3D Printing in Industrial Mold Manufacturing

1. The Rise of Molds

Traditional mold manufacturing relies on CNC machining, electrical discharge machining (EDM), and other subtractive processes, which have long cycles, high costs, and difficulty in modifications. 3D printing (additive manufacturing) can replace traditional processes. The analysis is as follows:

Shortened Development Cycle: Traditional mold manufacturing takes 4-8 weeks, while 3D printed molds can be completed in as fast as 24 hours.

Reduced Trial and Error Costs: The modification cost of traditional steel molds can reach tens of thousands of yuan, while 3D printed molds can be iterated at low cost.

Realization of Complex Structures: Designs such as conformal cooling channels and optimizations that are difficult to achieve with traditional processes.

In 2023, the global 3D printing mold market size reached $1.25 billion, and it is expected to exceed $3 billion by 2028 (CAGR 18.7%).

The automotive, medical, and consumer electronics sectors are the main application areas, accounting for over 60%.

2. Technical Comparison: 3D Printing vs. Traditional Mold Manufacturing

| Comparison Dimension | Traditional Molds (CNC/EDM) | 3D Printed Molds (SLA/FDM/SLM) |

|---|---|---|

| Development Cycle | 4-8 weeks | 1-7 days |

| Unit Cost | ¥10,000-¥50,000 | ¥1,000-¥10,000 |

| Modification Flexibility | Difficult (requires reprocessing) | Easy (direct modification of 3D model) |

| Applicable Batch Size | 10,000+ pieces | 1-1,000 pieces (small batch trial production) |

| Cooling Efficiency | Traditional linear channels | Conformal cooling (30% efficiency improvement) |

Mainstream 3D Printing Technologies:

-

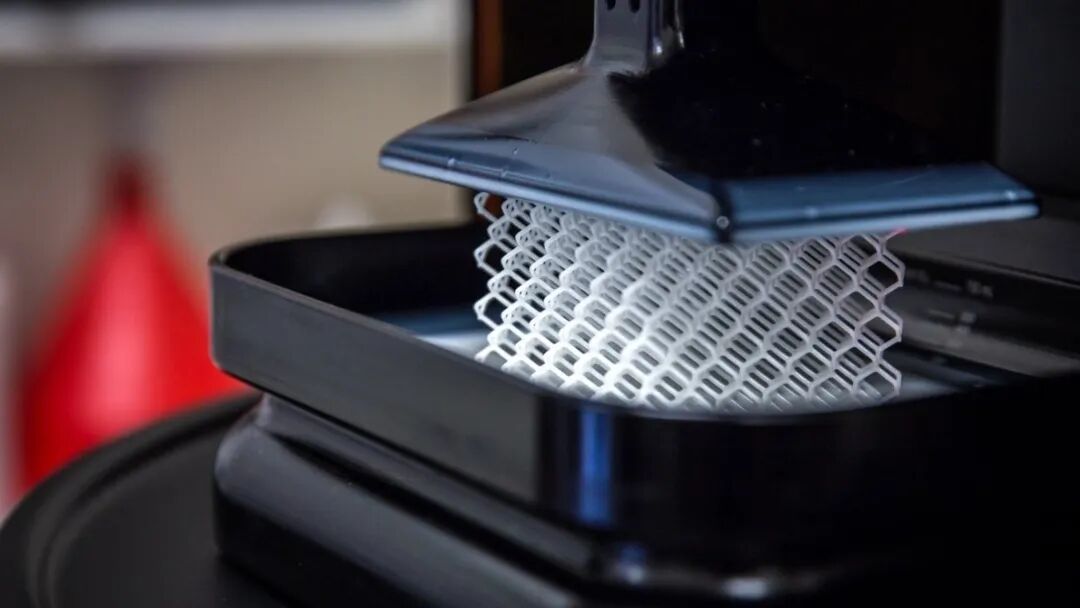

Stereolithography (SLA/DLP): High precision (±0.05mm), suitable for injection mold inserts, lost-wax casting.

-

Fused Deposition Modeling (FDM, industrial grade): Low cost, suitable for large mold frames, fixtures.

-

Metal 3D Printing (SLM/DMLS): Direct manufacturing of steel molds, die-casting molds, with a lifespan close to traditional molds.

3. Industry Pain Points and Challenges

Despite the clear advantages of 3D printed molds, there are still the following issues:

1. Material Performance Limitations

Stereolithography resin molds generally have a temperature resistance of **<200℃**, and high-temperature injection can easily cause deformation.

The cost of metal 3D printed molds is still high, with SLM equipment investments exceeding 2 million yuan.

2. Surface Treatment Requirements

3D printed molds usually require polishing, nickel plating, and PVD coating to meet mass production requirements.

3. Low Industry Awareness

Many manufacturing companies still believe that 3D printed molds are **”not durable”**, requiring more successful case validations.

4. Market Opportunities: Which Areas Are Worth Watching?

1. Automotive Industry:

Conformal cooling injection molds (30%+ cooling efficiency improvement)

Rapid mold testing (new model development cycle shortened by 50%)

2. Medical Industry:

Personalized dental molds (invisible aligners, implant guides)

Microfluidic chip injection molds (traditional CNC is difficult to process microchannels)

3. Consumer Electronics:

Small batch shell molds (smart wearable devices, headphone casings)

4. Aerospace:

Composite material forming molds (lightweight carbon fiber/glass fiber molds)

5. Future Trends: The Advancement Direction of 3D Printed Molds

1. Hybrid Manufacturing

3D printing + CNC precision machining, balancing complex structures and high precision.

2. Smart Molds

Integrating temperature/pressure sensors for real-time monitoring of production status.

3. AI Optimized Design

Generative AI for automatic design topology optimization and cooling channels, enhancing mold lifespan.

4. Sustainable Materials

Bio-based resins and recyclable metal powders to reduce environmental burden.

6. 3D Printed Molds

3D printing will not completely replace traditional molds, but it will dominate in small batches, complex structures, and rapid iterations. With improved material performance and reduced costs, the 3D printed mold market is expected to see an upward trend in the next 3-5 years.

Short-term: Introduce 3D printing for rapid mold testing and conformal cooling optimization.

Long-term: Layout for metal 3D printing and smart molds, seizing the high-end market.