The Internet of Things (IoT) architecture has definitions from scientists and computer communication professionals. Today, we will discuss the IoT architecture in simple terms, how to structure it, and the core component, the gateway, along with recommendations for edge computing solutions.

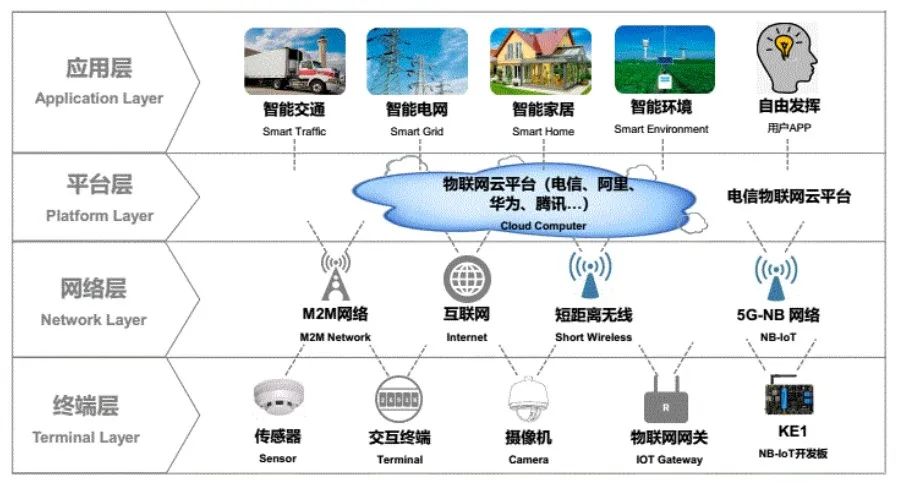

From a hardware perspective, the IoT is a system composed of interconnected sensors, computing devices, and machines that are connected through a network, forming a complete operational closed loop to achieve automated control functions. The IoT can connect cars, buildings, machines, and wearable devices/people. From a software perspective, the IoT consists of four layers: physical layer, network layer, platform layer, and application layer. This article mainly discusses the physical layer architecture and key device gateways, which require four components for the data flow from raw data collection to obtaining predictions or results:

-

Sensors/Actuators

-

Gateways and Networks

-

Cloud or Data Servers

-

Application Layer

Figure 1: Simplified IoT Architecture Diagram

01

Raw Data Collection

As the foundation of the IoT system, collecting data from target devices is essential. It requires sensors to gather the raw data needed for predictions. Sensors collect data from process or environmental conditions, such as quality control, temperature, humidity, assembly line speed, etc. The IoT architecture allows for bidirectional data flow in the form of instructions or commands, notifying actuators to take any actions required for control or maintenance processes. Commonly used sensors include:

-

Temperature Sensors

-

GPS/Proximity Sensors

-

Motion/Speed Sensors

-

Electric Actuators

-

Hydraulic Motors

02

IoT Gateways and Data Acquisition Systems (DAS)

The Data Acquisition System (DAS) plays a crucial role in converting raw analog data into programmable digital data. The IoT gateway provides network connectivity between sensors and the gateway to execute DAS. This network connection can be wireless or wired, including LAN, USB, or GPIO. In this layer of the IoT architecture, gateways and DAS also help control, filter, and select data, known as edge computing, to minimize the amount of information sent to the cloud, thereby reducing network data load.

Architecting the IoT is an engineering computation task that requires finding an appropriate balance between power consumption and performance for optimization. Power budgeting is a behavior that considers every detail of the possible power required to operate the entire IoT solution architecture. Engineers must consider the performance ratio or percentage that describes the relationship between actual energy output and computed energy output. By comparing theoretical and actual results, power budgeting can be calculated more accurately. Engineers need to consider three points:

-

Power Availability: Power budgeting ensures sufficient power is available for future operations.

-

Heat Generation: Maintaining an appropriate balance between power and performance to prevent overheating.

-

Cost: Greater power means larger components, leading to higher costs.

The data acquisition system requires processors such as SoC, DSP, FPGA, CPU, GPU, VPU, and NPU, along with NVME M.2 storage capabilities, to achieve calculations from small data comparisons to large data processing. Choosing processors with domestic ARM or RISC-V cores has become the technical route for IoT device manufacturers and solution providers in planning data acquisition systems.

According to I Love Solutions Network, for device manufacturers, procuring data acquisition and industrial control motherboards from solution providers has three 30% advantages: a 30% reduction in development time, a 30% decrease in board costs, and a 30% improvement in quality stability. Currently, Rockchip, Junzheng, Feiteng, Loongson, and Hisilicon motherboards are preferred by device manufacturers for control, data acquisition, and edge computing applications. Among them, purchasing core boards and self-developing baseboards is a popular procurement model that highlights product innovation for device manufacturers while effectively controlling costs.

Figure 2: Four-Layer IoT Architecture, with the Gateway Positioned Between the Terminal Layer and Network Layer

03

What is an IoT Gateway?

An IoT gateway is a physical device or software program controller that serves as a connection point between the cloud and devices, sensors, and smart devices. All data moving between IoT devices and the cloud passes through the IoT gateway, which can be a dedicated hardware device or software program. The IoT gateway can also be referred to as a smart gateway or control layer.

04

Functions of IoT Gateways

1. The IoT gateway acts as a network router, routing data between devices and the cloud, handling inbound and outbound bidirectional traffic. Outbound traffic is used to send IoT data to the cloud, while inbound traffic is used for device management tasks, such as updating device firmware.

2. The gateway can also preprocess data locally at the edge before sending it to the cloud. This allows devices to potentially eliminate duplicate data, summarize, or aggregate data to reduce the amount forwarded to the cloud.

3. Another benefit of the IoT gateway is that it can provide additional security for the IoT network and the data being transmitted.

4. IoT gateways often handle several different protocols. Some of these protocols include Z-Wave, BACnet, Bluetooth Low Energy, and Zigbee, which distinguishes them from standalone communication protocol gateways.

5. The gateway must also be able to route each type of IoT traffic to the appropriate destination. Data from industrial sensor collections may need to be sent to a database in the AWS cloud, while data from building security sensors may need to be directed to a SaaS vendor operating a cloud-based security portal.

6. One reason IoT gateways may be more complex than Wi-Fi routers is that they may need to cache data locally in case of internet interruptions or if the gateway is overwhelmed with data beyond its processing capacity.

Figure 3: Industrial IoT Gateway Applications

05

Recommended Gateways for IoT Use

ISG-503 Edge Computing Smart Gateway

The ISG-503 is a smart gateway for telecom/industrial device connections, suitable for edge computing and running containerized deployments. It features an RK3288 64-bit CPU, industrial-grade wide temperature design, supports wall mounting, rail mounting, and various external interfaces such as RS232, RS485, DI, DO, and supports 4G and 5G communications, making it usable in complex environments.

ISG-210 Protocol Conversion Smart Gateway

The ISG-210 series is a protocol conversion smart gateway that uses a high-performance embedded 32-bit processor, supports over 250 common PLC protocols, and can be equipped with NB-IOT, LoRa, ZigBee, and other modules, configured for self-running and self-controlling gateways, providing excellent protocol conversion and acquisition capabilities, and supporting remote management for users, facilitating large-scale IoT device deployment.

ISG-300 High-Performance Low-Power Edge Computing Gateway

The ISG-300 series is an industrial smart gateway designed with a high-performance low-power i.MX6 series CPU, large-capacity eMMC storage, excellent system configuration, various serial and communication interfaces, and a 7-inch resistive touch display, providing excellent localized display, edge processing, and human-machine interaction capabilities in industrial settings.

ISG-200 General Standard Smart Gateway

The ISG-200 series is a general standard smart gateway that uses a high-performance embedded computer platform, capable of supporting large-scale IoT device deployments, utilizing a high-performance embedded 32-bit processor, supporting over 250 common PLC protocols, configured for self-running, providing data computation, and self-controlling gateways with excellent protocol conversion and acquisition capabilities, supporting wide temperature operation.

ISG-100 High-Performance Protocol Conversion Smart Gateway

The ISG-100 series is a protocol conversion smart gateway that uses a high-performance embedded 32-bit processor, supports over 250 common PLC protocols, configured for self-running and self-controlling gateways, providing excellent protocol conversion and acquisition capabilities, and supporting remote management for users, facilitating large-scale IoT device deployment.

06

Edge Computing Processing

In this layer of the IoT architecture, all previously digitized and accumulated analog data will be summarized in this process, known as preprocessing or edge processing. At this stage, machine learning can be very helpful in providing feedback to the system and managing the entire ongoing process without waiting for instructions from the cloud. Therefore, machine learning helps reduce the amount of data sent to the cloud or data center by processing some data at the edge.

Edge computing can be deployed on gateways or edge servers. Robust edge computing preprocessing capabilities provide scalable advanced processing power through multi-core processors, massive data storage, and various I/O options. Thus, by leveraging powerful edge computing solutions to connect all sensors, devices, and IoT infrastructure, the IoT solution architecture process can be executed while reducing hardware footprint.

07

Further Analysis in the Cloud or Data Center

The IoT architecture cloud or data center serves as the brain extension of the entire IoT architecture process. Data centers or cloud-based systems are specifically designed to store, process, and analyze large amounts of data from sensors or sites for deeper analysis. At this stage, the data center combines all the collected data to obtain a more comprehensive overall IoT architecture diagram and actionable predictions. Finally, predictions can be sent back directly to sensors or actuators or to end-user applications.

08

Human-Machine Interface (HMI) for Status and Data Management

This is the final step of the IoT architecture. The final predictions from the cloud or data center will be sent back to the sensors/actuators or directly to the end users. Therefore, considering the IoT platform is crucial when interacting directly with end users. HMI or human-machine interface is a graphical user interface (GUI) that provides human-machine interaction. HMI allows operators to manage ongoing processes and display data visualization. Therefore, HMIs in IoT are essential for achieving remote interaction and visualization from machine systems.

09

Recommended Human-Machine Interaction Solutions

Smart Central Control Tablet Solution

The smart central control tablet uses the Junzheng X2000E chip, adopting a tri-core structure, equipped with dual XBurst®2, a main frequency of 1.2GHz, and a third cross-core XBurst®0 (240MHz), providing strong performance. It features a 7-inch touchscreen, supports multiple resolutions, POE network, and WIFI network, supports multiple input and output interfaces, 433 communication, and RFID card swiping. It supports voice input and output and 485 communication.

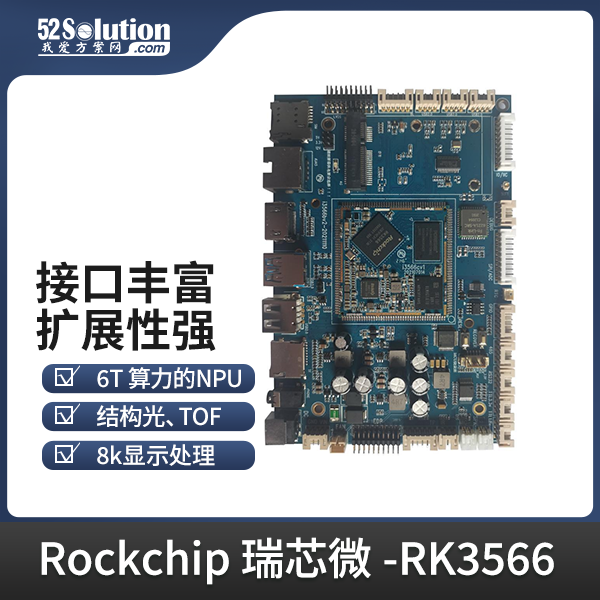

8K HD Display Visual Processing Development Board

The high-performance development board I3566 uses Rockchip’s new generation flagship high-end processor RK3566. The RK3566 is designed with an 8nm process, equipped with a quad-core A76 + quad-core A55 octa-core CPU and an Arm high-performance GPU, with an NPU that has 6T computing power. It has strong visual processing capabilities, supporting various fast face unlocking solutions such as structured light and TOF; it supports rich display interfaces with up to 8K display processing capabilities; it has strong expandability, supporting PCIE3.0, SATA3.0, dual TypeC/USB3.1 and other high-speed interfaces, suitable for AI computing, image data processing, etc. It is widely used in ARM PCs, high-end tablets, edge computing servers, virtual reality, NVR, 8K TVs, and other fields.

Single-Screen POS Cash Register AI Electronic Scale Motherboard

The RK3566 single-screen POS cash register AI electronic scale motherboard (Product Model: ZY3561) is very suitable for AI electronic scales, cash register POS machines, vending machines, and touch all-in-one machines. Considering the application scenarios and costs, this motherboard is suitable for single-screen devices, with one EDP or LVDS display output interface, interconnectivity using WIFI/Bluetooth (supports 2.4G/5G WIFI, default 2.4G), and does not have cellular communication capabilities. This motherboard uses Rockchip RK3566 low-power quad-core 64-bit Cortex-A55, with a maximum frequency of 1.8GHz, providing 0.8T computing power. It features a smart power management circuit, supports common external devices, is stable in performance, and supports current popular video and image codec formats.

Industrial Control Advertising Machine Touch All-in-One Commercial Display Motherboard

The industrial control advertising machine touch all-in-one motherboard uses the Rockchip RK3566 chip kit, which is a cost-effective commercial display motherboard. Its application fields include enterprise and education terminals, smart home appliances, smart security devices, tablets, advertising machines, etc. This solution is reliable in performance, with cumulative shipments exceeding 50k, helping consumer electronics device manufacturers quickly introduce products. The RK3566 is a high-cost performance general-purpose SoC, with a CPU using a 4-core A55 architecture processor, integrated G52 graphics processor, and built-in independent NPU, with a computing power of 0.8 Tops, supporting Android 11 or Linux systems.

RK3566 High-Cost Performance Video Motherboard

The high-cost performance video motherboard YNH-512 is an intelligent Android motherboard that uses the Rockchip RK3566 quad-core 64-bit processor, running Android 11.0, with a maximum frequency of 1.8GHz. The GPU is Mali-G52, supporting 1080P video decoding. It supports multiple video outputs and inputs, has rich interfaces, supports various peripheral expansions, and comes with a WIFI-2.4G/5G module, BT-4.0, and wired network; the board has a built-in hardware watchdog, making it the best choice for industries such as cash registers, advertising machines, and self-service terminals.