When designing Internet of Things (IoT) devices, whether to use a wireless module or a System on Chip (SoC) can be a critical and challenging decision. Each option has its unique advantages and disadvantages, and choosing the right technology requires a balance of performance, functionality, and cost. In this article, we will eliminate some uncertainties in this process by comparing the cost implications of wireless modules and SoCs in detail.

Understanding Wireless Modules and SoCs

Let’s briefly review the technologies being discussed.

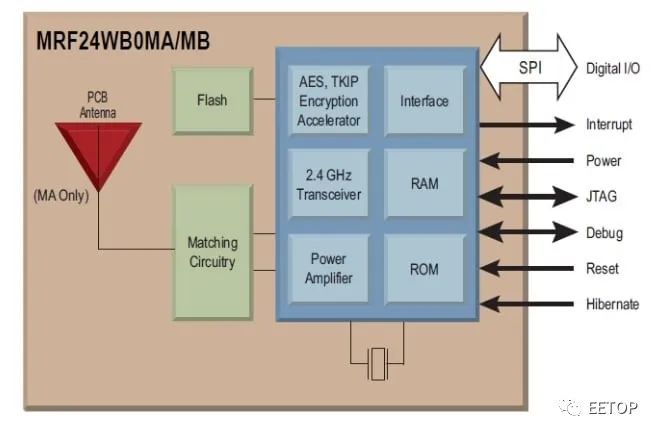

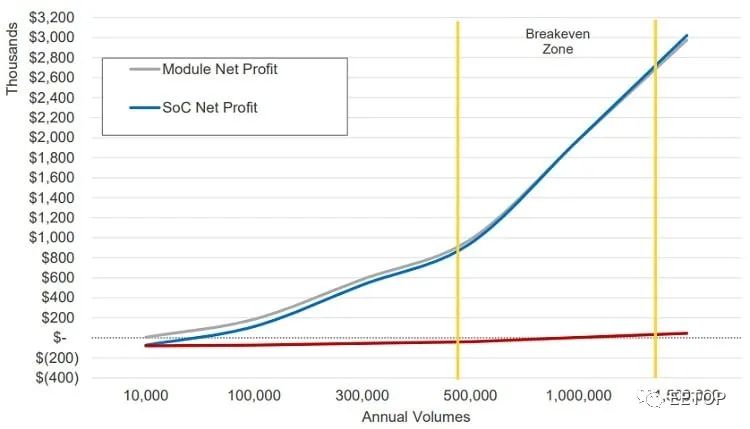

A wireless module is a pre-certified unit that serves as a complete wireless solution, typically containing a radio transceiver with a microcontroller, software stack, and antenna. Wireless modules are favored for their ease of use and reduced development time.

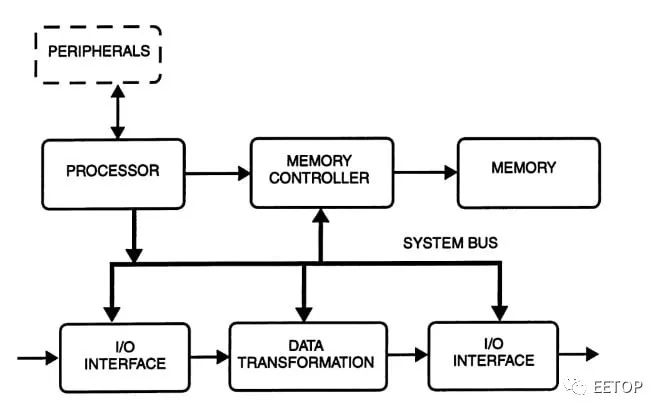

Figure 1. Block diagram of the MRF24WB0MA/MB 2.4 GHz IEEE 802.11b/g/n wireless module. Image provided by Microchip.

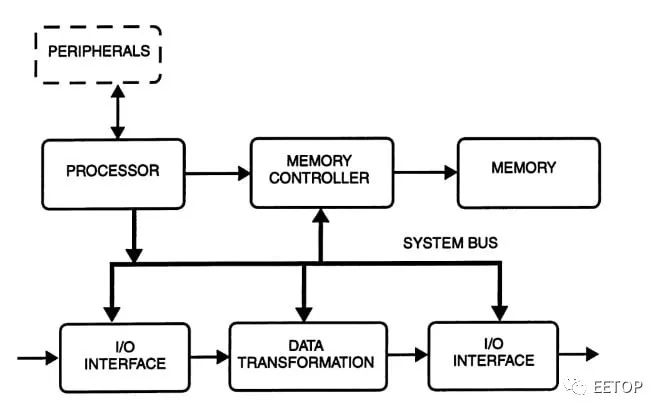

A System on Chip (SoC) is an integrated circuit that combines a microcontroller unit and a radio frequency (RF) front end on the same silicon chip.SoCs provide more control and flexibility, but require more design work.

Figure 2. General SoC schematic. Image provided by Michael Keating and Pierre Bricaud.

Cost Comparison of Wireless Modules and SoCs

We will use the following metrics to compare the costs of wireless modules and SoCs:

Initial Purchase and Development Costs

Wireless modules include pre-certified RF circuits, antennas, and software stacks, all of which increase the purchase cost. In contrast, SoCs are integrated circuits without additional components. Due to the absence of extra components found in wireless modules, the initial purchase cost is lower. This makes SoCs attractive for budget-constrained designers.

However, the same simplicity means that development costs can rise rapidly. Consider the following list of expenses related to development:

-

RF design and engineering fees.

-

Laboratory equipment and infrastructure investment.

-

PCB configuration and antenna selection costs.

-

Wireless modules come with pre-designed, pre-tested RF circuits, eliminating the need for in-house RF design expertise and reducing the need for laboratory testing. They are usually pre-certified and come with built-in antennas and pin arrangements, simplifying the PCB layout process. All these factors are included in the initial purchase cost, and no additional expenditure is needed during the development phase.

On the other hand, SoC-based designs require additional costs and time for design, testing, and certification before going to market. Designs based on wireless modules have a shorter time to market and a quicker return on investment.

Supply Chain and Scalability Costs

Procurement of modules is easier compared to all the individual components required for SoC-based designs. The latter option may lead to higher supply risks, especially for smaller companies or during component shortages. However, relying on module suppliers to ensure supply continuity can be costly. If SoC is chosen, larger companies or mass production may benefit from greater control over the supply chain.

Additionally, wireless modules often mean higher unit costs, which is a disadvantage when scaling up. For large-scale production, SoCs have lower unit costs that can offset higher development costs.

Break-Even Example: Wireless Modules vs. SoCs

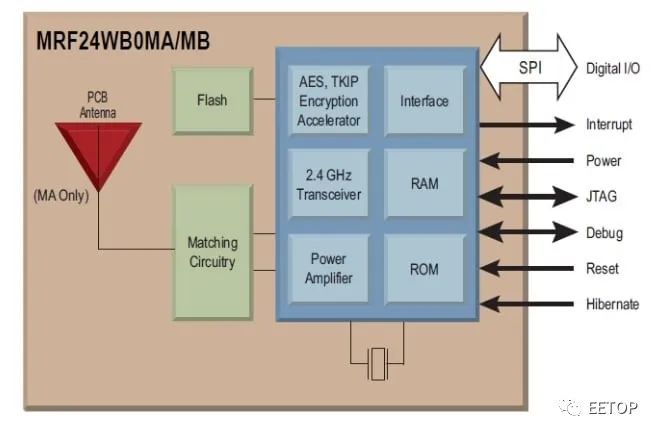

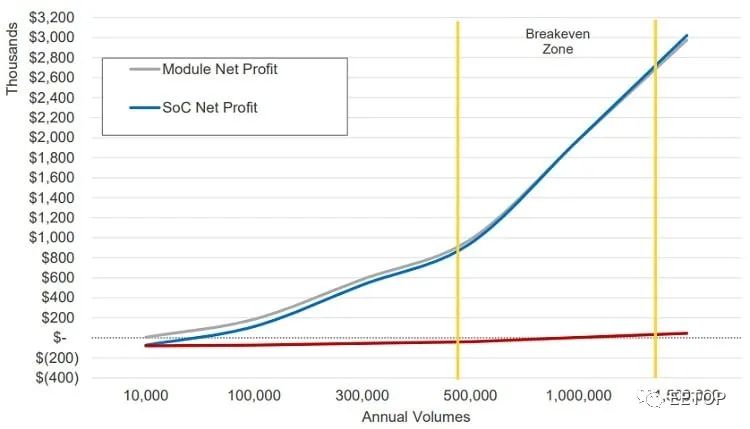

Tom Nordman, Joe Tillison, and Nick Dutton from Silicon Labs analyzed the costs of using wireless modules and SoCs in IoT design. They compared the costs of the BGM210P wireless Bluetooth module and the EFR32BG21 Bluetooth SoC (cost at a volume of 300,000 units).

Their cost comparison is based on the following assumptions:

-

Annual production volume of 10,000 to 300,000 units, with wireless modules and SoCs priced at $2.99 and $1.11, respectively.

-

The bill of materials (BoM) for the SoC, combined with testing during the manufacturing process, is estimated at $0.55 per unit. Of this, $0.05 is attributed to testing; $0.50 is the BoM.

-

They calculated a gross margin (the difference between product selling price and production cost) of $4.98 for their product.

-

The claimed gross margin of $4.98 is 40% higher than the module price, meaning profits are 40% higher than the costs incurred when using wireless modules in their product.

-

Due to the complex design, certification, and regulatory approval processes, the SoC is estimated to require an additional six months of development time. Based on an average engineer salary of $100,000, this is assumed to cost an additional $50,000.

Taking these factors into account, and considering the time to market and revenue loss associated with using SoCs, the break-even production volume ranges from 500,000 to 1,300,000 units. If we ignore the revenue loss due to the delay in time to market, the break-even point would drop to between 100,000 and 200,000 units. Here, both the break-even point and break-even production volume refer to the range of production where the profit from using SoCs begins to equal (and subsequently exceed) the profit from using wireless modules.

The analysis from the Silicon Labs team is illustrated in Figure 3. The area within the yellow line represents the break-even quantity. Due to risks and uncertainties in the production process, this number is a range rather than a point.

Figure 3. Break-even analysis for wireless SoCs and wireless modules. Image provided by Silicon Labs.

When production volume is below 500,000 units, using wireless modules is more profitable than using SoCs. This is due to the higher upfront costs and longer time to market associated with SoCs. However, once production volume reaches the break-even range, these upfront costs can be spread over enough units, making SoCs the more profitable choice.

The authors note that SoCs may not be the best choice for all high-volume products. For instance, due to the challenges of miniaturization in IoT devices, some of the best-selling mobile devices choose wireless modules, and this break-even comparison does not take that into account. Wireless modules offer compact designs (SiP modules), comprehensive global certifications, and competitive component costs. Although SoCs have potential cost benefits at scale, there are also unquantifiable risks such as technical issues or certification problems.

Best Choice

Designing with SoCs allows product developers to flexibly customize their systems and integrate the hardware and software features they need. The flip side of this customizability is increased complexity and longer development time—designers need to have a deep understanding of the SoC architecture and the software running on it.

In contrast, pre-made wireless modules typically require less development time and expertise but may lack in customization and integration. For smaller production runs, or if rapid time to market is critical, wireless modules may be more cost-effective; for larger volumes, or if there is in-house expertise, SoCs may be more cost-effective.

So what is ultimately the most cost-effective choice? It’s an unstable answer, depending on many factors: specific products, designers, urgency of product release, production volume, and so on. We hope this article helps you make an informed choice.

This article is compiled and organized by EETOP from allaboutcircuits.

New course launched, limited-time 25% discount coupon!