Special Training Course on Simulation and Design of Distillation Towers

Online – Problem-Solving Ideas for Organic Synthesis in Pharmaceutical and Chemical Engineering Special Training Course

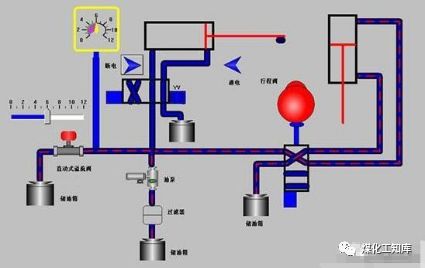

DCS (Distributed Control System), also known as a distributed control system, is a type of computer control system that is developed and evolved from centralized control systems.PLC (Programmable Logic Controller).

PLC and DCS

PLC and DCS

PLC:

-

Developed from switch control to sequential control and transport processing, it is an upward evolution.

-

Continuous PID control and other multifunctions, with PID in interrupt stations.

-

A single PC can serve as the master station, with multiple identical PLCs as slave stations.

-

Also, one PLC can serve as the master station with multiple identical PLCs as slave stations, forming a PLC network. This is more convenient than using a PC as the master station because when programming, users do not need to know the communication protocol, just follow the manual format.

-

The PLC grid can serve as an independent DCS or as a subsystem of DCS.

-

PLC is mainly used for sequential control in industrial processes, and new PLCs also have closed-loop control functions.

DCS:

-

DCS integrates 4C (Communication, Computer, Control, CRT) technologies into a monitoring technology.

-

A large system with a top-down tree topology, where communication is key.

-

PID in interrupt stations, connecting computers with field instruments and control devices in a tree topology and parallel continuous link structure, with many cables running from relay stations to field instruments.

-

Analog signals, A/D – D/A, with microprocessor hybrids.

-

Each instrument connects to I/O with a pair of wires, linked to the local area network (LAN) by the control station.

-

DCS has a three-level structure of control (engineer station), operation (operator station), and field instruments (field measurement and control station). It is used for large-scale continuous process control, such as in petrochemicals.

Industry Experts Discuss the Differences Between PLC and DCS

PLC and DCS cannot be compared; PLC is a controller, an isolated product, while DCS is a system. However, PLC can be compared with the control station of DCS; the cycle time of PLC is around 10 milliseconds, while that of DCS control stations is around 500 milliseconds. PLC has better openness and stronger independent operational capability as a product.

—— OMRON Company

DCS is a system that includes upper-level software, networks, and controllers, while PLC is just a controller; to form a system, it also needs an upper-level SCADA system and the connected network.

Regarding PID loop control, Mitsubishi’s process controllers can now achieve FBD programming similar to SAMA configuration; DCS systems are larger, with more control loops and more control and algorithms, allowing for more complex inter-loop control. The hardware reliability is about the same. DCS can achieve I/O redundancy, while PLC cannot. Relatively speaking, systems built with PLCs are more cost-effective.

—— Manager of Precision Control Department, Mitsubishi Electric Automation

DCS is a type of “distributed control system,” hardware-wise including field controllers, operator station computers, engineer station computers, and the network system connecting them; DCS software is a complete solution addressing all technical issues of a system, with tight integration between system components.

PLC is a device, hardware-wise equivalent to the field controller in DCS; software-wise, it is a local solution with loose organization between stations.

—— Technical Manager for APROL Product Application Development, B&R Automation

Analyzing the differences between DCS and PLC, the two key points are: first, DCS is distributed control with a global database; second, PLC uses a sequential scanning mechanism, while DCS is time-based control. Our system meets the first point; for example, a modification of an I/O tag can also be reflected synchronously in the HMI.—— Product Manager for Process Market, Rockwell Automation

Copyright Statement

Disclaimer: The copyright of the article belongs to the original author. If there are issues regarding the content, copyright, or other matters, please contact us for deletion! The content of the article reflects the author’s personal views and does not represent the views of this public account. This public account reserves the final interpretation rights for this statement.