A sensor refers to a device or apparatus that can sense a specified measurement and convert it into a usable output signal according to certain rules. It usually consists of a sensitive element and a conversion element. The sensitive element refers to the part of the sensor that can directly (or respond to) the measured variable. The conversion element refers to the part of the sensor that can convert the variable sensed (or responded to) by the sensitive element into an electrical signal for transmission and/or measurement.

01

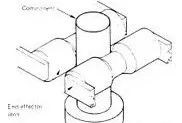

Proximity Sensing

Proximity sensing typically means detecting:

a. The presence of an object.

b. The size or simple shape of the object.

Proximity sensors can be further divided into contact or non-contact types, as well as analog or digital during operation. The selection of sensors depends on physical, environmental, and control conditions, including:

Mechanical:

Any suitable mechanical/electrical switch can be used, but due to the need for a certain force to operate mechanical switches, micro switches are often used.

Pneumatic:

These proximity sensors work by disrupting or disturbing airflow. Pneumatic proximity sensors are examples of contact sensors. However, these products cannot be used for lightweight components that may be blown away.

Optical:

In its simplest form, optical proximity sensors work by breaking a light beam that falls on a light-sensitive device such as a photoelectric cell. These are examples of non-contact sensors.

It is worth noting that the lighting environment for these sensors must be particularly careful; for example, optical sensors may be obscured by flashes during arc welding processes, and dust and smoke in the air may hinder light transmission.

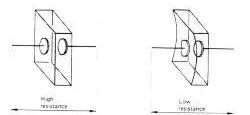

Electrical:

Electrical proximity sensors can be contact or non-contact. Simple contact sensors operate by forming a complete circuit between the sensor and the component. Non-contact electrical proximity sensors rely on inductive principles to detect metals or capacitive methods to detect non-metals.

Range Sensing:

Distance sensing involves detecting how close or far a component is from the sensing position, although they can also serve as proximity sensors. Distance or range sensors use non-contact analog techniques. Short-range sensing from a few millimeters to several hundred millimeters is done using capacitive, inductive, and magnetic technologies. Various types of emitted energy waves (such as radio waves, sound waves, and lasers) are used for longer-range sensing.

02

Force Sensing

There are six types of forces that may need to be sensed. In each case, the application of force can be static (stationary) or dynamic. Force is a vector, as it must be specified in both magnitude and direction. Therefore, force sensors operate in an analog manner and are sensitive to the direction of their application. The six forces are:

① Tension

② Compression

③ Shear

④ Torsion

⑤ Bending

⑥ Friction

These involve situations where motion is to be restricted, thus “friction can be indirectly detected using a combination of force and motion sensors. For example:

03

Touch Sensing

Touch refers to sensing through contact. The simplest type of tactile sensor uses a simple array of touch sensors arranged in rows and columns, often referred to as matrix sensors.

Each individual sensor is activated when it comes into contact with an object. By detecting which sensors are active (digital) or the magnitude of the output signal (analog), the imprint of the component can be determined. This imprint is then compared with previously stored imprint information to ascertain the size or shape of the component.

Currently, mechanical, optical, and electronic tactile sensors have been implemented.

04

Thermal Sensing

As part of process control or as a safety control measure, thermal sensing may be required. There are various methods available, and the choice mainly depends on the temperature to be detected.

Some common methods are: bimetal strips, thermocouples, resistance temperature detectors, or thermistors. For more complex systems involving low-level heat sources, infrared thermal imaging may be employed.

05

Sound Sensing (Hearing)

Acoustic sensors can detect and sometimes differentiate between various sounds. They can be used for voice recognition to issue verbal commands or identify abnormal sounds, such as explosions. The most common acoustic sensor is a microphone.

In industrial environments, a significant issue with acoustic sensors is the high level of background noise.

Of course, we can also simply adjust acoustic sensors to respond only to certain frequencies, thus enabling them to differentiate between different noises.

06

Gas Sensing (Smell)

Gas or smoke sensors sensitive to specific gases rely on chemical changes in the materials contained in the sensor, which result in physical expansion or generate enough heat to trigger the switching device.

07

Robot Vision (Sight)

Vision may be the most active area of current research in robotic sensory feedback.

Robot vision refers to capturing images in real-time through some camera and converting that image into a form that can be analyzed by a computer system. This conversion typically means transforming the image into a digital field that a computer can understand. The entire process of image capture, digitization, and data analysis should be fast enough for the robotic system to respond to the analyzed image and take appropriate actions during the execution of a set of tasks.

The refinement of robotic vision will enable artificial intelligence to fully realize its potential in industrial robots. Its applications include detecting presence, position, and movement, recognizing and identifying different components, styles, and features.

However, even the simplest vision technologies require a significant amount of computer memory and may need a considerable amount of processing time.

☞Source: iPEBG Equipment Health Management Department ☞Editor: You Xiaoxiu☞Reviewer: Zhang Weiguan

☞Advertising Cooperation: Sun Ha 13811718902

Statement: If there are any copyright issues with the videos, images, or text used in this article, please inform us immediately, and we will confirm the copyright based on the materials you provide and pay remuneration according to national standards or delete the content immediately!

Statement: If there are any copyright issues with the videos, images, or text used in this article, please inform us immediately, and we will confirm the copyright based on the materials you provide and pay remuneration according to national standards or delete the content immediately!