【Introduction】

Aluminum Alloy Materials for Automotive Use

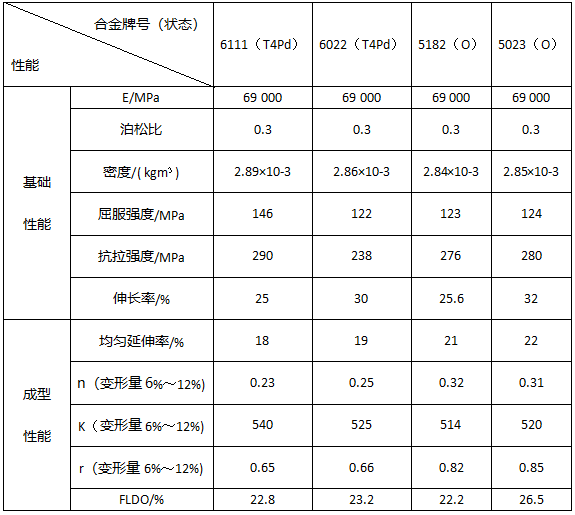

The reduction of weight in the automotive body structure is key to achieving lightweight vehicles. Aluminum alloys, with their high specific strength, good corrosion resistance, formability, and connectivity, are among the preferred materials for reducing the weight of the body structure. Currently, commonly used deformed aluminum alloys in automotive body structures include the 5xxx and 6xxx series, while the 7xxx series is less frequently used due to cost reasons.

Table 1 Commonly Used Deformed Aluminum Alloy Grades and Properties in Automotive Body Structures

1.Audi e-tron

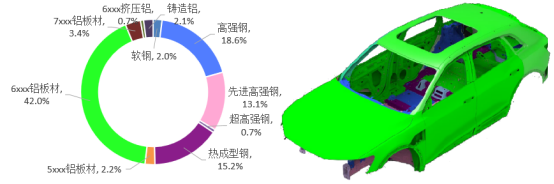

Audi e-tron is a typical model that transitioned from a previous generation steel body (with aluminum accounting for about 18%) to a steel-aluminum hybrid body (with aluminum accounting for about 50%). The Audi e-tron not only extensively uses aluminum alloy materials for its exterior components but also employs a certain proportion of aluminum alloy materials in its structural components. The main aluminum alloy sheet used is from the 6xxx series, accounting for 42%, as shown in Figure 1.

Figure 1 Material Composition of Audi e-tron Body Structure

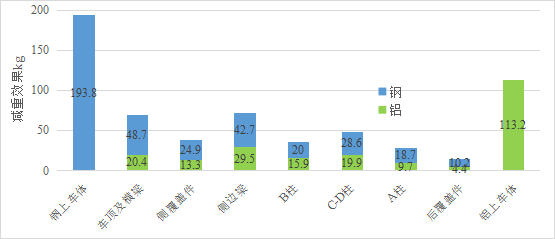

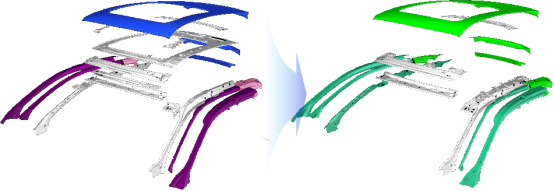

From Figure 2, it can be seen that the most significant weight reduction effect of aluminum alloy is in the roof and crossbeams, achieving a weight reduction ratio of 58%. The aluminum-intensive upper structure of the vehicle compared to the steel upper structure results in a weight reduction of 80.6 kg.

Figure 2 Weight Reduction Effect of Aluminum Alloy in Audi e-tron Body Structure

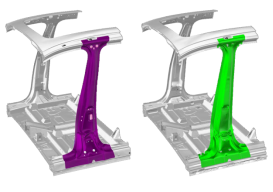

Among the components of the aluminum solution in Audi e-tron, a typical and concerning point for designers is the aluminum B-pillar solution used in the Audi e-tron and its corresponding crash safety results. The upper part of the B-pillar uses high-strength 6xxx aluminum alloy as the outer panel and 7xxx aluminum alloy as the inner panel, while the lower part uses laser welded 6xxx aluminum alloy. The B-pillar design achieves structural safety equivalent to hot-formed steel during side impacts, validating the safety of this aluminum B-pillar solution, as shown in Figure 3.

Figure 3 Aluminum B-Pillar Solution in Audi e-tron

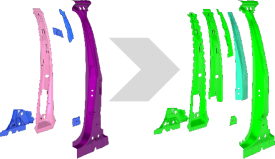

Compared to the steel B-pillar solution, the aluminum B-pillar, although increasing the number of integrated components, achieves a weight reduction of 2.1 kg, as shown in Figure 4.

Figure 4 B-Pillar Structural Design Illustration

In addition to the B-pillar, the design of the roof integrated component in the Audi e-tron has also undergone significant changes. Besides extensively using aluminum alloy materials, the structure has been adjusted accordingly, integrating the design of the roof beam and reducing the use of internal reinforcement components, thereby reducing the original 20 components to 14, with the weight decreasing from 48.7 kg to 20.4 kg, as shown in Figure 5.

Figure 5 Roof Structural Design

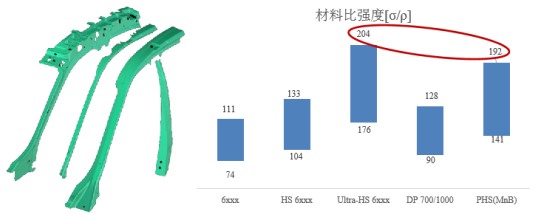

Since the roof beam and B-pillar are crucial for the overall collision safety of the vehicle, the safety of the aluminum material replacement solution is also a key consideration for body engineers. From Figure 6, it can be seen that the specific strength of the aluminum materials used in the e-tron is comparable to that of hot-formed steel, even slightly higher than that of hot-formed steel. Therefore, the aluminum material solution can achieve a certain degree of weight reduction while ensuring safety.

Figure 6 Comparison of Specific Strength of Different Material Solutions for Audi e-tron Roof and B-Pillar

2.Chevrolet Corvette

Compared to Audi e-tron, the application of aluminum materials in Chevrolet Corvette has new features, including the use of aluminum profiles, cast aluminum, and aluminum profiles with embedded enhanced structures.

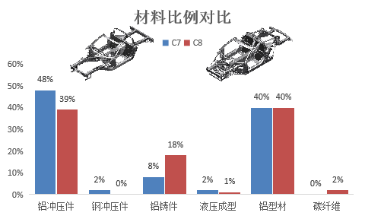

Figure 7 Chevrolet Corvette Body Structure Forming Method Distribution

1)Use of Aluminum Profiles.

As seen in Figure 7, the materials used in Chevrolet Corvette mainly consist of aluminum sheets and aluminum profiles. The C8 has seen a reduction in the use of aluminum stamped parts compared to the C7, mainly due to the increased price of aluminum sheets, while the use of aluminum castings has increased. The use of aluminum profiles has consistently remained at 40%, one of the main reasons being that the mold costs for aluminum profiles are significantly lower than for aluminum sheets. Japanese companies have also been developing technologies for aluminum profiles for a long time.

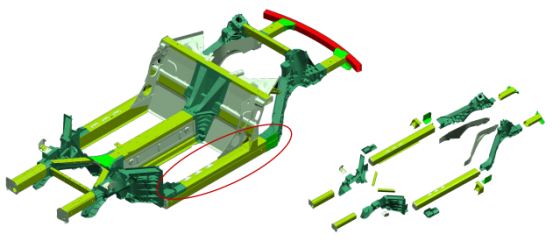

The frame structure of the Chevrolet Corvette body extensively uses aluminum castings inserted into aluminum profiles, as shown in Figure 8. If the inserted aluminum profiles have variable cross-sections or vacuum structures, their energy absorption effect is higher than that of general stamped parts, allowing high-strength areas to use 7xxx aluminum alloy instead of hot-formed steel, achieving very good results.

Figure 8 Use of Aluminum Profiles in Body Structure

2)Use of Cast Aluminum

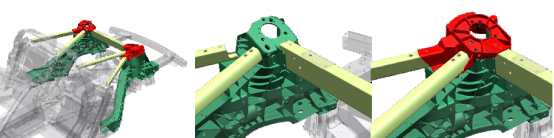

For the tower structure in the body frame, as a stress concentration point, higher crush strength and fatigue strength are often required. Using cast aluminum as the material for the tower structure allows for the addition of more reinforcement ribs, achieving higher strength than steel, as shown in Figure 9. More importantly, through casting processes, significant cost savings can be achieved in transportation, assembly, and connections, leading to better economic efficiency and more carbon-efficient results.

Figure 9 Use of Cast Aluminum

3)Enhanced Embedded Structures

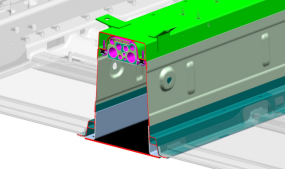

Due to the higher material cost of 7xxx aluminum alloys compared to 6xxx aluminum alloys, and the production efficiency being only one-third of that of 6xxx aluminum alloys, the most commonly used aluminum profiles in Chevrolet Corvette are still 6xxx aluminum alloys. However, for the 6xxx aluminum alloys, the design of this model adopts enhanced embedded structures to achieve higher strength, as shown in Figure 10.

Figure 10 Use of Enhanced Embedded Structures for Aluminum Profiles

Note: The images and data referenced in this article are sourced from ECB2021.

【Important Conference Notice】

The China Body Technology Research Working Group Meeting is Coming Soon

Registration Method:

Qin Lipeng 15222516296

Dong Xiuhui 13311453750