and then execute it on the equipment.

5. Data-Driven Modeling for Intelligent Analysis

Considering our limited understanding of the world, physical and chemical equations can only describe laws within linear intervals. As the uncertainty in manufacturing increases and the demands for speed and precision rise, machines and equipment work under highly nonlinear and uncertain environments. More knowledge needs to be explored, which requires the use of “data-driven modeling”—this also involves learning and model training.

Of course, if we reduce all problems to mathematical problems, it becomes easier to understand that the manufacturing world is all about models.

3. Software for Equipment Development—Often Overlooked

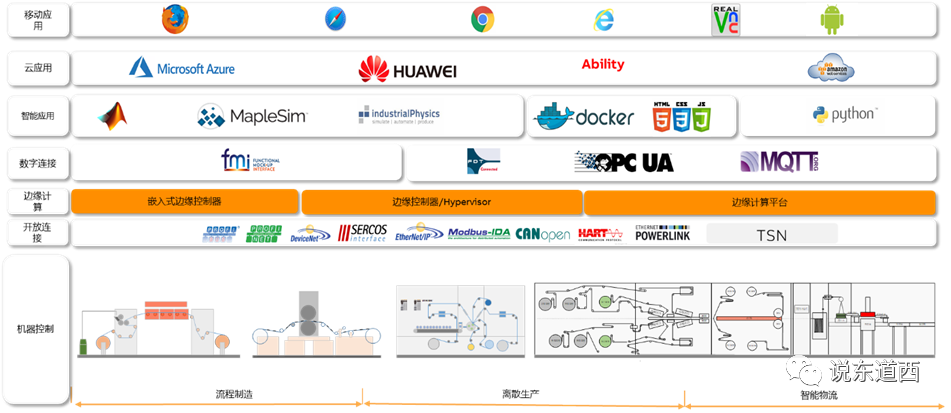

Figure 3 shows the value system of industrial automation software, which I have used for many years. For equipment, software is ubiquitous. Moreover, during the development period of industrial software, we still find that there is insufficient attention to such embedded control systems. Mr. Zhao Min from Innovance has indeed pointed out this issue in various occasions to experts and leaders.

Figure 3: Software System for Equipment Automation

(1) Operating System RTOS: The core features of on-site embedded systems are “periodicity” and “real-time performance,” which require real-time operating systems to run these software. RTOS will also have an abstract layer of software with chips like Intel/ARM to enable the system to achieve independence. This includes tasks, resource scheduling, file operations, and network resource allocation and scheduling for on-site control systems such as PLC/industrial PCs.

(2) Application Software: Each industry has its own Know-How, encapsulated in software as a container.

(3) Standard Encapsulation: IEC6113-3, IEC61499, etc., have promoted the standardization of software processes to reduce the difficulty of equipment development and production line integration.

(4) Interfaces with Other Industrial Software: Equipment development must also collaborate with CAD/CAE and process simulation software, requiring standard interfaces.

(5) Data-Driven Modeling: Machine learning and deep learning are increasingly being used in the industry to solve quality, cost, and scheduling efficiency issues.

4. Specialized and Innovative is a Good Policy

Industrial software enterprises are typical specialized and innovative enterprises that need good support.

Figure 4: Specialized and Innovative

Equipment enterprises and industrial software enterprises belong to specialized and innovative types, derived from the idea of “invisible champions,” which is particularly suitable for equipment-related enterprises.

1. The “Bottleneck” Problem Belongs to Subdivision Areas

In fact, if we look closely, there are many places where we are “bottlenecked,” but they are particularly fragmented, all belonging to technologies that need to be carefully polished in specific directions.

2. Equipment Belongs to Specialized and Innovative Development

Equipment enterprises are usually not large in scale along the industrial chain, except for large-scale engineering machinery (after all, they are also large items), in other equipment fields, the scale of individual enterprises is often not particularly large, especially in Europe and America.

However, it is definitely a niche market. Just like when I discussed with friends in the printing industry a few days ago, although printing has multiple fields such as gravure, flexo, offset, and post-press, they are all part of the printing industry, but there is basically no relationship between these specialized enterprises because the differences are significant.

3. Industrial Software Also Has This Attribute

I have communicated with experts from a research institute, and software like CAD tends to be highly concentrated, but in niche areas of processing, it is often difficult to form large software enterprises.

Fluid analysis, electromagnetic, material property analysis, vibration/breathing analysis, failure analysis, and dynamic simulation software are generally targeted at specific fields because they are difficult to generalize; therefore, they are often developed by highly talented experts who come out of the field to start their own businesses. This requires capital support, but the return cycle of financial capital is short and not suitable. It is more suitable for support from industrial policies or industrial capital.

Specialized and innovative also particularly suits industrial software enterprises; in fact, they do not face difficulties in funding, but rather in having no opportunity to test and verify.

5. Demand-Side Pull Issues

Of course, the terminal demand is the foundation; otherwise, it is impossible to profit, and equipment enterprises will find it difficult to develop.

1. The Demand for Efficient Production in Manufacturing

This is a logical chain: Consumer demand for high-quality and diversified products, as well as the manufacturing enterprises’ ability to respond to these demands, will drive the demand for higher-quality equipment. If there are widespread counterfeit products on platforms like Pinduoduo, then large-scale equipment producing these low-quality products will not lead to the upgrading of the manufacturing industry. How can we talk about the demand for high-end equipment and how to drive the demand for industrial software?

2. Industrial Coordination

The demand for high-end equipment from the demand side pulls and organizes collaborative innovation among machinery, electrical, and software sectors, which requires effective organization. The government, industry associations, universities and research institutions, standardization organizations, and industry stakeholders should be effectively organized. How to organize may still need to be led by associations and research institutions as ecological center nodes; ultimately, a neutral organization is needed for collaboration. Establishing expert committees to outline effective paths for industrial development, tackle key issues, and assist in project applications and evaluations is essential. This has not been absent in the past, but it still requires professionals to do professional work and neutral individuals to organize it, and there must be legal guarantees for organization.

6. The Importance of Standard System Construction for Industrial Software Development

In the entire construction of industrial software, special attention must be paid to today’s industrial software application scenarios, such as intelligent manufacturing and the industrial internet, which inevitably involve “integration”; therefore, software must collaborate, making standards and norms crucial.

1. The Ecological Center of Industrial Software is Standards

To enable industrial software to develop healthily, it must rely on the upstream and downstream of the industrial chain, including collaboration between vertically oriented enterprises. This collaboration cannot be achieved through administration, and while interests can bind, it still needs to be implemented, that is, relying on standards for docking.

This is also the peculiarity of the manufacturing ecosystem; its alliances must connect through a common language that everyone follows.

2. Engineering Standard Interfaces for Mechatronics Integration

In industrial software, CAD/CAE, simulation software, and on-site embedded systems software need to collaborate through standards.

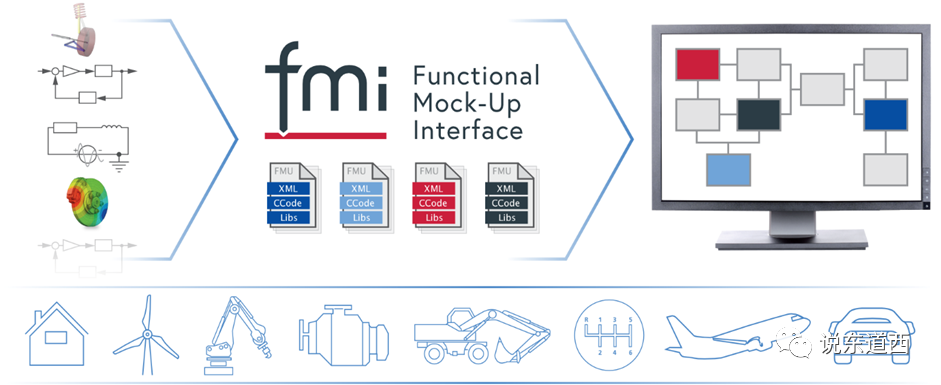

The FMU/FMI interface promoted by the Modelica organization is typical; it enables software like Dassault, PTC, MapleSoft, and IndustrialPhysics to exchange model data.

Figure 5: FMU/FMI Standards Promoted by the Modelica Organization

We discussed earlier that industrial software aims to reduce engineering design and knowledge reuse. The current development of equipment must involve complex mechatronic process collaborative simulation issues, which requires establishing this import between existing software to achieve collaboration among multiple industrial software.

Digital twins must establish this bidirectional interaction between physical and digital systems. FMU/FMI is the standard for achieving this.

Figure 6: Import and Export of FMU/FMI in Beckhoff Automation Studio

Beckhoff implemented FMU import in Automation Studio in 2016 and achieved FMU export based on the FMI interface in 2022.

3. Analysis of the Role of OPC UA Standards in Collaboration

In addition to the collaboration between digital design and runtime software like FMU/FMI, another key standard is OPC UA; it is not merely a communication standard as commonly understood, but a key to achieving collaboration between software.

Manufacturing is complex software collaboration, and complex problems must be simplified: The information modeling of OPC UA and the service-oriented architecture (SoA) separate data from events, allowing different applications to share data in memory; the server provides standardized and regulated data, encapsulated as usable packages. In addition to previous PackML and EUROMAP, VDMA and the OPC Foundation are also collaborating on a unified information model for machines, allowing machines to have universal interfaces with MES/ERP instead of modeling separately in vertical industries. This work appears to be monumental.

Figure 7: Collaboration Between Manufacturing System Software Through OPC UA

In addition to machine modeling, OPC UA has also constructed OPC UA FX for on-site communication, incorporating TSN, 5G/Wi-Fi 6 into communication to achieve fast communication connections. In the cloud and intelligent systems, the AAS asset management shell standardizes the model for information exchange and establishes information modeling in various fields such as vision, logistics barcodes (AutoID), and on-site energy.

4. Standards Require Global Collaboration

In terms of standard construction, it is essentially a strict product development engineering process. In standard construction, some have raised concerns that standards are controlled by foreign entities, suggesting a need for self-construction. This is not a good idea; first, from an economic perspective, the workload is too large; second, from a future trade perspective, our equipment and products must also be exported, and we must interface with global standards; third, from a restrictive perspective, standards based on “connection” norms differ from trade access, market barriers, and mandatory standards; their purpose is not to set barriers but to open connections.

Therefore, we need to abandon confrontational thinking and instead adopt the mindset of “you are in me, I am in you,” gradually strengthening standardization capabilities through the three steps of “learning,” “participating,” and “leading,” ultimately achieving leadership; this is a process that does not need to be rushed.

7. IT Resources Applied to Manufacturing Equipment Development

The collaboration between IT and OT must extensively utilize resources from the IT world to serve innovation in manufacturing.

For example, Beckhoff’s exOS is built on integrating IT resources, such as the Linux ecosystem, into machine learning algorithms, database applications, simulation applications, and real-time system tasks through effective interfaces.

Figure 8: Beckhoff exOS Extending OT to the IT Resource World

The IT world has a wealth of software programming languages and a large number of engineers who understand the application of these languages, including rich algorithms from open-source communities like Linux. Of course, this requires aligning with the demands of OT, combining certainty and periodicity in tasks, each leveraging their strengths; IT software excels in algorithms, while OT has a strong understanding of the field—domain knowledge.

Thanks

During the preparation of this speech, I discussed with experts such as Mr. Zhao Min from Innovance, Mr. Zhao Yutang from Suwei Software, Mr. Li Xue from NIO, Professor Chen Bing from Huazhong University of Science and Technology, Mr. Ma Jijun from ABB Software R&D, General Manager Wang Jian from 702 Institute and Qingneng Dechuang, and friends like Lao Yin and Yin Tongxue, who all provided their insights. I had serious discussions with them, which inspired me greatly.