Set as Star “★” to avoid getting lost, let’s hit the highway together!

Reading this article takes about 3.5 minutes

Note: Attachments can be found in the comments (please contact for repairs if expired); if you need other materials, feel free to leave a message in the comments, and I will send them out if found.

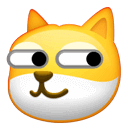

Introduction: A pulley mechanism is a simple mechanical device that can lift heavy objects and reduce effort. It consists of a small wheel (pulley) with grooves around the edge that can rotate around an axis, along with a flexible cord (such as rope, tape, steel cable, chain, etc.) that passes over the wheel. Depending on whether the position of the central axis moves, pulleys can be classified as fixed or movable. (Note: Reference materials are at the end of the article)

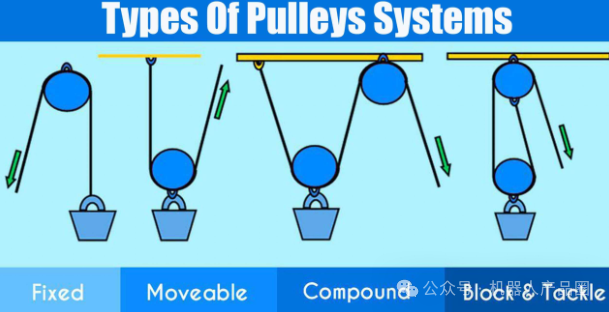

1. Fixed Pulley

The position of the central axis of a fixed pulley is fixed; it essentially acts as a lever with equal arms, providing no mechanical advantage but changing the direction of the force. This has many applications in daily life, such as curtains with a pull cord in homes, which use a fixed pulley mechanism to conveniently change the opening and closing direction of the curtains.

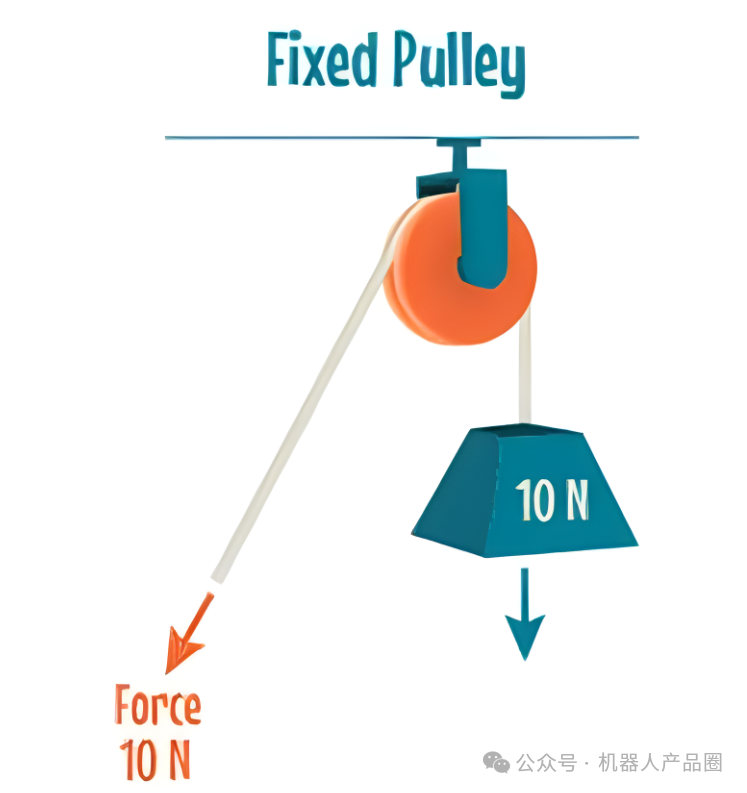

2. Movable Pulley

A movable pulley has a central axis that can move, allowing it to reduce effort but requiring more distance. This is because a movable pulley is typically connected to two segments of rope, with each segment bearing part of the weight of the load, thus reducing the total pulling force while increasing the distance moved. In lifting equipment, such as cranes, the pulley on the hook is a movable pulley, which allows the crane to lift heavy objects easily.

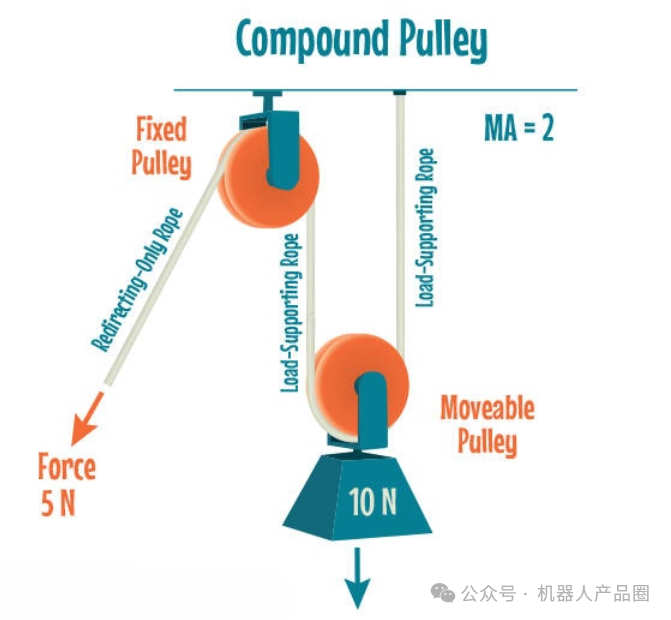

3. Compound Pulley

The pulley mechanism can also be assembled from multiple movable and fixed pulleys to create a pulley system for more complex movements and functions. A pulley system can both reduce effort and change the direction of force, widely used in various lifting and hoisting devices.

4. Complex Pulley System

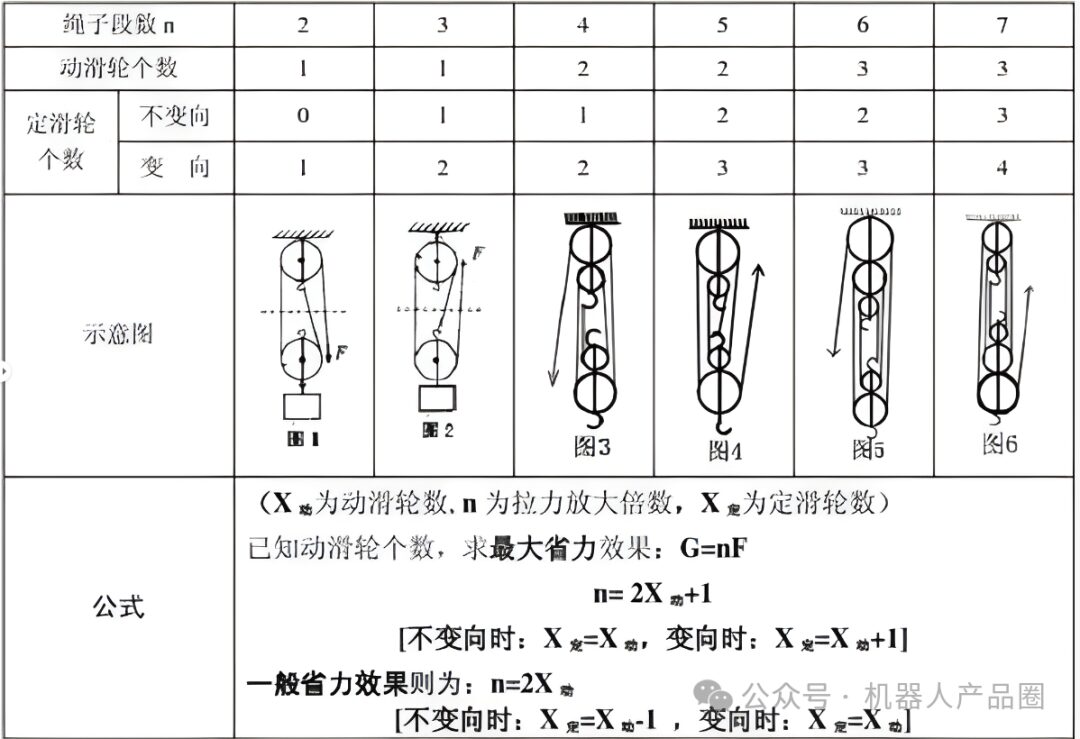

A complex pulley system is a mechanical system composed of multiple pulleys of different sizes, featuring flexible and efficient force conversion and movement functions. In a pulley system, the stretching of ropes or chains allows for force distribution and direction changes. The design of a complex pulley system must consider various factors such as pulley size, material, and friction coefficients, and can adjust the number of movable and fixed pulleys as well as the number of rope segments based on actual needs to achieve effort reduction and force direction changes. In practical applications, complex pulley systems are widely used in large equipment such as tower cranes, elevators, hoists, and winches for lifting and moving heavy objects.

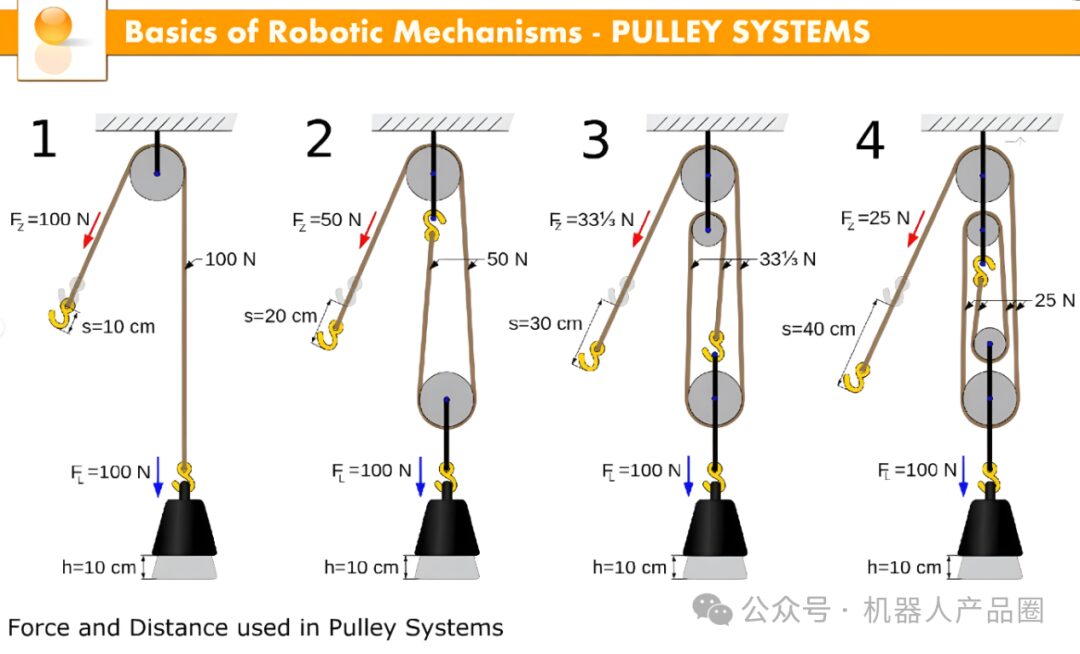

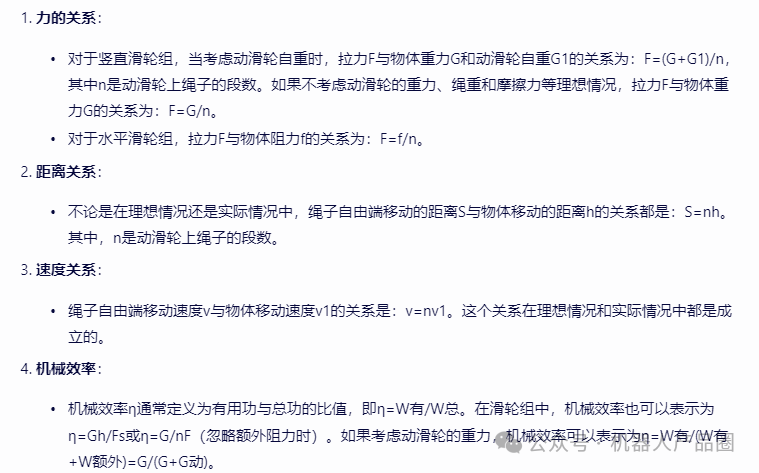

5. Calculating Pulley Mechanisms

The calculation of pulley mechanisms mainly involves the relationships of force, distance, speed, and mechanical efficiency. In terms of force relationships, one must consider the weight of the object, the weight of the movable pulley, and the impact of the number of rope segments on the pulling force. The distance relationship indicates that the distance moved by the free end of the rope is proportional to the distance moved by the object and is related to the number of rope segments. The speed relationship states that the speed of the free end of the rope is also influenced by the number of rope segments.

6. Advantages and Disadvantages of Pulley Mechanisms

Advantages:

1. Change the direction of force: The pulley mechanism can easily change the direction of force, making it easier and more flexible to apply force. This is very important in many practical applications, such as needing to change the direction of force to suit specific spatial constraints or working conditions.

2. Effort-saving effect: By reasonably combining pulleys, the pulley mechanism can achieve an effort-saving effect. Movable pulleys can save half of the effort, while pulley systems can adjust the degree of effort saving as needed. This effort-saving effect is particularly useful when lifting heavy objects or performing high-intensity work.

3. Simple and compact structure: The structure of the pulley mechanism is relatively simple, with good interchangeability of parts, lightweight, and easy layout. This makes it easier to implement during the design and manufacturing process, and the maintenance cost is relatively low.

4. High transmission efficiency: In pulley rope mechanisms, the friction between the joint axis and the pulley, and between the pulley and the rope is low, resulting in high transmission efficiency. This helps improve the efficiency and performance of the entire mechanical system.

Disadvantages:

1. Cannot save effort and change the direction of force simultaneously: Fixed pulleys can change the direction of force but do not provide effort-saving benefits; while movable pulleys can save effort but cannot change the direction of force. Therefore, in practical applications, one must weigh and choose based on specific needs.

2. Rope wear and slack issues: In pulley rope mechanisms, the rope is intermittently tightened and slackened during operation, which can easily lead to slack over long-term use, affecting the precise control of the fingers. Additionally, ropes are prone to wear and need to be replaced regularly to ensure proper operation of the mechanism.

3. Uneven force distribution: In some cases, the pulley mechanism may experience uneven force distribution, which can lead to damage to the pulleys or ropes and even affect the stability and safety of the entire mechanical system.

4. Space limitations: The pulley mechanism requires a certain amount of space for layout and operation, so it may not be suitable in confined spaces.

7. Products Using Pulley Mechanisms in Daily Life

1. Bicycle chains and awnings

2. Tower cranes

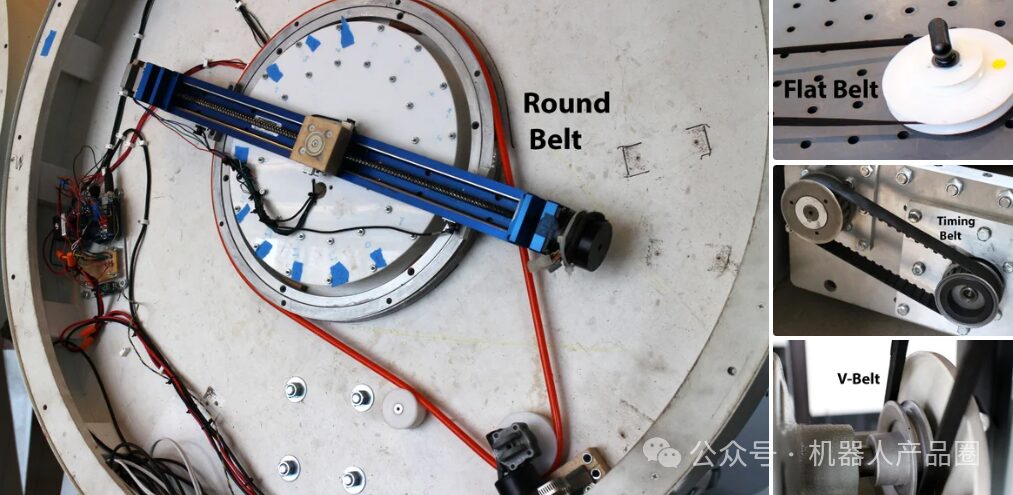

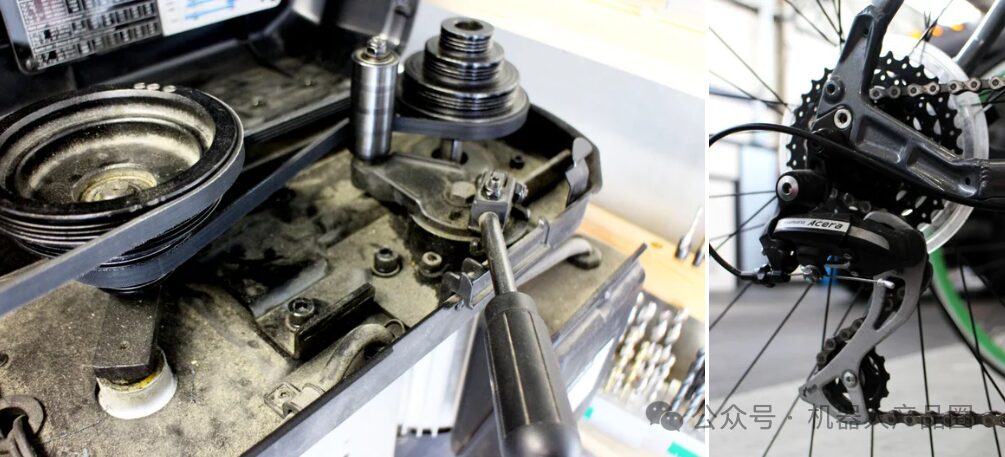

3. Belt pulleys, etc.

4. Some roller shutters

5. Track wheels

6. Some winches (for fishing!)

7. Motor drive components

8. Tensioning mechanisms

References:

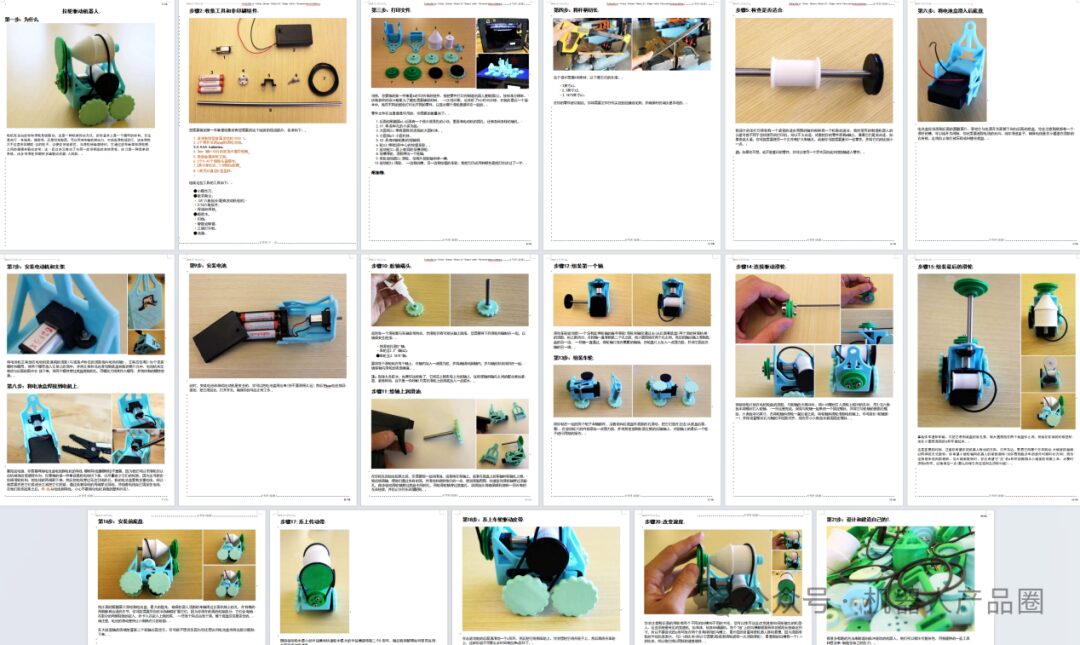

1. DIY Pulley Cable Robot

Includes 3D printing files and assembly tutorials.

For specific steps to obtain attachments, refer to the article below:

Instructions for obtaining attachment materials (no tasks or complicated processes required):

Material Acquisition&Contact Author&Join Discussion Group:

Disclaimer: Some content is sourced from the internet; please contact for removal if copyright issues arise!

“Share”“Looking”“Like” to get more friends on the highway!